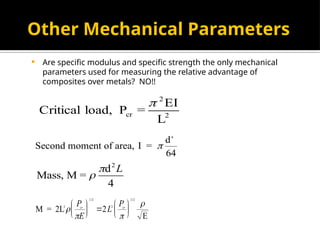

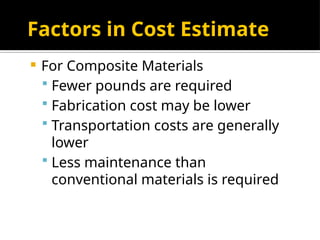

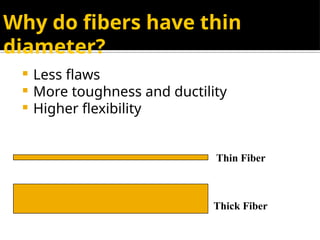

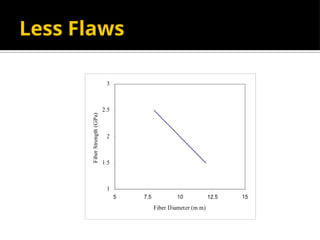

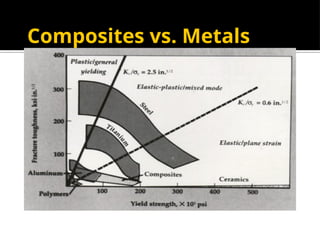

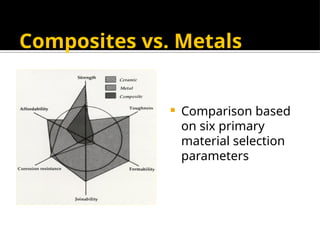

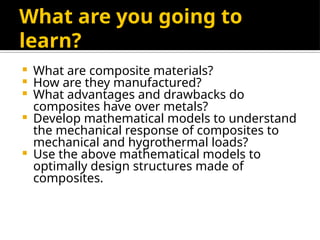

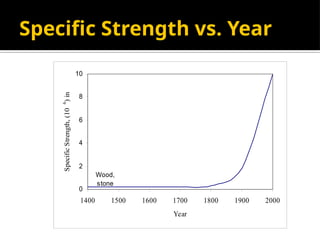

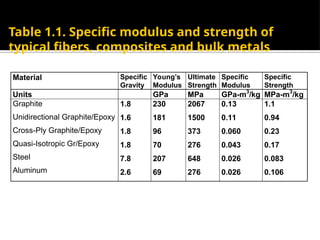

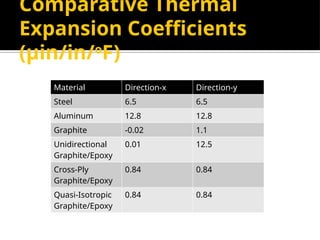

The document serves as an introduction to composite materials, focusing on their definition, manufacturing processes, advantages over metals, and applications. It discusses material properties, including strength and stiffness, while also covering the historical development of fiber and matrix composites. Additionally, it highlights the challenges of using composites, such as cost and complexity in design and repair.

![Specific Strength vs Specific Modulus

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

0 100 200 300 400 500 600

Specific Modulus [Msi-in

3

/lb]

Specific

Strength

[Ksi-in

3

/lb]

Steel

Aluminum

Quasi-isotropic

Graphite/Epoxy

Cross-Ply

Graphite/Epoxy

Unidirectional

Graphite/Epoxy

Graphite Fiber](https://image.slidesharecdn.com/composite1-250124093134-514e2ea1/85/composite-materials-introduction-materail-23-320.jpg)