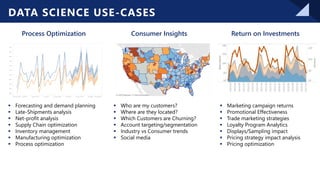

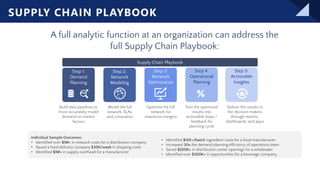

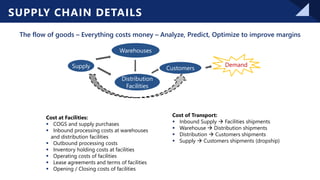

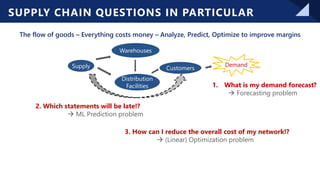

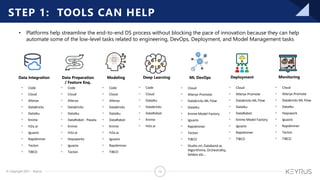

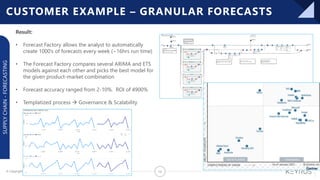

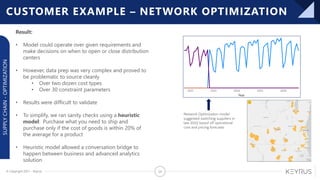

The document provides examples of how data science can be applied to solve complex supply chain problems for customers. It discusses forecasting demand at a granular level for a spirits company, using machine learning to predict late shipments for a CPG company, and optimizing a distribution network for a durable goods company. The goal is to show how data science tools and services can help businesses address challenges in forecasting, logistics planning, and operations optimization.