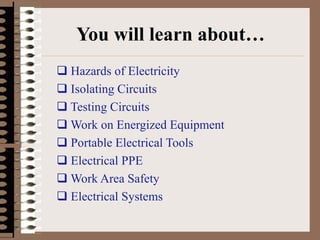

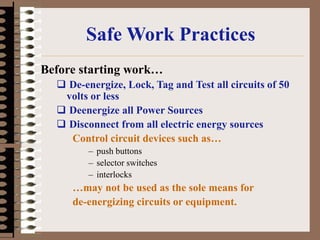

This document outlines electrical safety guidelines for working with electrical equipment and systems. It discusses hazards of electricity, safe work practices such as locking out and tagging equipment, protective equipment, and safety measures for working with energized and portable electrical tools. Special training and authorization is required for electrical work. Guidelines cover isolating circuits, releasing stored energy, verifying equipment is de-energized, and ensuring safety of work areas, tools, and personal protective equipment. Marking of equipment, circuits and protective devices is also addressed.