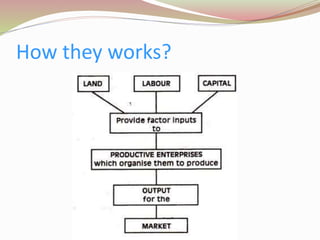

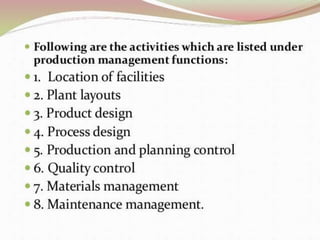

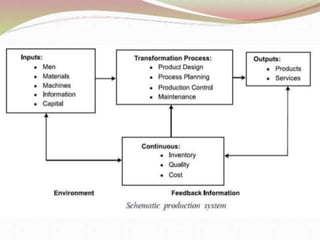

The document discusses the intersection of economics and engineering, focusing on production engineering and the economic principles that inform decision-making in resource allocation. It outlines the factors of production, such as land, labor, capital, and entrepreneurship, and emphasizes the importance of engineering in contributing to economic growth and sustainability. Additionally, it addresses challenges faced by the manufacturing sector, the significance of research and development, and the role of standards in manufacturing innovation.