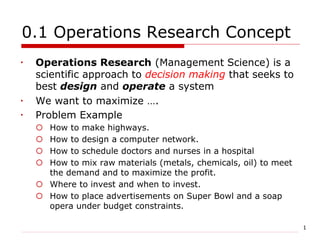

This document provides examples to illustrate operations research concepts and applications. It discusses using mathematical models and a scientific approach to decision making to optimize systems like production planning, investment strategies, inventory management, and patient scheduling. The goal is to maximize objectives and minimize costs by determining the best design and operation of a system using techniques like linear programming, simulation, and queuing theory.