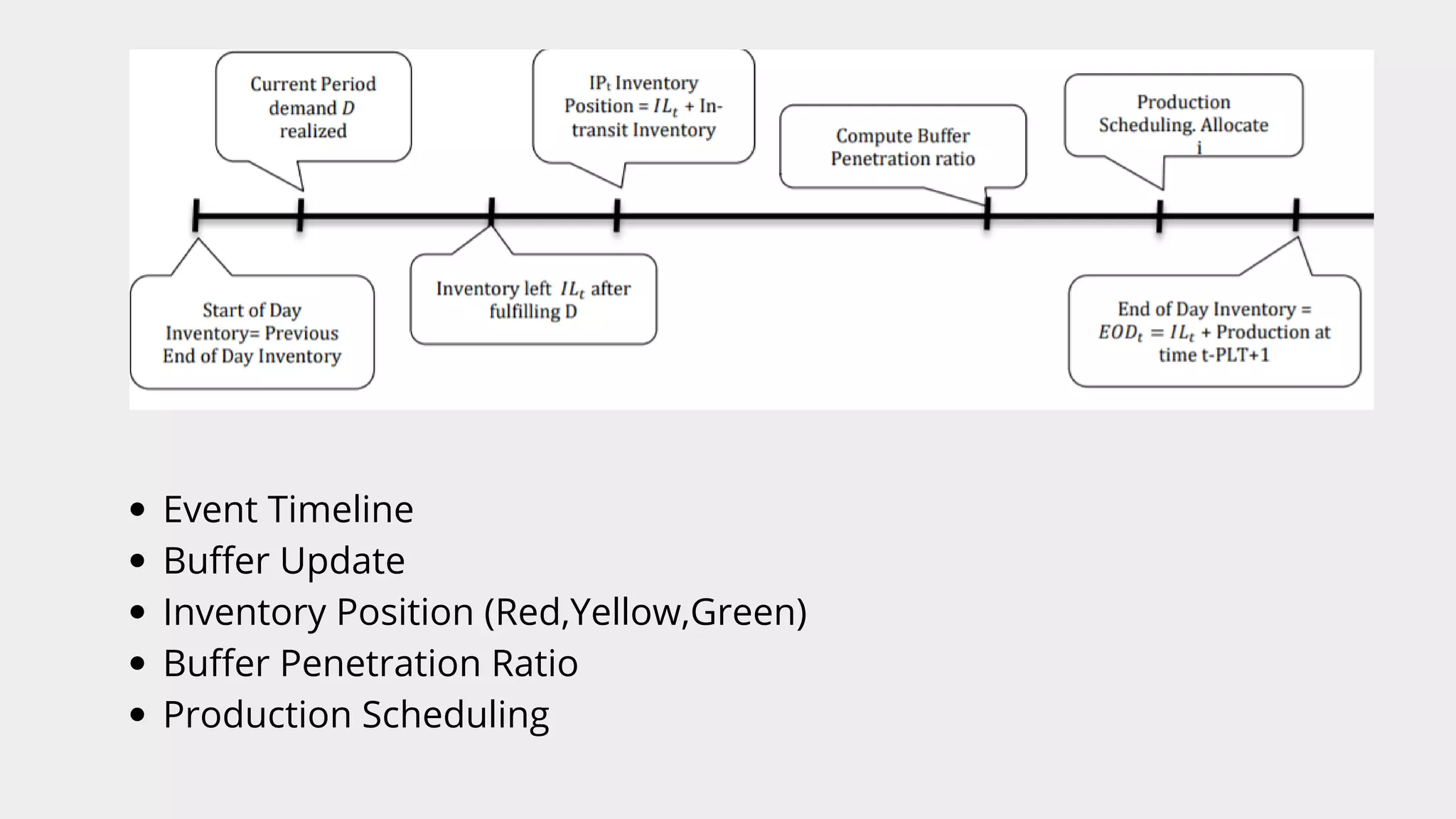

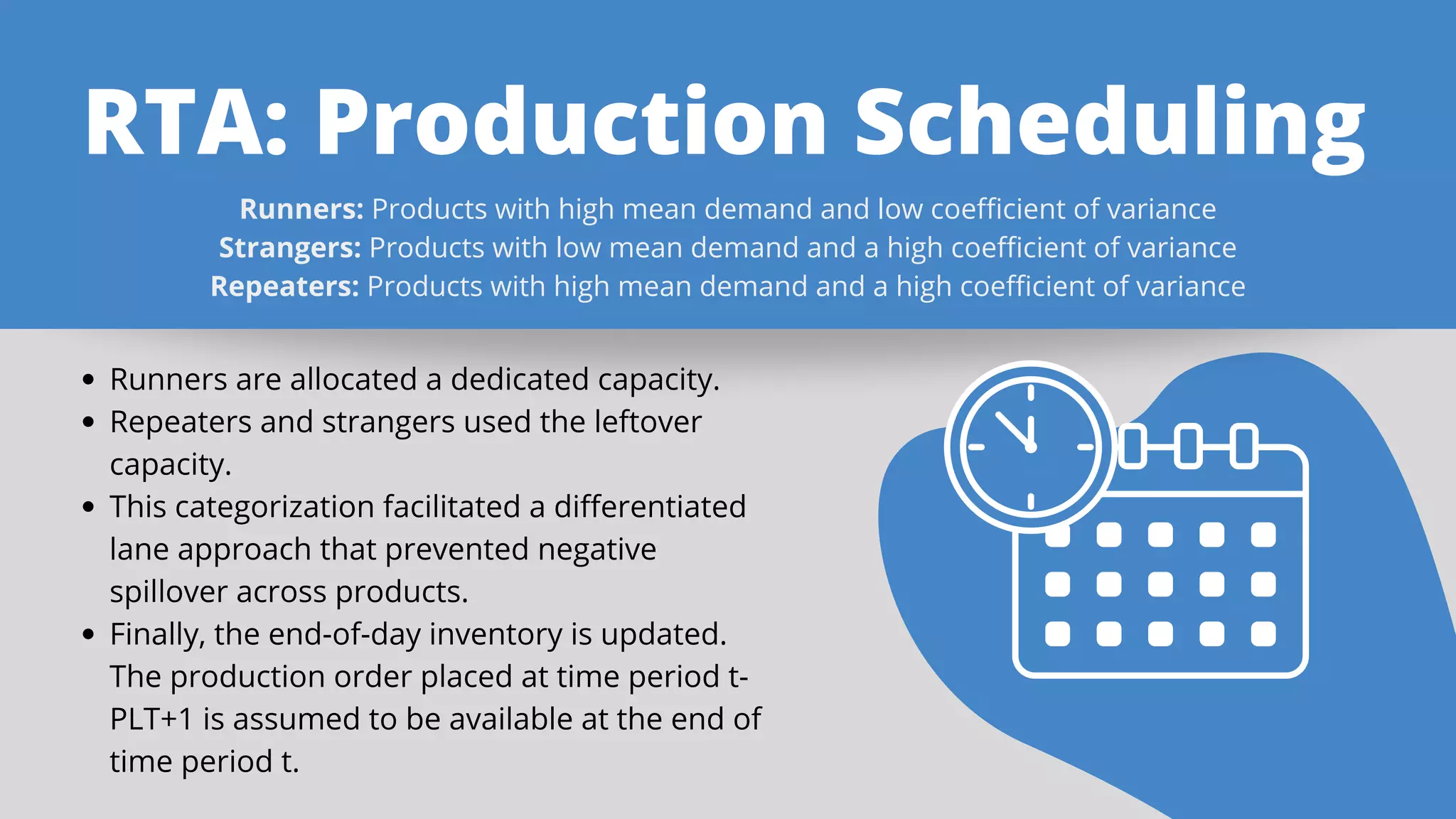

Dr. Reddy's Laboratories is facing challenges with its current inventory management policy (rtc-p), which leads to increased switching costs and poor supply chain performance due to resource competition among stock-keeping units. A consultant recommends evaluating an alternative approach, replenish to consumption-dedicated (rtc-d), which allocates production capacity more effectively based on product demand variability. This new strategy aims to enhance efficiency by segregating production lanes and updating buffer levels according to demand forecasts.