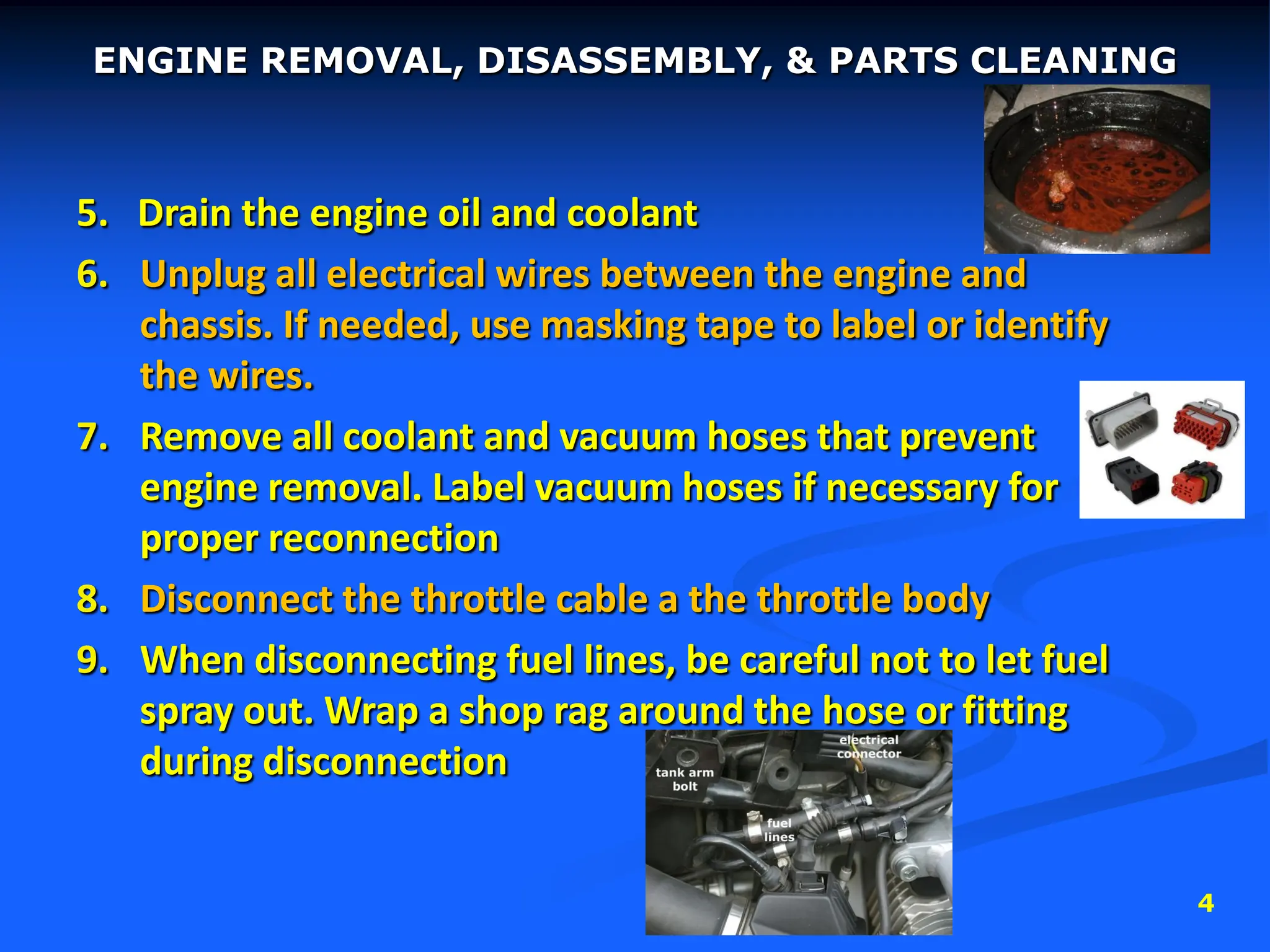

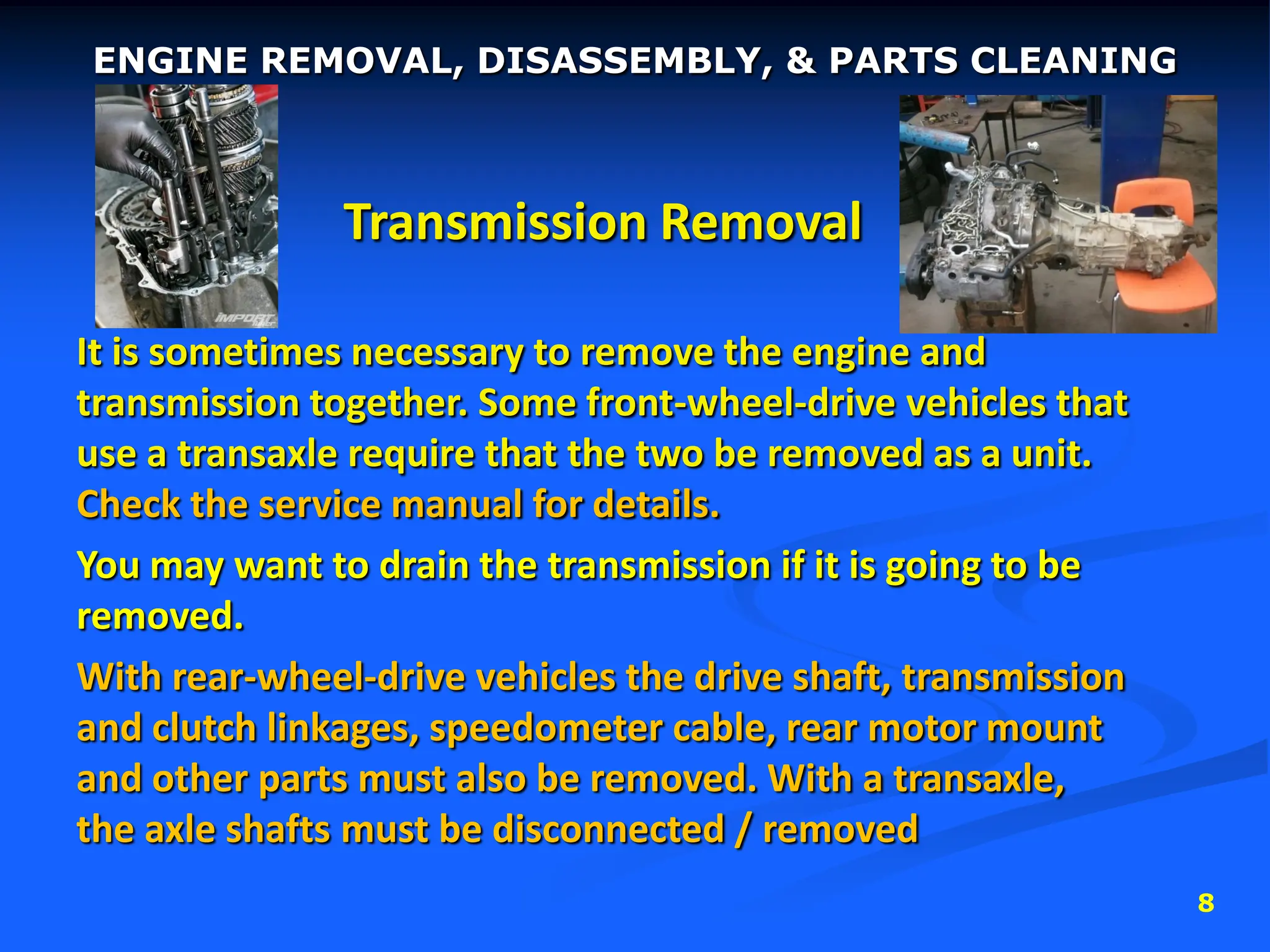

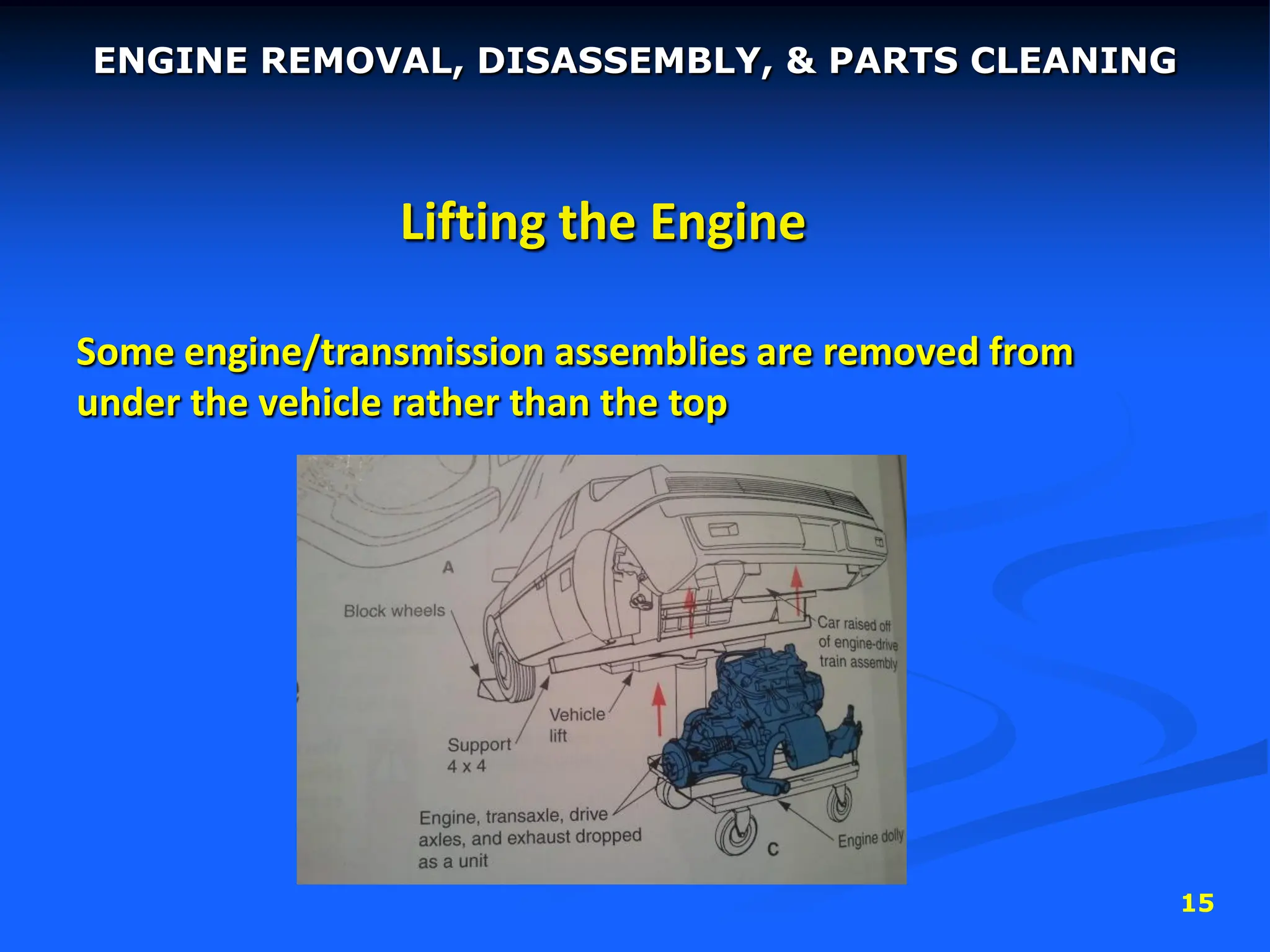

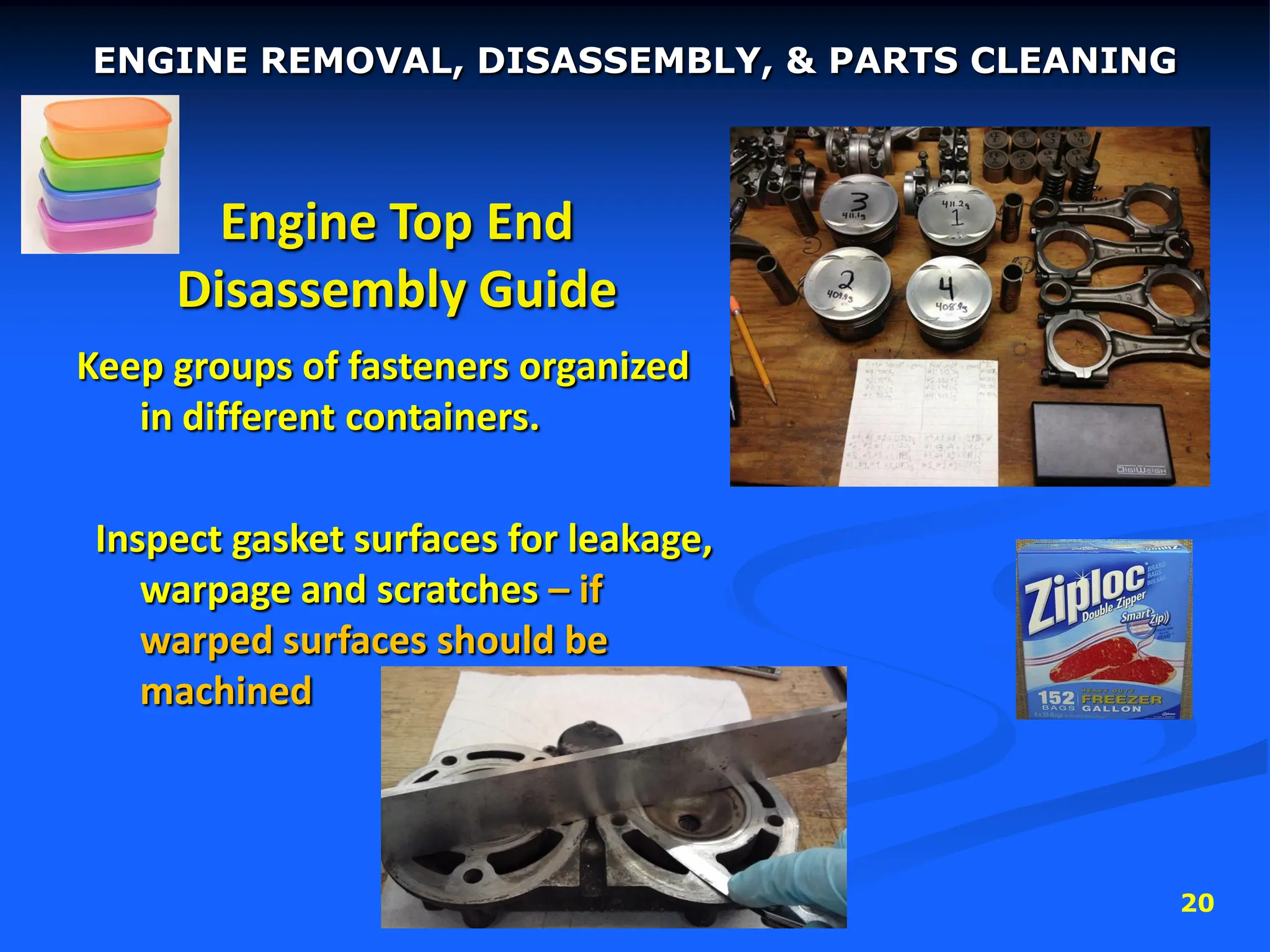

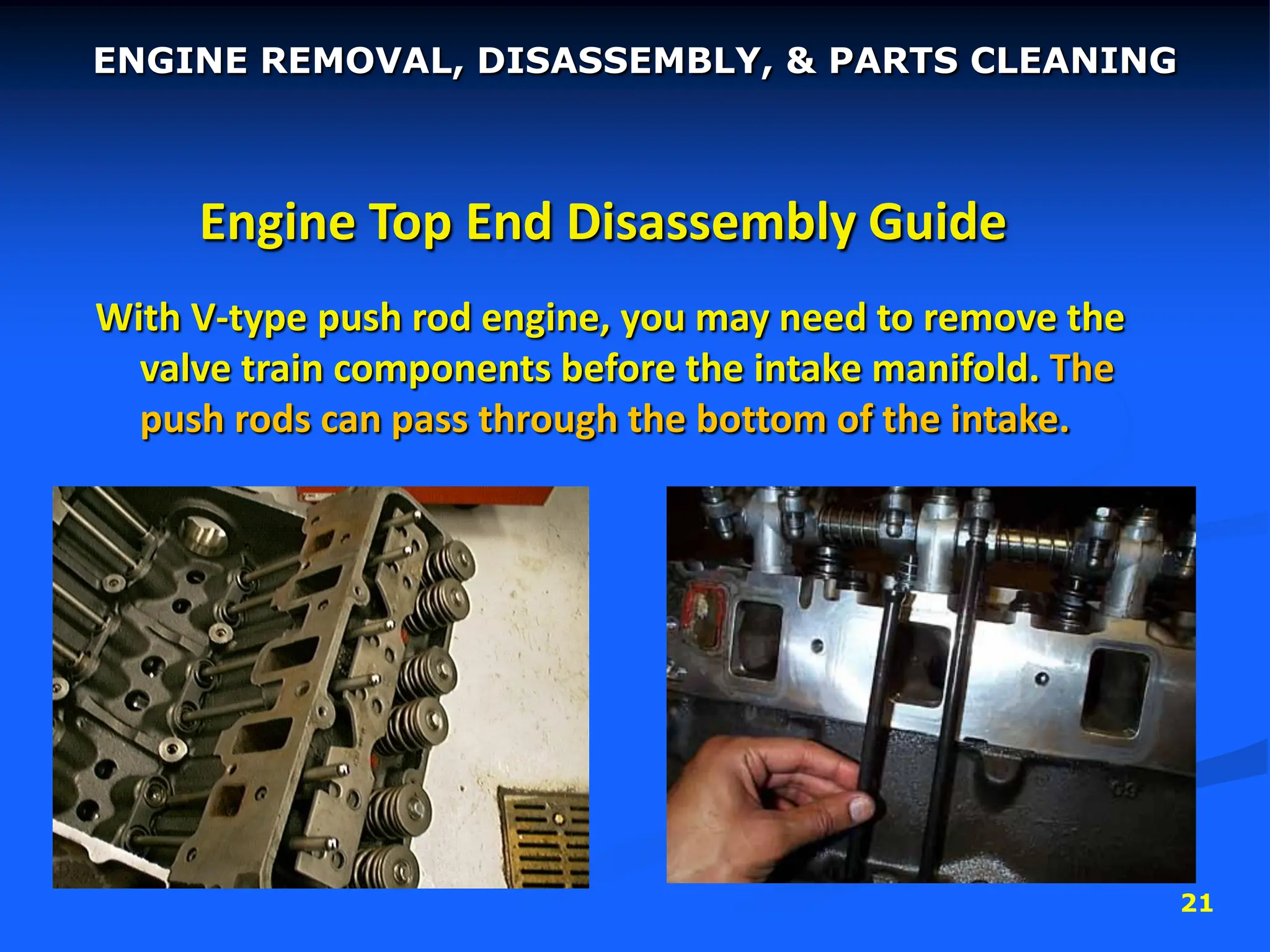

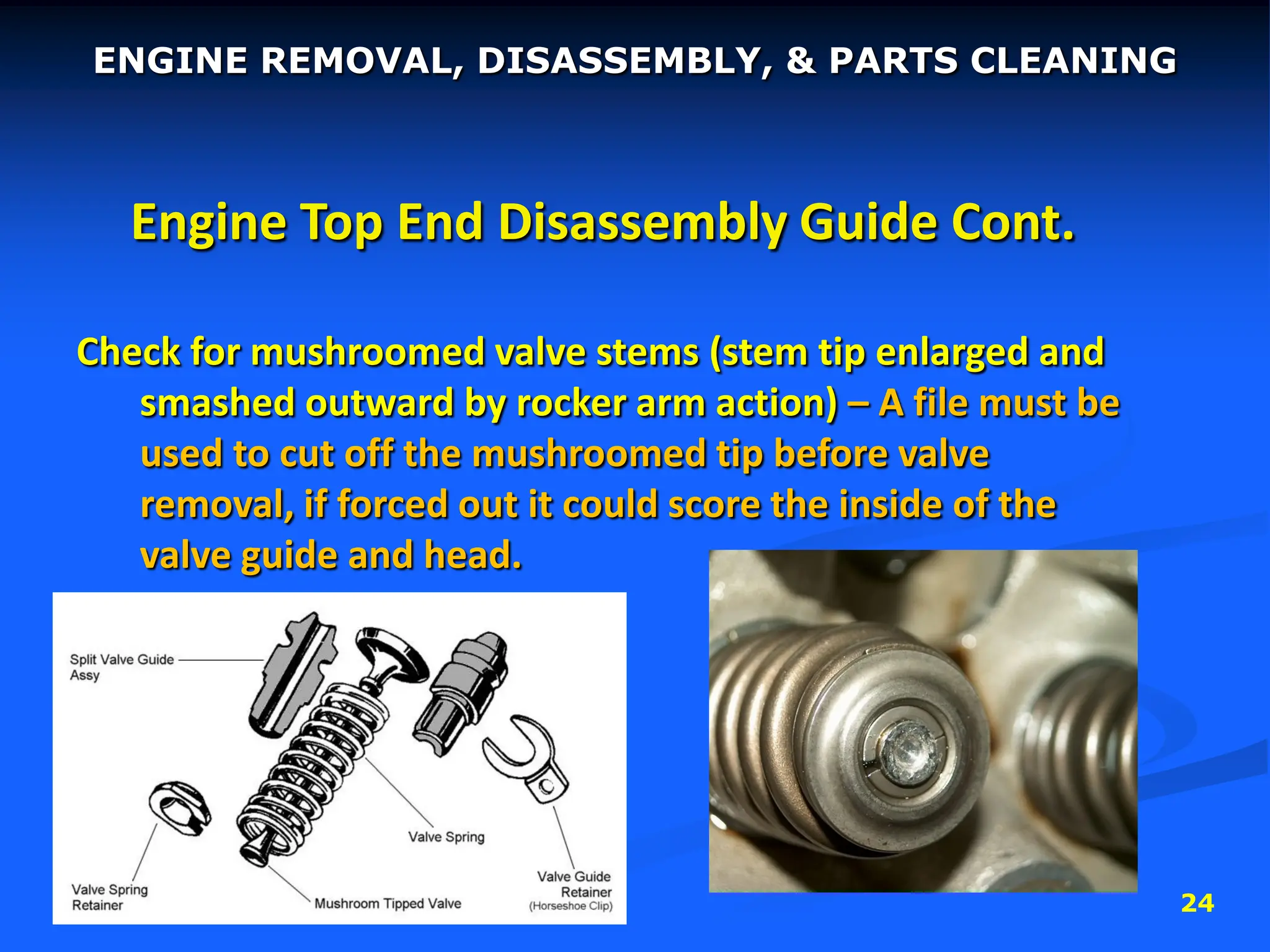

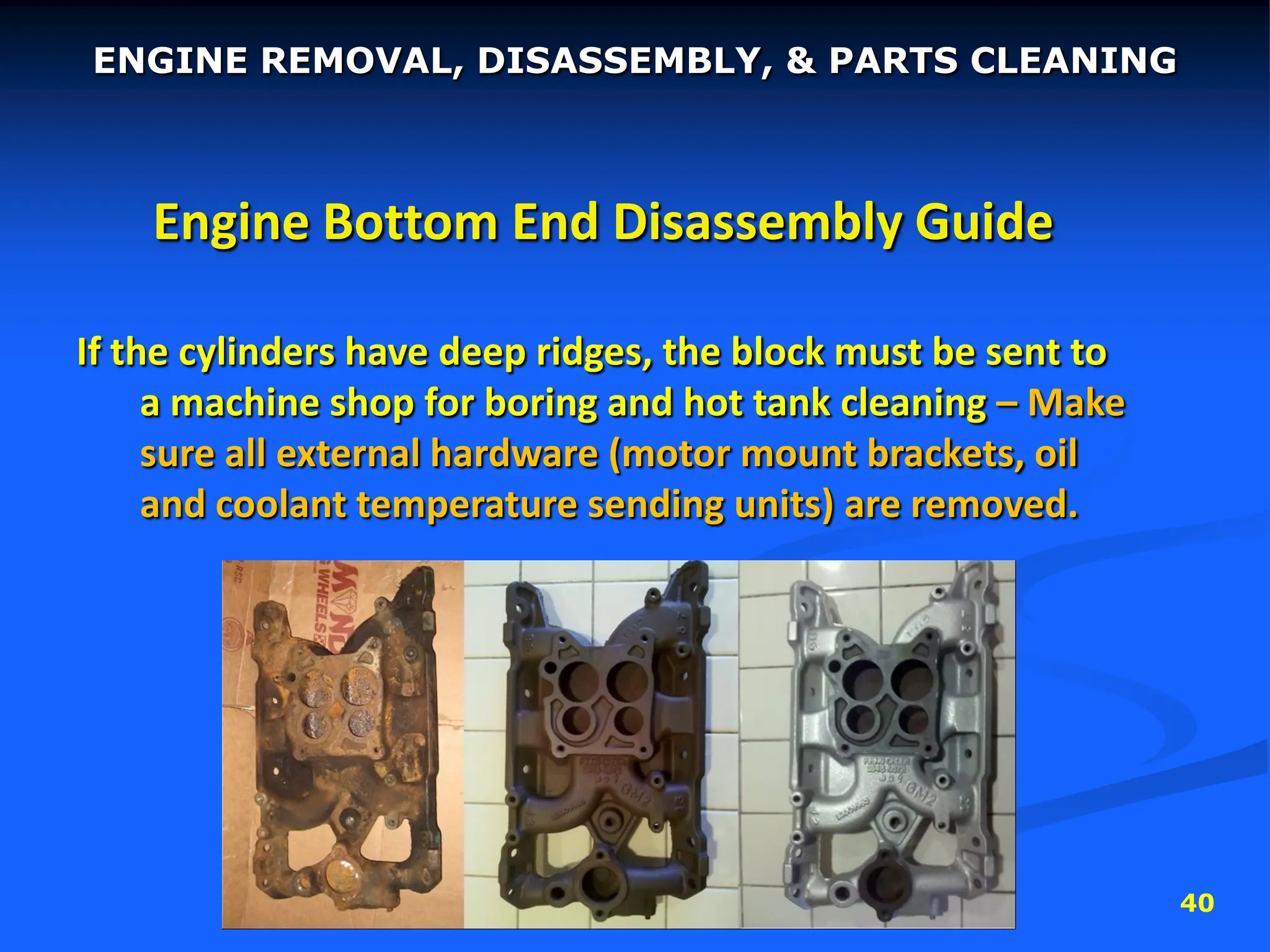

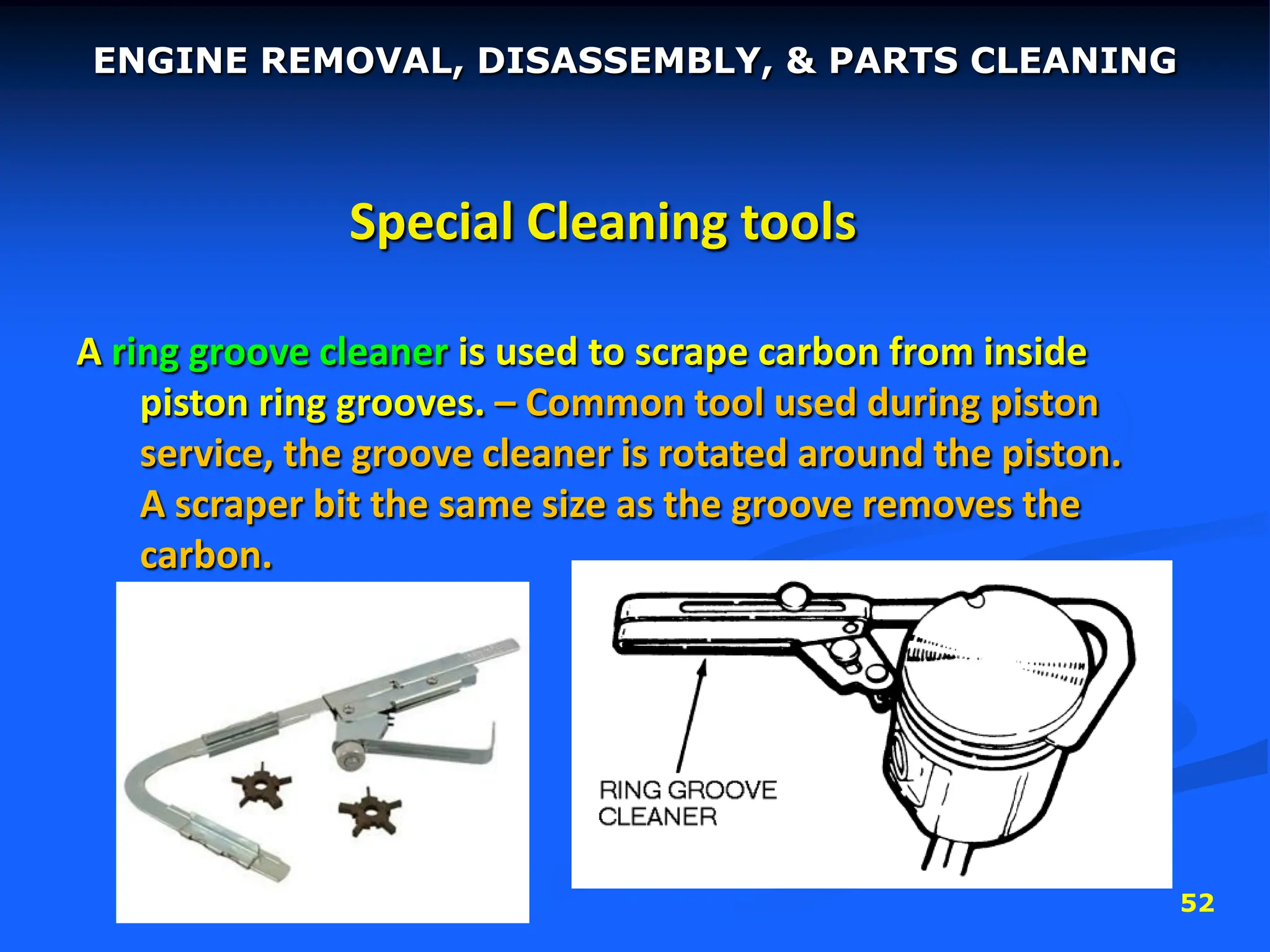

This document outlines the steps for the removal, disassembly, and cleaning of an engine, emphasizing the importance of following manufacturer guidelines. Key steps include preparing the vehicle, disconnecting components, organizing fasteners, and safely lifting the engine. It also covers disassembly procedures and cleaning techniques to ensure effective maintenance and repair.