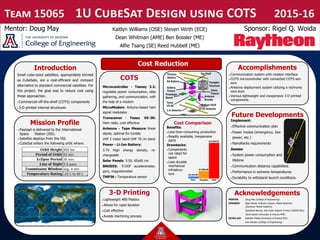

This document summarizes a 1U CubeSat project that aimed to reduce costs using commercial off-the-shelf (COTS) components and 3D printed structures. The CubeSat will be delivered to the International Space Station then deploy from there into a low Earth orbit. It utilizes a variety of inexpensive COTS parts like a Teensy microcontroller, Yaesu radio, and lithium-ion battery. The team accomplished communication capabilities with a modem interface, sensor integration, antenna deployment, and 3D printed structures. Future work includes assessing the system's performance in space conditions.