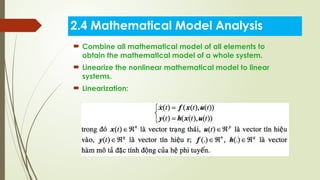

The document outlines a course on system modeling and identification, structured into various chapters that cover topics such as functional analysis, physical characteristic analysis, and different systems including mechanical, electrical, fluid, and thermal systems. Each section discusses analysis procedures, mathematical modeling, and examples, particularly emphasizing the importance of understanding how components interact and the application of physical laws. The course materials include textbooks and references to support the curriculum designed by Dr. Van-Phong Vu from the Department of Automatic Control.

![Textbook and References

[1] Bài gi ng Mô hình hóa và nh n d ng h th ng

ả ậ ạ ệ ố , PGS. TS. Huỳnh Thái

Hoàng, ĐHQG TPHCM.

[2] Giáo trình mô hình hóa và mô ph ng

ỏ , PGS. TS. Quy n Huy Ánh,

ề

ĐHSPKT 2010.

[3] D. L. Smith, Introduction to Dynamic Systems Modeling for Design,

Prentice-Hall, 1994.

[4] L. Ljung, System Identification – Theory for the users, 2nd

Edition,

Prentice-Hall, 1999.

[5] R. Johansson, System Modeling and Identification, Prentice-Hall,

1993.

[6] L. Ljung, System Identification ToolboxTM

Getting Started Guide in

Matlab, The MathWorks, Inc, 2016

Dr. Van-Phong Vu-Department of Automatic Control](https://image.slidesharecdn.com/chapter2systemmodeling1-241031032410-4f1a967e/85/Chapter-2_System-Modeling-using-computer-1-pptx-2-320.jpg)

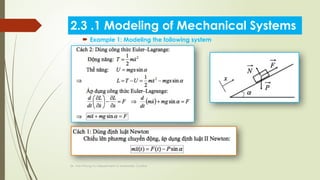

![Dr. Van-Phong Vu-Department of Automatic Control

Mechanical System:

Basic Variables:

Distance (quantity) x [m]

Force (potentiality) F [N]

Velocity v [m/s]

Basic elements:

Dashpot ( Piston cylinder):

2.3 .1 Modeling of Mechanical Systems

𝑓 =𝑏

𝑑𝑥

𝑑𝑡

=𝑏𝑣](https://image.slidesharecdn.com/chapter2systemmodeling1-241031032410-4f1a967e/85/Chapter-2_System-Modeling-using-computer-1-pptx-29-320.jpg)

![Dr. Van-Phong Vu-Department of Automatic Control

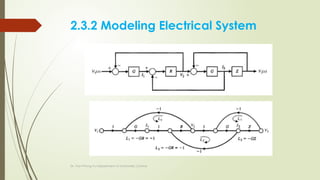

Electrical System:

Basic variables:

Charge (đi n l ng) q [C]

ệ ượ

Voltage (đi n th ) u [V]

ệ ế

Current ( dòng đi n) I [A]

ệ

Basic elements

Resistance: Capacitance:

Inductance:

2.3.2 Modeling Electrical System](https://image.slidesharecdn.com/chapter2systemmodeling1-241031032410-4f1a967e/85/Chapter-2_System-Modeling-using-computer-1-pptx-48-320.jpg)

![Dr. Van-Phong Vu-Department of Automatic Control

Fluid Systems:

Basic variables:

Pressure (áp su t) p [N/m

ấ 2

]

Volume (th tích) V [m

ể 3

]

Flow ( l u l ng) z [m

ư ượ 3

/s]

Basic elements

Hydraulic resistance

2.3.4 Modeling the Fluid Systems](https://image.slidesharecdn.com/chapter2systemmodeling1-241031032410-4f1a967e/85/Chapter-2_System-Modeling-using-computer-1-pptx-60-320.jpg)