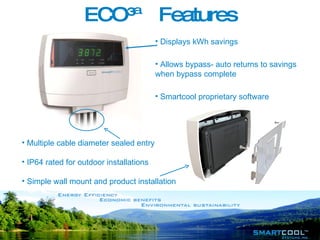

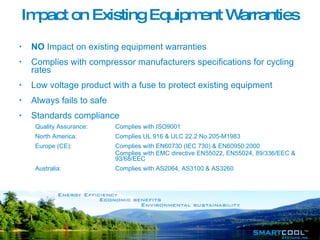

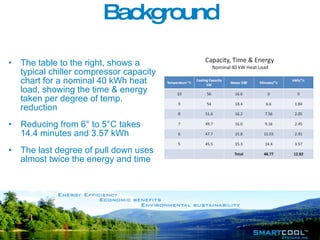

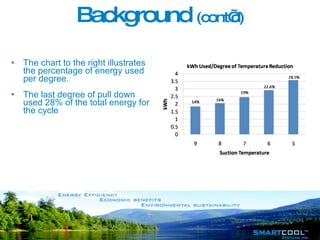

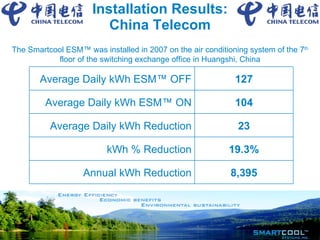

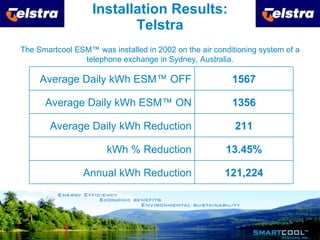

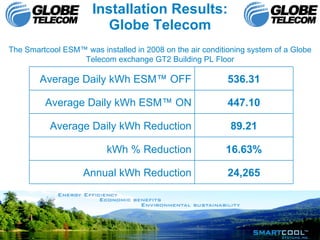

The document introduces the Energy Savings Module (ESM) and ESM ECO3, energy saving devices developed by Smartcool Technology to reduce energy consumption in air conditioning and refrigeration systems. The ESM and ECO3 utilize proprietary software and control algorithms to optimize compressor run times, achieving energy savings averaging 20% without impacting equipment performance or warranties. Case studies on installations in China, Australia, and the Philippines demonstrate annual energy savings ranging from 8,395 to 121,224 kWh.

![Questions? Contact Email: [email_address] Phone:+91 9910347700](https://image.slidesharecdn.com/dnssmartcooltelecom-12523963505209-phpapp02/85/Dns-Smartcool-Telecom-18-320.jpg)