This document discusses heat transfer aspects of energy. It begins by introducing heat transfer and the underlying thermodynamic principles. The first law of thermodynamics states that energy cannot be created or destroyed, only changed from one form to another. Heat transfer occurs between bodies or systems at different temperatures until thermal equilibrium is reached. Various heat transfer mechanisms such as conduction, convection, and radiation are then examined. Case studies on heat exchangers and solar collectors are also presented to demonstrate applications of heat transfer concepts.

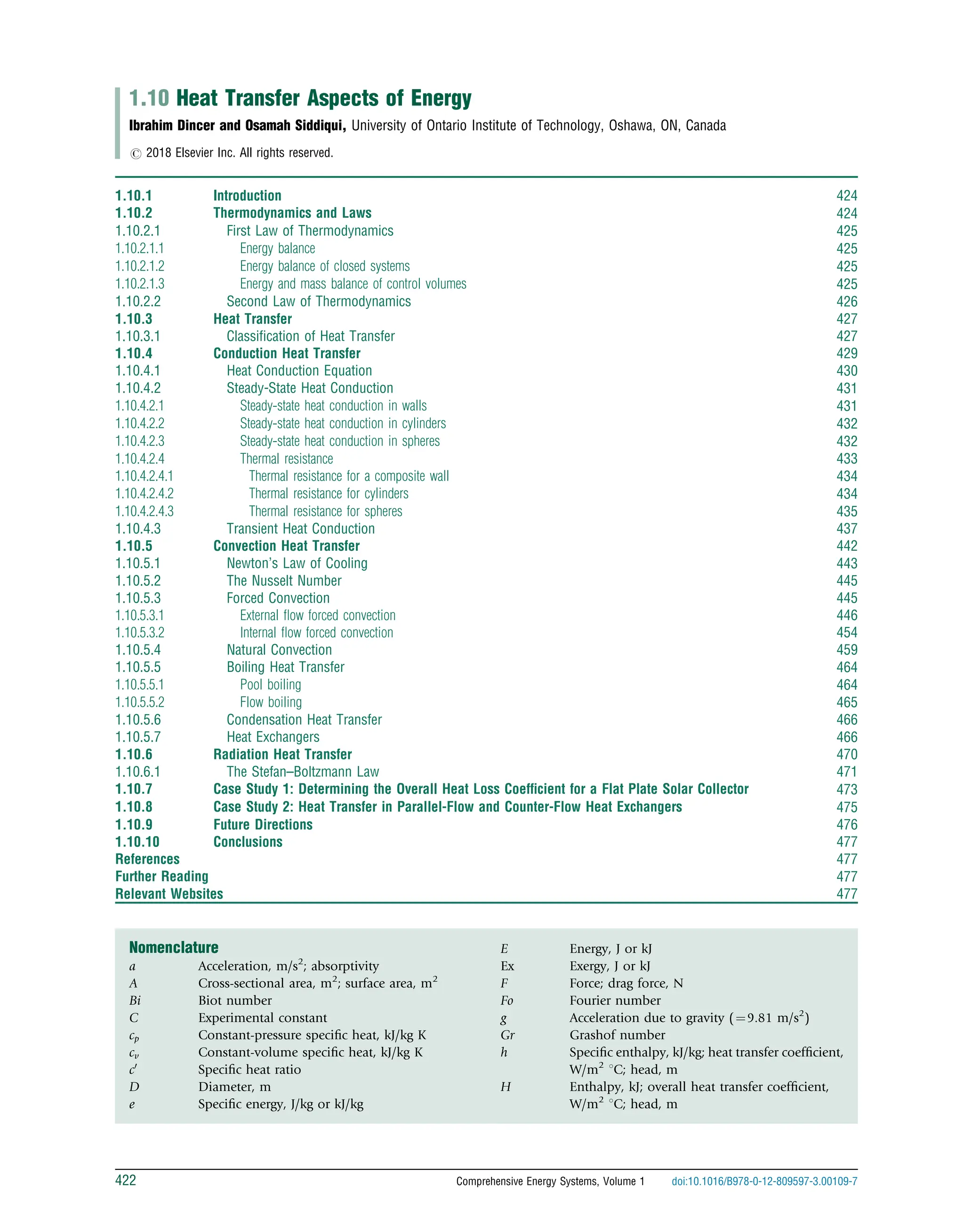

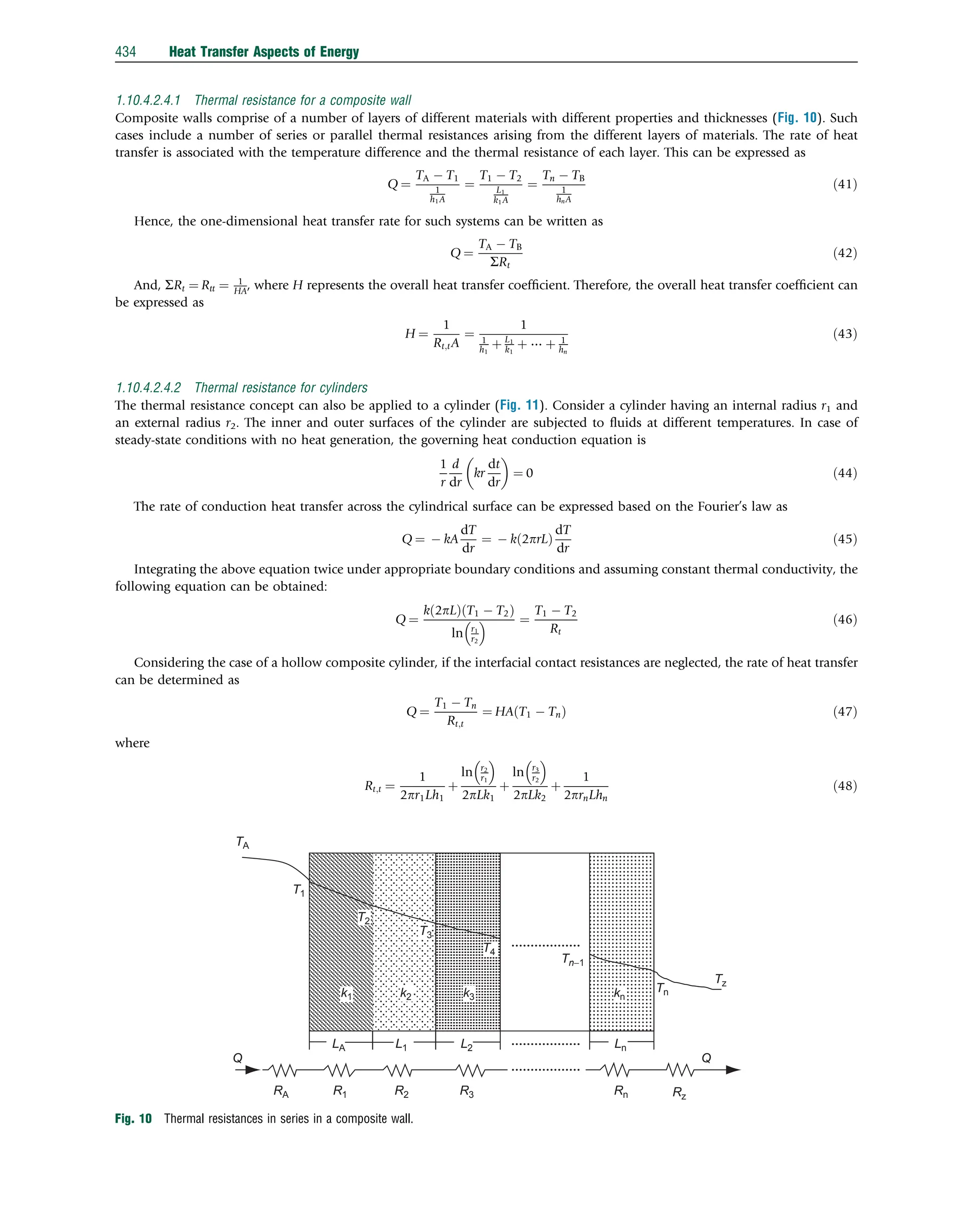

![Example 7: An individual dried fig was formed by hand as an infinite slab and refrigerated until the center temperature of 21.61C

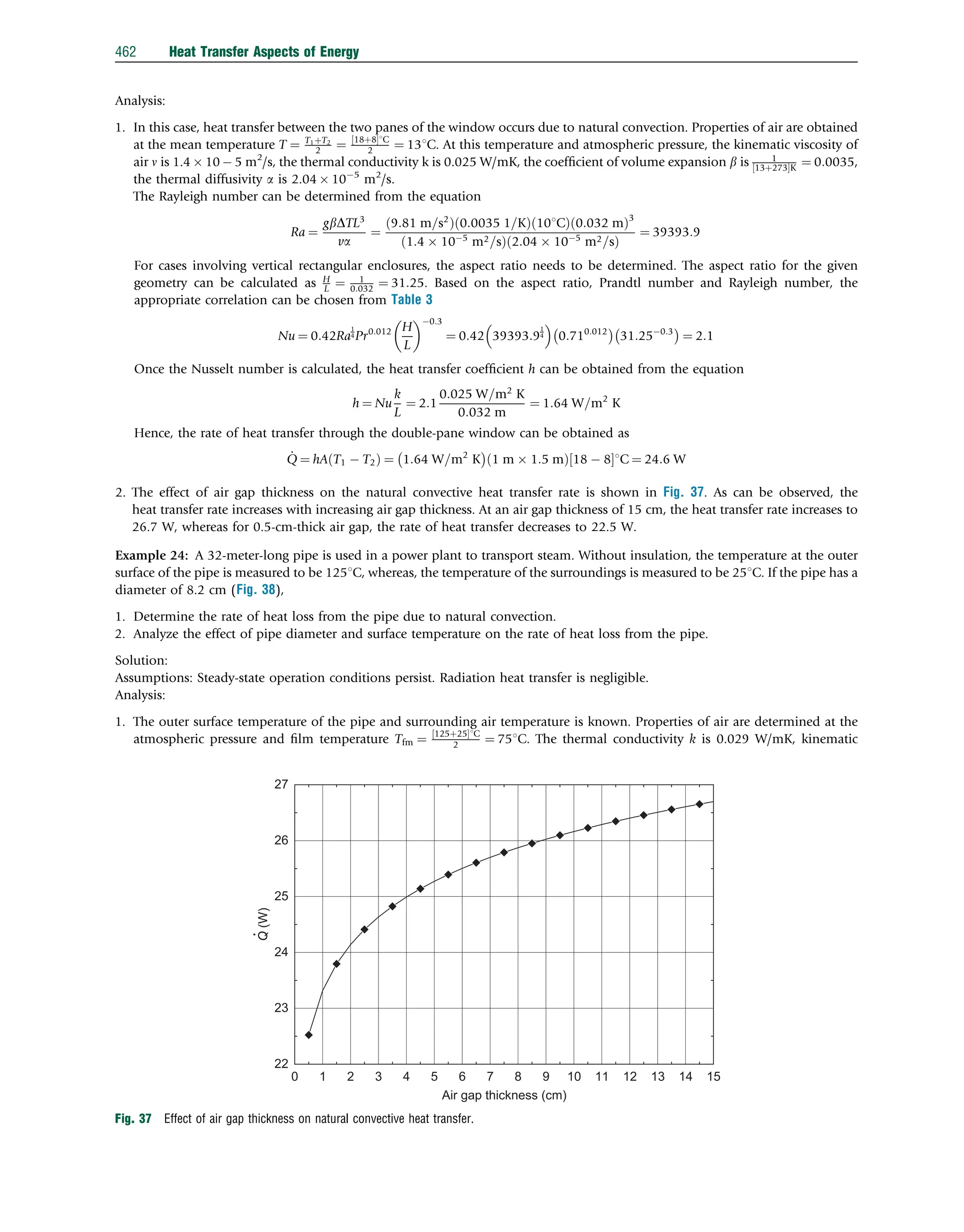

reached 221C in a freezer cabinet at Ta ¼ 221C. During this refrigeration process, the center temperature distribution of the

sample was measured at 30-s intervals, and the measurement was repeated three times. Some physical and thermal properties

are L¼0.01 m, l¼0.05 m, X¼0.04 m, k¼0.2367 W/m 1C, a¼9.88 108

m2

/s, and h¼9.045 W/m2

1C. Further information on

the experiments and analysis technique, along with the relevant data can be found in Ref. [1]. Here, we will compute the center

temperature distribution of this slab product and compare it with the experimental data.

Solution: From the data we have, the Biot number is calculated as Bi ¼ hl

k ¼ 9:045 0:005=0:2367 ¼ 0:191 here, the Biot number

is between 0.1rBir100, leading to a convection boundary condition problem. By knowing the Biot number, the values of m1 and

A1 can be found as m1 ¼0.422 and A1 ¼1.03. The theoretical dimensionless center temperature is calculated from the following

equation, considering Fo40.2:

yt ¼ A1B1 ¼ 2Bi Bi2

þ m2

1

0:5

=m1 Bi2

þ Bi þ m2

1

h i

exp m2

1Fo

¼ 1:03 exp 0:4222

Fo

where Fo¼at/l2

¼9.88 108

t/0.0052

.

The results are shown in Fig. 14.

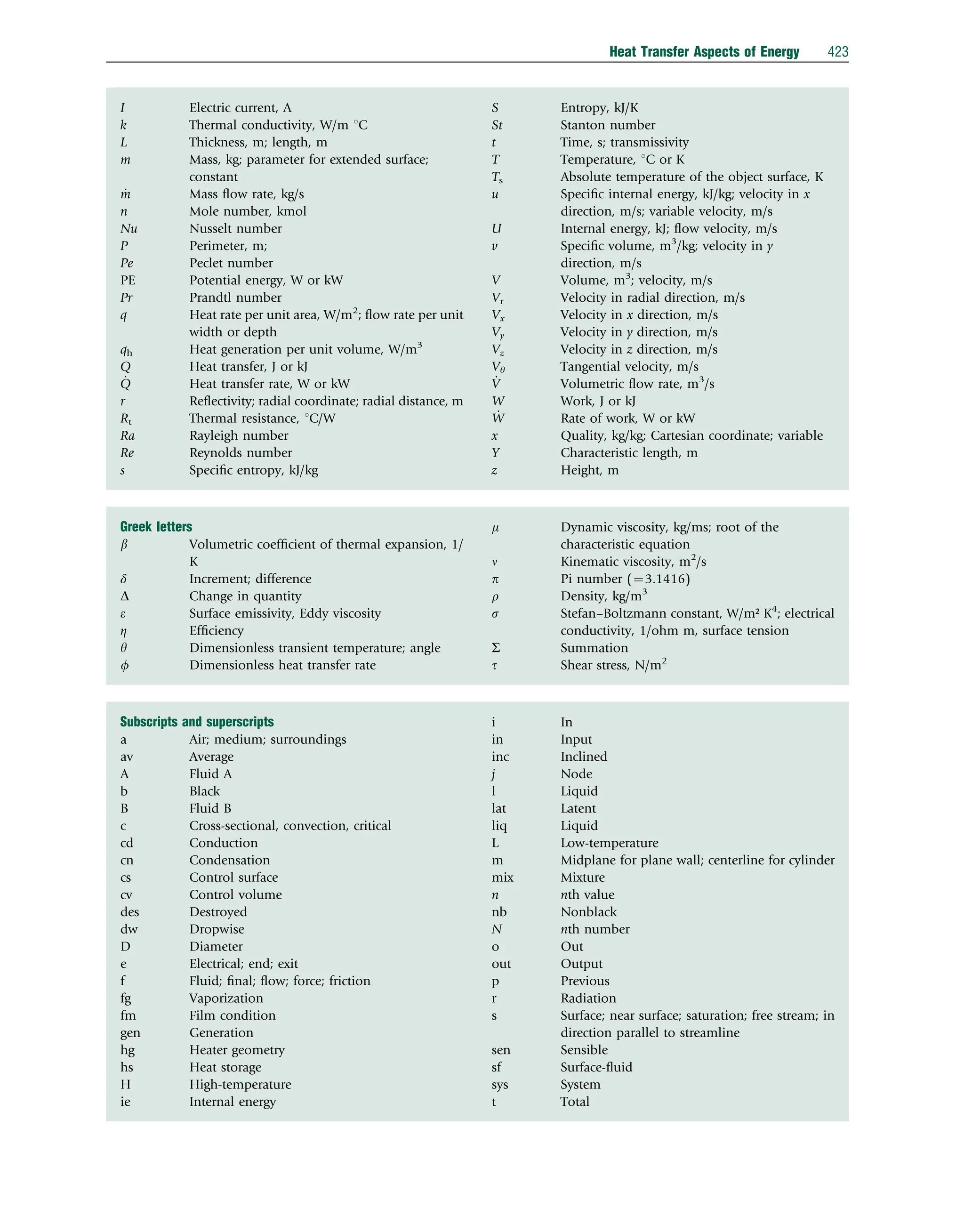

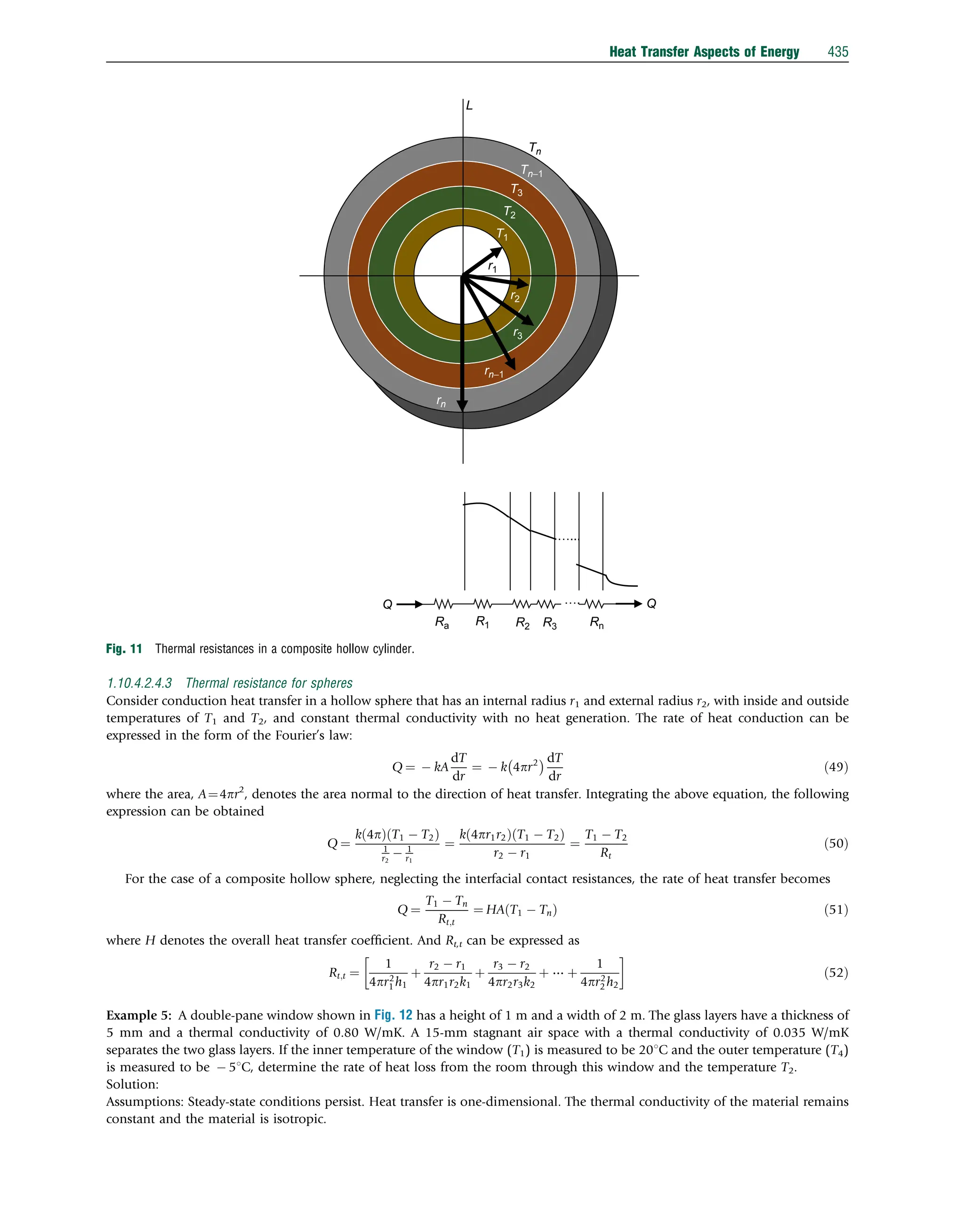

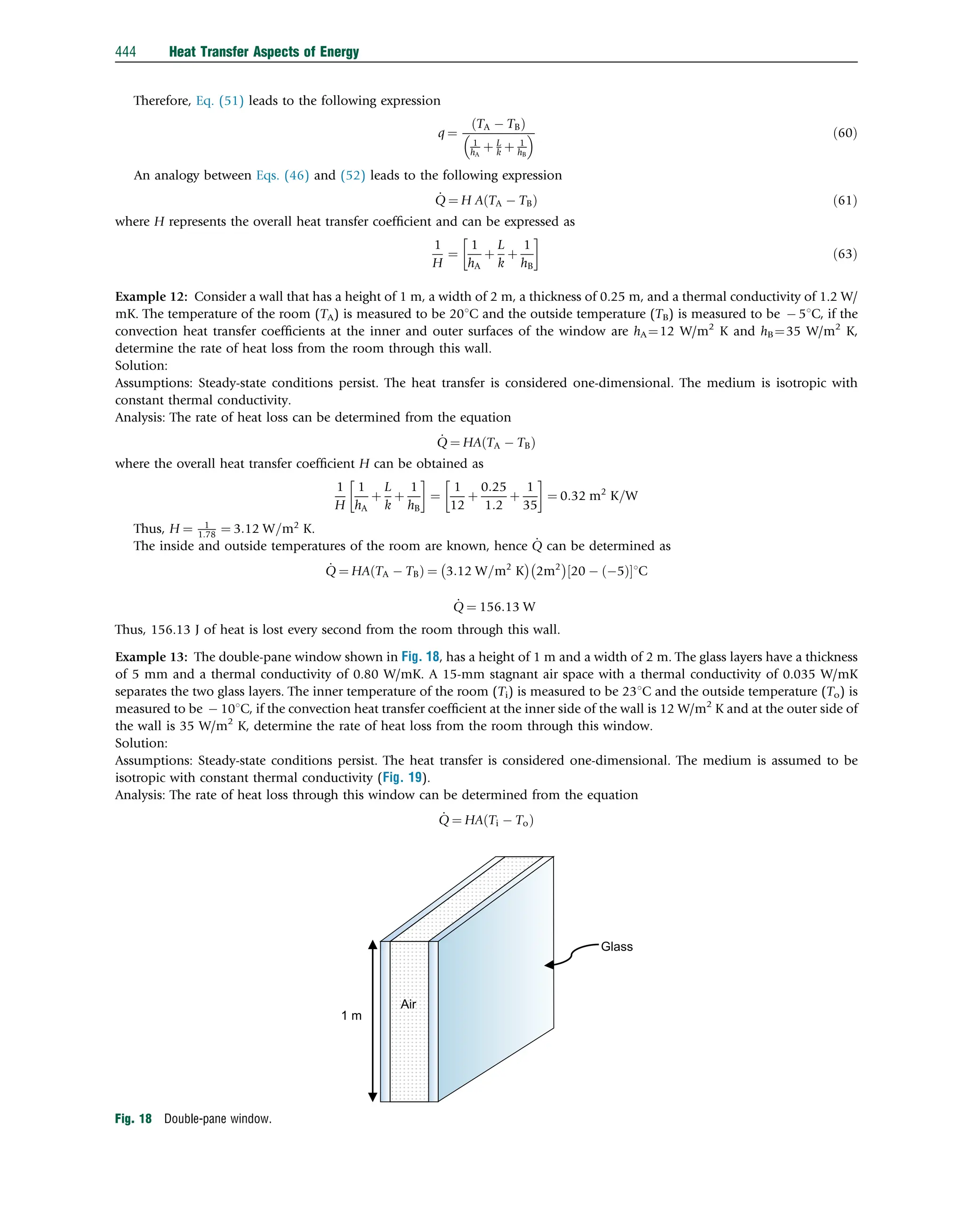

Example 8: An individual cylindrical eggplant was cooled until the center temperature of 221C reached 71C in the water pool of a

hydro cooling unit at a temperature of 11C. During the cooling process, the center temperature distribution of the product was

measured at 30-s intervals. Some physical and thermal properties of the product are: R¼0.0225 m, J¼0.142 m, k¼0.6064 W/m

1C, a¼1.438 107

m2

/s, and h¼44.15 W/m2

1C. Further information on the experiments and analysis technique, along with the

relevant data, can be found in Ref. [2]. Here, we will determine the theoretical center temperature distribution of the cylindrical

eggplant and compare it with the experimental data.

Table 1 Dimensionless transient temperatures

Equations or series solutions

For Bio0.1

y¼eBiFo

For 0.1rBir100

Infinite slab

y ¼

P

1

n ¼ 1

AnBnCn

An ¼ 1

ð Þnþ1

2Bi Bi2

þ m2

n

0:5

=mn Bi2

þ Bi þ m2

n

Bn ¼ exp m2

nFo

Cn ¼ cosmnG

Infinite cylinder

y ¼

P

1

n ¼ 1

AnBnCn

An ¼ 2Bi= m2

n þ Bi2

J0 mnR

ð Þ

Bn ¼ exp m2

nFo

Cn ¼ J0 mnG

ð Þ

Sphere

y ¼

P

1

n ¼ 1

AnBnCn An ¼ 1

ð Þnþ1

2Bi m2

n þ Bi 1

ð Þ2

h i0:5

= Bi2

Bi þ m2

n

Bn ¼ exp m2

nFo

Cn ¼ sinmnG=mnG

For Bi4100

Infinite slab

y ¼

P

1

n ¼ 1

AnBnCn

An ¼ 1

ð Þnþ1

2=mn

ð Þ

Bn ¼ exp m2

nFo

Cn ¼ cosmnG

mn ¼ 2n 1

ð Þp=2

Infinite cylinder

y ¼

P

1

n ¼ 1

AnBnCn

An ¼ 2=mnJ1 mn

ð Þ

Bn ¼ exp m2

nFo

Cn ¼ J0 mnG

ð Þ

J0 mnG

ð Þ ¼ 1 m2

n=22

þ m4

n=22

42

m6

n=22

42

62

Sphere

y ¼

P

1

n ¼ 1

AnBnCn

An ¼ 2 1

ð Þnþ1

Bn ¼ exp m2

nFo

Cn ¼ sinmnG=mnG

mn ¼ np

438 Heat Transfer Aspects of Energy](https://image.slidesharecdn.com/13comprehensiveenergysystems-240412072703-d37af1a8/75/Comprehensive-energy-systems-pdf-Comprehensive-energy-systems-pdf-17-2048.jpg)

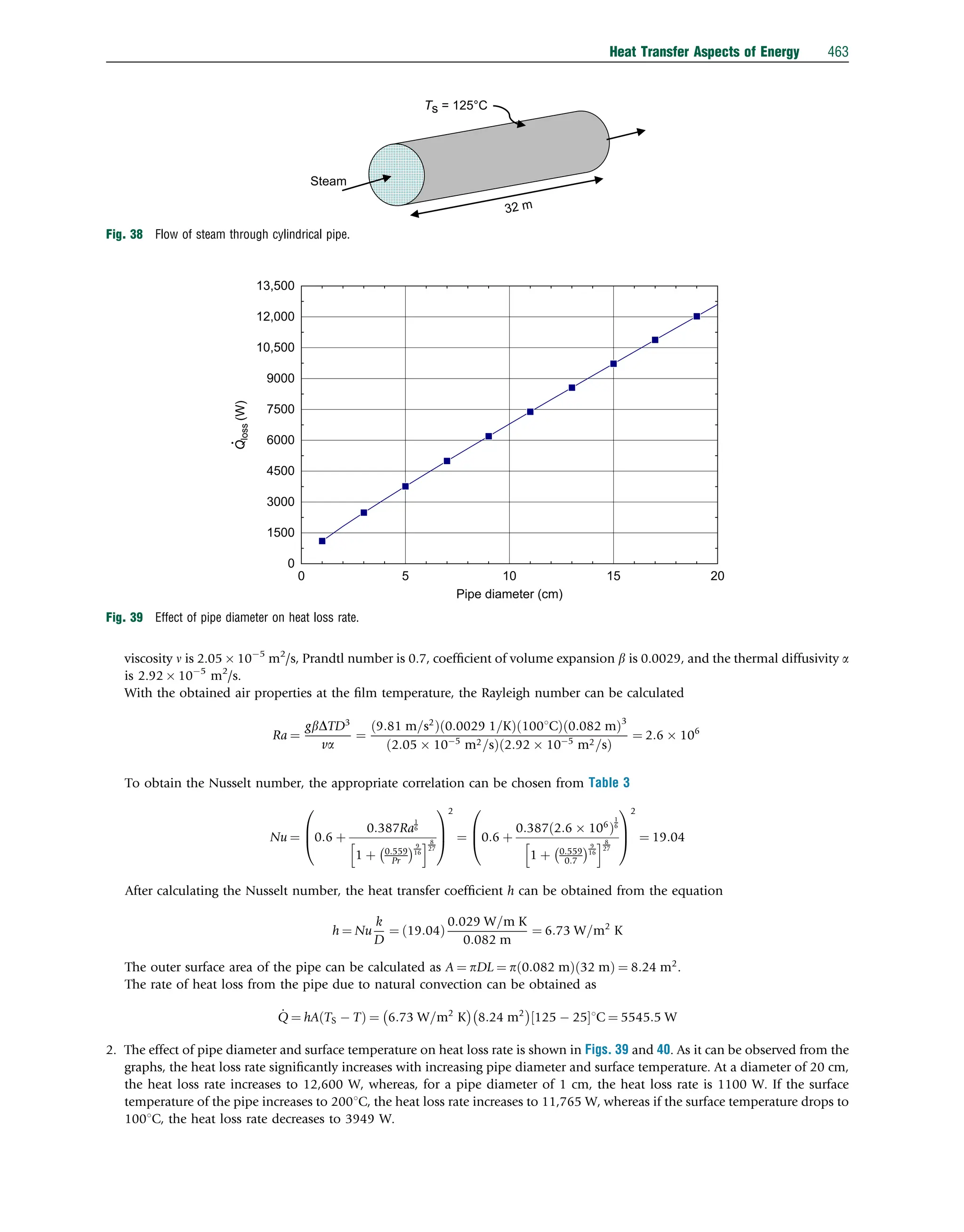

![Here, the Biot number is between 0.1rBir100, leading to a convection boundary condition problem. By knowing the Biot

number as 1.64, the values of mn and An for n¼1 6, which are considered sufficient terms, are taken as m1¼1.497, m2 ¼4.219,

m3 ¼7.242, m4 ¼10.332, m5 ¼13.445 and m6 ¼16.571 and A1 ¼1.297, A2 ¼ 0.427, A3¼0.203, A4 ¼ 0.119, A5 ¼0.0823, and

A6 ¼ 0.0589. The theoretical dimensionless center temperature is calculated from the following equation, considering Fo40.2:

yt ¼

X

1

n ¼ 1

AnBn ¼

X

6

n ¼ 1

Anexp m2

nFo

¼ 1:297 exp 1:4972

Fo

0:427 exp 4:2192

Fo

þ 0:203 exp 7:2422

Fo

0:119 exp 10:3322

Fo

þ 0:0823 exp 13:4452

Fo

0:0589 exp 16:5712

Fo

where Fo¼at/R2

¼1.438 107

t/0.02252

.

The computed results are shown in Fig. 15. The experimental results can also be obtained from Ref. [2].

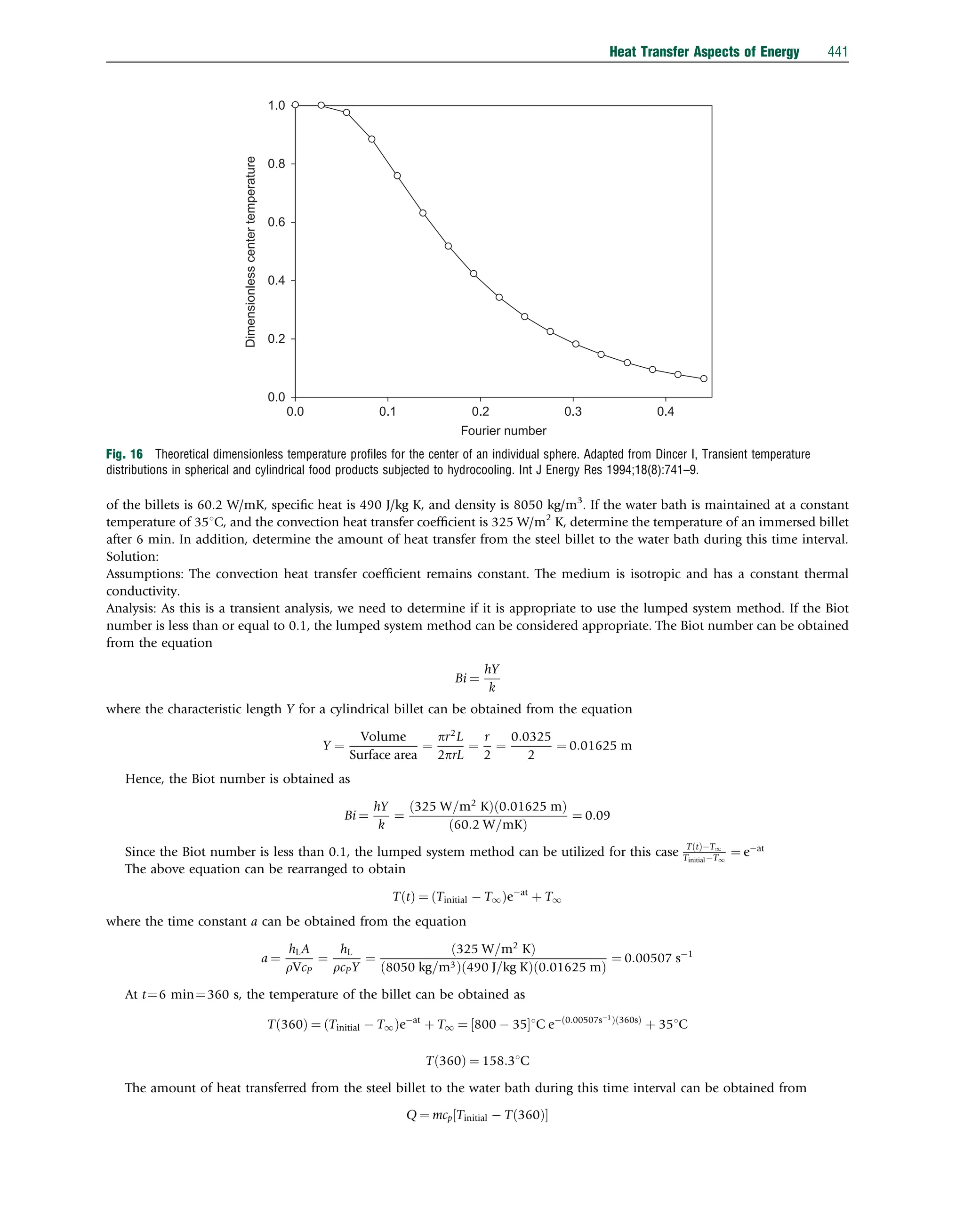

Example 9: An individual spherical pear was cooled until the center temperature of 221C reached 21C in the water pool of a hydro

cooling unit at a temperature of 11C. During the cooling process, the center temperature distribution of the product was measured

at 30-s intervals. Some physical and thermal properties of the product are: R¼0.03 m, k¼0.5527 W/m 1C, a¼1.378 107

m2

/s,

and h¼160.56 W/m2

1C. Further information on the experiments, and analysis technique, along with the relevant data, can be

found in Ref. [2]. Here, we will determine the theoretical center temperature distribution of the spherical pear and compare it with

the experimental data.

Solution: From the data we have, the Biot number can be calculated as

Bi ¼

hR

k

¼ 160:56 0:030=0:5572 ¼ 8:64

Here, the Biot number is between 0.1rBir100, leading to a convection boundary condition problem. By knowing the Biot

number as 8.64, the values of mn and An for n¼1–6, which are considered sufficient terms, are taken as m1 ¼2.79, m2 ¼5.646,

m3 ¼8.581, m4 ¼11.578, m5 ¼14.618 and m6 ¼17.618 and A1 ¼1.903, A2 ¼ 1.657, A3¼ 1.42, A4 ¼ 1.196, A5 ¼1.018, and

A6 ¼ 0.878. The theoretical dimensionless center temperature is calculated from the following equation, considering Fo40.2:

yt ¼

X

1

n ¼ 1

AnBn ¼

X

6

n ¼ 1

Anexp m2

nFo

¼ 1:903 exp 2:792

Fo

1:675 exp 5:6462

Fo

þ 1:42exp 8:5812

Fo

1:196 exp 11:5782

Fo

þ 1:018 exp 14:6182

Fo

0:878 exp 17:6862

Fo

where Fo¼at/R2

¼1.378 107

t/0.032

. The computed results are shown in Fig. 16, the experimental results can also be obtained

from Ref. [2].

Example 10: Steel billets are used extensively in the manufacturing of various products for numerous industries. The heat

treatment process of steel billets involves heating the billets to a temperature of 8001C and immersing them in a water bath until

they are cooled to a specified temperature. The billets have a diameter of 6.5 cm and a length of 100 cm. The thermal conductivity

1.0

0.8

0.6

0.4

Dimensionless

center

temperature

0.2

0.0 0.1 0.2

Fourier number

0.3 0.4 0.6

0.5 0.7

Fig. 15 Theoretical dimensionless temperature profiles for the center of an individual eggplant.

440 Heat Transfer Aspects of Energy](https://image.slidesharecdn.com/13comprehensiveenergysystems-240412072703-d37af1a8/75/Comprehensive-energy-systems-pdf-Comprehensive-energy-systems-pdf-19-2048.jpg)

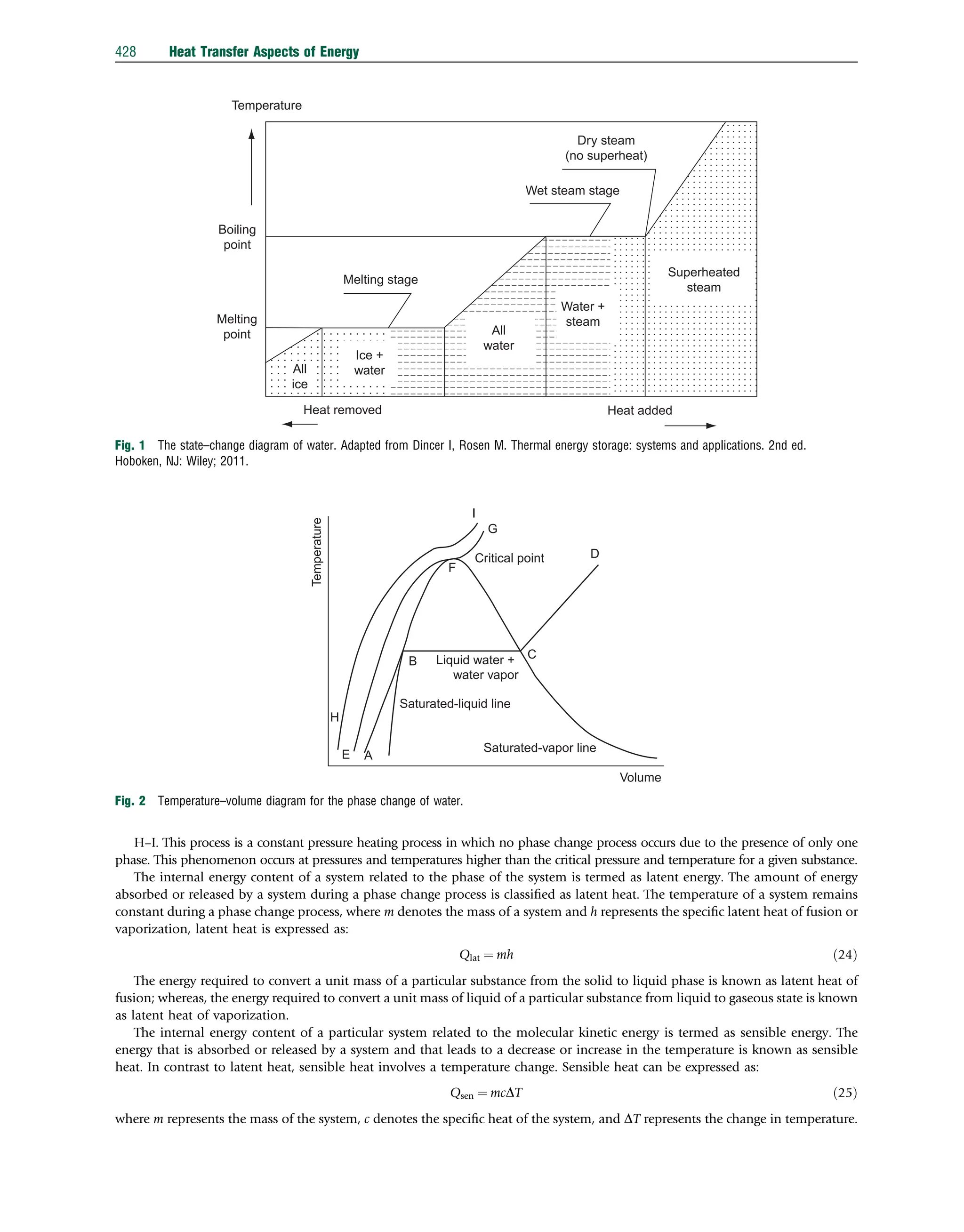

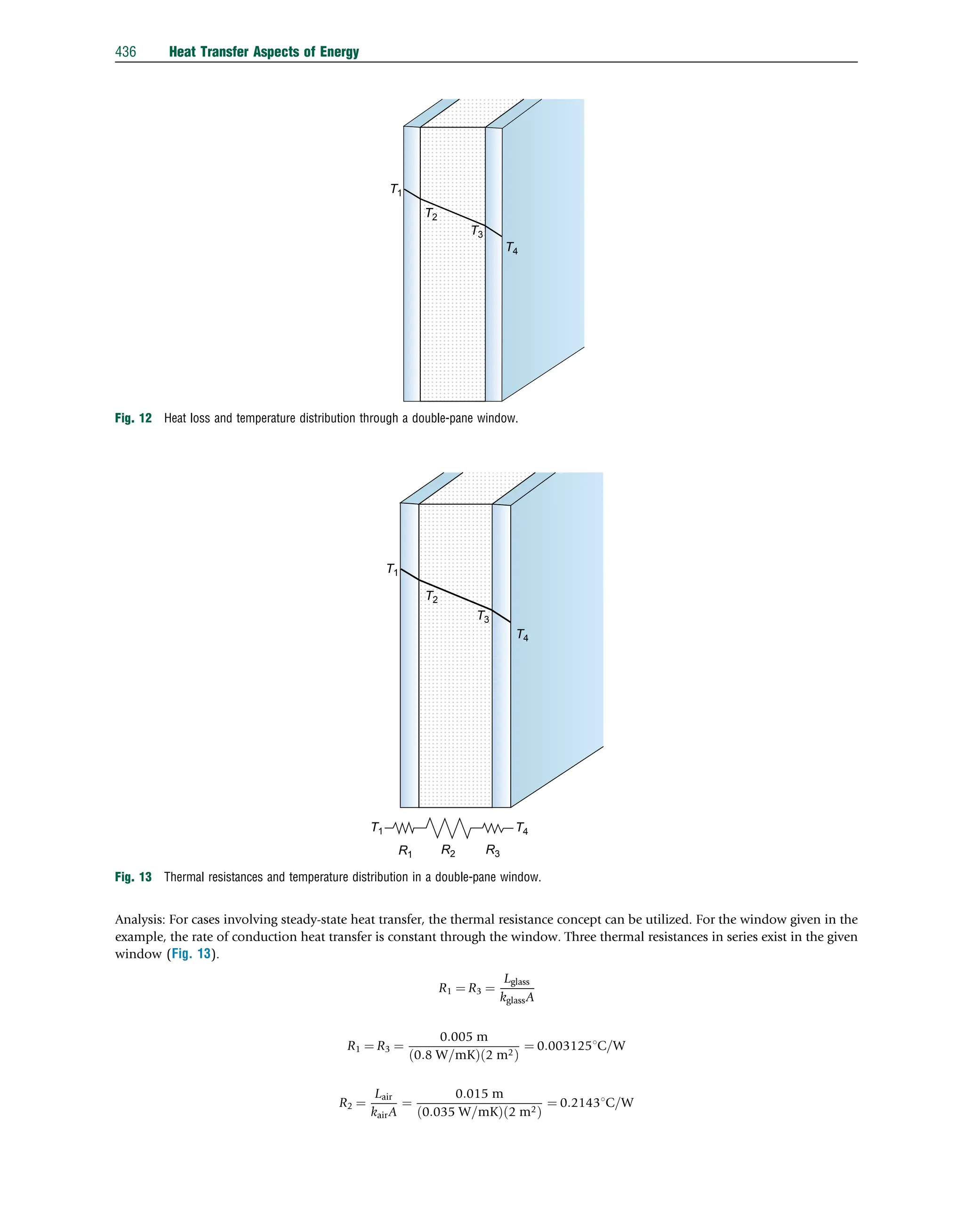

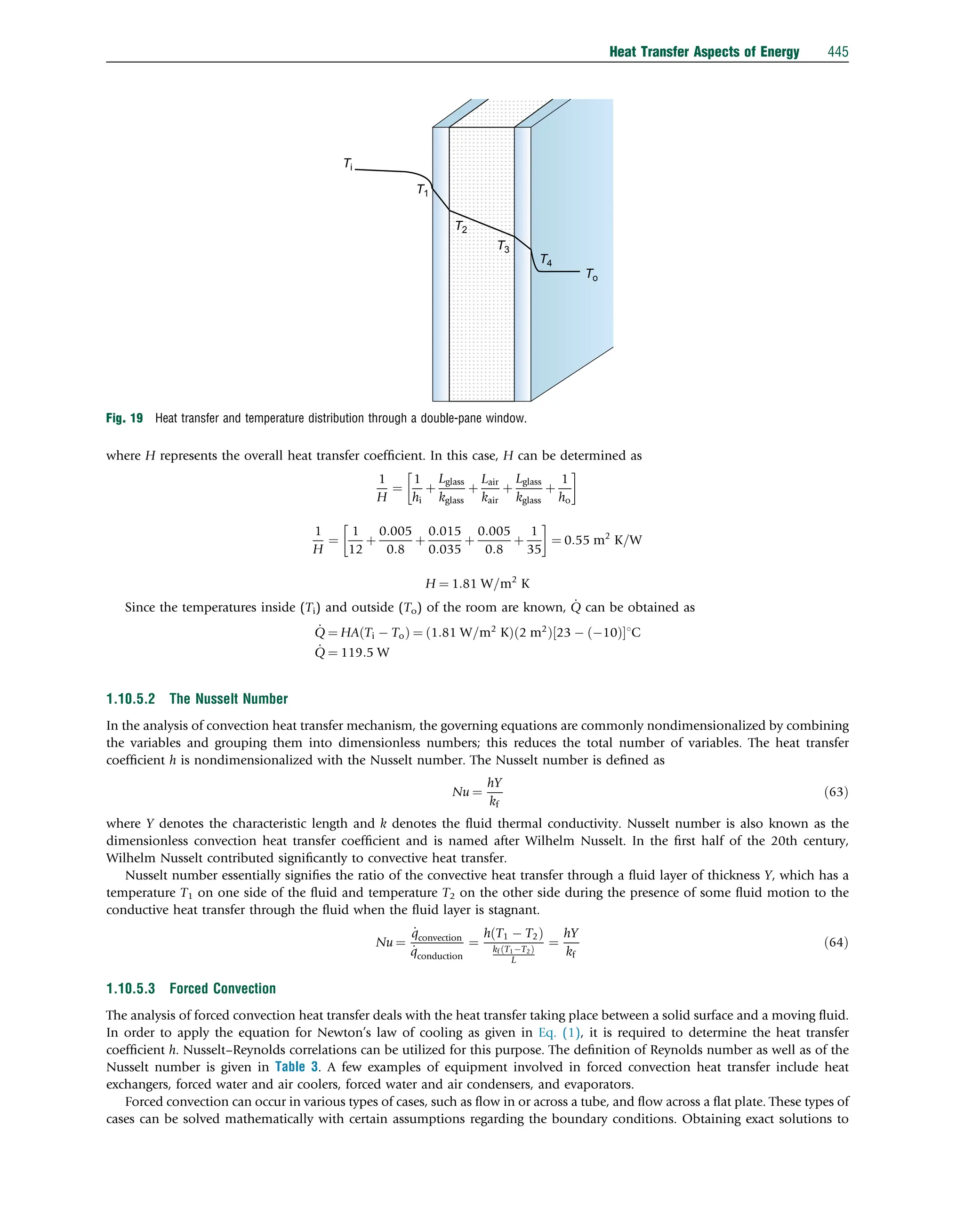

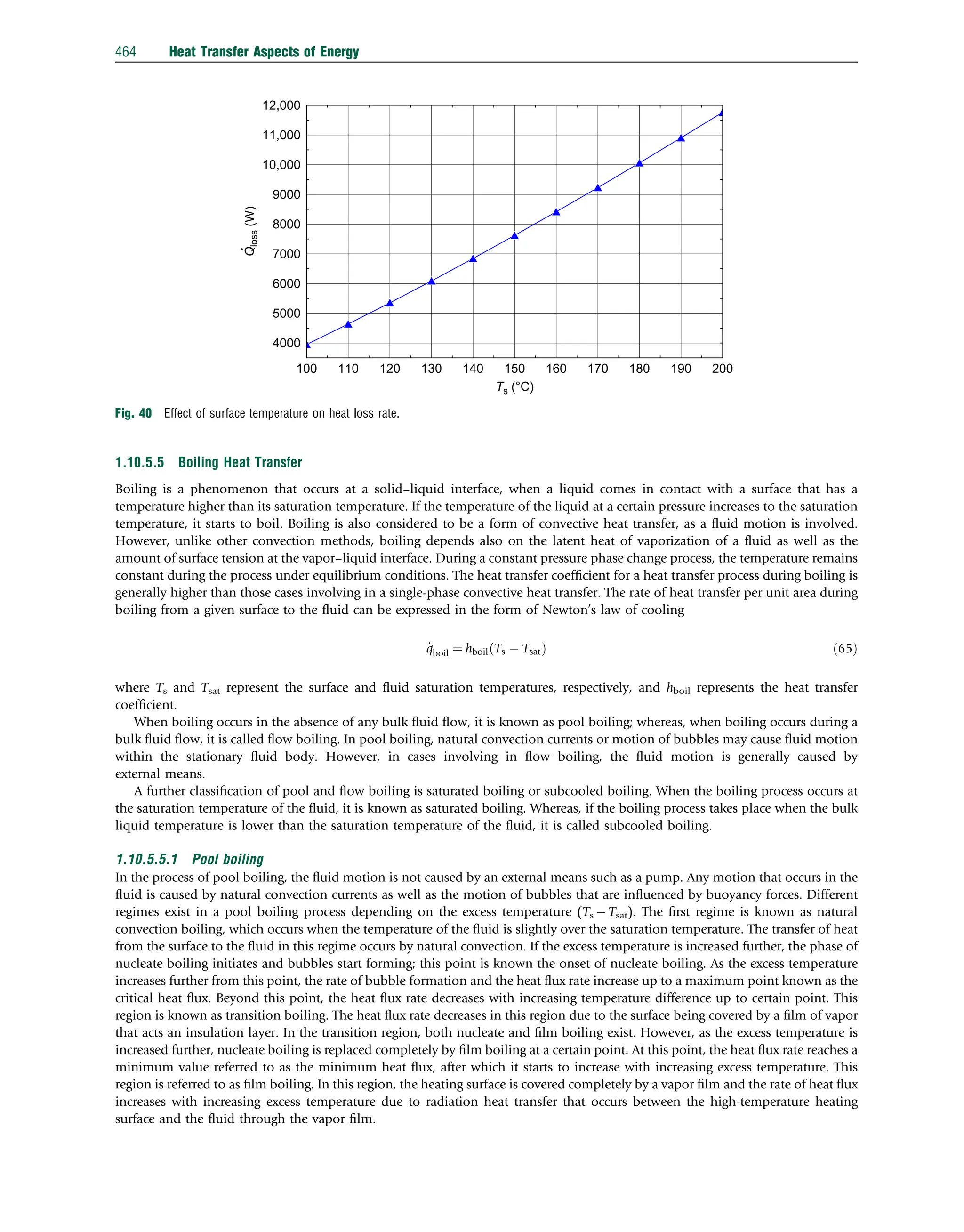

![The Reynolds number at the plate end can be determined as follows:

Re ¼

UY

v

¼

8:3 m=s

ð Þ 3m

ð Þ

ð1:66 105

Þm2=s

¼ 15 105

45 105

Since the Reynolds number is greater than the critical Reynolds number, a suitable correlation to be used for this case is

Nu ¼ 0:037Re

4

5 871

Pr

1

3 ¼ 0:037 15 105

4

5

871

0:71

1

3 ¼ 2097

Table 4 Forced convection heat transfer correlations and equations

Equation or correlation

Correlations for external flow over a flat plate

Nu¼0.332Re1/2

Pr1/3

for PrZ0.6 for laminar; local; Tfm

Nu¼0.664Re1/2

Pr1/3

for PrZ0.6 for laminar; average; Tfm

Nu¼0.565Re1/2

Pr1/2

for Prr0.05 for laminar; local; Tfm

Nu¼0.0296Re4/5

Pr1/3

for 0.6rPrr60 for turbulent; local; Tfm, Rer108

Nu¼(0.037Re4/5

871)Pr1/3

for 0.6oPro60 for mixed flow; average; Tfm, Rer108

Correlations for external cross-flow over circular cylinders

Nu¼cRen

Pr1/3

for PrZ0.7 for average; Tfm; 0.4oReo4 106

where

c¼0.989 and n¼0.330 for 0.4oReo4

c¼0.911 and n¼0.385 for 4oReo40

c¼0.683 and n¼0.466 for 40oReo4000

c¼0.193 and n¼0.618 for 4000oReo40,000

c¼0.027 and n¼0.805 for 40,000oReo400,000

Nu¼cRen

Prs

(Pra/Prs)1/4

for 0.7oPro500 for average; Ta; 1oReo106

where

c¼0.750 and n¼0.4 for 1oReo40

c¼0.510 and n¼0.5 for 40oReo1000

c¼0.260 and n¼0.6 for 103

oReo2 105

c¼0.076 and n¼0.7 for 2 105

oReo106

s¼0.37 for Prr10

s¼0.36 for Pr410

Nu¼0.3 þ [(0.62Re1/2

Pr1/3

)/(1 þ (0.4/Pr)2/3

)1/4

][1 þ (Re/28,200)5/8

]4/5

for RePr40.2 for average; Tfm

Correlations for internal flow in tubes

Nu¼4.36 for constant surface heat flux; fully developed; laminar

Nu¼3.66 for constant surface temperature; fully developed; laminar

Nu¼3.66 þ (0.065(D/L) Re Pr)/(1 þ 0.04[(D/L) Re Pr)]2/3

for constant surface temperature; developing flow; laminar

Nu¼0.023Re4/5

Prn

for 0.7rPrr160; turbulent; fully developed; ReZ10,000; n¼0.4 for fluid heating; n¼0.3 for fluid

cooling

Nu¼4.8 þ 0.0156Re0.85

Prs

0.93

for liquid metal flow; constant surface temperature; 104

oReo106

Nu¼6.3 þ 0.0167Re0.85

Prs

0.93

for liquid metal flow; constant surface heat flux; 104

oReo106

Correlations for external cross-flow over spheres

Nu/Pr1/3

¼0.37Re0.6

/Pr1/3

for average; Tfm; 17oReo70,000

Nu¼2 þ (0.4Re1/2

þ 0.06Re2/3

)Pr0.4

(ma/ms)1/4

for 0.71oPro380

for average; Ta; 3.5oReo7.6 104

; 1o(ma/ms)o3.2.

Correlation for falling drop

Nu¼2 þ 0.6Re1/2

Pr1/3

[25(x/D)0.7

] for average; Ta

Source: Reproduced from Dincer I. Heat transfer in food cooling applications. Washington, DC: Taylor Francis; 1997.

Air

Ta = 22°C

U = 8.3 m s−1

3m

Ts = 50°C

Fig. 20 Heat transfer from a flat plate solar collector.

Heat Transfer Aspects of Energy 447](https://image.slidesharecdn.com/13comprehensiveenergysystems-240412072703-d37af1a8/75/Comprehensive-energy-systems-pdf-Comprehensive-energy-systems-pdf-26-2048.jpg)

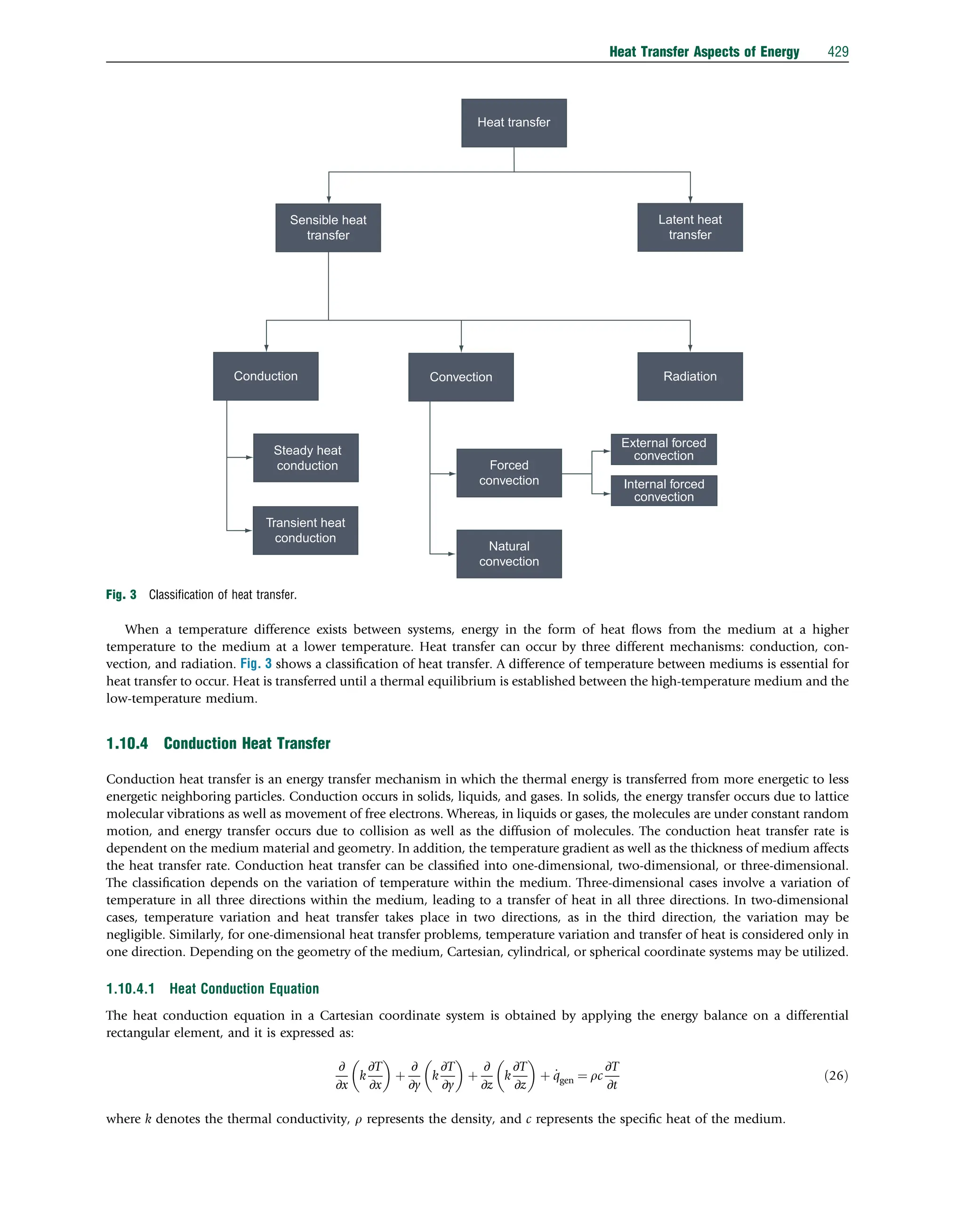

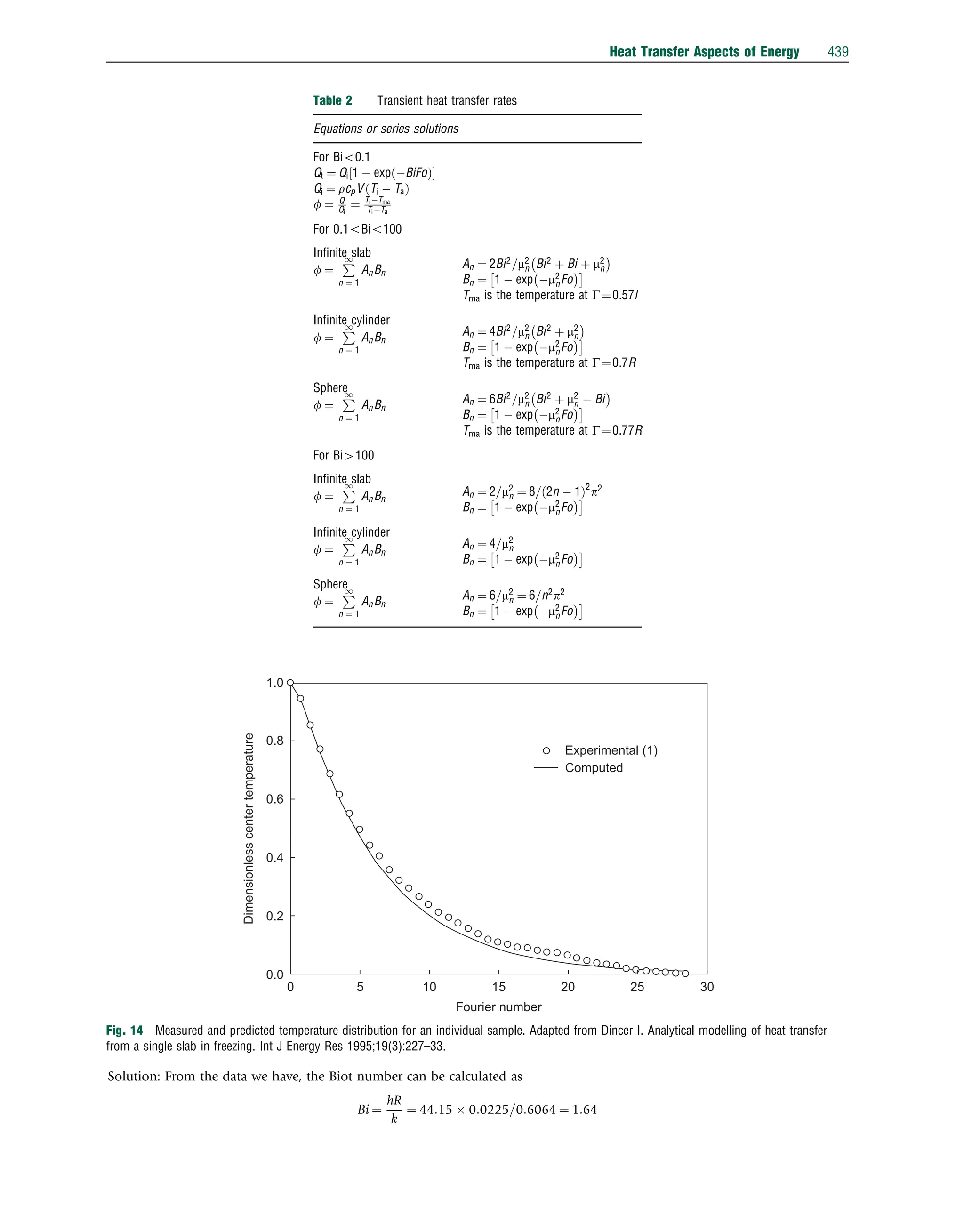

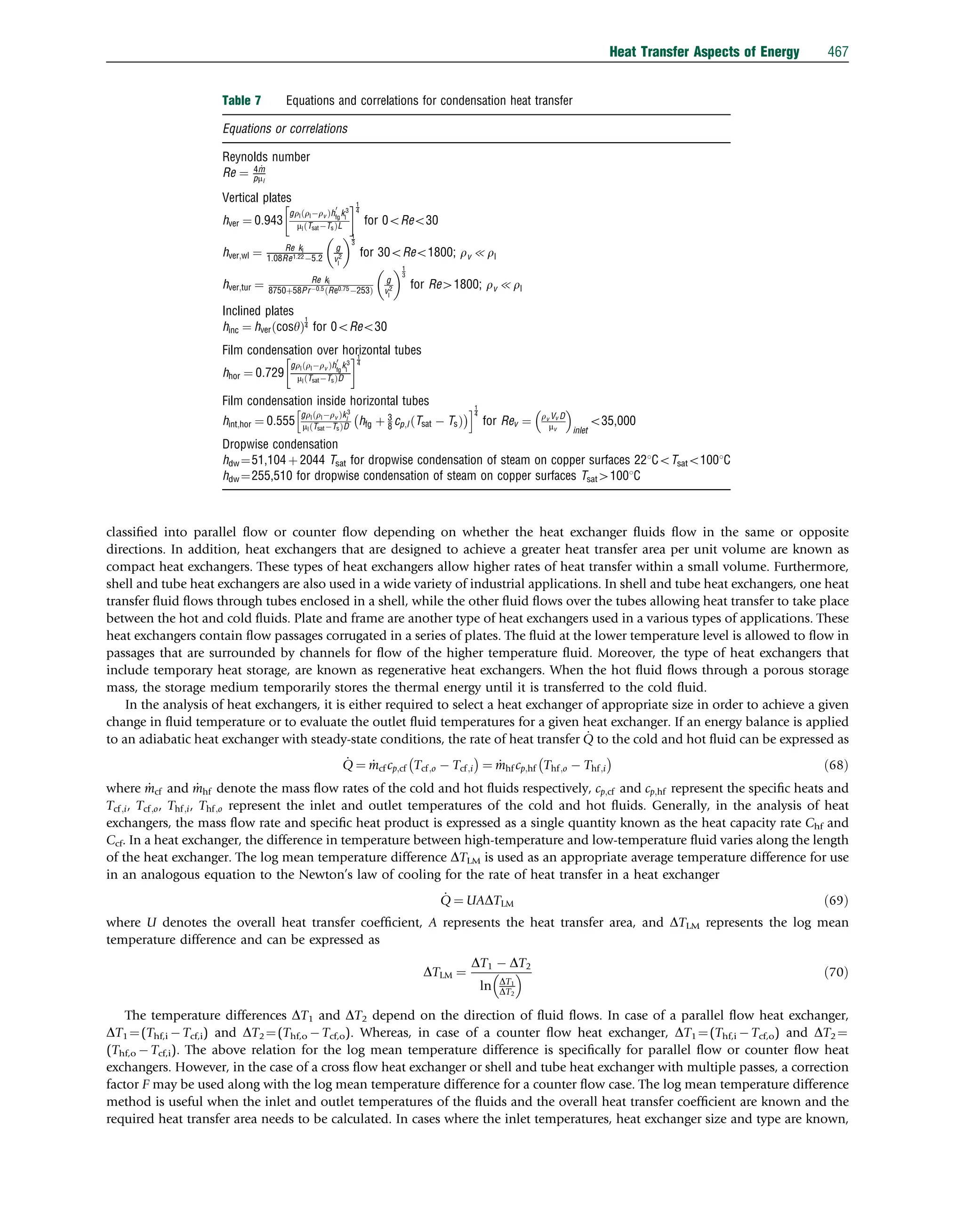

![Example 22: Consider a flat plate solar collector. The collector is placed with a tilt angle of 45 degree and has dimensions

0.5 m 0.5 m. The absorber plate and the glass cover are positioned 2 cm apart. If the temperatures of the glass cover and the

absorber plate are measured to be 651C and 881C, respectively, determine the rate of heat loss due to natural convection from the

absorber plate of the collector (Fig. 35).

Solution: The mean temperature can be obtained as Tm ¼ 65þ88

½ 1C

2 ¼ 76:51C. The properties of air are obtained at this mean

temperature. The thermal conductivity k is 0:029 W=m2

K, kinematic viscosity n is 2.1 105

m2

/s, thermal diffusivity a is

2.9 105

m2

/s, and coefficient of volume expansion b is 1

273þ76:5

½ K ¼ 0:0029.

After obtaining the properties, the Rayleigh number can be determined

Ra ¼

gbDTL3

va

¼

9:81 m=s2

ð Þ 0:0029 1=K

ð Þ 231C

ð Þ 0:021m

ð Þ3

2:1 105

m2=s

ð Þ 2:9 105

m2=s

ð Þ

¼ 8480:5

Table 5 Natural convection heat transfer equations and correlations

Equation or correlation

General equations

Nu¼hY/kf ¼cRan

and Ra¼Gr Pr¼gb(Ts Ta)Y3

/na

where n is 1/4 for laminar flow and 1/3 for turbulent flow. Y is height for vertical plates or pipes, diameter for horizontal pipes and

spheres Tfm(Ts þ Ta)/2

Correlations for vertical plates (or inclined plates, inclined up to 60 degree)

Nu¼[0.825 þ 0.387Ra1/6

/(1 þ (0.492/Pr)9/16

)4/9

]2

for an entire range of Ra

Nu¼0.68 þ 0.67Ra1/4

/(1 þ (0.492/Pr)9/16

)4/9

for 0oRao109

Correlations for horizontal plates (YAs/P)

For upper surface of heated plate or lower surface of cooled plate:

Nu¼0.54Ra1/4

for 104

rRar107

Nu¼0.15Ra1/3

for 107

rRar1011

For lower surface of heated plate or upper surface of cooled plate:

Nu¼0.27Ra1/4

for 105

rRar1010

Correlations for horizontal cylinders

Nu¼hD/k¼cRan

where

c¼0.675 and n¼0.058 for 1010

oRao102

c¼1.020 and n¼0.148 for 102

oRao102

c¼0.850 and n¼0.188 for 102

oRao104

c¼0.480 and n¼0.250 for 104

oRao107

c¼0.125 and n¼0.333 for 107

oRao1012

Nu¼[0.60 þ 0.387Ra1/6

/(1 þ (0.559/Pr)9/16

)8/27

]2

for an entire range of Ra

Correlations for spheres

Nu¼2 þ [0.589Ra1/4

/(1 þ (0.469/Pr)9/16

)4/9

] for PrZ0.7 and Rar1011

Correlations for enclosures

Rectangular inclined enclosures

Nu¼1 þ 1.44[1–(1708/Ra cosy)]þ

(1 1708 (sin 1.8y)1.6

/Ra cosy) þ [(Ra cosy)1/3

/18) 1]þ

Vertical rectangular enclosures

Nu¼0.18[Ra (Pr/(0.2 þ Pr))]0.29

for 1oH/Lo2; RaPr/(0.2 þ Pr)4103

Nu¼0.22[Ra (Pr/(0.2 þ Pr))]0.28

(H/L) 1/4

for 2oH/Lo10; Rao1010

Nu¼0.42Ra1/4

Pr0.012

(H/L) 0.3

for 10oH/Lo40; 1oPro2 104

; 104

oRao107

Nu¼0.046Ra1/3

for 1oH/Lo40; 1oPro20; 106

oRao109

Concentric cylinders

keff/k¼0.386(Pr/(0.861 þ Pr))1/4

(Fc Ra)1/4

Heat transfer correlations

Gr Pr¼1.6 106

Y3

(DT)

where Y in m; DT in 1C

h¼0.29 (DT/Y)1/4

for vertical small plates in laminar range

h¼0.19 (DT)1/3

for vertical large plates in turbulent range

h¼0.27 (DT/Y)1/4

for horizontal small plates in laminar range (facing upward when heated or downward when cooled)

h¼0.22 (DT)1/3

for vertical large plates in turbulent range (facing downward when heated or upward when cooled)

h¼0.27 (DT/Y)1/4

for small cylinders in laminar range

h¼0.18 (DT)1/3

for large cylinders in turbulent range

Source: Reproduced from Dincer I. Heat transfer in food cooling applications. Washington, DC: Taylor Francis; 1997.

460 Heat Transfer Aspects of Energy](https://image.slidesharecdn.com/13comprehensiveenergysystems-240412072703-d37af1a8/75/Comprehensive-energy-systems-pdf-Comprehensive-energy-systems-pdf-39-2048.jpg)

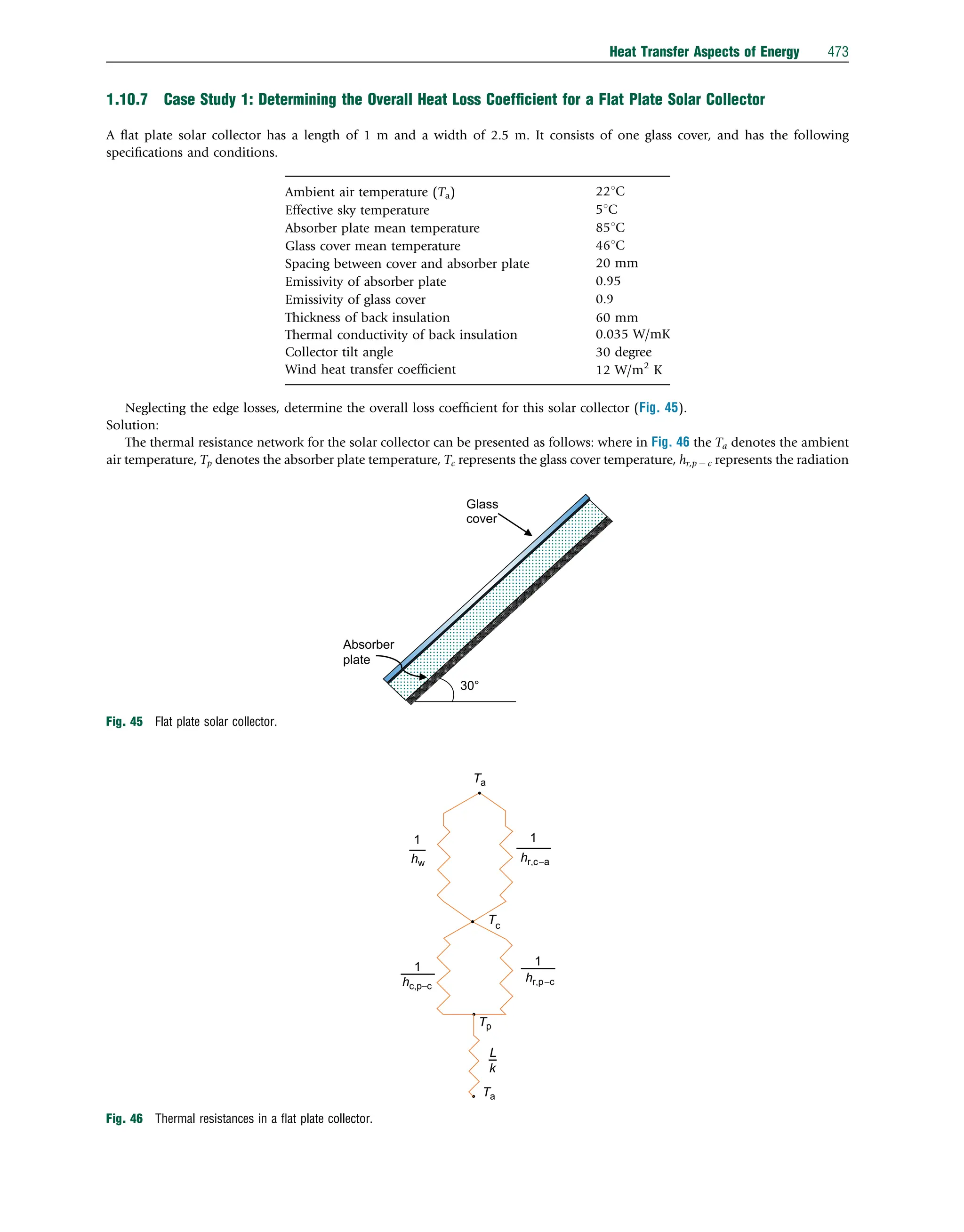

![as size and shape of heat pipes in different applications. Moreover, composite materials with significantly high thermal con-

ductivity are being investigated for the enhancement of heat transfer in different applications. Various compositions and materials

are being studied in this regard. Extended surfaces such as fins are used extensively in various applications to enhance the heat

transfer rate. Numerous studies are being conducted to investigate the performance of different types, shapes, configurations,

combinations, and materials of fins for different applications. Furthermore, the effect and characteristics of vortex generators with

regard to heat transfer are also being investigated.

1.10.10 Conclusions

This chapter is focused on the heat transfer aspects of energy. The chapter first discusses the first law of thermodynamics and energy

balance, which is the underlying principle for heat transfer analysis. Further, the analysis of different modes of heat transfer for

different types of cases and geometries is discussed. Heat transfer analysis forms an integral part of different aspects of energy

applications. The chapter relates the analysis of heat transfer to different energy applications. For instance, heat transfers though

walls or windows, which are essential to determine the heating or cooling load of a building, are discussed and analyzed.

Furthermore, determining the rate of heat loss from solar collectors, which is essential to analyze their performance, is also

discussed. In addition, analysis of heat exchangers, which is essential in numerous applications, is also briefly described. Analyzing

the rate of heat loss or gain by a given system is vital to study its overall performance.

References

[1] Dincer I. Analytical modelling of heat transfer from a single slab in freezing. Int J Energy Res 1995;19(3):227–33.

[2] Dincer I. Transient temperature distributions in spherical and cylindrical food products subjected to hydrocooling. Int J Energy Res 1994;18(8):741–9.

Further Reading

Cengel YA, Boles MA. Thermodynamics: an engineering approach. Boston: McGraw-Hill; 2002.

Cengel YA, Ghajar AJ. Heat and mass transfer: fundamentals applications. New York, NY: McGraw-Hill Education; 2015.

Dincer I. Thermodynamics, exergy and environmenptal impact. In: Proceedings of the ISTP-11, the eleventh international symposium on transport phenomena, Hsinchu, Taiwan;

1998. p.121–125, 29 November–3 December, 1998.

Duffie JA, Beckman WA. Solar engineering of thermal processes. Hoboken, NY: Wiley; 2013.

Relevant Websites

https://www.asme.org/engineering-topics/heat-transfer

American Society of Mechanical Engineers.

https://www.britannica.com/science/heat-transfer

Encyclopedia Britannica.

https://www.thermalfluidscentral.org/encyclopedia/index.php/Main_Page

Thermal-FluidsPedia.

Heat Transfer Aspects of Energy 477](https://image.slidesharecdn.com/13comprehensiveenergysystems-240412072703-d37af1a8/75/Comprehensive-energy-systems-pdf-Comprehensive-energy-systems-pdf-56-2048.jpg)