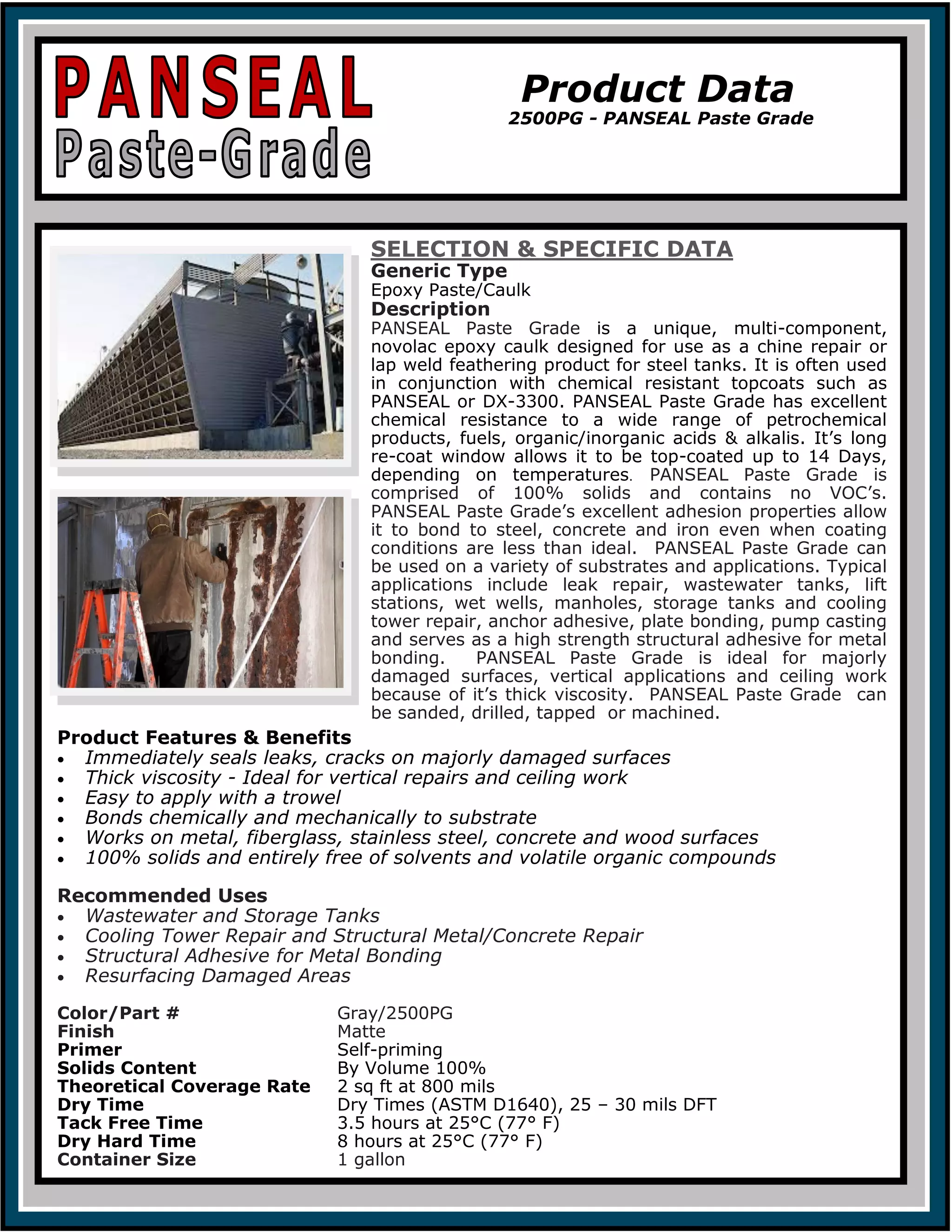

PANSEAL Paste Grade is a two-component, no-VOC epoxy paste designed for steel tank repairs. It bonds well to steel, concrete, and other surfaces. It can seal cracks and leaks and is suitable for vertical and overhead applications due to its thick viscosity. PANSEAL Paste Grade dries hard in 8 hours at room temperature and can be topcoated within 14 days or machined after curing.