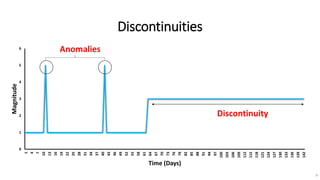

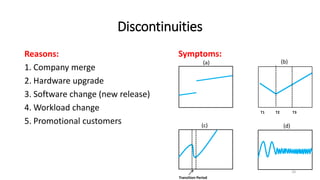

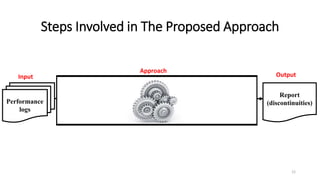

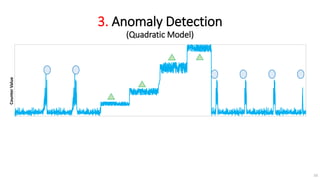

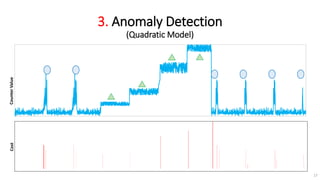

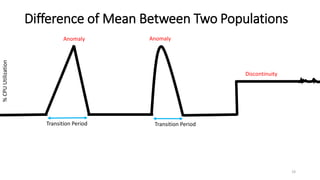

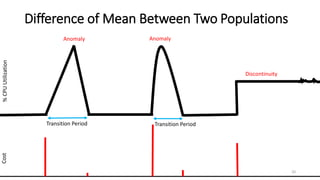

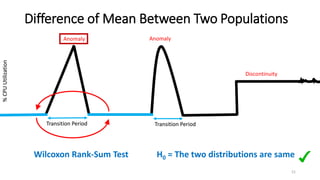

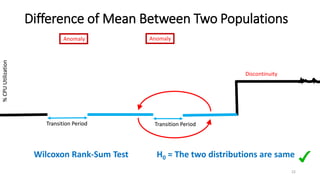

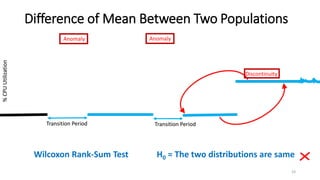

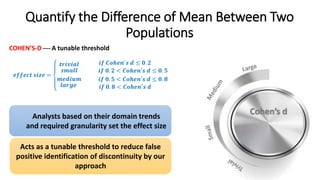

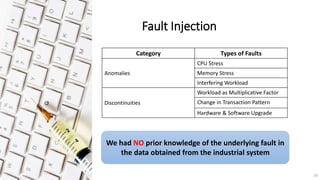

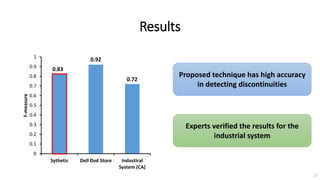

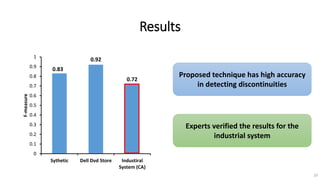

The document proposes an automated approach to help analysts identify discontinuities in large-scale system performance data. The approach involves 4 steps: 1) data preparation to filter noise, 2) metric selection using PCA, 3) anomaly detection using quadratic modeling, and 4) discontinuity identification by comparing distributions using Cohen's D effect size. The approach was tested on synthetic, ecommerce, and industrial system data and achieved high accuracy in detecting discontinuities, which were verified by experts. However, limitations include difficulty distinguishing overlapping discontinuities and sensitivity to the effect size threshold.