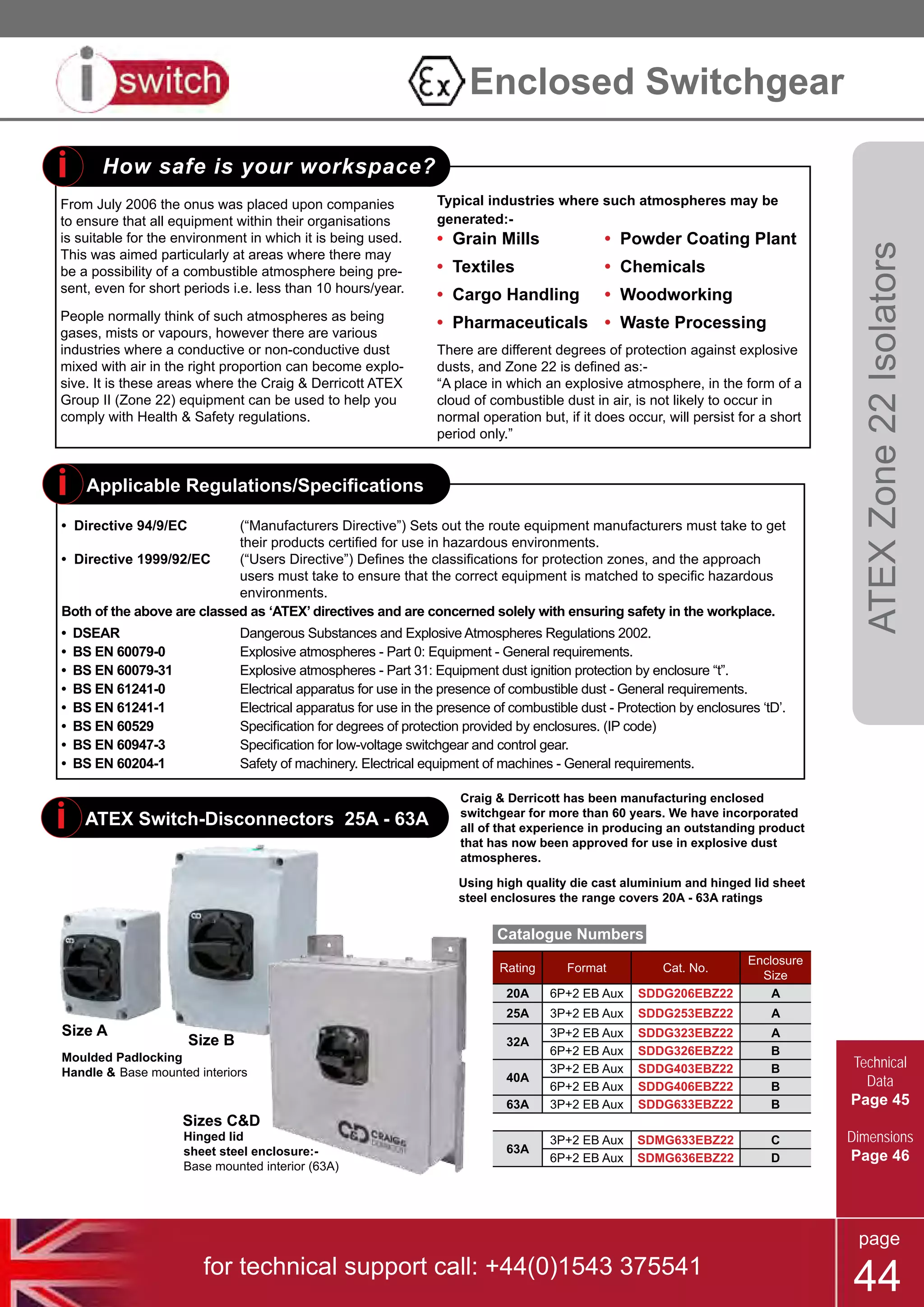

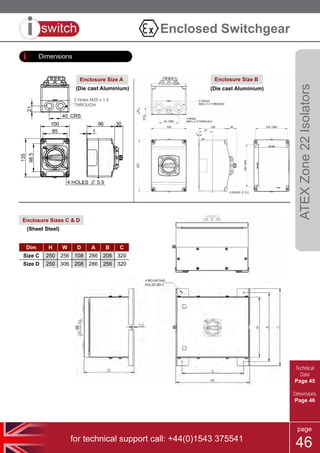

This document provides information on ATEX Zone 22 certified switch-disconnectors and isolators from Craig & Derricott for use in explosive dust atmospheres. It lists product ratings from 20A to 63A, certifications that comply with relevant standards, technical specifications including short circuit ratings, and enclosure size dimensions from A to D. Applications include grain mills, powder coating plants, chemicals handling, and other industries where combustible dust may be present for short periods.