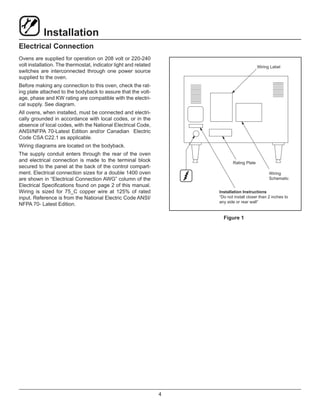

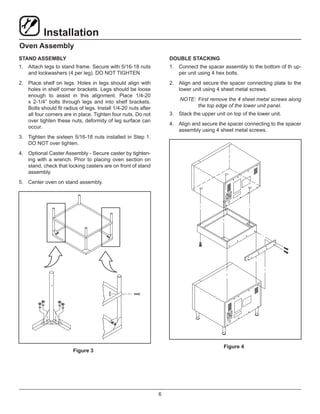

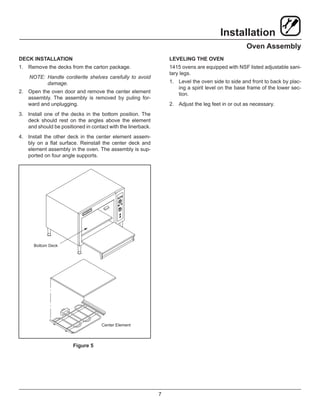

This document provides installation, operation and maintenance instructions for a Blodgett electric compact deck oven. It includes specifications for the oven, instructions for delivery and location, electrical connection, assembly, operation of the control panel, and cleaning and preventative maintenance procedures.