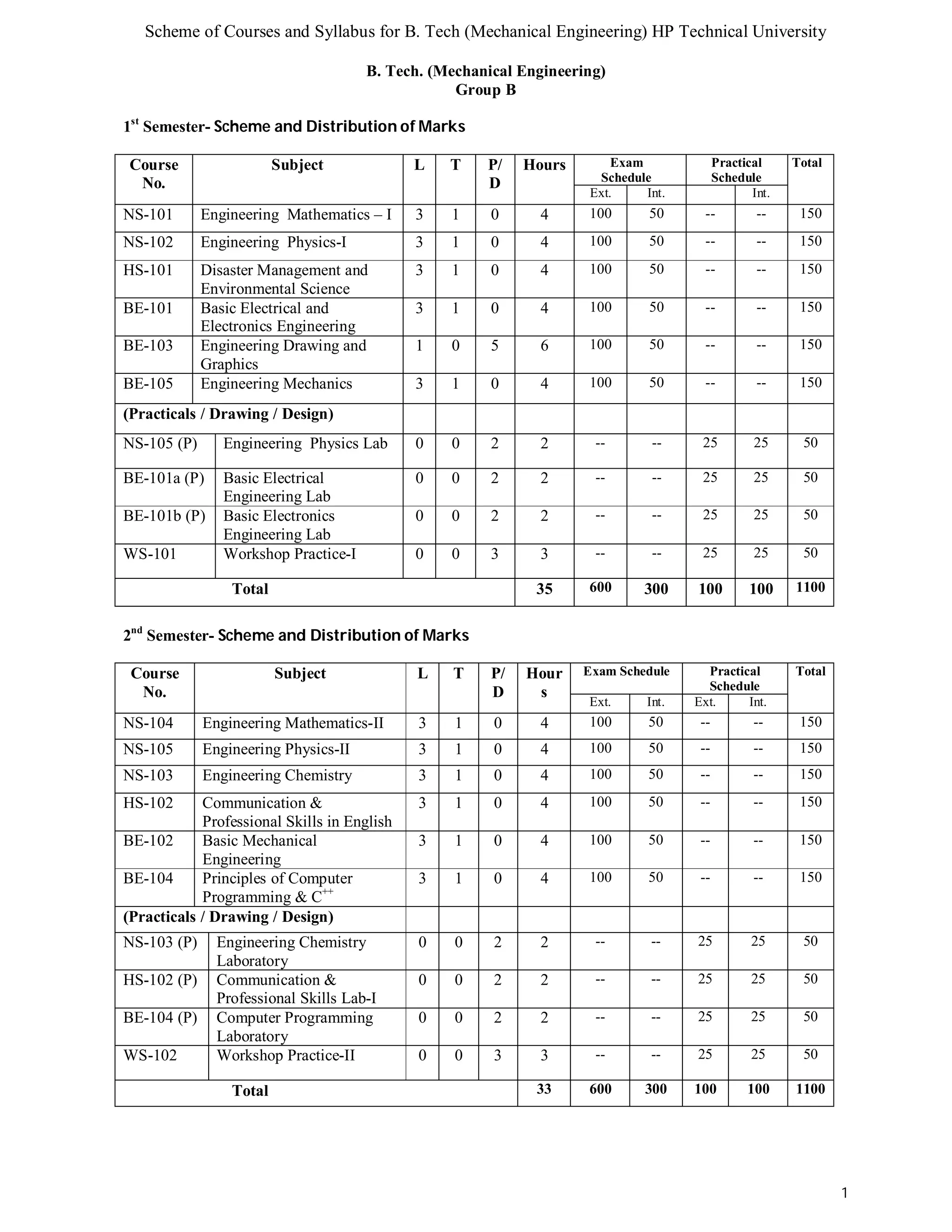

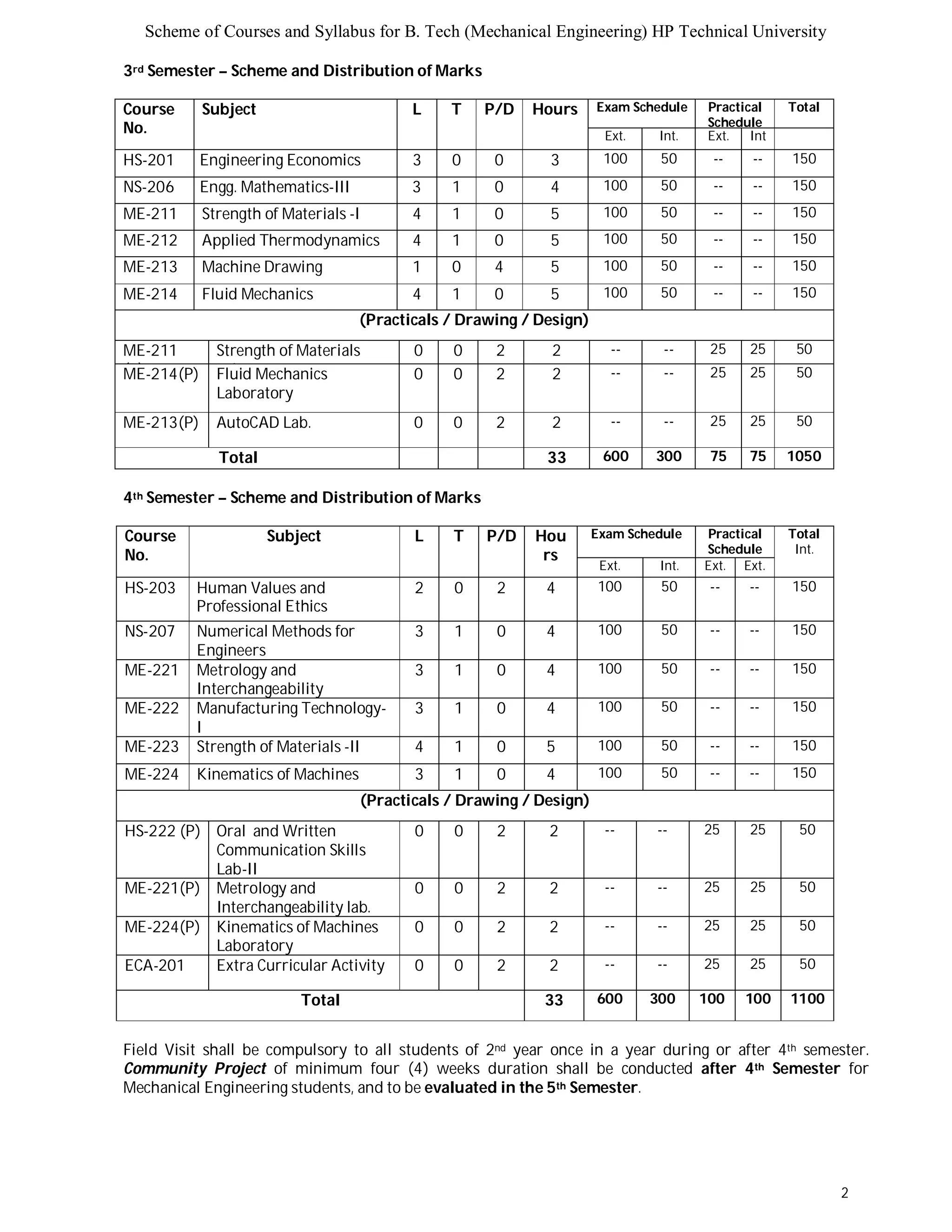

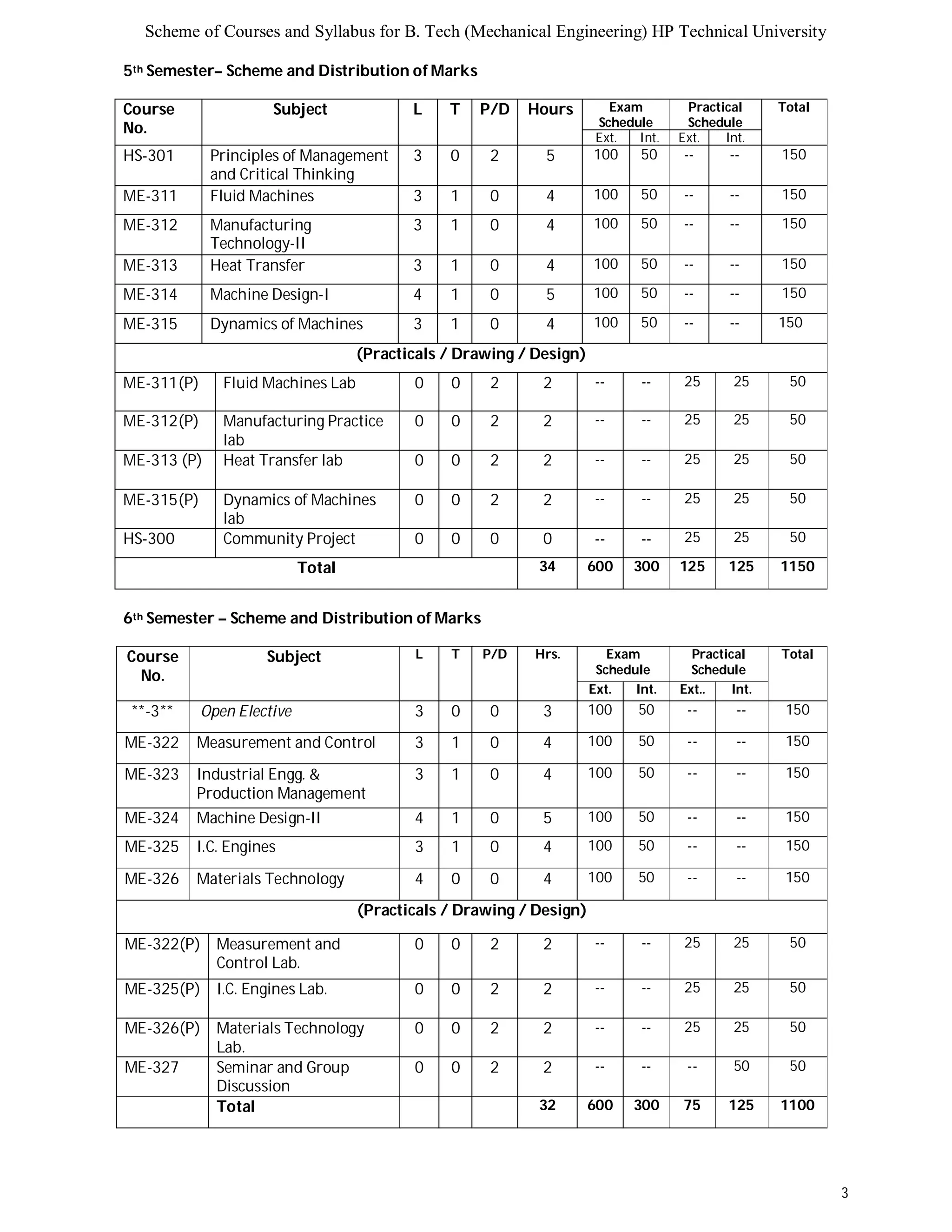

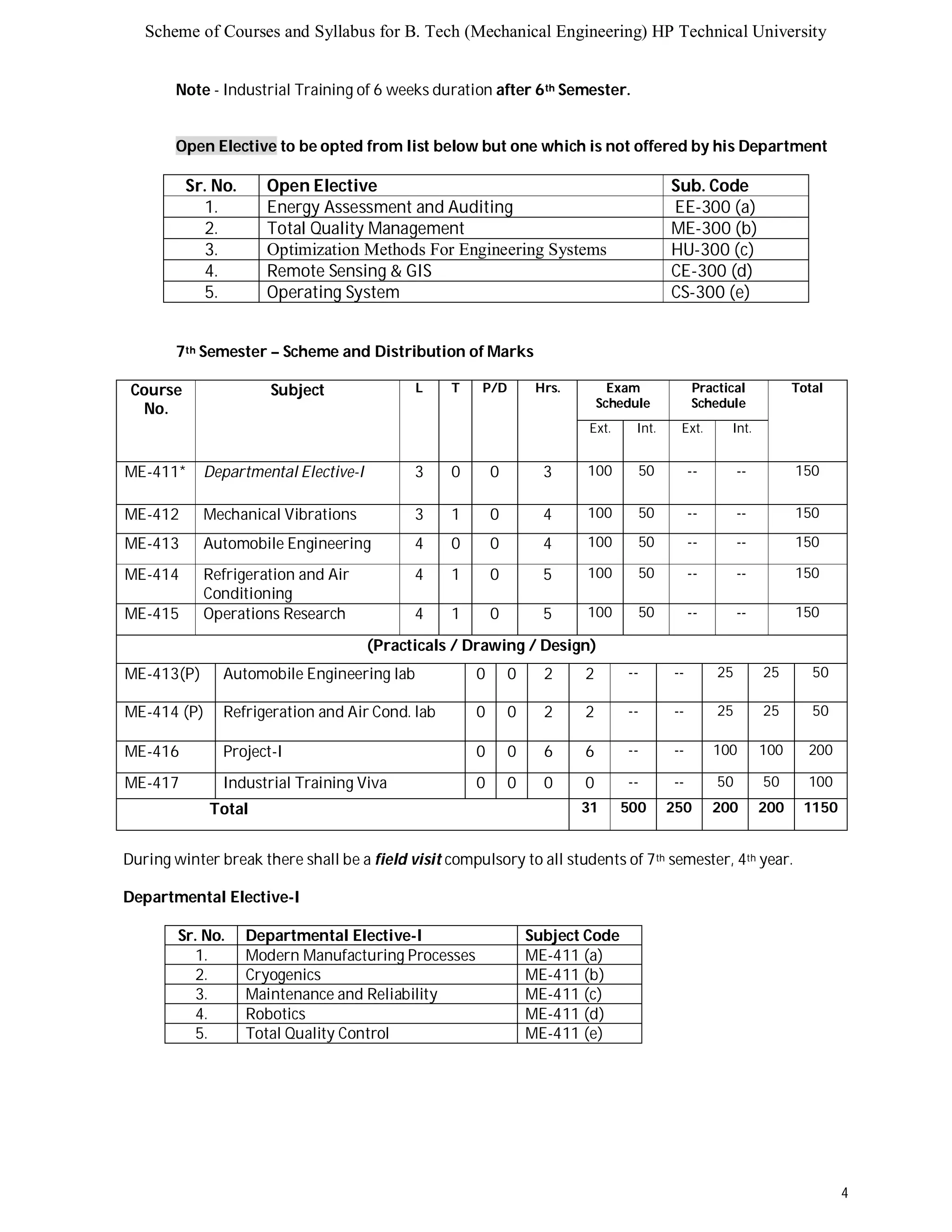

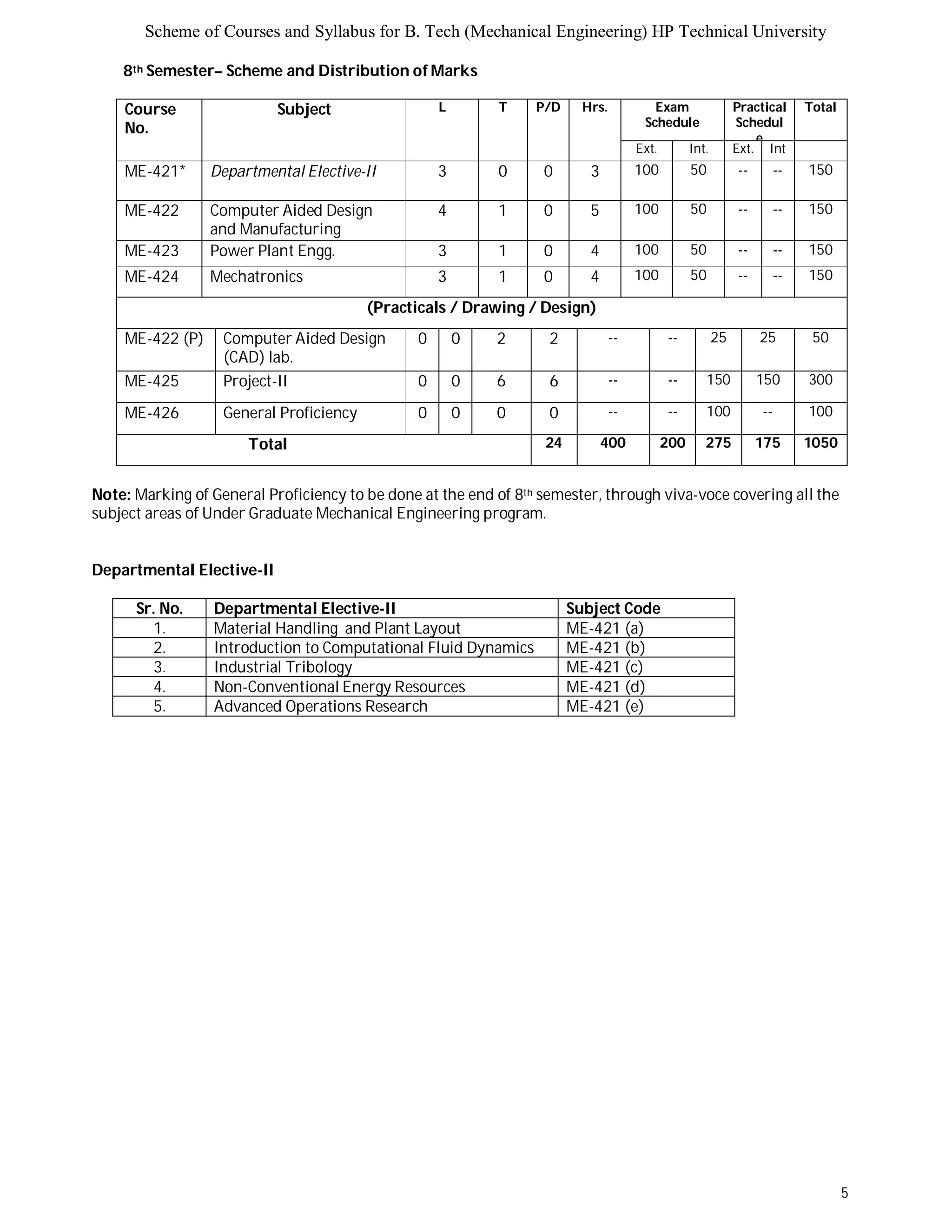

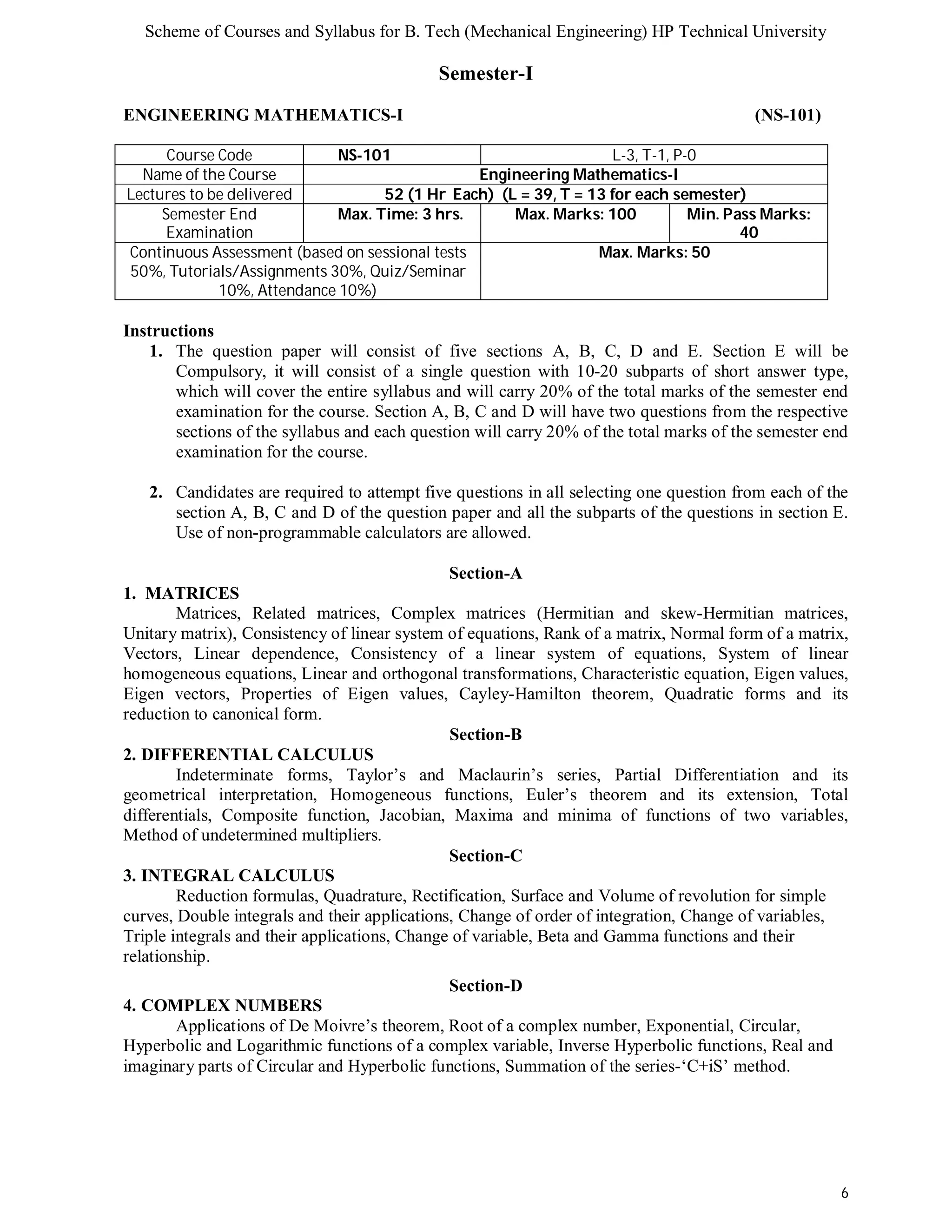

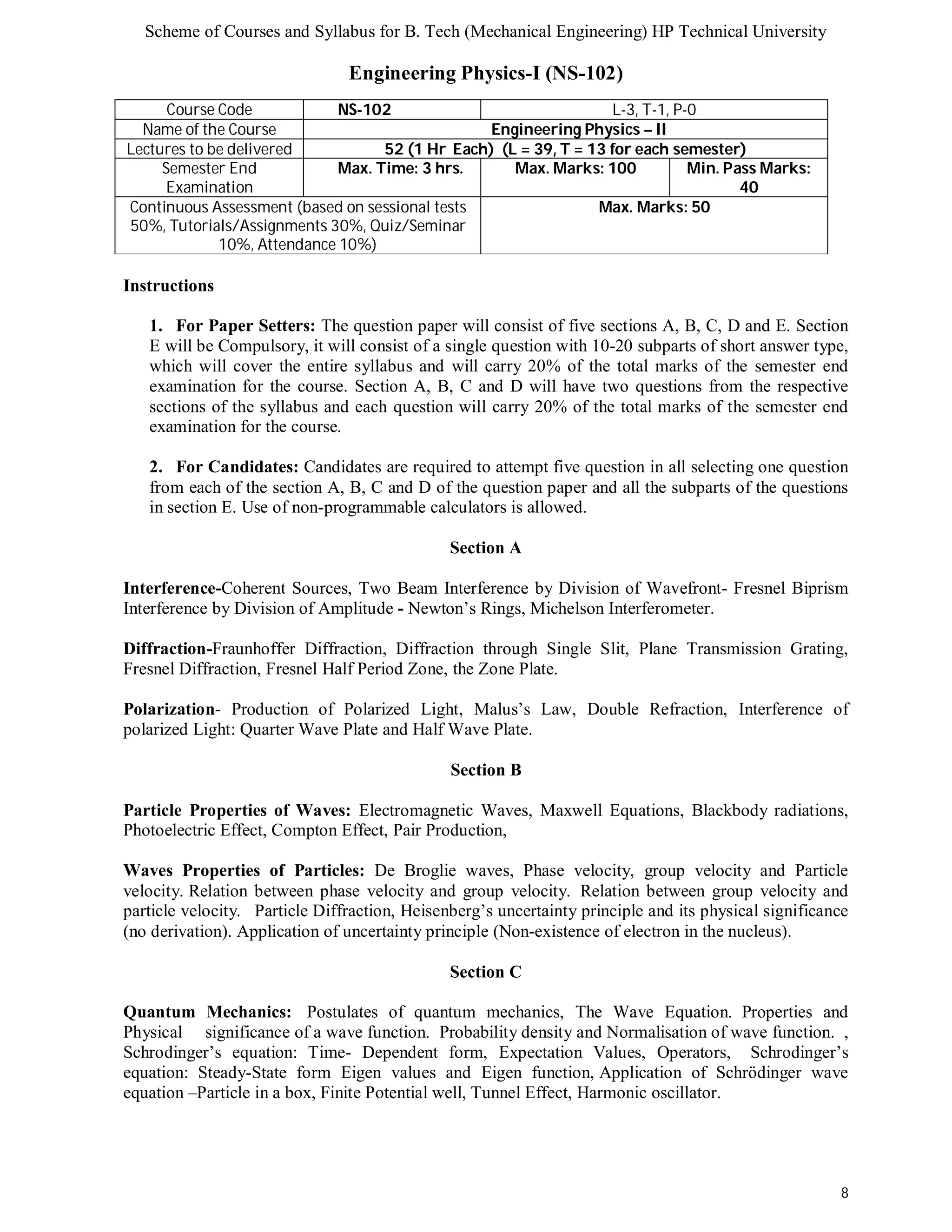

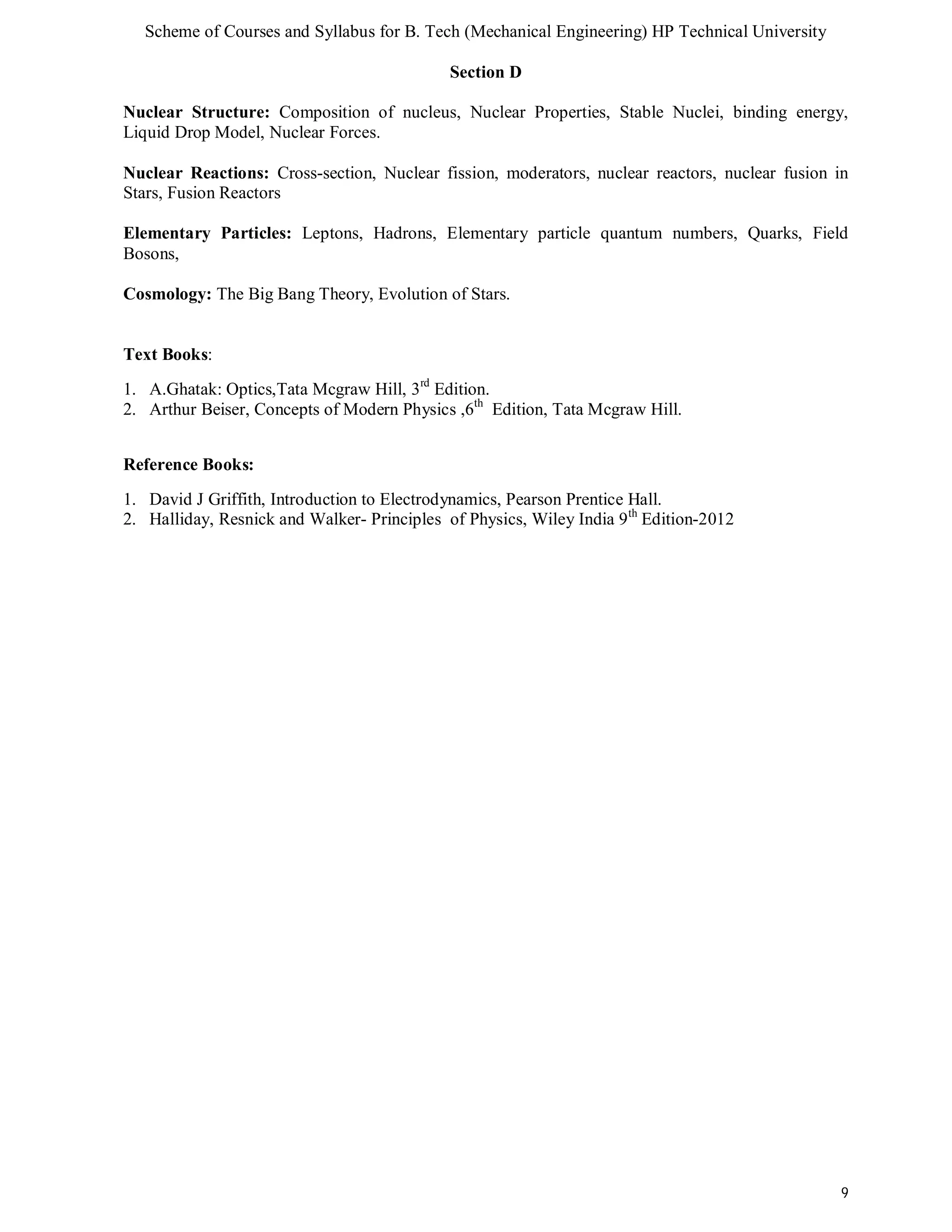

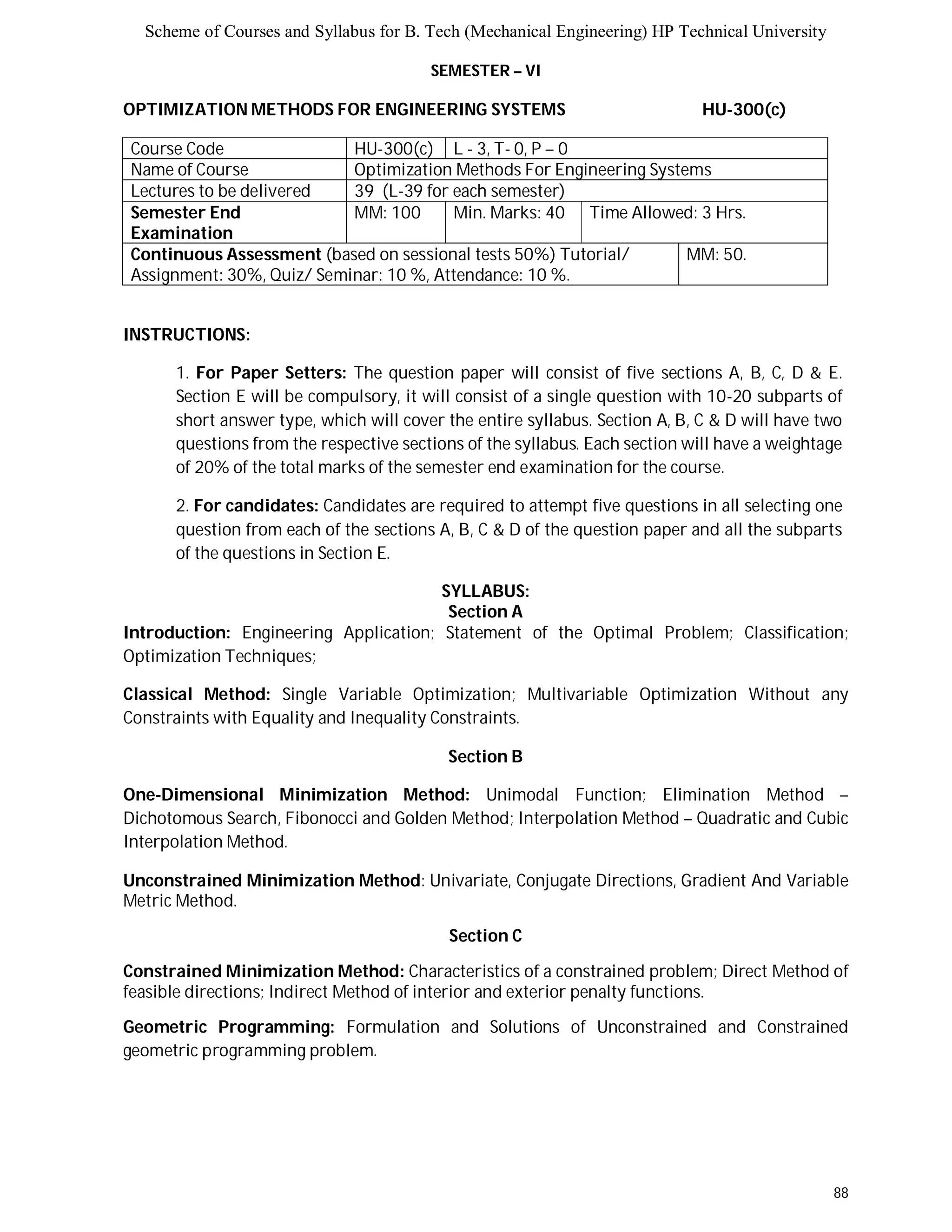

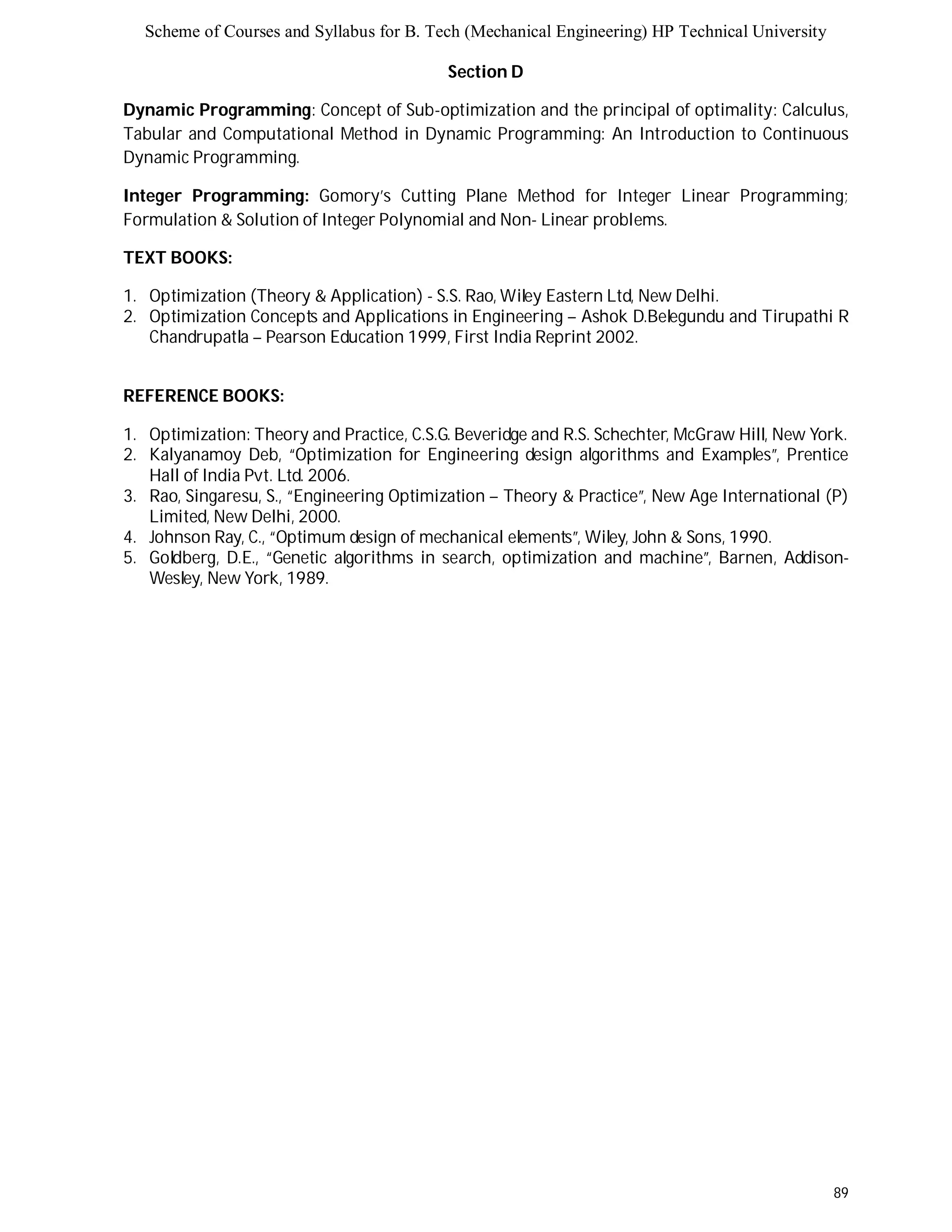

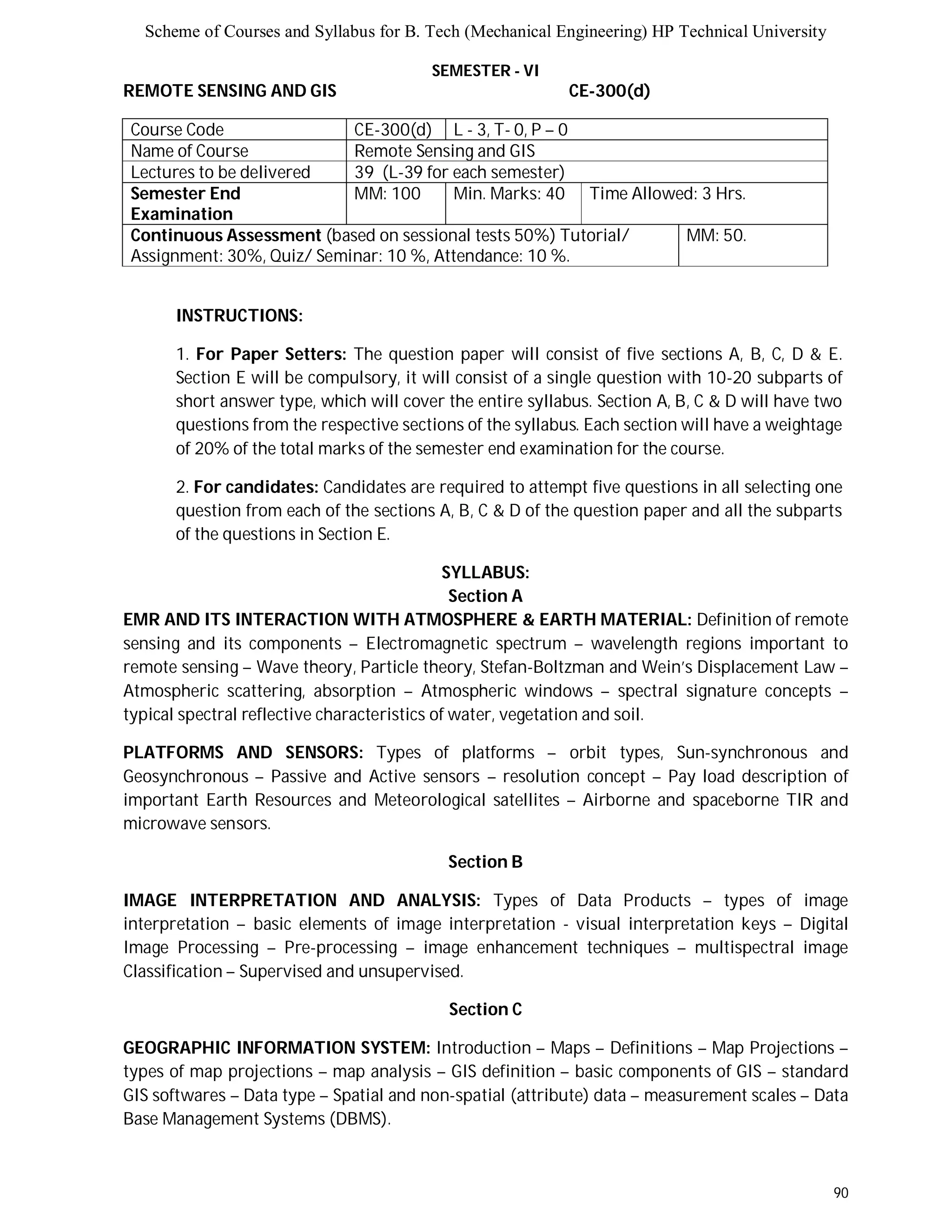

The document is the syllabus for the B.Tech Mechanical Engineering program at H.P. Technical University. It outlines the course structure over 8 semesters, including the subjects covered each semester, course codes, credit hours, and exam and evaluation details. In the first year, courses include Engineering Mathematics, Physics, Chemistry, Engineering Drawing, Mechanics, and workshops. Later semesters cover subjects like Strength of Materials, Thermodynamics, Machine Design, Manufacturing Processes, and electives. Labs, projects, internships, and community work are also included. Evaluation involves internal and external exams, with theory and practical components. The syllabus aims to provide students with knowledge across various domains of Mechanical Engineering

![H.P. TECHNICAL UNIVERSITY

HAMIRPUR (H.P.)

Syllabus

[Effective from the Session: 2012-13]

B. Tech. (Mechanical Engineering)](https://image.slidesharecdn.com/completesyllabusmechanical-141021230117-conversion-gate02/75/Complete-syllabus-mechanical-1-2048.jpg)