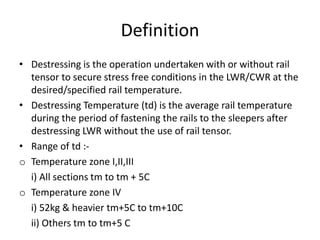

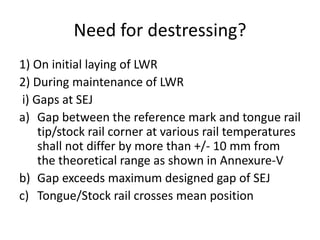

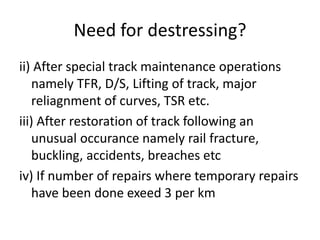

Destressing is the process of securing stress-free conditions in long welded rails (LWR) at a specified rail temperature. It is needed during initial laying of LWR, maintenance like gap adjustments at rail joints, and after special track work. There are two methods - without using a rail tensor, which is the conventional practice but can only be used within certain temperature ranges, and with a tensor, which requires more skilled supervision and block time but can be used at lower temperatures. The procedure without a tensor involves loosening fastenings, cutting the rail, and refastening from the center outwards while placing rollers between sleepers to allow free movement.