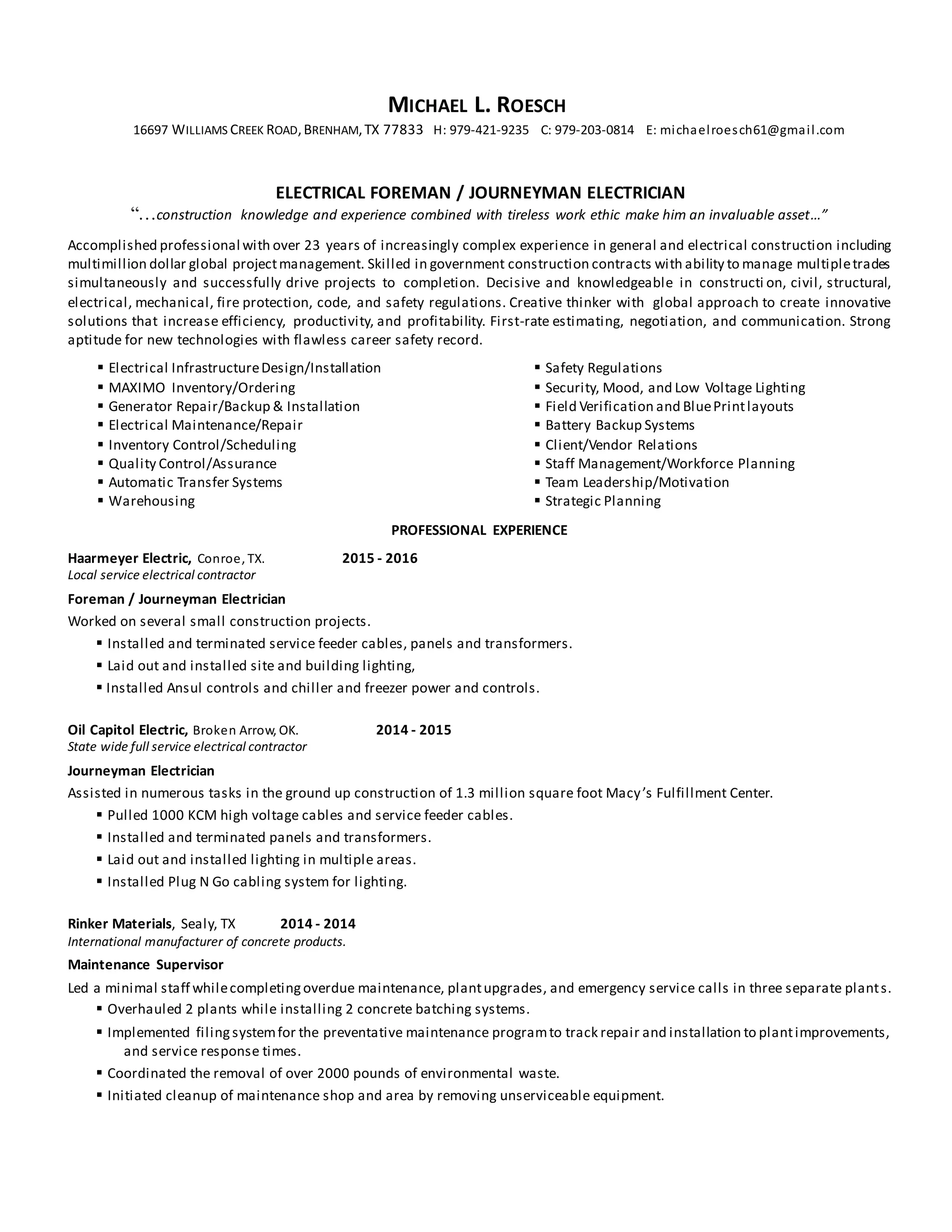

This document is a resume for Michael L. Roesch, an electrical foreman and journeyman electrician with over 23 years of experience in electrical construction. It summarizes his extensive experience managing electrical projects and personnel for various companies. He has worked on multimillion dollar projects around the world and has specialized expertise in areas like electrical infrastructure design, generator installation, and safety regulations.