Powertrac is an ISO 9001-2008 certified company based in Gujarat, specializing in manufacturing and supplying maintenance-free earthing electrodes, lightning arrestors, and other electrical solutions. They employ advanced technology, such as 'chemo' MF earthing electrodes and 'srip' soil resistivity improver, to ensure safety and efficiency in earthing systems. The company aims to provide complete earthing and lightning protection solutions through customized design, installation, and maintenance services.

![AN ISO 9001-2008 CERTIFIED CO. | CRISIL SE-3C RATED CO

------------------------------------------------------------------------------------------------------------------------------------------

Group of Companies

1. ELECTRA ENERGY PROJECTS: -

[Consultancy, Engineering, Design, Procurement Erection, Installation &

Commission of Solar PV Projects]

Office: - 101, Raj Market, Opp. Sur Sagar Milk Dairy,

Surendranagar – Wadhwan Road,

Surendranagar – 363030 (Gujarat)

Ph : 0275 – 2326329

GSM : +91 9909954615

E-Mail ID : electra@powertracgroup.in

2. POWERTRAC INDUSTRIES: -

[Manufacturer & Supply for All Types of Anchor & Fasteners]

Office: - Plot No. 451, B/h Ardik Engineering,

Wadhwan - GIDC,

Surendranagar – 363030 (Gujarat)

Ph : 0275 – 2326329

GSM : +91 9909954616

URL : www.powertracgroup.com

E-Mail ID : fasteners@powertracgroup.in www.powertracgroup.in

5](https://image.slidesharecdn.com/clpowertracenergy-130330013202-phpapp01/85/Powertrac-Vapi-Earthing-Products-5-320.jpg)

![AN ISO 9001-2008 CERTIFIED CO. | CRISIL SE-3C RATED CO

------------------------------------------------------------------------------------------------------------------------------------------

COPPER:

Metal oxides are generally not very good conductors. In fact, most are Dielectrics and hence

non-conductors.

CU & AL are much better conductors than their corresponding Oxides at any temperature

linemen will encounter. Copper, lead, and aluminum oxides formed by corrosion are

decidedly poor Conductors.

Copper is generally used as TINNED COPPER to avoid oxidation effect on the bare copper

conductors when used.

The copper oxide is poor conductor is proved by the practice of cleaning the copper contacts

in the Switchgear by emery paper /sand paper periodically to maintain the contact

conductivity.

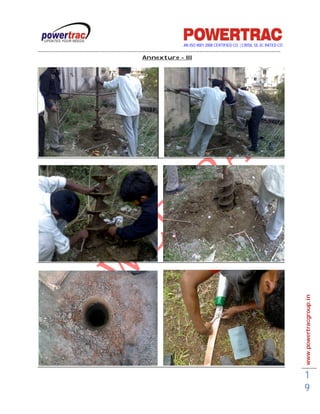

How “CHEMO” M.F. Earthing System Works?

An example of the “CHEMO” M.F. Earthing as per the following spec. which can be compared with

the other systems for your analytical ref.

1. The Hollow pipe is filled with Chemical: Known as HCC (This is used to dissipate the heat

generated due to Phase to Phase and Phase to Earth fault Which is very high and cause of all

electrical Hazards and fires)

2. “SRIP” [Soil resistivity Improver Powder] Compound which is used to maintain the moisture

in the earthing system for its efficient working.

3. The electrode is installed 2 or 3 mtr deep and is surrounded by “SRIP” Compound in thick

slurry to maintain the moisture level for long period of time.

4. The parameters for success of “CHEMO” M.F. Earthing Electrode are Capacity to clear the

fault current- avoid electrical Hazards, To dissipate the heat – to avoid the failure of earthing

system, To maintain the moisture level - to achieve the low ohmic values

5. The heat is dissipated because of HCC filled in the pipe which has a melting temperature of

2500°c.

6. The “SRIP” Compound has a property to absorb water 15 times of its weight and doesn’t

dissolve in the water. It remains wet for a very long period of time.

www.powertracgroup.in

9](https://image.slidesharecdn.com/clpowertracenergy-130330013202-phpapp01/85/Powertrac-Vapi-Earthing-Products-9-320.jpg)

![AN ISO 9001-2008 CERTIFIED CO. | CRISIL SE-3C RATED CO

------------------------------------------------------------------------------------------------------------------------------------------

Technical Specification of “CHEMO” M.F. Earthing Electrode

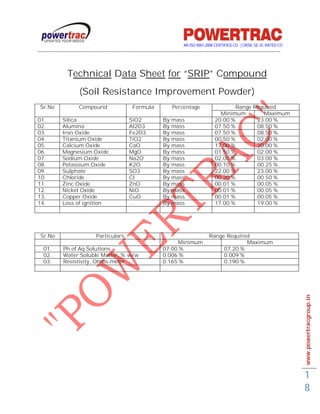

‘SRIP” [Soil resistivity Improver Powder ] Compound

Minimum 30kg Packing Bag

It is soil enrichment chemical mainly consisting of Aluminum Silicate

It absorbs moisture but doesn’t get dissolved in water.

It can absorb water 15 times of its weight.

It remains wet for a very Long Time

“CHEMO” M.F.Earthing Electrode

Earth fault capacity :15 to 80 KA RMS FOR 1 Second

Surface Area :314000 TO 471000mm

Seal Plate :5MM HDGI

Diameter of the pipe :50 to 80mm

Thickness of the pipe :2.5mm (16 S.W.G.)

Length of the pipe : 2 Mtr, 2.5 Mtrs, 3Mtrs

Galvanized Thickness :80-120 Micron

Type of galvanizing :HDGI

Size of the conductor :32X5MM, 50X6MM HDGI strip

Terminal Length : 200MM with 12 mm Hole

Chemical Filled in pipe : HCC (Highly Conductive Compound)

www.powertracgroup.in

1

0](https://image.slidesharecdn.com/clpowertracenergy-130330013202-phpapp01/85/Powertrac-Vapi-Earthing-Products-10-320.jpg)

![AN ISO 9001-2008 CERTIFIED CO. | CRISIL SE-3C RATED CO

------------------------------------------------------------------------------------------------------------------------------------------

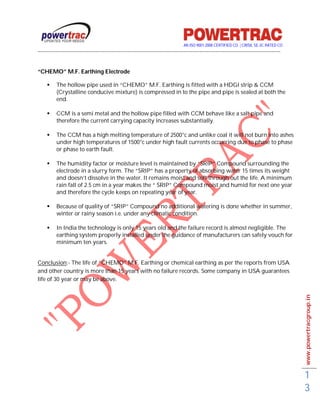

How is price comparable Cu V/s Chemical Earthing?

Electrode Earthing System Details of Costing:

Please Note Copper Used Is Electrolytic copper, Coal Used Is A-Grade (Coke), Salt Used Is Rock Salt

Superior Quality, Salt & Coke Used in Ratio of 1/1 to maintains desired level of moisture

Sr.No. Particular Conversional Earthing “CHEMO” M.F. Earthing Electrode

Commercially Comparison [ Industrial Model i.e PT-803, Load Up to 80 KA RMS ]

01 CU Plate Size Dia: 80MM, 3000 MM Long, 2.5 mm

Cu Plate/Pipe Size 600*600*6 mm Thickness

02 20Kg, Rs. 465/Kg 25 Kg, 80-120 Micron

Approximate Weight / Rs, Cost = Rs. 9300 Rs. 8000 [ Filled with CCM Chemical ]

03 Copper / HDGI Strip 25X6 MM 50X6MM

04 2 Kg, Rs. 465/Kg 2 Kgs

Approximate Weight / Rs. Cost = Rs. 930 Rs. 750

05 90 Kg, Rs 25/Kg “SRIP’ Back fill Compound

Cost = Rs. 2250 60 Kg, Rs. 35/ Kgs

Char coal Cost = Rs. 2100

06 50 Kg Rs. 8/Kg Cost Not Require

Salt Cost = Rs. 400

07 Brick or Civil Work Cost = Rs. 750 Not require

08 2 to 3 Mtrs Not require

Water Pipe with Funnel Cost Rs. 750

09 Rs. 1500 Rs. 750 [ Only 300mm Dia & 3 Mtrs

Digging or Installation charges Bore require

10 CI Top Cover Rs. 500 Not Require

11 Termination & Mislaneousce Rs. 300 Rs. 300

Total Sum Of Rs. Rs. 15180 Rs. 11600

01 Expected Life Span : 4 T0 5 Years 10 to 15 Years

02 Fault current capacity 10 to 15 KA RMS 50 TO 80 RMS

03 Electrode is Directly contact Yes, with Soil, salt & Char No, “SRIP” Compound is media between

with Soil coal Electrode & Soil, i.e BFC

04 Corrosion ratio Fast NO Corrosion

05 Fluctuation of Ohmic Value More Least

06 Frequency & Voltage Maintain Difficult Constant or Low fluctuation

07 Layer or Galvanization or Zinc 20 TO 30 Microns 80 TO 100 Micron

coating

08 Maintenance cycle Require Fit & Forget

www.powertracgroup.in

09 Current dissipations Stage Single stage Multi stage

10 Maintain potential voltage [ Volt No Yes

Betn Neutral & Earthing ]

11 Metal alloy and technology Different grade or Quality Unique metal with special alloy as

homogeneous materials

12 Surface area Very less More

13 Installation space More area require Less area require

14 ECO Effect Corrosion Eco Friendly

15 Season Effect Yes No

1

6](https://image.slidesharecdn.com/clpowertracenergy-130330013202-phpapp01/85/Powertrac-Vapi-Earthing-Products-16-320.jpg)

![AN ISO 9001-2008 CERTIFIED CO. | CRISIL SE-3C RATED CO

------------------------------------------------------------------------------------------------------------------------------------------

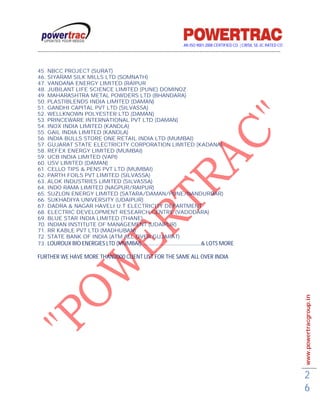

ANNEXTURE – Iv

Major CustoMer List

A] Our Satisfied Customer for Continuous Service

01. ESSAR INDIA LIMITED (MUMBAI/VADINAR/PARADEEP)

02. HINDUSTAN PETROLEUM CORPORATION LIMITED (AJMER/JAIPUR/REWARI/SANGRUR/BAHADURGARH)

03. TATA MOTORS LIMITED (PUNE)

04. TATA CHEMICALS LIMITED (MEETHAPUR)

05. SUNFLAG IRON & STEEL LIMITED (BHANDARA)

06. MUNDRA PORT & SPECIAL ECONOMIC ZONE LIMITED (MUNDRA)

07. ADANI WILMAR LIMITED (MUNDRA)

08. ASIA MOTOR WORKS LIMITED (BHUJ) ESSAR GROUP

09. PARKSONS PACKAGING LIMITED (DAMAN/PUNE/UTTARANCHAL)

10. MICRO INKS LIMITED (A HUBER GROUP – VAPI)

11. BILAG INDUSTRIES LIMITED (A BAYER GROUP – VAPI)

12. JINDAL SAW LIMITED (KUTCH – SAMAGOGHA/NANAYAKAPA/PARAGPAR)

13. ANCHOR ELECTRICALS LIMITED (DAMAN/VALSAD)

14. HINDUSTAN UNI LEVER LIMITED (GANDHIDHAM/SILVASSA)

15. STEEL AUTHORITY OF INDIA LIMITED (WEST BENGAL)

16. PARLE INTERNATIONAL (SILVASSA)

17. AARTI INDUSTRIES LIMITED (VAPI)

18. KISSAN MOULDINGS LIMITED (SILVASSA/DEWAS/BANGLORE/RAIPUR/HARYANA)

19. STAR ORCHEM INTERNATIONAL PVT LTD (NAGPUR)

20. CREATIVE TEXTILE MILLS PVT LTD (VAPI/DAMAN)

21. RUSHIL DECORE LIMITED (GANDHINAGAR/SURENDRANAGAR)

22. VAHANVATI CONSULTANT PVT LTD (ALIBAG/MUMBAI)

23. AMBIKA WARE HOUSE LIMITED (MOTAPONDA)

24. AAP MEDIA PVT LTD (OKHLA)

25. WIPRO WATER LIMITED (NAVI MUMBAI)

26. CUMMINS INDIA LIMITED (DAMAN)

27. JACKSONS LIMITED (SILVASSA)

28. KLJ POLYMERS & CHEMICALS LTD (SILVASSA)

29. WAAREE SENSORS PVT LTD (VAPI)

30. BONETTI WAAREE INDIA PVT LTD (UMERGAON)

31. WAAREE ENERGY LIMITED (RAJKOT)

32. TUFFROPES PRIVATE LIMITED (SILVASSA)

33. SUPREME NON WOVEN INDUSTRIES PVT LIMITED (BHILAD/VAPI)

www.powertracgroup.in

34. INDIAN RAYON LIMITED (VERAVAL) ADITYA BIRLA GROUP

35. BIRLA COPPER LIMITED (DAHEJ) ADITYA BIRLA GROUP

36. HINDALCO ALLUNIMIUM LIMITED (MOUDA) ADITYA BIRLA GROUP

37. BHILOSA INDUSTRIES PVT LTD (SILVASSA)

38. JAI CROP LIMITED (SILVASSA/DAMAN)

39. WELSPUN SYNTEX LIMITED (SILVASSA)

40. ACG CAPSULES PVT LIMITED (DAHNU)

41. UNITED 2IN, 4STAR HOTEL PANCARD CLUB (THANE

42. KRISHAK BHARATI CO-OPERATIVE LIMITED

43. ADOR WELDING LIMITED (PUNE)

44. DWARKA & NAVADARA LIGHT HOUSE (ARMY)

2

5](https://image.slidesharecdn.com/clpowertracenergy-130330013202-phpapp01/85/Powertrac-Vapi-Earthing-Products-25-320.jpg)