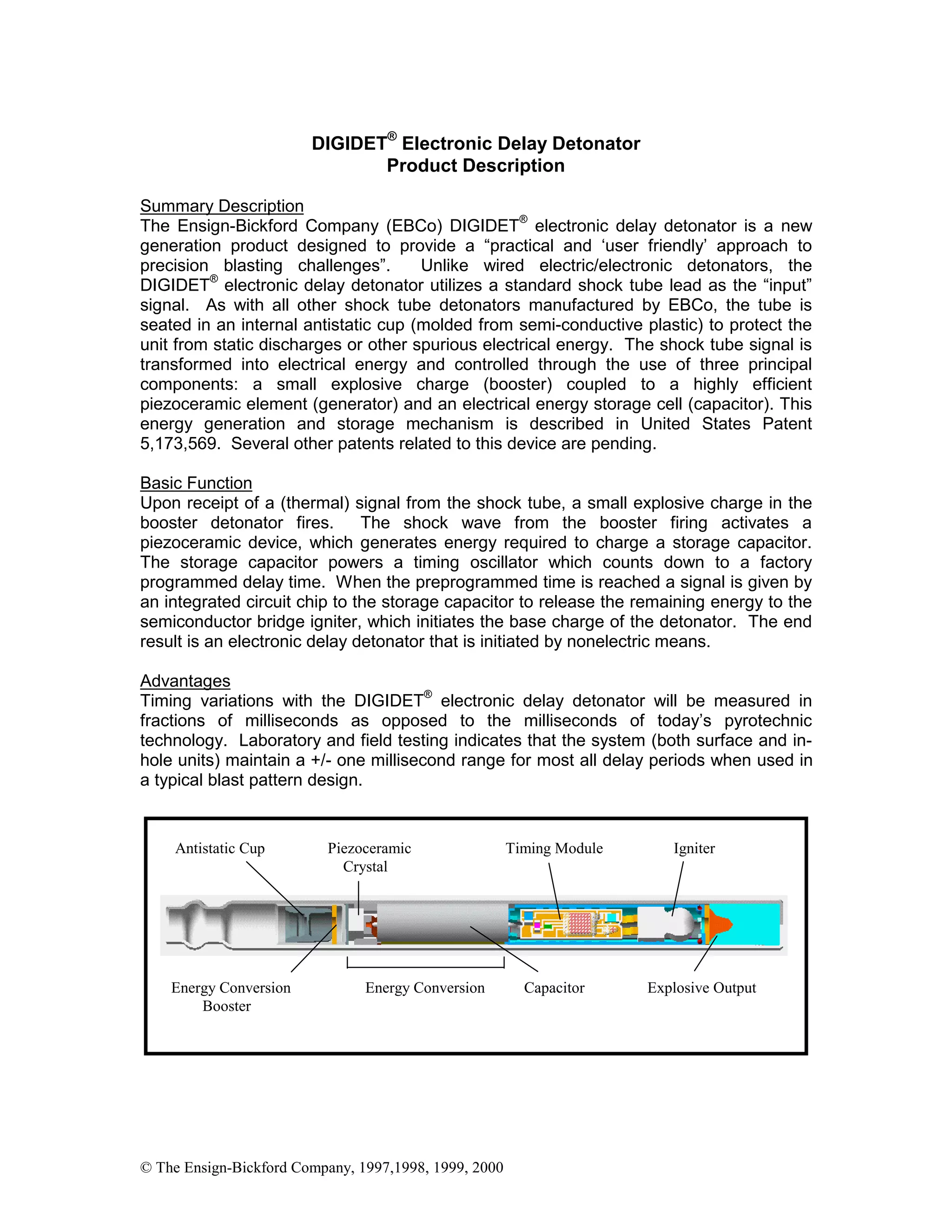

The Ensign-Bickford Company developed the DIGIDET electronic delay detonator to provide precise blasting with an easy-to-use system like conventional nonelectric detonators. It uses a shock tube input and piezoceramic generator to charge a capacitor that powers an integrated circuit to delay ignition from milliseconds to hours. This allows for more precise timing than pyrotechnic detonators within 1 millisecond while maintaining simplicity of use comparable to existing nonelectric systems.