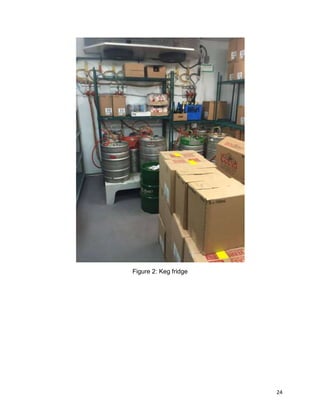

This document provides a summary of a waste audit conducted at the Cambridge Mill restaurant. The audit aimed to identify and quantify sources of food waste and glass waste. It found that the largest sources of glass waste were beer bottles from weddings and the restaurant, totaling around 350 bottles per week. The audit identified opportunities to reduce glass waste such as using a larger collection bin and arranging more frequent pick-ups from the Beer Store. It also suggested replacing some bottled beer with draught beer to reduce the number of beer bottles. The audit provided information to help the restaurant implement cleaner production practices and reduce its environmental impact.