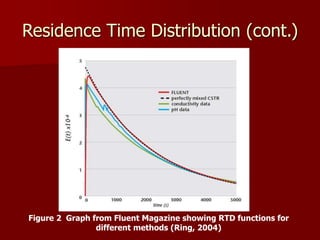

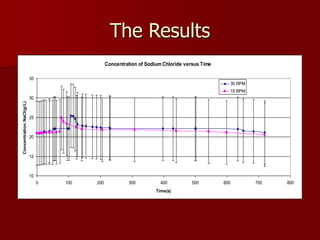

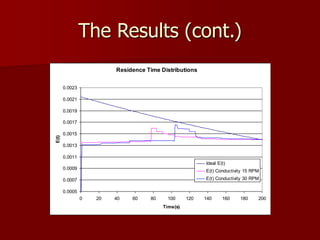

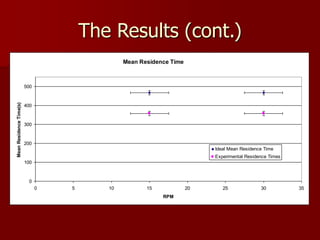

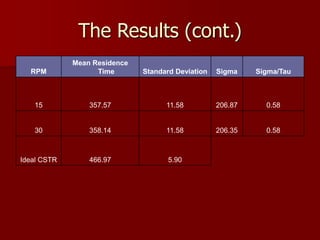

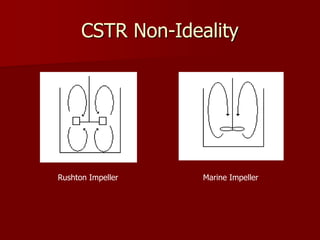

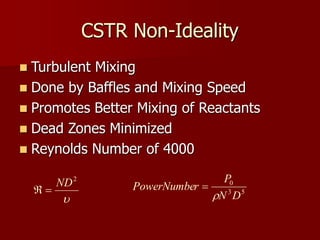

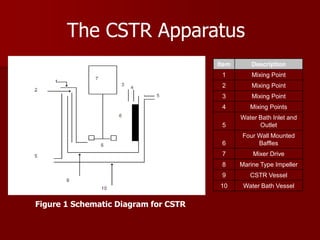

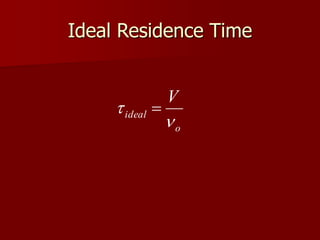

This document summarizes an experiment characterizing the ideality of a continuous stirred tank reactor (CSTR). Sodium chloride was used as a tracer to determine the reactor's residence time distribution at different mixer speeds. The results showed that mean residence times approached the ideal CSTR value as speed increased, but non-ideality was still observed due to factors like poor mixing and dead zones. Recommendations included using a marine impeller design to promote turbulence and minimizing dead zones.

![Residence Time Distribution

end

t

mean

mean dt

t

tE

t

0

)

(

end

t

m dt

t

E

t

t

0

2

)

(

)

(

end

t

dt

t

C

t

C

t

C

t

C

t

E

0

)]

0

(

)

(

[

)

0

(

)

(

)

(](https://image.slidesharecdn.com/cstrstudy-rtdforcalciner-221225075227-c41d2c71/85/CSTR-study-RTD-for-Calciner-ppt-9-320.jpg)