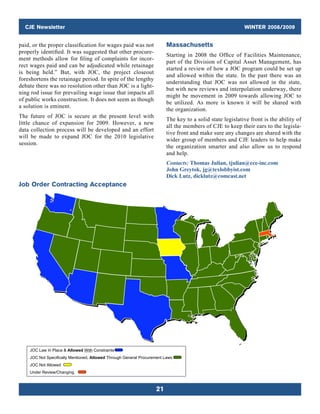

The document discusses the importance and benefits of job order contracting (JOC) as a cost-effective solution for publicly funded renovation and construction projects, particularly in a challenging economic environment. It emphasizes that JOC allows for better budget control, reduced risks, and improved communication while addressing the backlog of renovation demands and supporting sustainability efforts. Furthermore, it outlines the strategic goals for 2009 regarding membership growth, regional chapter establishment, and enhancing support for the job order contracting community.