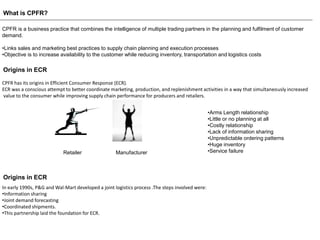

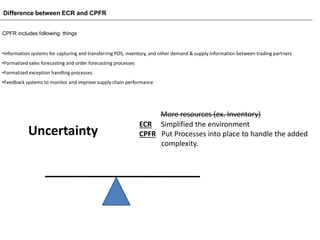

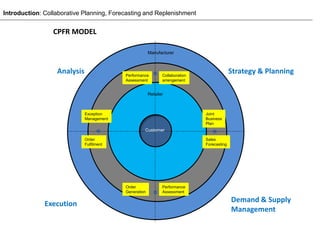

CPFR has its origins in Efficient Consumer Response (ECR), where Procter & Gamble and Walmart developed processes like information sharing, joint demand forecasting, and coordinated shipments in the early 1990s. CPFR builds on this by linking sales and marketing practices to supply chain planning and execution between trading partners to increase customer availability while reducing costs. It includes information systems to share demand data, formalized forecasting and order processes, and exception handling to monitor performance.