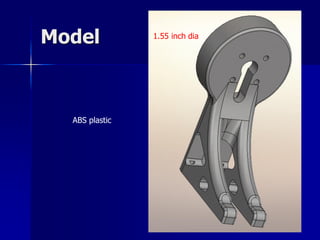

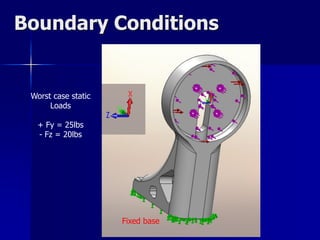

A molded plastic part experienced a defect from post-machining, leading to an analysis of its impact on strength and safety. Finite Element Analysis (FEA) revealed that while the original part had a factor of safety of 1.5, the flawed part dropped to 0.75, indicating significant risk in shipment. Ultimately, FEA proved essential for assessing potential failure not directly at the defect site.