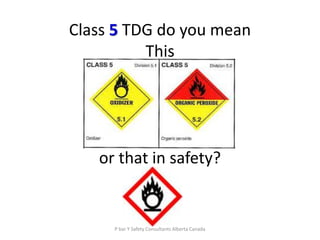

Class 5 tdg do you mean

- 1. Class 5 TDG do you mean This or that in safety? P bar Y Safety Consultants Alberta Canada

- 2. As GHS roles into the workplace • As GHS roles into the workplace we now require under law for workers to be not just GHS ( WHMIS2015) but because those changes Dangerous Goods/Hazmat trained due to the cross of over in worker knowledge. P bar Y Safety Consultants Alberta Canada

- 3. 27 into 9 goes Learning Dangerous Goods is easy all you have to remember is all 9 Classes and 27 Hazard Classes to Competent in TDG/Hazmat, now add all the GHS knowledge! P bar Y Safety Consultants Alberta Canada

- 4. GHS vs TDG/Hazmat Oxidizing liquids category 1, 2, 3 Class 5 Division 5.1: Oxidizing substances, Packing group I, II, III Oxidizing solids category 1, 2, 3 Class 5 Division 5.1: Oxidizing substances, Packing group I, II, III Organic peroxides type A See explosives. May not be allowed for transport. Organic peroxides type B, C, D, E, F Class 5 Division 5.2: Organic peroxides Organic peroxides type G Not dangerous goods P bar Y Safety Consultants Alberta Canada

- 5. Class 5 TDG/Hazmat P bar Y Safety Consultants Alberta Canada

- 6. Class 5 is divided into two divisions as follows: • Division 5.1 Oxidizing substances Substances which, while in themselves not necessarily combustible, may, generally by yielding oxygen, cause, or contribute to, the combustion of other material. Such substances may be contained in an article; • Division 5.2 Organic peroxides Organic substances which contain the bivalent -0-0- structure and may be considered derivatives of hydrogen peroxide, where one or both of the hydrogen atoms have been replaced by organic radicals. Organic peroxides are thermally unstable substances, which may undergo exothermic self- accelerating decomposition. In addition, they may have one or more of the following properties: (i) be liable to explosive decomposition; (ii) burn rapidly; (iii) be sensitive to impact or friction; (iv) react dangerously with other substances; (v) cause damage to the eyes. P bar Y Safety Consultants Alberta Canada

- 7. Fire or Boom Additionally, organic peroxides may be liable to explosive decomposition, burn rapidly, be sensitive to impact or friction, react dangerously with other substances or cause damage to eyes. P bar Y Safety Consultants Alberta Canada

- 8. Common but not all of them Commonly Transported Oxidizers; Organic Peroxides • Chemical oxygen generators • Ammonium nitrate fertilizers • Chlorates • Nitrates • Nitrites • Perchlorates • Permanganates • Persulphates • Aluminium nitrate • Ammonium dichromate • Ammonium nitrate • Ammonium persulphate • Calcium hypochlorite • Calcium nitrate • Calcium peroxide • Hydrogen peroxide • Magnesium peroxide • Lead nitrate • Lithium hypochlorite • Potassium chlorate • Potassium nitrate • Potassium chlorate • Potassium perchlorate • Potassium permanganate • Sodium nitrate • Sodium persulphate P bar Y Safety Consultants Alberta Canada

- 9. Two Separate Guides pending risk In the Emergency response guide book P bar Y Safety Consultants Alberta Canada

- 10. Common but not always Commonly transported class 5 dangerous goods include hydrogen peroxide, potassium permanganate, sodium nitrite, ammonium nitrate fertilizers and oxygen generators. P bar Y Safety Consultants Alberta Canada

- 11. Class 5 has two divisions: • (a) Class 5.1, Oxidizing Substances, which consists of substances that yield oxygen thereby causing or contributing to the combustion of other material, as determined in accordance with section 2.5.2 of Chapter 2.5 of the UN Recommendations; and • (b) Class 5.2, Organic Peroxides, which consists of substances that – (i) are thermally unstable organic compounds that contain oxygen in the bivalent "-O-O-" structure, as determined in accordance with section 2.5.3 of Chapter 2.5 of the UN Recommendations, – (ii) are liable to undergo exothermic self-accelerating decomposition, – (iii) have one or more of the following characteristics: • (A) they are liable to explosive decomposition, • (B) they burn rapidly, • (C) they are sensitive to impact or friction, • (D) they react dangerously with other substances, or • (E) they cause damage to the eyes, or – (iv) are in the list of currently assigned organic peroxides in section 2.5.3.2.4 of Chapter 2.5 of the UN Recommentations. P bar Y Safety Consultants Alberta Canada

- 12. 5.1 • The packing group of a Division 5.1 material which is a solid shall be assigned using the following criteria: – Packing Group I, for any material which, in either concentration tested, exhibits a mean burning time less than the mean burning time of a 3:2 potassium bromate/cellulose mixture. – Packing Group II, for any material which, in either concentration tested, exhibits a mean burning time less than or equal to the mean burning time of a 2:3 potassium bromate/cellulose mixture and the criteria for Packing Group I are not met. – Packing Group III for any material which, in either concentration tested, exhibits a mean burning time less than or equal to the mean burning time of a 3:7 potassium bromate/cellulose mixture and the criteria for Packing Group I and II are not met. • The packing group of a Division 5.1 material which is a liquid shall be assigned using the following criteria: – Packing Group I for: • Any material which spontaneously ignites when mixed with cellulose in a 1:1 ratio; or • Any material which exhibits a mean pressure rise time less than the pressure rise time of a 1:1 perchloric acid (50 percent)/cellulose mixture. – Packing Group II, any material which exhibits a mean pressure rise time less than or equal to the pressure rise time of a 1:1 aqueous sodium chlorate solution(40 percent)/cellulose mixture and the criteria for Packing Group I are not met. – Packing Group III, any material which exhibits a mean pressure rise time less than or equal to the pressure rise time of a 1:1 nitric acid (65 percent)/cellulose mixture and the criteria for Packing Group I and II are not met. P bar Y Safety Consultants Alberta Canada

- 13. Type 5.2 has Type, B to F, of organic peroxides, Organic peroxides - organic compounds with the bivalent R-O-O-R structure where at least one R is a carbon chain, except for materials that meet class 1 (Explosive) P bar Y Safety Consultants Alberta Canada

- 14. A through G on 5.2 • Type A. Organic peroxide type A is an organic peroxide which can detonate or deflagrate rapidly as packaged for transport. Transportation of type A organic peroxides is forbidden. • Type B. Organic peroxide type B is an organic peroxide which, as packaged for transport, neither detonates nor deflagrates rapidly, but can undergo a thermal explosion. • Type C. Organic peroxide type C is an organic peroxide which, as packaged for transport, neither detonates nor deflagrates rapidly and cannot undergo a thermal explosion. • Type D. Organic peroxide type D is an organic peroxide which- – Detonates only partially, but does not deflagrate rapidly and is not affected by heat when confined; – Does not detonate, deflagrates slowly, and shows no violent effect if heated when confined; or – Does not detonate or deflagrate, and shows a medium effect when heated under confinement. • Type E. Organic peroxide type E is an organic peroxide which neither detonates nor deflagrates and shows low, or no, effect when heated under confinement. • Type F. Organic peroxide type F is an organic peroxide which will not detonate in a cavitated state, does not deflagrate, shows only a low, or no, effect if heated when confined, and has low, or no, explosive power. • Type G. Organic peroxide type G is an organic peroxide which will not detonate in a cavitated state, will not deflagrate at all, shows no effect when heated under confinement, and shows no explosive power. A type G organic peroxide is not subject to the requirements of this subchapter for organic peroxides of Division 5.2 provided that it is thermally stable (self-accelerating decomposition temperature is 50 °C (122 °F) or higher for a 50 kg (110 pounds) package). An organic peroxide meeting all characteristics of type G except thermal stability and requiring temperature control is classed as a type F, temperature control organic peroxide. P bar Y Safety Consultants Alberta Canada

- 15. It has a quantifying feature • The material meets one of the following conditions: For materials containing no more than 1.0 percent hydrogen peroxide, the available oxygen, as calculated using the equation, is not more than 1.0 percent, or • For materials containing more than 1.0 percent but not more than 7.0 percent hydrogen peroxide, the available oxygen, content (Oa) is not more than 0.5 percent, when determined using the equation: where, for a material containing k species of organic peroxides: P bar Y Safety Consultants Alberta Canada

- 16. Packing Groups • Packing Groups • (1) The determination of packing groups for Class 5.1, Oxidizing Substances, must be made – (a) for solids, using a test sample of a 4:1 or 1:1 mixture of substance and cellulose by mass, prepared and tested in accordance with section 2.5.2.2 of Chapter 2.5 of the UN Recommendations; or – (b) for liquids, using a test sample of a 1:1 mixture of substance and cellulose by mass, prepared and tested in accordance with section 2.5.2.3 of Chapter 2.5 of the UN Recommendations. • (2) Substances included in Class 5.1, Oxidizing Substances, are included in one of the following packing groups: – (a) for solids, • (i) Packing Group I, if the test sample exhibits an average burning time less than the mean burning time of a 3:2 mixture by mass of potassium bromate and cellulose, • (ii) Packing Group II, if the test sample exhibits an average burning time less than or equal to the mean burning time of a 2:3 mixture by mass of potassium bromate and cellulose and the criteria for inclusion in Packing Group I are not met, or • (iii) Packing Group III, if the test sample exhibits an average burning time less than or equal to the mean burning time of a 3:7 mixture by mass of potassium bromate and cellulose and the criteria for inclusion in Packing Group I or II are not met; or – (b) for liquids, • (i) Packing Group I, if the substance in a 1:1 mixture by mass of substance and cellulose spontaneously ignites or the mean pressure rise time is less than or equal to that of a 1:1 mixture by mass of 50 percent perchloric acid and cellulose, • (ii) Packing Group II, if the mean pressure rise time is less than or equal to the mean pressure rise time of a 1:1 mixture by mass of 40 per cent aqueous sodium chlorate solution and cellulose and the criteria for inclusion in Packing Group I are not met, or • (iii) Packing Group III, if the mean pressure rise time is less than or equal to the mean pressure rise time of a 1:1 mixture by mass of 65 per cent aqueous nitric acid solution and cellulose and the criteria for inclusion in Packing Group I or II are not met. • (3) Class 5.2, Organic Peroxides, are included in Packing Group II. • (4) The type, B to F, of organic peroxides must be determined in accordance with section 2.5.3.3 of Chapter 2.5 of the UN Recommendations. P bar Y Safety Consultants Alberta Canada

- 17. Did you Segregate it properly Check the tables ! P bar Y Safety Consultants Alberta Canada

- 18. P bar Y Safety Consultants Alberta Canada

- 19. Where the worker gets confused P bar Y Safety Consultants Alberta Canada

- 20. GHS Oxidizer • In chemistry, an oxidizing agent (oxidant, oxidizer) is a substance that has the ability to oxidize other substances (cause them to lose electrons). Common oxidizing agents are oxygen, hydrogen peroxide and the halogens. • In one sense, an oxidizing agent is a chemical reaction that removes an electron from another atom. It is one component in an oxidation–reduction (redox) reaction. In the second sense, an oxidizing agent is a chemical species that transfers electronegative atoms, usually oxygen, to a substrate. Combustion, many explosives, and organic redox reactions involve atom- transfer reactions. P bar Y Safety Consultants Alberta Canada

- 21. Free Radicals P bar Y Safety Consultants Alberta Canada

- 22. APPLIED As heat is applied to a combustible material, the molecules that compose the material start to vibrate rapidly. If the vibrations become strong enough, the molecules break into fragments known as free radicals. The process of breaking into free radicals is known as pyrolysis and is endothermic (requiring heat from an outside source). The free radicals encounter oxygen in the air. Oxygen has a great attraction for electrons (electronegativity) and reacts with the free radicals. The reaction that occurs is known as oxidation and is simply the forming of a chemical bond between a free radical and oxygen. The bond-forming process is exothermic (heat producing) and is, in essence, combustion P bar Y Safety Consultants Alberta Canada

- 23. Gases For oxidizing compressed gases in cylinders, a unique hazard is that fire can result from the gas passing through a gauge or piping system that is not free of hydrocarbons, even in trace amounts. Spontaneous ignition of the hydrocarbon will occur. This ignition can result in an explosion accompanied by fragmentation of the equipment and possible fire. A second hazard unique to oxidizing gases is the potential to concentrate in a room or other unvented or poorly vented space. In oxidizer-enriched environments, the flammable range of flammable gases and liquids is widened at both the upper and lower flammable limits. They will burn when normally they would be either too rich or lean. Flash points and ignition temperatures are also lowered. In some cases, flash points and ignition temperatures are lowered to the point that the substance can ignite at room temperature. P bar Y Safety Consultants Alberta Canada

- 24. Solids Oxidizing solids also have a few unique properties. Oxidizing solids include: • Oxysalts such as potassium permanganate, sodium nitrate, sodium persulfate, and other nitrates, nitrites and chlorates. • Inorganic peroxides include alkali metal (Na, K, Rb, Li, Cs, Fr) peroxides and transition metal (e.g., Cu, Zn, Co, Fe, Cr, Se, Ag, Pb, etc.) peroxides. When wetted, alkali metal peroxides can produce sufficient heat to ignite nearby combustibles (or explosively rupture their containers). Transition metal peroxides are less reactive than those of alkali metals. Solid oxidizers in solution may be too dilute to react with combustible materials to produce a fire. However, if a combustible material (e.g., a paper towel or a lab coat) is contaminated with a solution containing an oxidizer, as the solution dries, the oxidizer is concentrated. This can cause the combustible material to spontaneously ignite and burn intensely. Solid oxidizers saturated with combustible materials can be explosive. An example is the explosive behavior of ammonium nitrate combined with fuel oil. P bar Y Safety Consultants Alberta Canada

- 25. Hazards of the oxidizing materials that you use in the workplace • An example is ammonium perchlorate. This material is a white or colourless, odourless crystals. It is used in explosives and fireworks; as an oxidizing agent in solid rocket and missile propellants; as an adhesive; as an engraving agent; laboratory (analytical) reagent; chemical intermediate for alkali and alkaline metal perchlorates; animal feed supplement; and in oxygen-generating devices for life- support systems in submarines, spacecraft, bomb shelters and breathing apparatus. • Ammonium perchlorate can decompose at high temperatures forming toxic gases, such as chlorine, hydrogen chloride and nitrogen oxides. Closed containers or tanks may rupture and explode if heated. It does not burn but is a powerful oxidizer and explosive when mixed with combustible materials. It is highly reactive and impact or high temperatures can cause violent decomposition or explosion. It can form shock-sensitive mixtures with finely powdered metals, metal oxides, strong reducing agents, sulfur and phosphorus. It may cause eye irritation. P bar Y Safety Consultants Alberta Canada

- 26. Any Oxidizing materials can: • speed up the development of a fire and make it more intense. • cause substances that do not normally burn readily in air to burn rapidly. • cause combustible materials to burn spontaneously without the presence of obvious. ignition sources such as a spark or flame. • What happens when an oxidizing material comes in contact with a combustible substance largely depends on the chemical stability of the oxidizing material. The less stable an oxidizing material is, the greater the chance that it will react in a dangerous way. P bar Y Safety Consultants Alberta Canada

- 27. Oxidizer Storage • Store oxidizing materials according to the occupational health and safety regulations and the fire and building codes that apply to your workplace. These laws may specify the kinds of storage areas such as storage rooms or buildings allowed for different oxidizers. They may also specify how to construct these storage areas, and the amounts of oxidizing materials that can be stored in each area. • Before storing, inspect all incoming containers to ensure that they are undamaged and properly labelled. Do not accept delivery of defective containers. • Store oxidizing materials in containers that the chemical supplier recommends. Normally these are the same containers in which the material was shipped. Repackaging can be very dangerous especially when using contaminated or incompatible containers. Protect containers against banging or other physical damage when storing, transferring or using them. Do not use wooden pallets or other combustible pallets for storing containers of oxidizing materials. • Make sure containers are suitably labelled. For oxidizing materials requiring temperature control, the recommended storage temperature range should be plainly marked on the container. It is also a good practice to mark the date that the container was received and the date it was first opened. • Normally keep containers tightly closed when storing unless the supplier's instructions state otherwise. This helps to avoid contamination of the material or evaporation of solvents used to dilute oxidizers, such as organic peroxides, to safer concentrations. • Some oxidizing agents, such as solutions of 8% or higher hydrogen peroxide in water, must be stored with specially vented caps. Hydrogen peroxide gradually decomposes at room temperature to produce oxygen gas and water. The properly working vent will prevent the build-up of pressure inside containers. The normal build-up of pressure could rupture an unvented container. Check vent caps regularly to ensure that they are working properly. Keep vented containers in the upright position. NEVER stack vented containers on top of each other. P bar Y Safety Consultants Alberta Canada

- 28. Temperature • For these oxidizers, ensure that the storage temperature is kept at least 14°C (25°F) below their decomposition temperature. Avoid storing any oxidizer at temperatures above 49°C (120°F). • Storage areas may need alarms that provide a warning when storage temperatures are higher or lower than required. P bar Y Safety Consultants Alberta Canada

- 29. Risks everyone should know • The main hazard related to organic peroxides are their fire and explosion hazards. Organic peroxides may also be toxic or corrosive. Depending on the material, route of exposure (inhalation, eye or skin contact, or swallowing) and dose or amount of exposure, they could harm the body. Corrosive organic peroxides can also attack and destroy metals. • It is the double oxygen of the "peroxy" group that makes organic peroxides both useful and hazardous. The peroxy group is chemically unstable. It can easily decompose, giving off heat at a rate that increases as the temperature rises. Many organic peroxides give off flammable vapours when they decompose. These vapours can easily catch fire. • Most undiluted organic peroxides can catch fire easily and burn very rapidly and intensely. This is because they combine both fuel (carbon) and oxygen in the same compound. Some organic peroxides are dangerously reactive. They can decompose very rapidly or explosively if they are exposed to only slight heat, friction, mechanical shock or contamination with incompatible materials. • Organic peroxides can also be strong oxidizing agents. Combustible materials contaminated with most organic peroxides can catch fire very easily and burn very intensely (i.e., deflagrate). This means that the burn rate is very fast: it can vary from 1 m/sec to hundreds of metres per second. Also the combustion rate increases as the pressure increases and the combustion (or reaction) zone can travel through air or a gaseous medium faster than the speed of sound. However, the speed of combustion in a solid medium does not exceed the speed of sound. • This is one characteristic that distinguishes deflagration from detonation. We mention these two terms because they are used in classifying organic peroxide formulations (see next question). Deflagrations and detonations are similar chemical reactions except that in detonations the burn rate in a solid medium is faster than the speed of sound. This supersonic speed results in a shock wave being produced. They can transmit the shock wave at speeds of about 2,000 to 9,000 m/sec and is not dependent on the surrounding pressure. This is another difference between detonation and deflagration: deflagration rates increase as the pressure becomes greater. P bar Y Safety Consultants Alberta Canada

- 30. Fire Extinguishing Agents for Oxidizer Fires Extinguishing fires involving an oxidizer is difficult. A carbon dioxide extinguisher is not an effective choice for an oxidizer-fed fire because it works on the principle of excluding atmospheric oxygen, and atmospheric oxygen is not required for an oxidizer-fed fire. Dry chemical extinguishing agents will also be ineffective for the most part. They act to interrupt the chemical chain reaction, but will be overcome by the oxidizer in all but the smallest fires. P bar Y Safety Consultants Alberta Canada

- 31. NFPA and GHS Class 1 Oxidizers: • slightly increase the burning rate of combustible materials. • do not cause spontaneous ignition when they come in contact with them. Class 2 Oxidizers: • increase the burning rate of combustible materials moderately with which they come in contact. • may cause spontaneous ignition when in contact with a combustible material. Class 3 Oxidizers: • severely increase the burning rate of combustible materials with which they come in contact. • will cause sustained and vigorous decomposition if contaminated with a combustible material or if exposed to sufficient heat. Class 4 Oxidizers: • can explode when in contact with certain contaminants. • can explode if exposed to slight heat, shock, or friction. • will increase the burning rate of combustibles. • can cause combustibles to ignite spontaneously. P bar Y Safety Consultants Alberta Canada

- 32. Organic Peroxides can form • Yes, some chemicals can form explosive peroxides when they are stored (e.g., isopropyl ether, vinylidene chloride). Exposure to light and heat can increase the rate of peroxide formation. Others form peroxides that become hazardous when concentrated (e.g., by distillation). Some examples include ethyl ether, tetrahydrofuran (THF), p-dioxane, some secondary alcohols like 2-propanol and 2- butanol, and some unsaturated hydrocarbons like propyne (an acetylene compound), cyclohexene, and tetra-and deca-hydronaphthalenes. • Another kind of peroxide-forming compound are unsaturated monomers that, in the presence of a peroxide, can polymerize exothermically (i.e., produces heat when it reacts). For example, uninhibited styrene can form a peroxide that can cause the styrene to polymerize. It can occur explosively under certain conditions. Other examples of some unsaturated monomeric compounds are acrylic acid, acrylonitrile, butadiene, methyl methacrylate, and vinyl chloride. • To generalize, the kinds of chemicals that can form peroxides include aldehydes, ethers, and numerous unsaturated hydrocarbon compounds (i.e. hydrocarbon compounds having double or triple bonds). Examples in this group include allyl compounds, haloalkenes, dienes, monomeric vinyl compounds, vinylacetylenes, unsaturated cyclic hydrocarbons like tetrahydronaphthalene or dicyclopentadiene. P bar Y Safety Consultants Alberta Canada

- 33. NFPA 432 "Code for the Storage of Organic Peroxide Formulations" In general: • Class I formulations are capable of deflagration but not detonation. • Class II formulations burn very rapidly and are a severe reactivity hazard. • Class III formulations burn rapidly and have a moderate reactivity hazard. • Class IV formulations burn in the same manner as ordinary combustibles and have a minimal reactivity hazard. • Class V formulations burn with less intensity than ordinary combustibles or they do not support combustion and present no reactivity hazard. P bar Y Safety Consultants Alberta Canada

- 34. Waste• Oxidizing wastes are hazardous. Always handle them safely. Consider oxidizing materials accidently mixed with an unknown or foreign material as contaminated and do not use. Dispose of contaminated material immediately. • "Empty" drums, bottles, bags, sacks and other "oxidizing agent" containers usually have hazardous oxidizing residues inside them. NEVER use these containers for anything else, no matter how clean they seem. Treat them as oxidizing wastes. The chemical supplier can give advice about how to safely handle or decontaminate "empty" containers or other packaging material. • Store oxidizing wastes, including contaminated empty combustible containers, in the same way as unused oxidizing materials. Only use compatible containers for oxidizing wastes. Identify their contents with suitable labels. • NEVER dispose of oxidizers in ordinary garbage or down sinks or drains that connect to sanitary or storm sewers. Dispose of them according to the supplier's directions, or through hazardous waste collection and disposal companies. In all cases, dispose of oxidizing wastes according to the environmental laws that apply to your jurisdiction. Contact the appropriate environmental officials for details. P bar Y Safety Consultants Alberta Canada