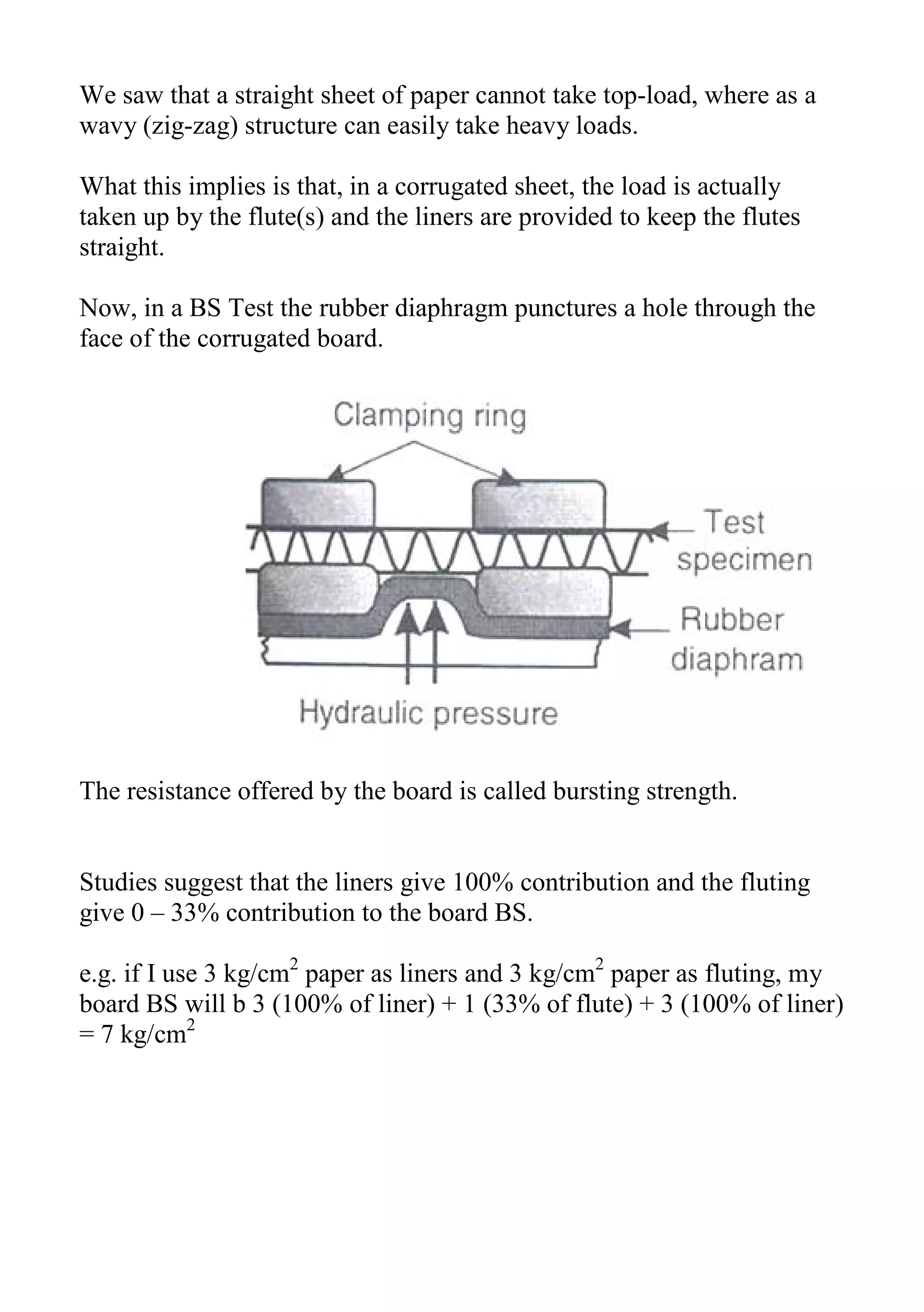

The document discusses the performance of corrugated cartons and issues with commonly used quality parameters like bursting strength.

1. Bursting strength does not accurately reflect a carton's ability to withstand compression from stacked loads in warehouses, which is where most damage occurs. The lowest cartons collapse not from bursting but from compression.

2. Bursting strength can be easily manipulated by changing paper weights without improving actual compression strength. This fools buyers into thinking quality is higher when performance may be lower.

3. Proper quality parameters should evaluate performance under compression loads rather than just material properties. Standards like edge crush test are better indicators of how cartons withstand warehouse storage conditions.