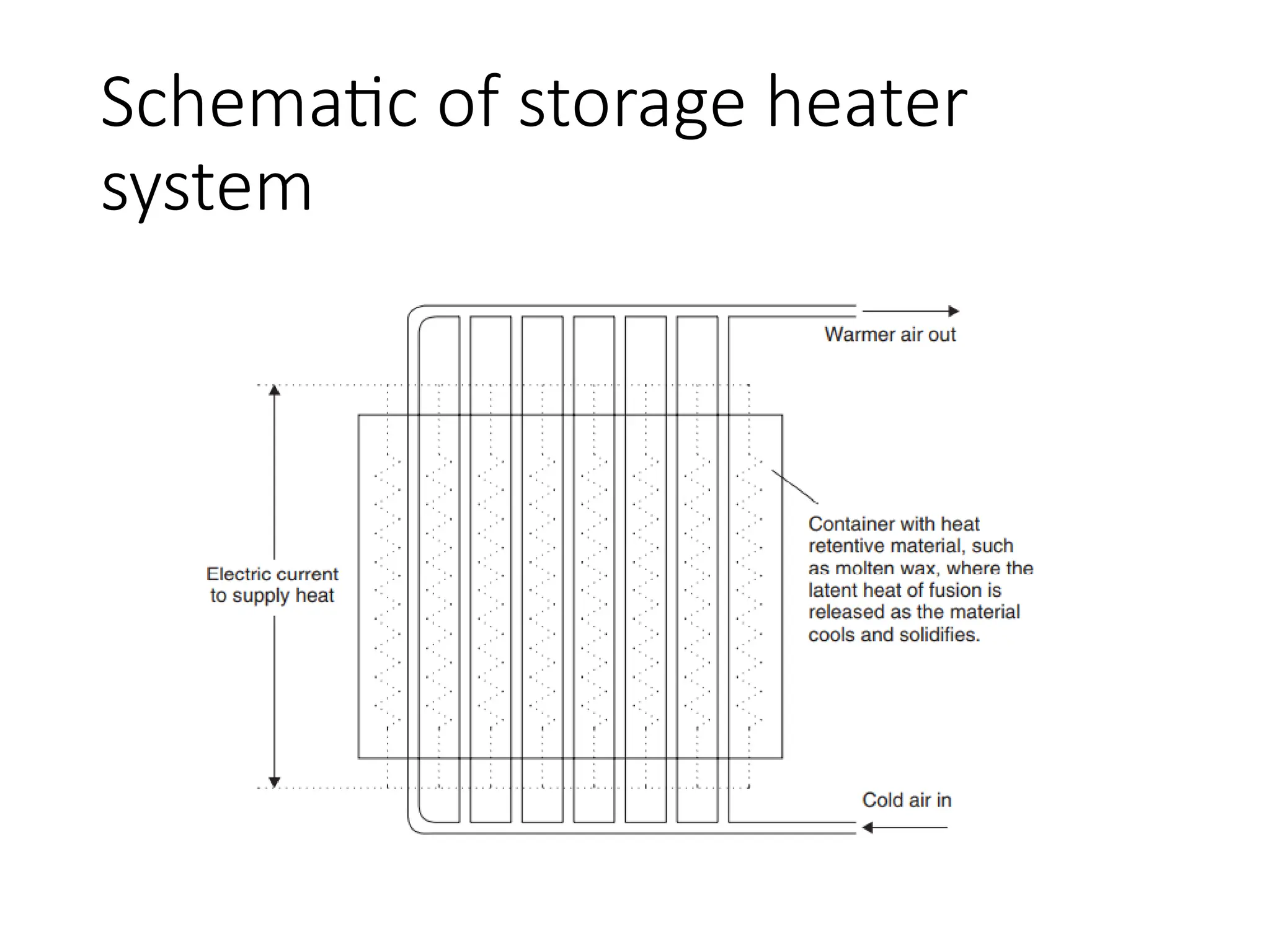

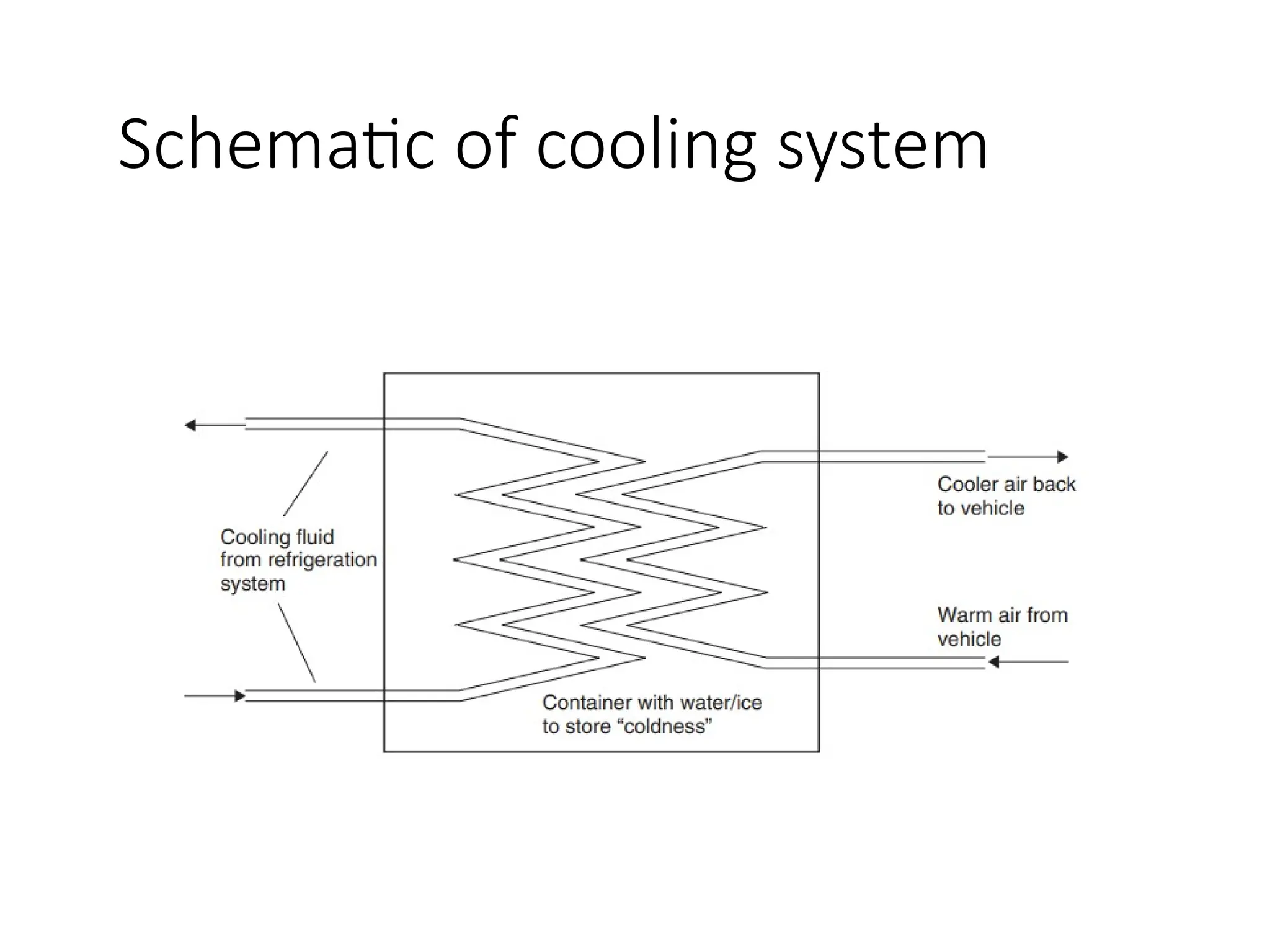

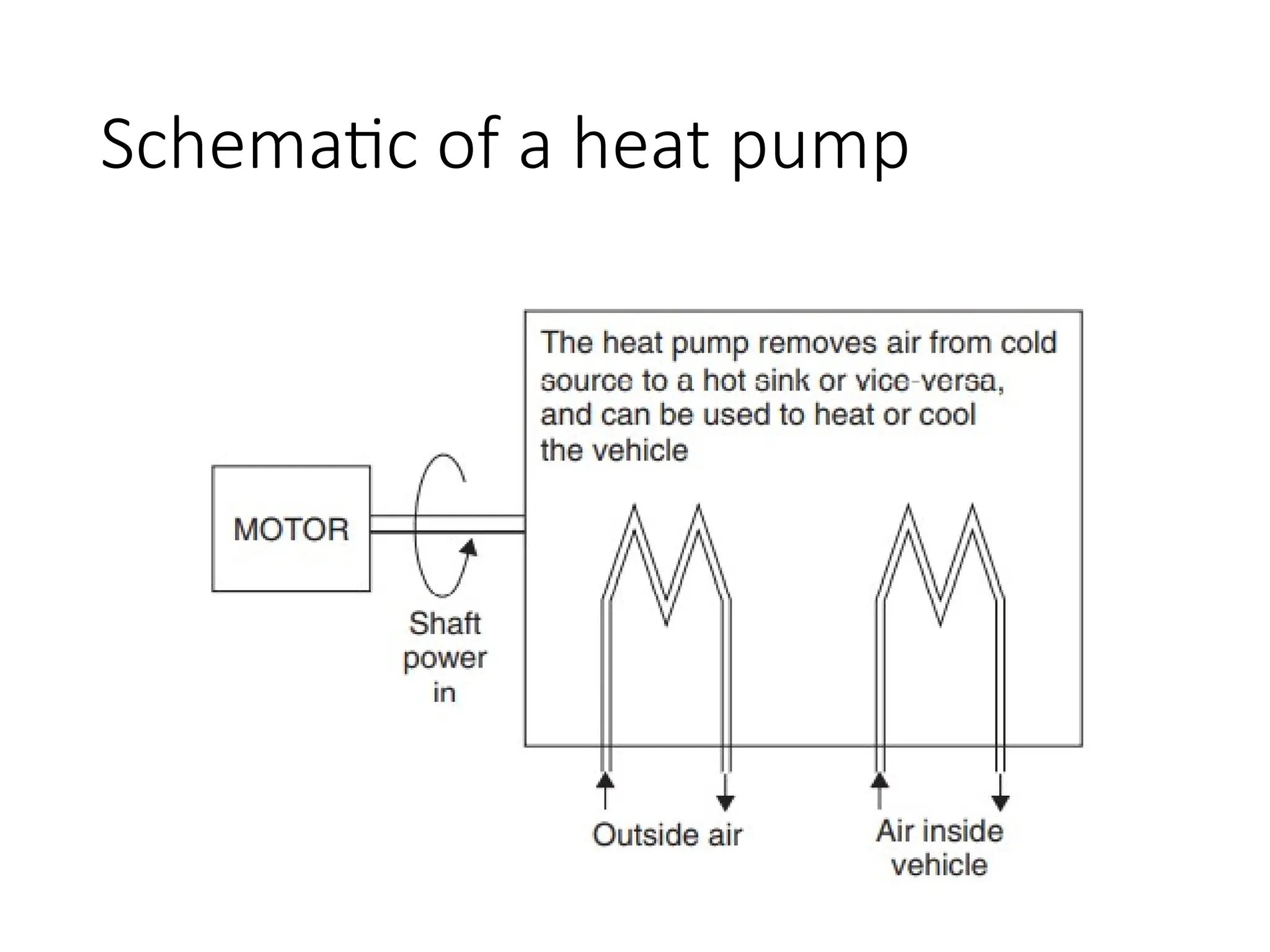

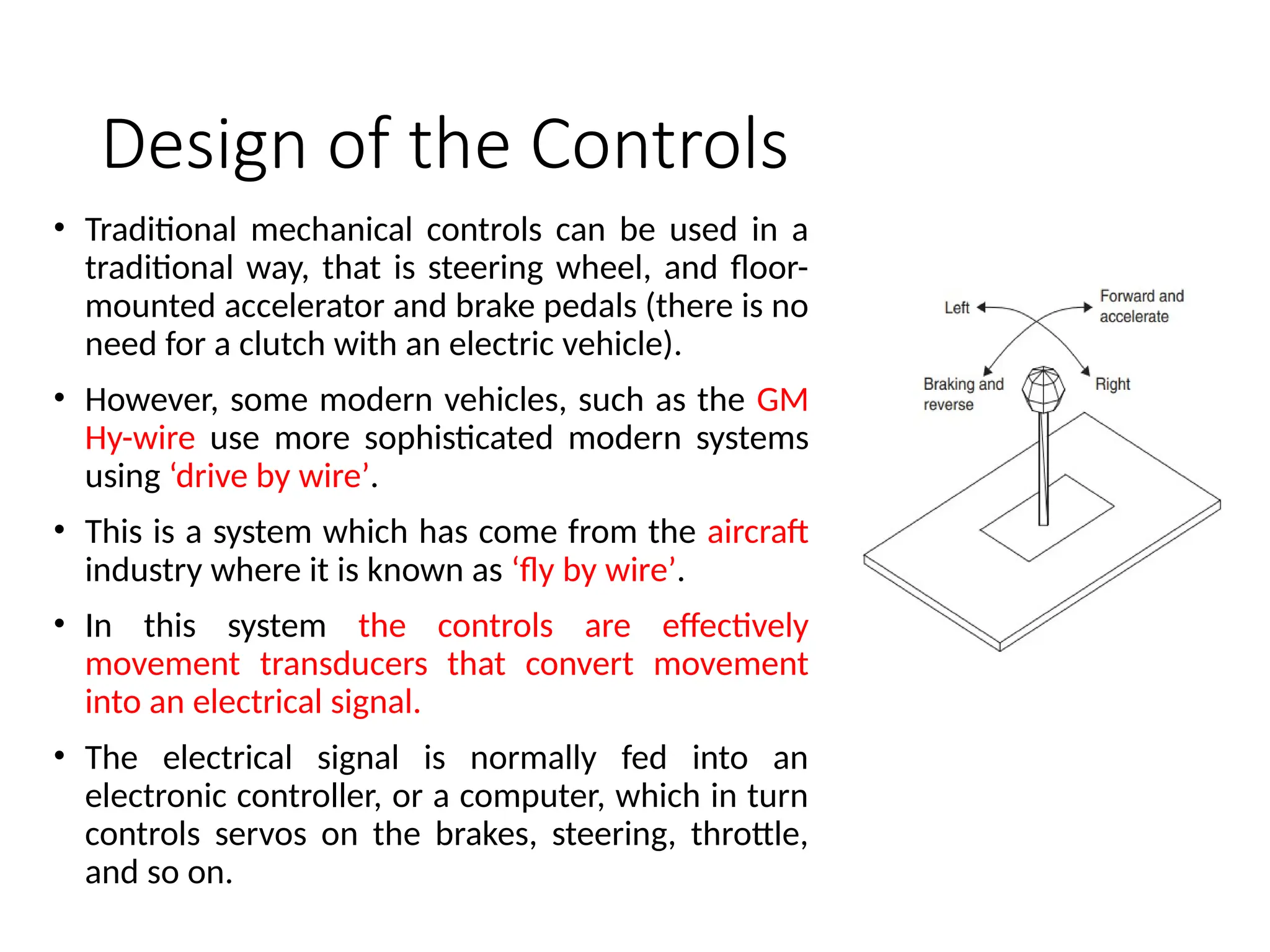

The document discusses the design considerations for ancillary systems in electric vehicles, focusing on energy-efficient heating and cooling systems, power steering, and aerodynamic features. It highlights the importance of utilizing heat pumps, thermal storage, and insulation to improve energy efficiency, as well as using advanced control systems to optimize performance and energy conservation. Additionally, it advocates for the use of low-rolling-resistance tires and modern video systems to enhance vehicle aerodynamics and reduce energy consumption.