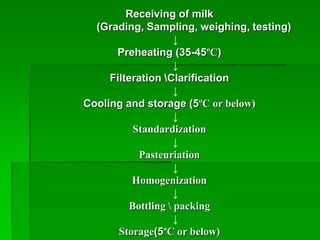

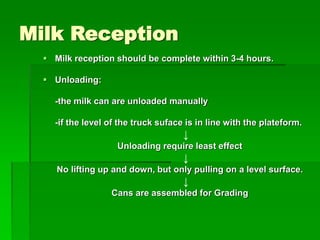

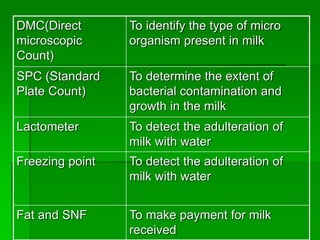

The document outlines the dairy processing steps for milk from reception to bottling, including grading, testing, and storage. It emphasizes the importance of timely milk reception and various quality control tests to determine milk quality and detect adulteration. Key tests include acidity, ethanol, clot-on-boiling, and total bacterial count to ensure the milk meets safety standards.