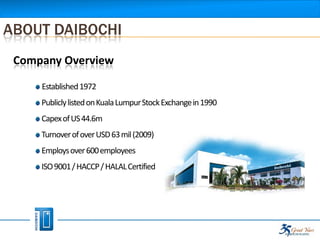

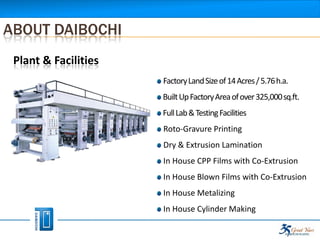

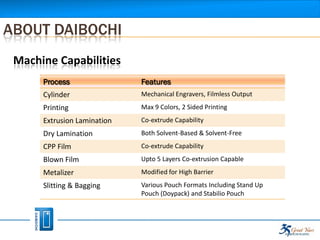

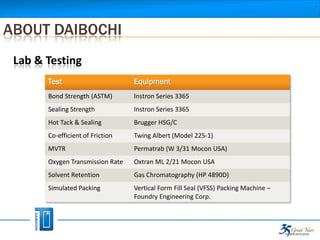

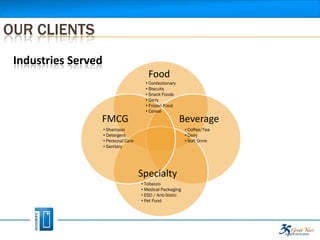

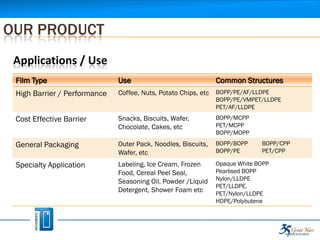

Daibochi Plastic and Packaging is a major Malaysian manufacturer of laminated packaging films established in 1972. It has over 600 employees, annual turnover of $63 million, and manufacturing facilities covering 325,000 square feet. Daibochi supplies international brands in Asia Pacific and Europe with high-quality printed packaging films through rotogravure printing and extrusion lamination. It focuses on food safety, print quality, production capacity, and cost competitiveness to meet customer needs across industries like food, beverages, and personal care.