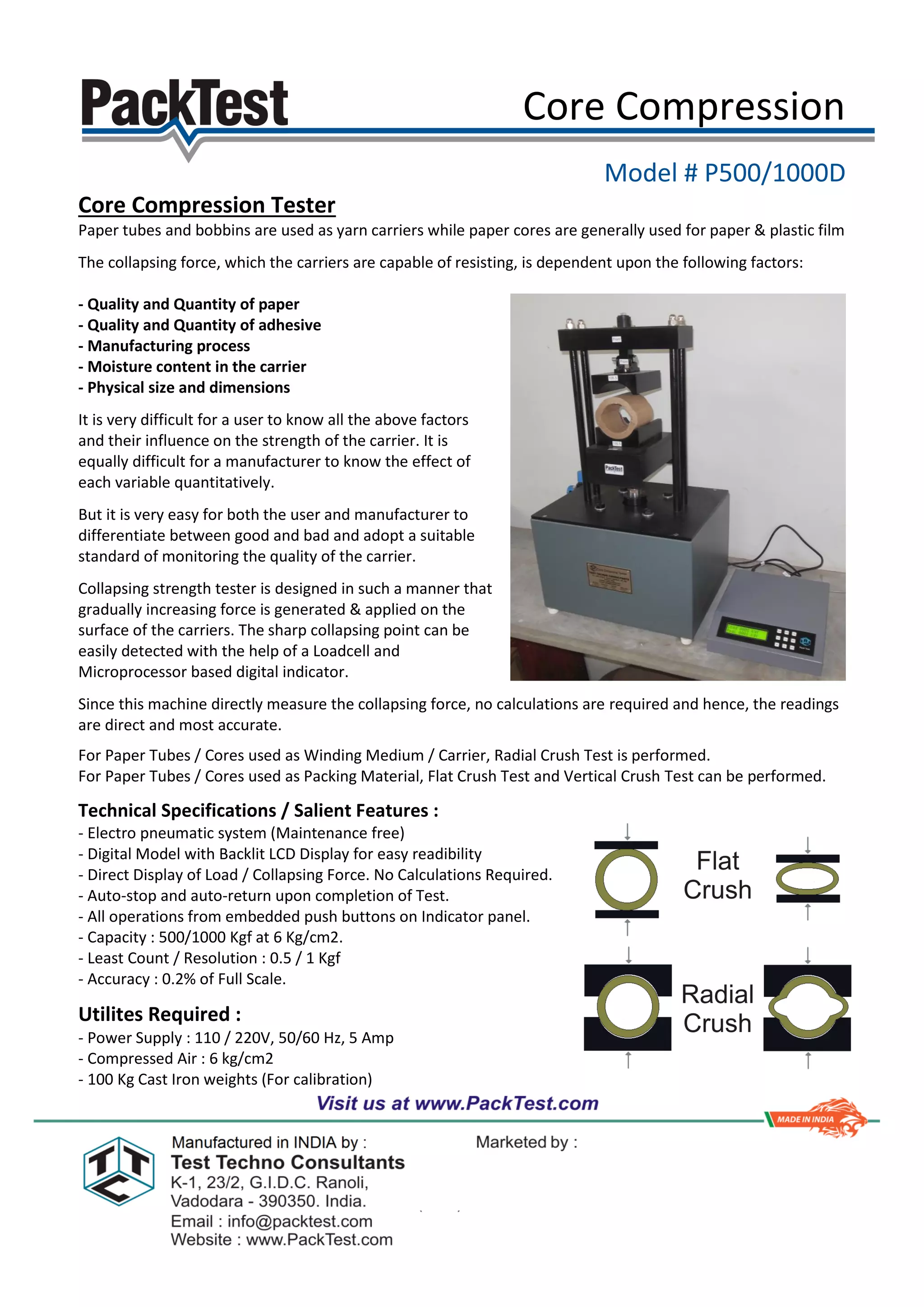

This document describes the Core Compression Model #P500/1000D, a machine used to test the collapsing strength of paper tubes, bobbins, and cores. It directly measures the collapsing force without requiring calculations. The collapsing strength depends on factors like the quality and quantity of paper and adhesive used, the manufacturing process, and moisture content. The machine applies gradually increasing force to the carrier and easily detects the sharp collapsing point using a loadcell and digital indicator. It can perform radial, flat, or vertical crush tests depending on the intended use of the paper tube or core.