This document provides an introduction and overview to the National Pesticide Applicator Certification Core Manual. It acknowledges the contributors and reviewers involved in producing the manual. The manual was created with support from the EPA to provide guidance on pesticide applicator certification. It contains chapters on topics like pest management, federal pesticide laws, pesticide labeling, safety, and more. The goal is to help inform those seeking certification on important concepts and requirements regarding pesticide application.

![CHAPTER 1

and other animals. Since the 1972 EPA

ban on DDT use in the United States,

regulatory action has been taken against

many chemicals, including pesticides,

thought to pose significant environ-

mental and health hazards. Public

concern has led to stringent regulation

of pesticides and changes in the types

of pesticides used.

Pests are organisms that cause

problems in various ways. Some

compete with people for food or fiber.

Others interfere with the raising of

crops, livestock, or poultry. Certain

types of pests damage property and

personal belongings or disfigure

ornamental plantings. Others

transmit or cause plant, animal, or

human diseases.

Before trying to control a pest,

you need to identify it. Be certain any

injury or observed damage is actually

due to the identified pest and not some

other cause. Once you have identified

the pest and confirmed that it is causing

damage, become familiar with its life

cycle, growth, and reproductive habits.

Then, use this information to form your

pest control plans. Misidentification

and lack of information about a pest

could cause you to choose the wrong

control method or apply the control

at the wrong time. These are the

most frequent causes of pest control

failure.

In addition, some plants are

damaged by non-living agents. These

include such things as weather extremes,

air pollutants, road salt, and inadequate

or excessive fertilization. Sometimes

this damage is mistaken for that caused

by living pests.

Ways to Identify Pests

Identify a pest by using the guide-

lines included in this chapter and then

consulting reference materials such as

identification books, Extension bul-

letins, and field guides that contain

pictures and biological information

on the pest. Another option is to have

pests examined and identified by pest

management specialists. When having

pests identified, always collect several

specimens. Have plastic bags, vials, or

other suitable containers available when

collecting samples in the field. For plant

diseases, submit undamaged specimens,

such as healthy foliage, along with the

damaged foliage. For insects and their

relatives, kill them first and send them

to the specialist in a manner that will

not damage body parts that aid in their

identification. For weed/plant samples,

it is best to submit whole plants,

including roots, vegetative structures,

and flowers, if possible. Plants may be

pressed flat between paper or cardboard

to prevent leaf crinkling or placed

in plastic bags. Be sure to include the

location and date of the collection.

The difficulty in identifying certain

insects and most mites, nematodes, and

plant pathogens in the field is their

small size. Accurate identification

requires the use of a hand lens or micro-

scope, special tests, or careful analysis

of damage. Often the pest’s host (the

animal or plant on which an organism

lives) and location are important

to making positive identifications.

Information on the environmental

conditions where you collect pests and

the time of year of collection provides

clues to the pest’s identity.

co

O

c

yo

in

du

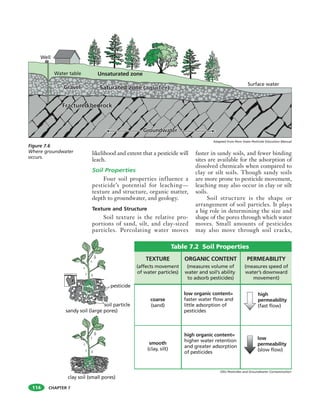

The Four Main Groups of Pests

• Weeds (undesirable plants).

• Invertebrates (insects, mites,

ticks, spiders, snails, and slugs).

• Disease agents or pathogens

(bacteria, viruses, fungi,

nematodes [roundworms],

mycoplasmas [parasitic

microorganisms], and other

microorganisms).

• Vertebrates (birds, reptiles,

amphibians, fish, and rodents

and other mammals).

PEST RECOGNITION

da

cy

Th

p

fa

da

Invertebrate pest.

Weed pest.

Disease pest.

4

Larry Schulze, University of Nebraska](https://image.slidesharecdn.com/coremanual2-150205121000-conversion-gate01/85/Coremanual2-19-320.jpg)

![FEDERAL PESTICIDE LAWS

are individuals who use or supervise the

use of any restricted-use pesticide for

any purpose on any property except for

those provided for under the definition

of a private applicator.

Only certified applicators or indi-

viduals under their direct supervision

may mix, load, or apply restricted-

use pesticides. To become certified,

a person must exhibit a broad-based

knowledge of and competency in pes-

ticide use and handling. This provides

an alternative to more stringent con-

trols on, or even cancellation of, the

use of these pesticides.

The certified applicator is not

permitted to use any pesticide for any

use other than that stated on the label

except when specific exemptions are

granted under Section 2 (ee) of FIFRA.

Section 2 (ee) contains provisions that

exclude several application procedures

from being classified as uses “incon-

sistent with product labeling.” (Note:

Not all regulatory agencies recognize

the provisions of Section 2 [ee] under

FIFRA. Before making pesticide

applications, you need to consult your

pesticide regulatory agency to see if

your respective state, tribe, territory,

or agency recognizes these provisions.)

These provisions allow:

• A pesticide may be applied to

control a target pest not spec-

ified on the label if the pesticide

is applied to a crop, animal, or

site specifically listed on the

label (e.g., interior of a home,

food-handling establishments,

exterior ornamental plants, corn,

tomatoes, etc.).

• Any method of application may

be used that is not prohibited by

the label.

• A pesticide may be applied at a

dosage, concentration, or fre-

quency less than that specified

on the label, except in the case of

termiticides labeled for precon-

struction treatments.

• A pesticide-fertilizer mixture

may be used if the mixture is not

prohibited by the label.

The certification process by all the

states, tribes, and territories must be

accomplished through EPA-approved

programs. Each state is responsible for

implementing the certification program.

In addition, all states have signed coop-

erative agreements with the EPA that

designate an agency within the state (i.e.,

the state lead agency) to enforce the

provisions of FIFRA. In some situations,

more than one agency within a state may

be designated to enforce various compo-

nents of FIFRA (e.g., some states have

structural pest control boards respon-

sible for regulating the structural pest

control industry).

States, tribes, territories, and some

local jurisdictions have their own legal

requirements concerning pesticide use.

You are responsible for knowing about

these requirements and complying with

them. Be sure you are up-to-date on legal

requirements at all governmental levels—

laws and regulations are constantly

evolving as pesticide application becomes

more complex and more is learned about

potential hazards. Ignorance of the law is

never an accepted excuse for a violation.

21

PESTICIDE REGISTRATION

Only certified

applicators

or individuals

under their

direct super-

vision may mix,

load, or apply

restricted-use

pesticides.

No pesticide can be registered or

offered for sale unless its labeling

provides for reasonable safeguards to

prevent injury to humans and adverse

effects on the environment. There

are several types of registration and

exemption actions that enable pesticides

to be used in the United States:

• The federal registration of pesti-

cides under Section 3 of FIFRA.

• Special local need registrations

under Section 24(c).

• Emergency exemptions under

Section 18.

• Exemption of minimum-risk

pesticides from registration

under Section 25(b) of FIFRA.

All of these registration and exemption

actions are discussed in detail in Chapter](https://image.slidesharecdn.com/coremanual2-150205121000-conversion-gate01/85/Coremanual2-36-320.jpg)

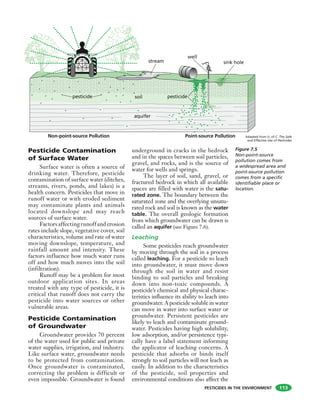

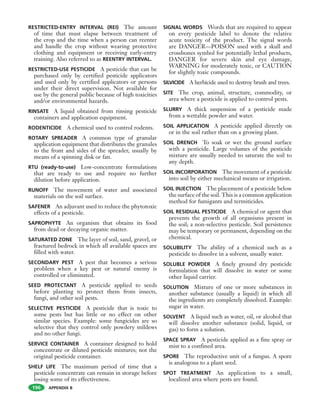

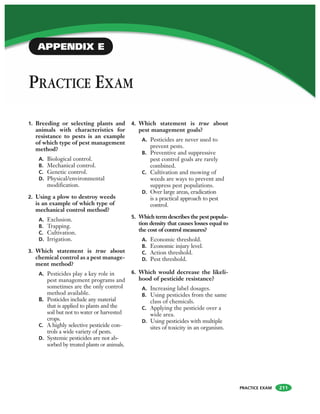

![CHAPTER 3

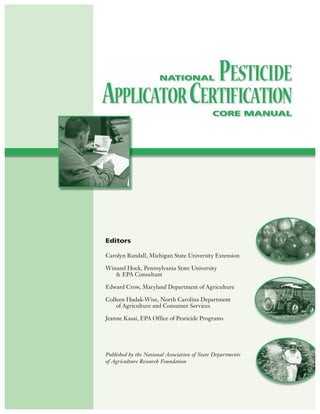

Physical and Chemical Properties

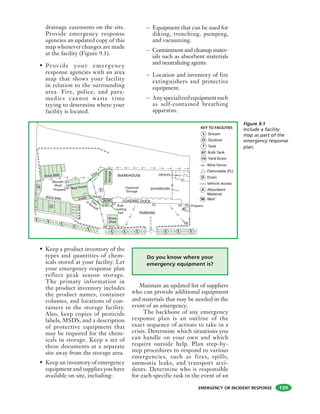

This section describes the prod-

uct’s physical appearance and provides

information about how the product

behaves under certain physical and

chemical conditions. Particularly rel-

evant are the measures for solubility

in water, vapor pressure, stability, and

freezing/boiling point.

Water solubility is a factor in

whether a substance is likely to be carried

off the site in runoff water or in leachate.

In general, the lower the solubility, the

more likely the substance is to bind to soil

particles or organic matter rather than to

dissolve in water. A relatively high solu-

bility in water can be a benefit, however,

because water-soluble products are

excreted in urine rather

than stored in body fat.

A substance’s vapor

pressurehelpsdetermine

whether the substance

is likely to volatilize,

or form a gas. Other

factors involved include

temperature; how tightly

the substance binds to

soil particles, plants, or

the site of application;

and how much water is

present (combined with

the substance’s water

solubility). Products

with relatively high vola-

tility are more likely to

be detected through smell than products

with low volatility. Some MSDS provide

direct information about the odor of a

product. Products may range from prac-

tically odorless to very apparent.

Stability and freezing and boiling

points of a substance determine

whether a product can be stored over

the summer or winter. Freezing and

excessive heating may degrade the

product, resulting in a loss of efficacy

against the pest.

Fire and Explosion Hazards

Some substances can spontaneously

catch on fire at a certain temperature.

In such cases, the MSDS identifies the

temperature, called the flash point, at

which the substance catches fire. The

MSDS may list conditions to avoid,

such as materials that are incompatible

with the product. For instance, some

substances can react with galvanized

containers to form hydrogen gas, a

highly combustible material.

Toxicological Information/

Human Health Data

The MSDS identifies by what

route(s) of exposure the product may

be harmful (i.e., ingestion [oral],

through the mouth; dermal, through

the skin; and inhalation, by breathing

in the product’s vapors). The MSDS

also summarizes results of toxico-

logical tests performed on laboratory

animals and extrapolates them to the

potential for effects on humans. The

toxicological tests required by the EPA

include acute toxicity, chronic toxicity,

delayed toxicity, oncogenicity (ability

to cause tumors), carcinogenicity

(ability to cause malignant tumors, or

cancer), teratogenicity (ability to cause

birth defects), and fetotoxicity (other

adverse effects on the fetus, such as low

birthweight or spontaneous abortion).

The MSDS also lists symptoms of acute

overexposure and usually lists medical

conditions that may be aggravated by

exposure to the product.

It is important to remember that a

substance’s level of acute toxicity is not

related to its ability to cause chronic

or delayed effects. The MSDS usually

provides specific information about the

product’s ability to cause eye and skin

irritation or allergic responses. Allergic

responses are also not related to the

chemical’s level of acute toxicity. Thus,

it is possible for a slightly toxic pesticide

(Category III) to be associated with

adverse long-term effects or allergic

reactions and, conversely, for a highly

toxic pesticide (Category I) to have no

known long-term or allergic effects.

(See Chapter 5 for a discussion of tox-

icity categories.)

Cholinesterase Inhibition

If the pesticide can inhibit

cholinesterase (an enzyme that regu-

lates nerve impulses), the MSDS may

identify it as a cholinesterase inhibitor.

Such identification was not required

until recently.

46

Example of a physical

and chemical properties

section on a MSDS for an

herbicide product.

PHYSICAL AND CHEMICAL

PROPERTIES

Boiling Point: 212˚F Melting Point: NI

Evaporation Rate (Butyl Acetone = 1): NI

Vapor Pressure (mm Hg.): <17 @ 78 F

Vapor Density (Air = 1): >1

Specific Gravity (H20 = 1): 1.14600

Solubility in Water: Infinite

Appearance and Odor: Brown liquid;

amine odor.

Other Information:

pH = 7.5–8.0

Density = 9.63 pounds/gallon

Freezing point <35˚F

Percent volatile by volume 46%](https://image.slidesharecdn.com/coremanual2-150205121000-conversion-gate01/85/Coremanual2-61-320.jpg)