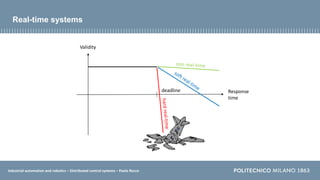

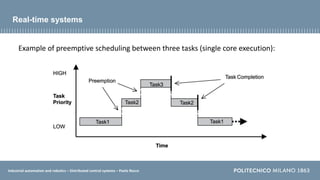

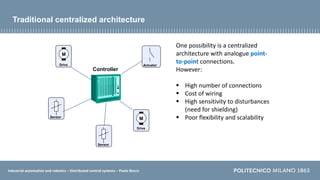

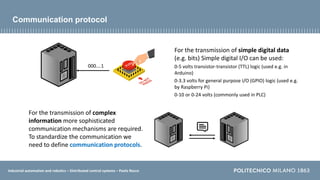

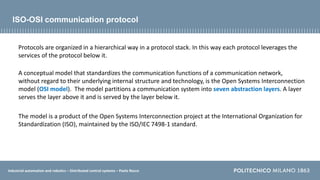

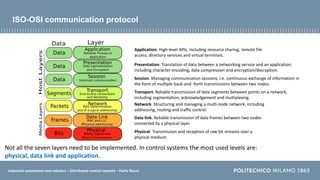

The document discusses distributed control systems and real-time systems. It explains that distributed control systems use digital communication buses to connect multiple control units to sensors and actuators, rather than point-to-point analog connections. It then defines real-time systems as those that must produce outputs within a specified time period in response to external inputs. It classifies real-time systems as soft or hard, depending on whether missing deadlines causes a decrease in performance or catastrophic failure. It also discusses characteristics of real-time operating systems and hardware.