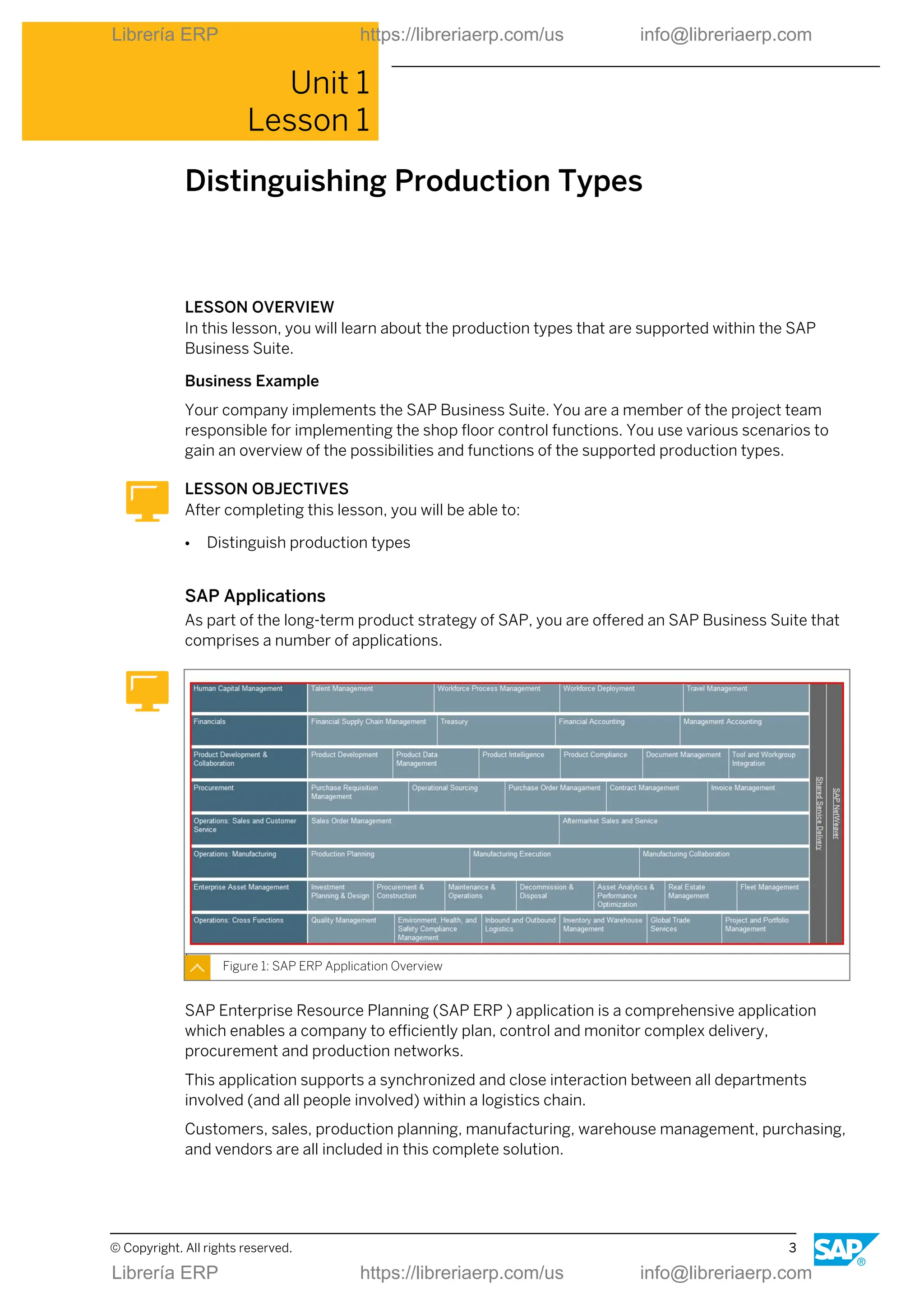

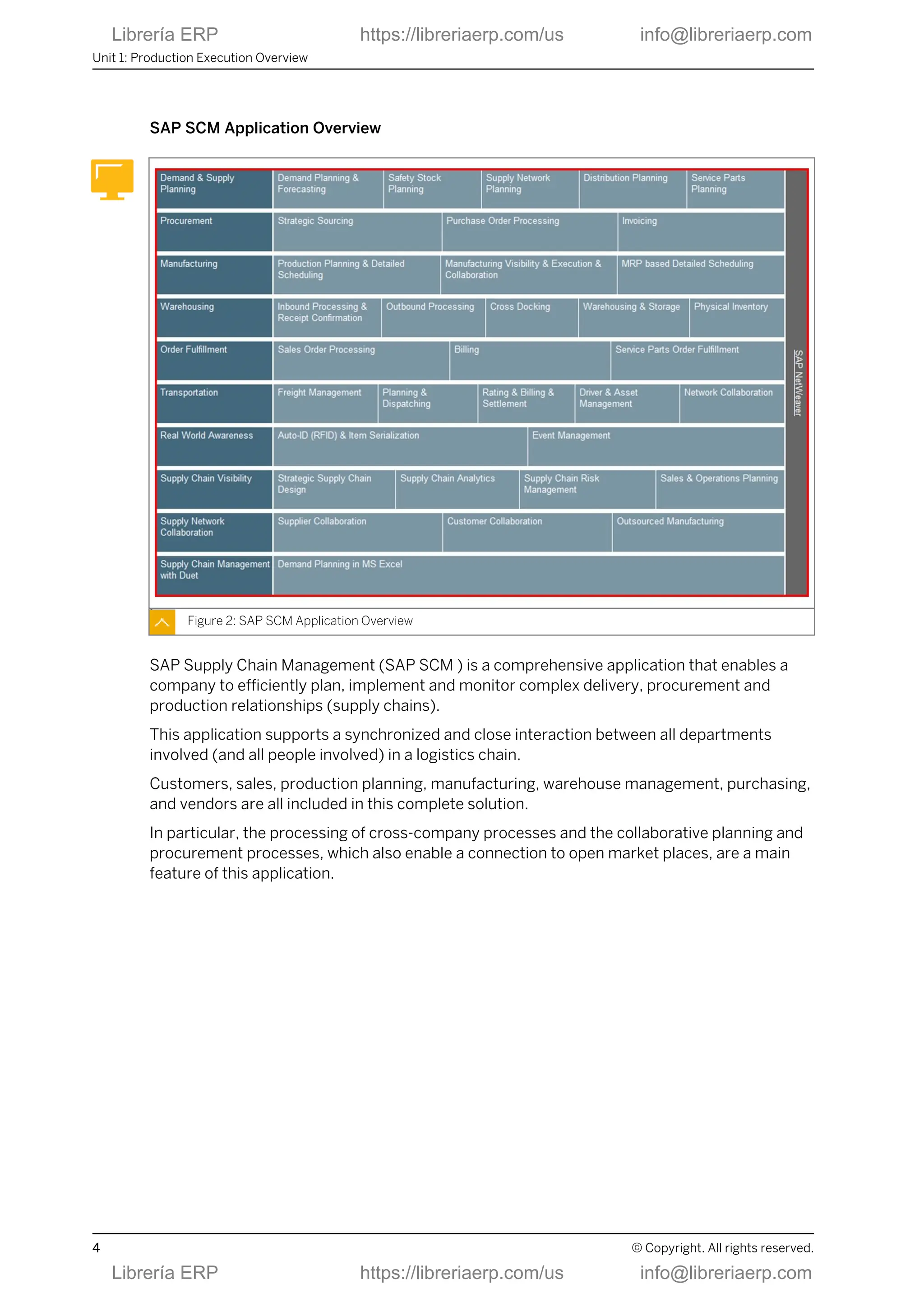

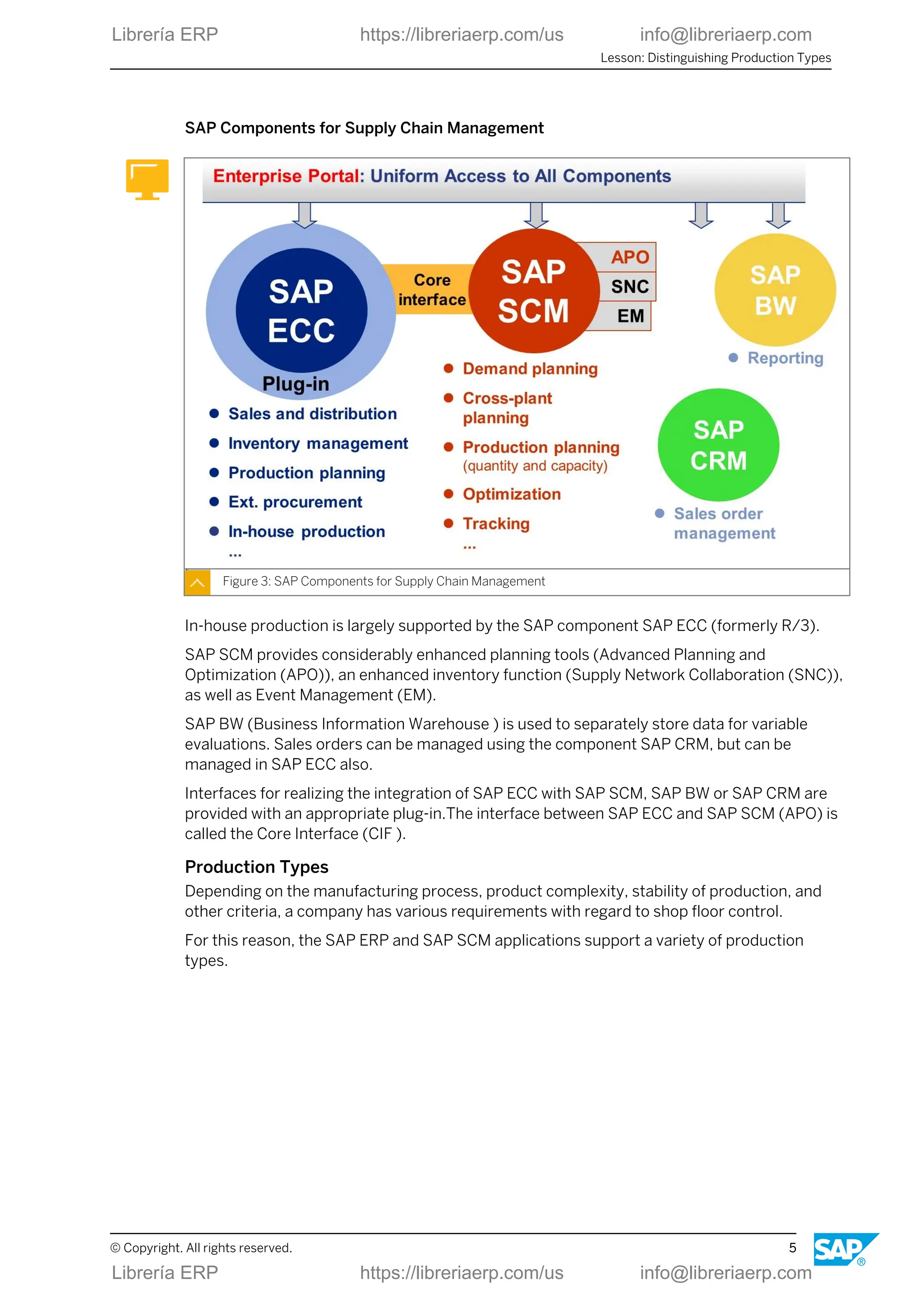

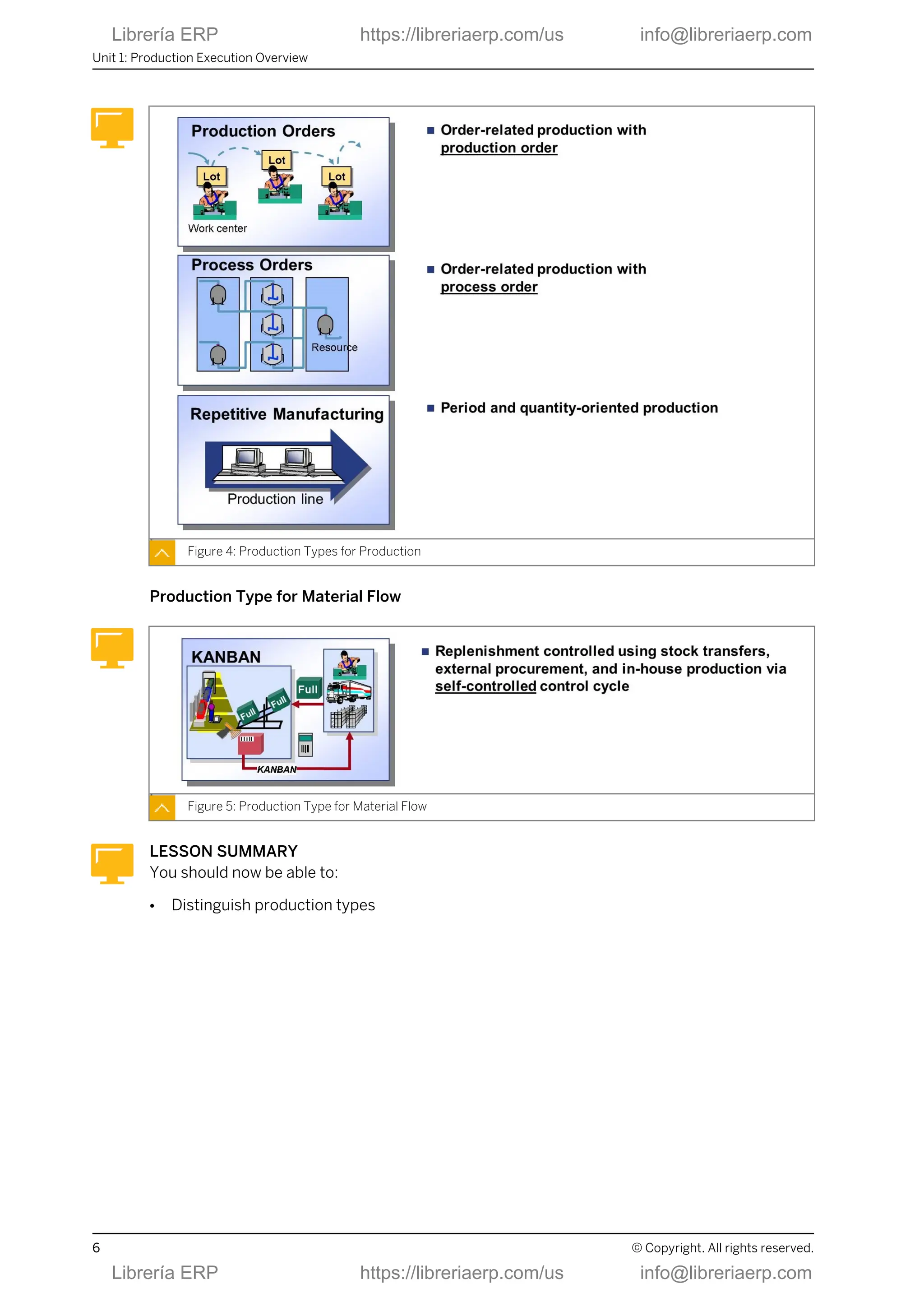

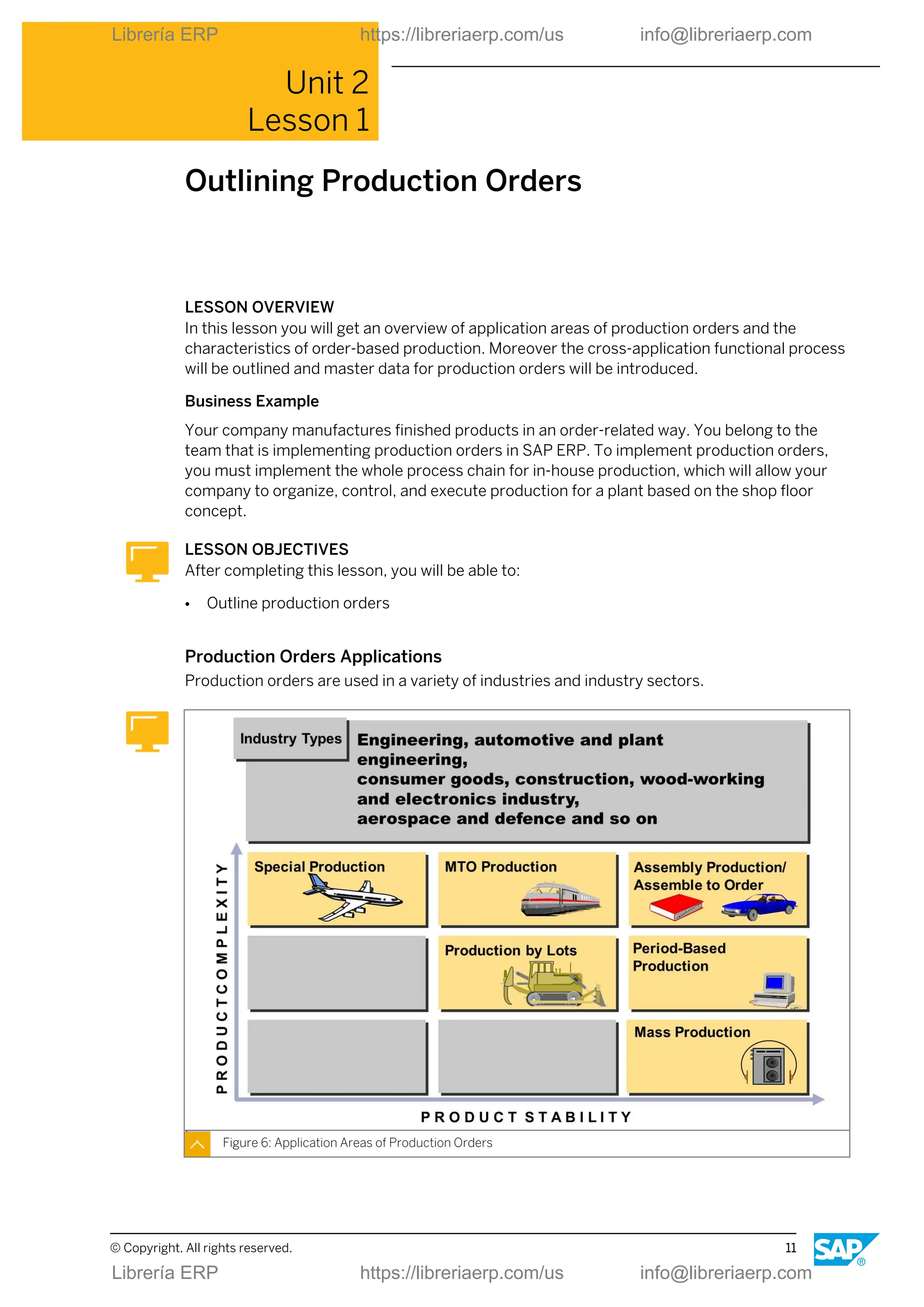

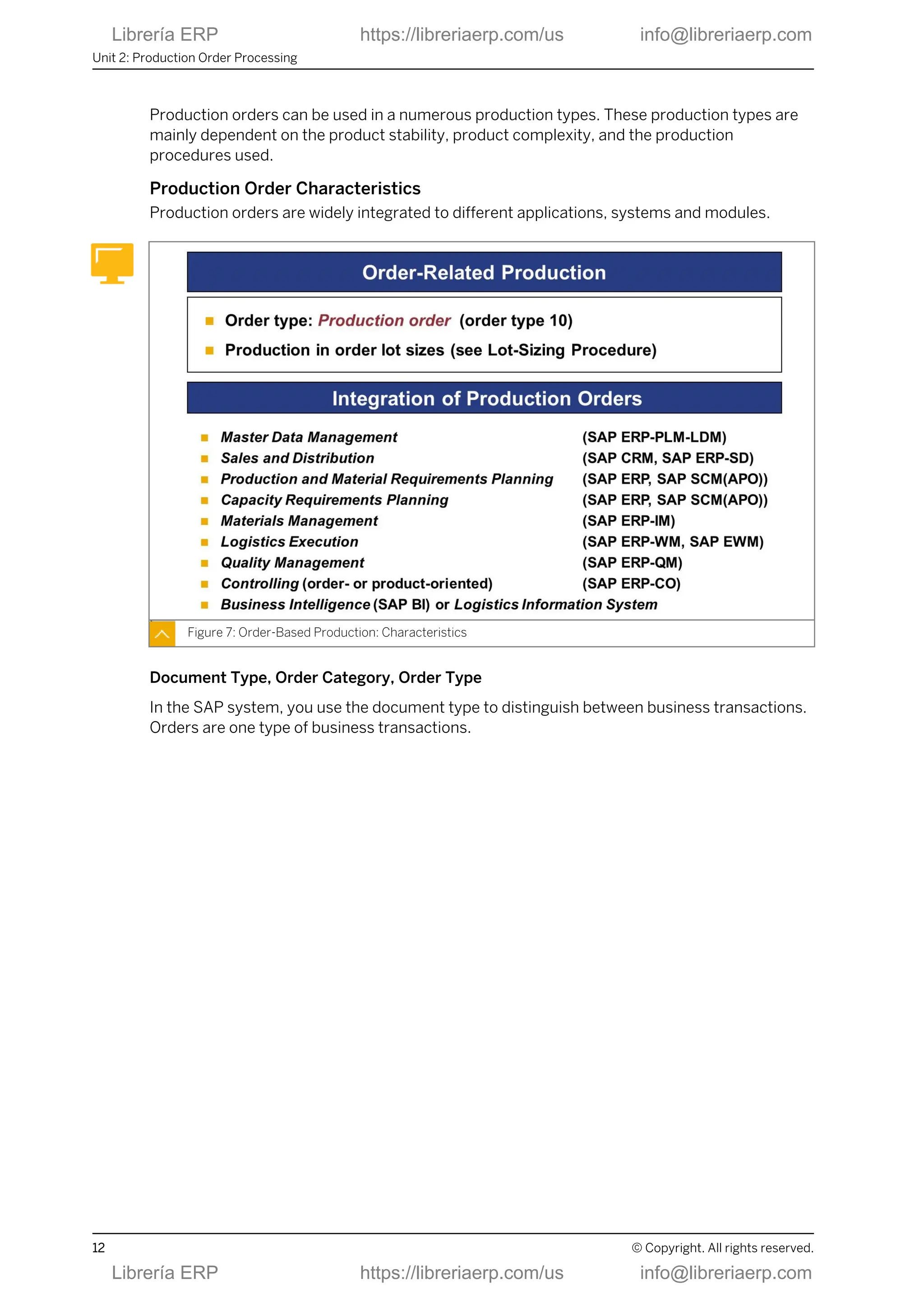

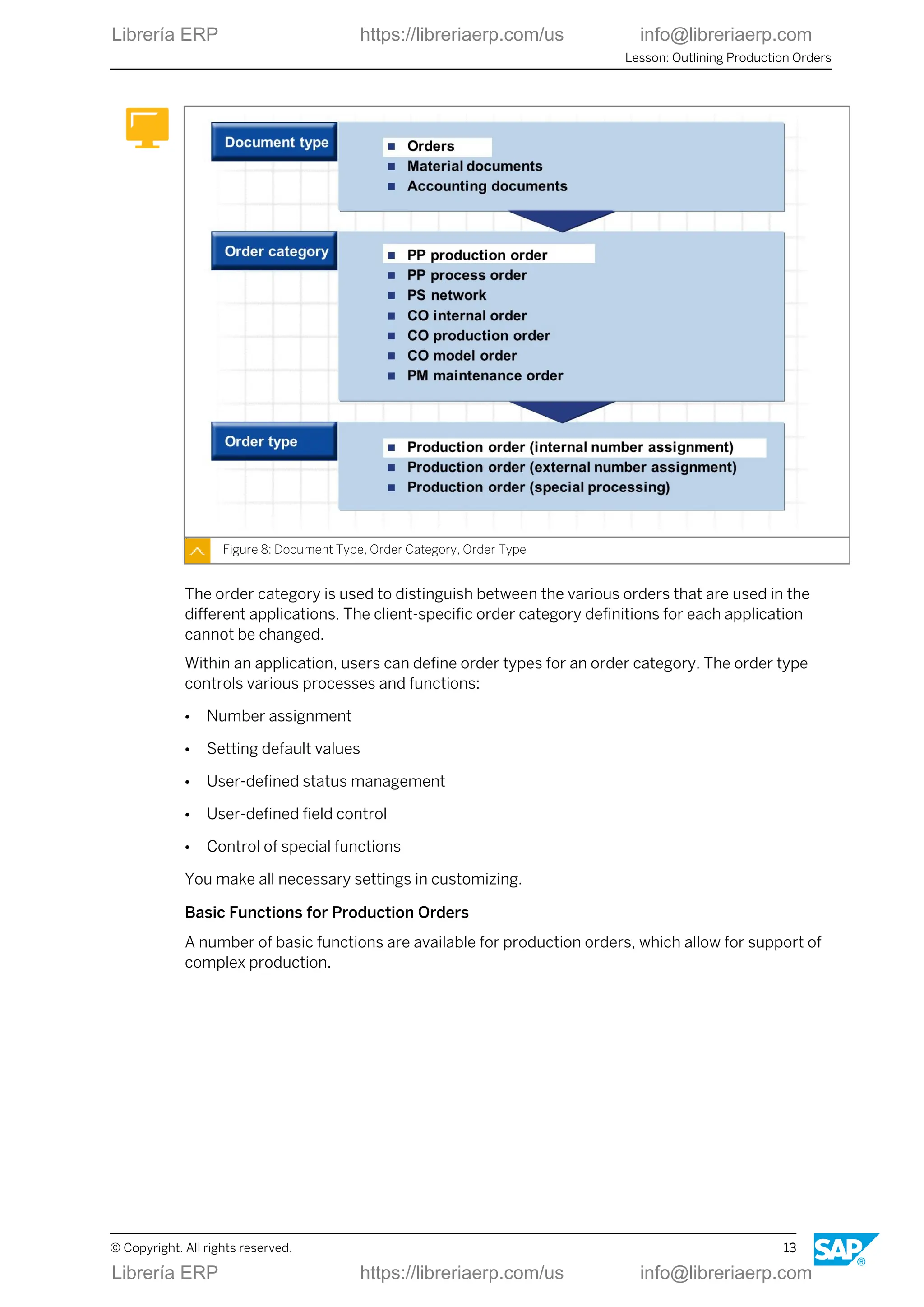

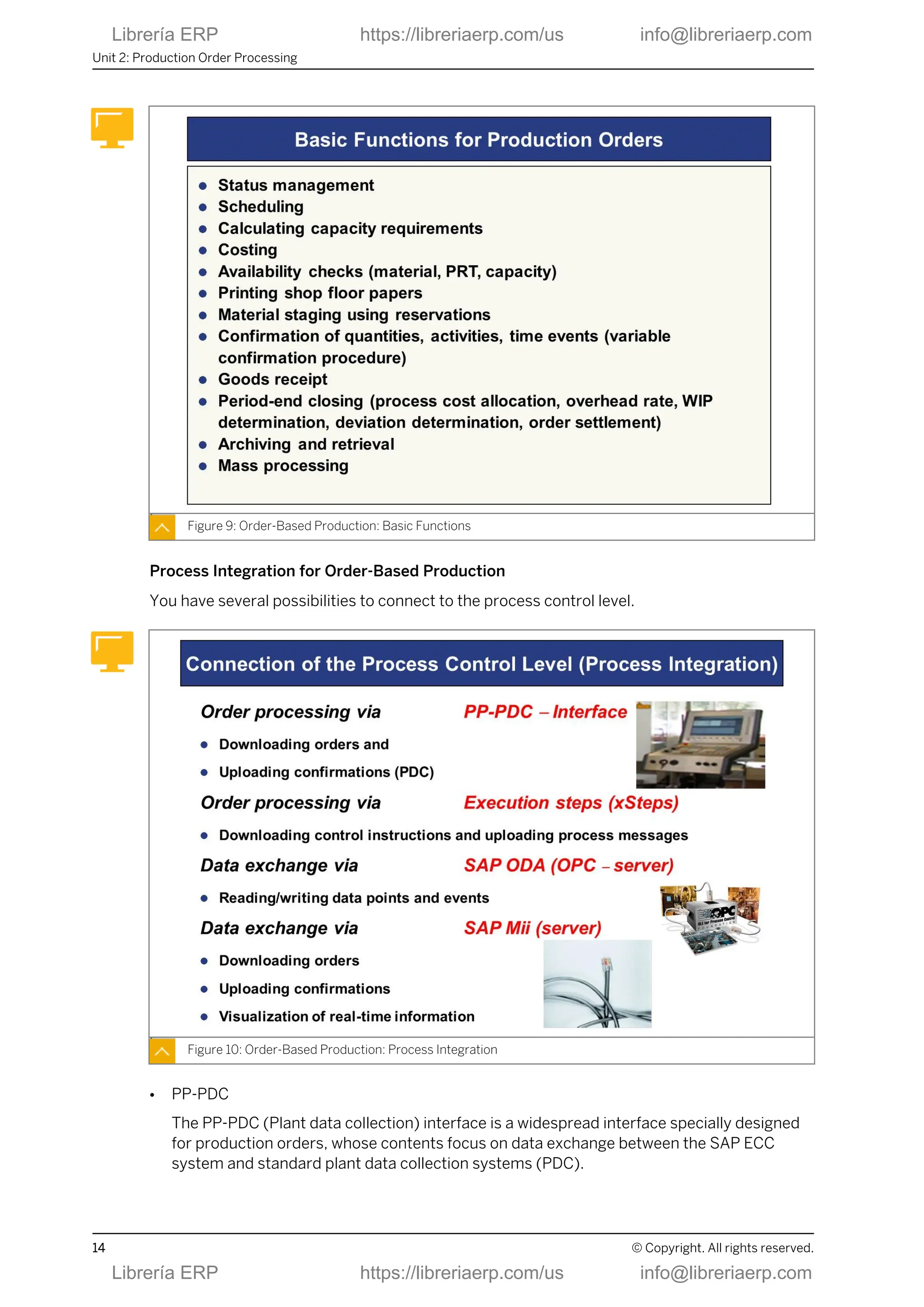

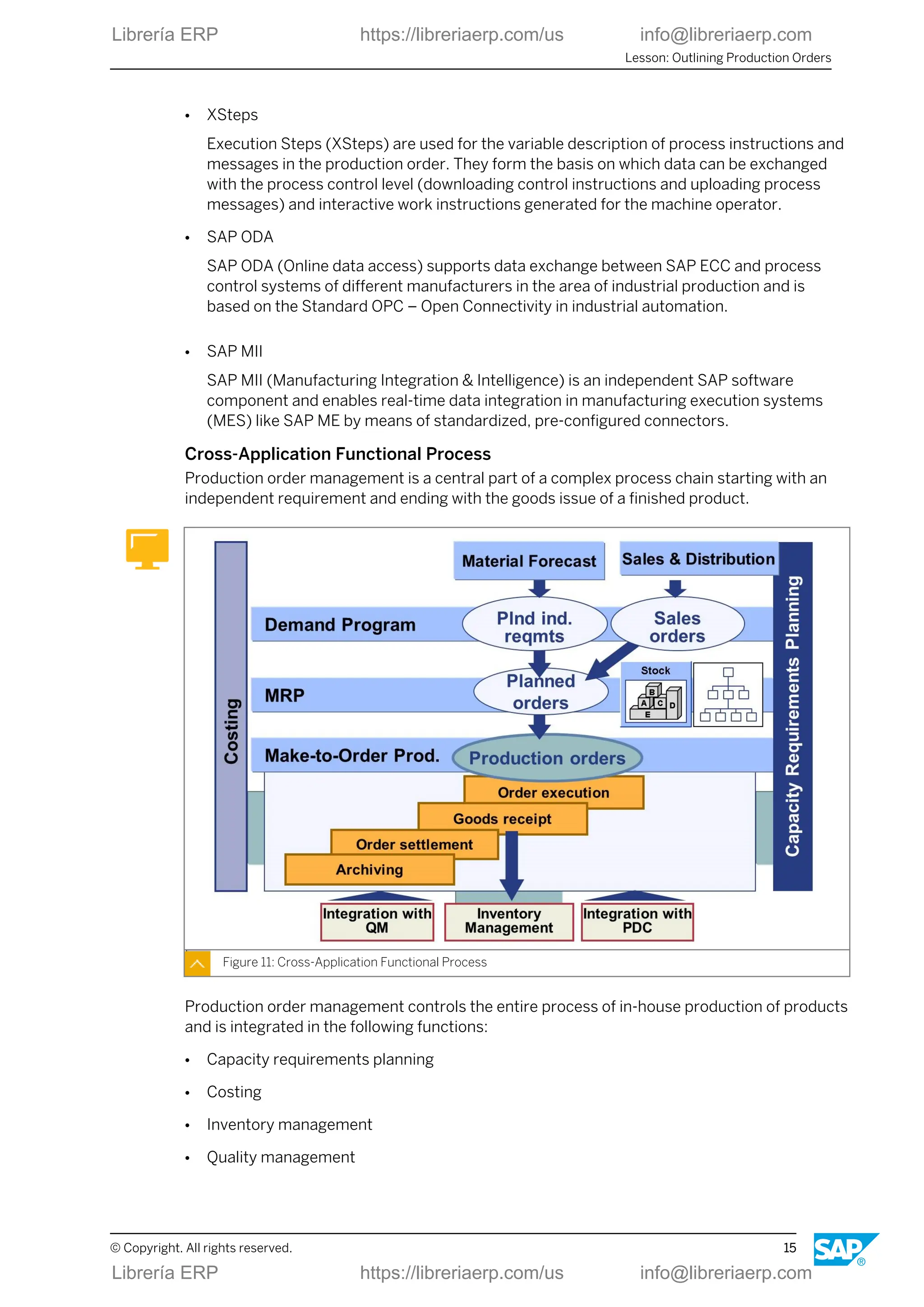

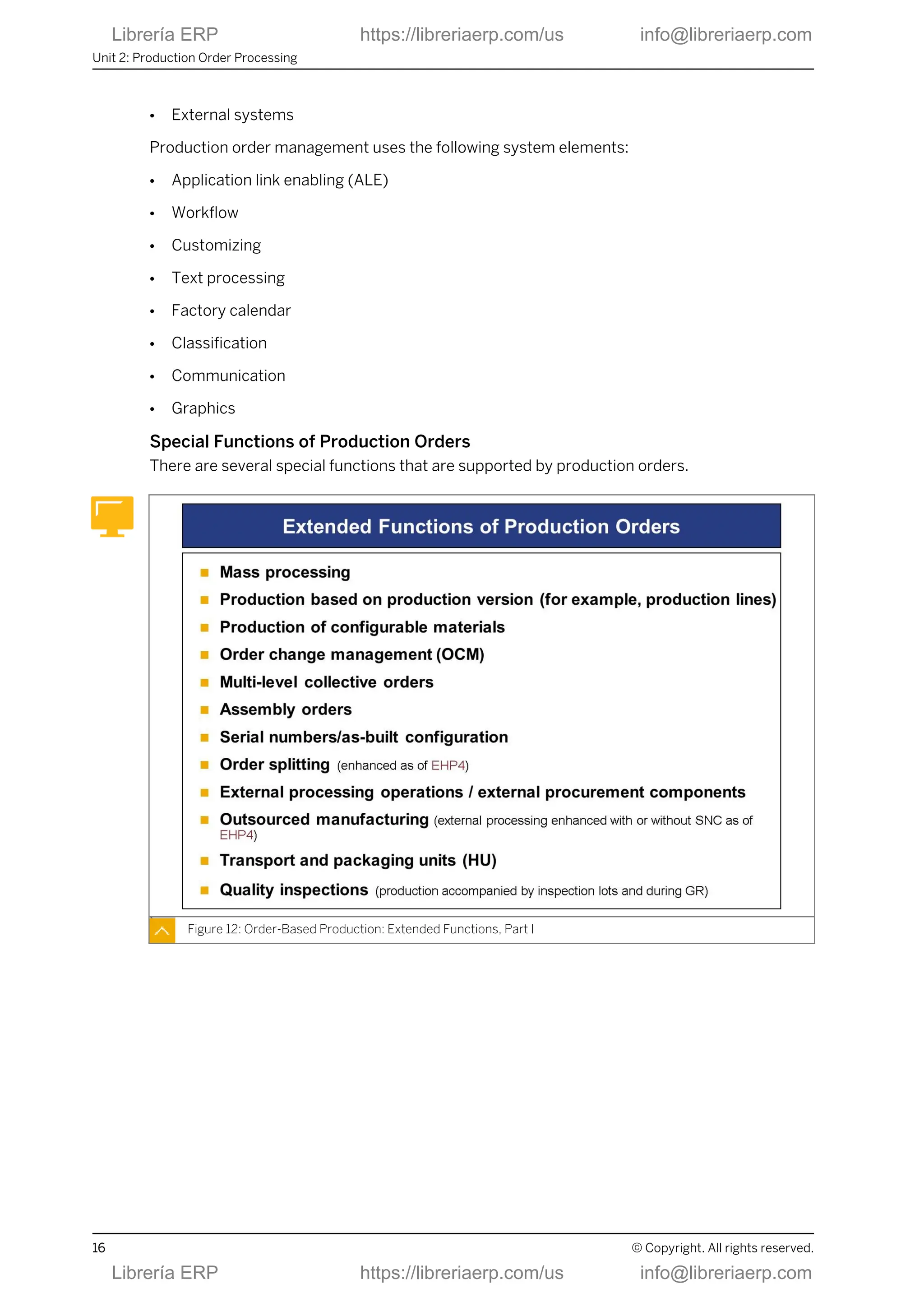

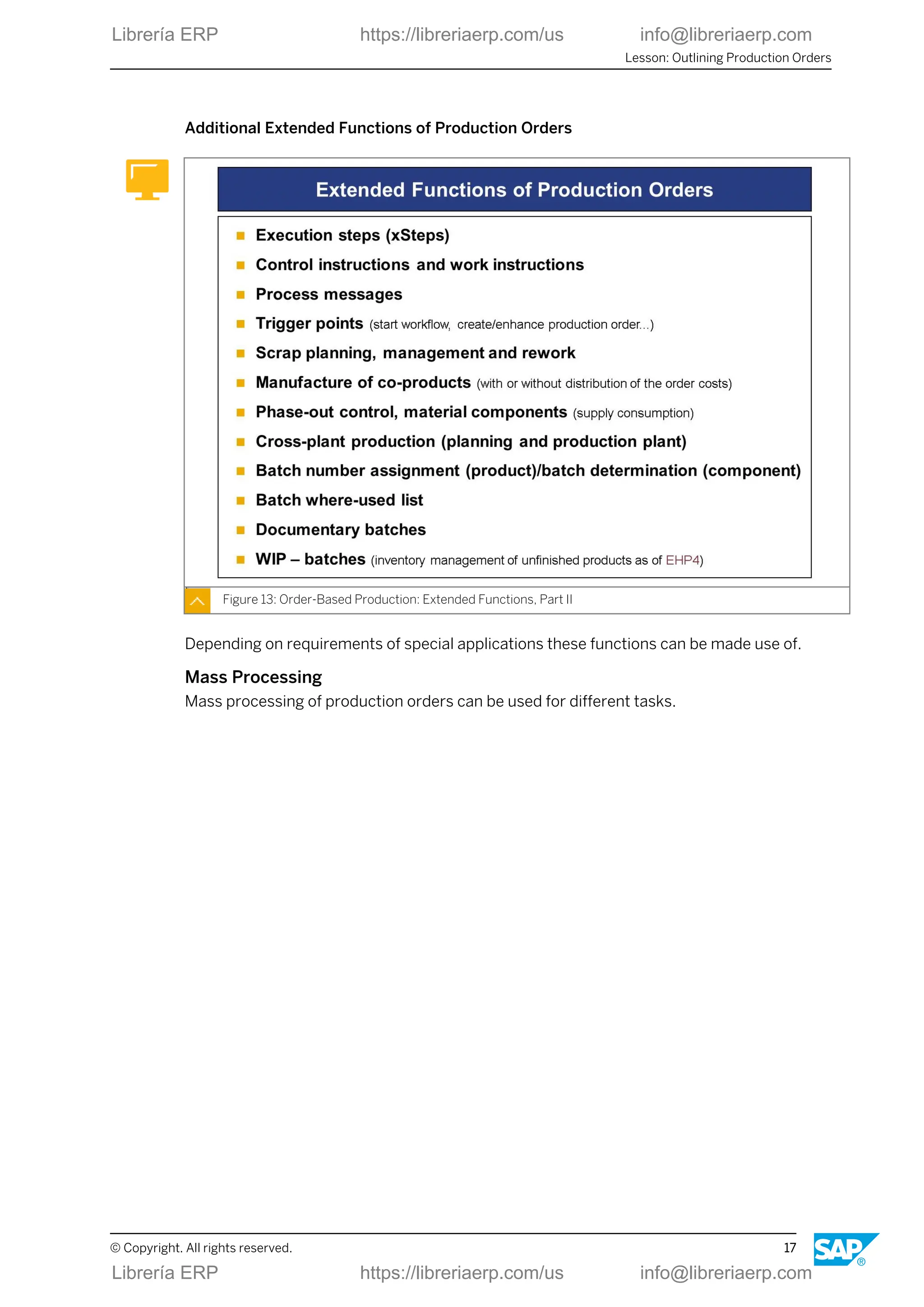

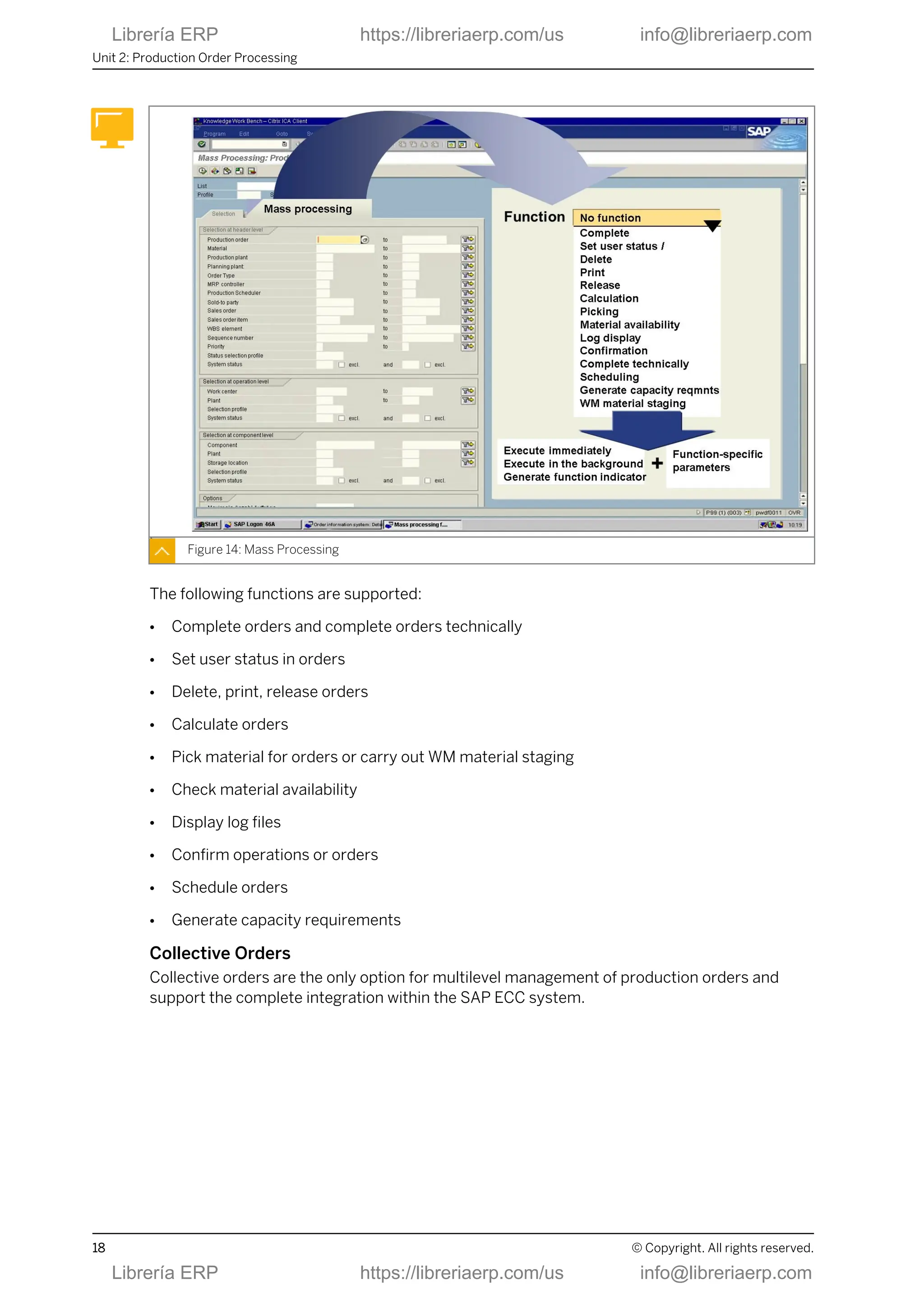

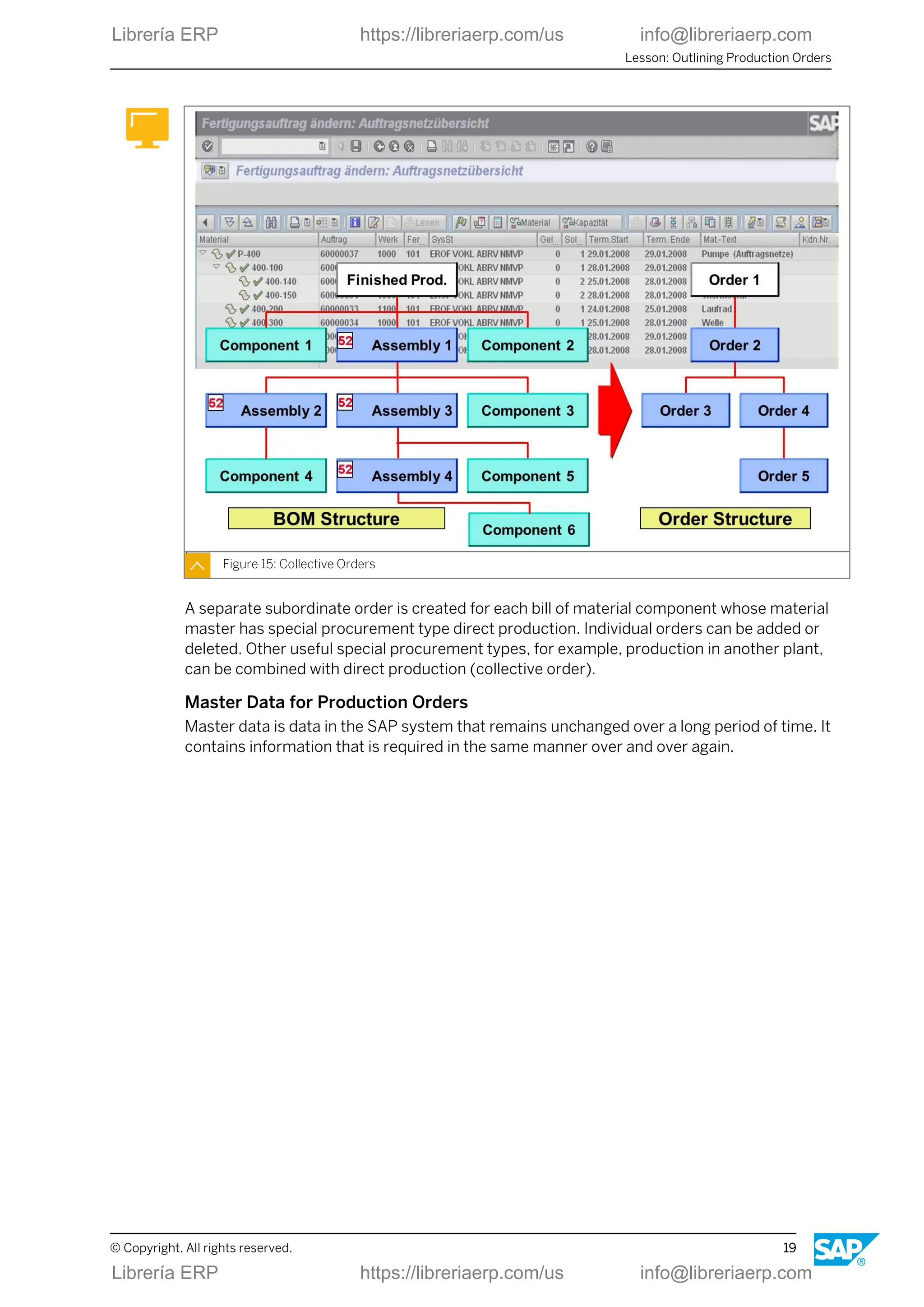

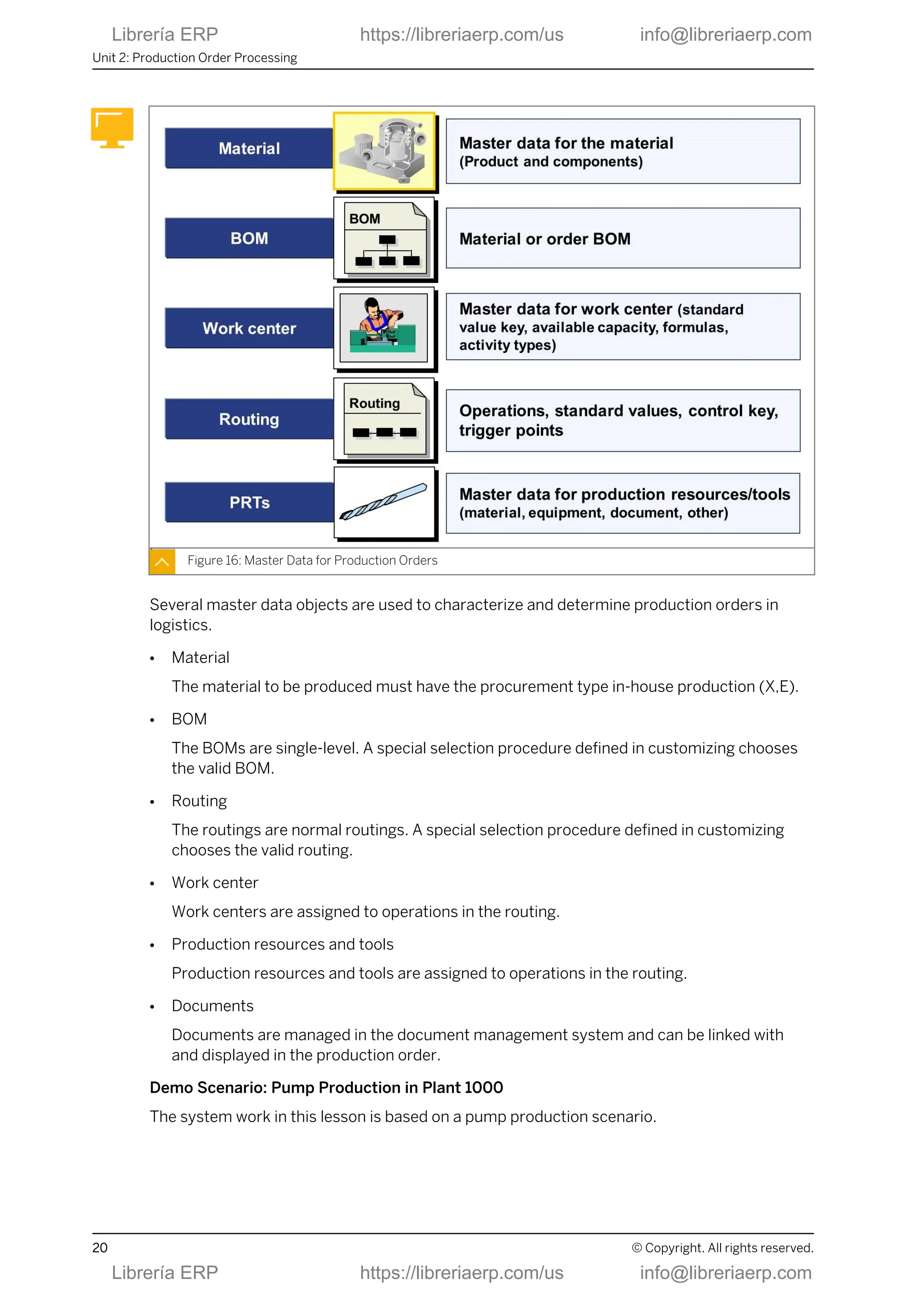

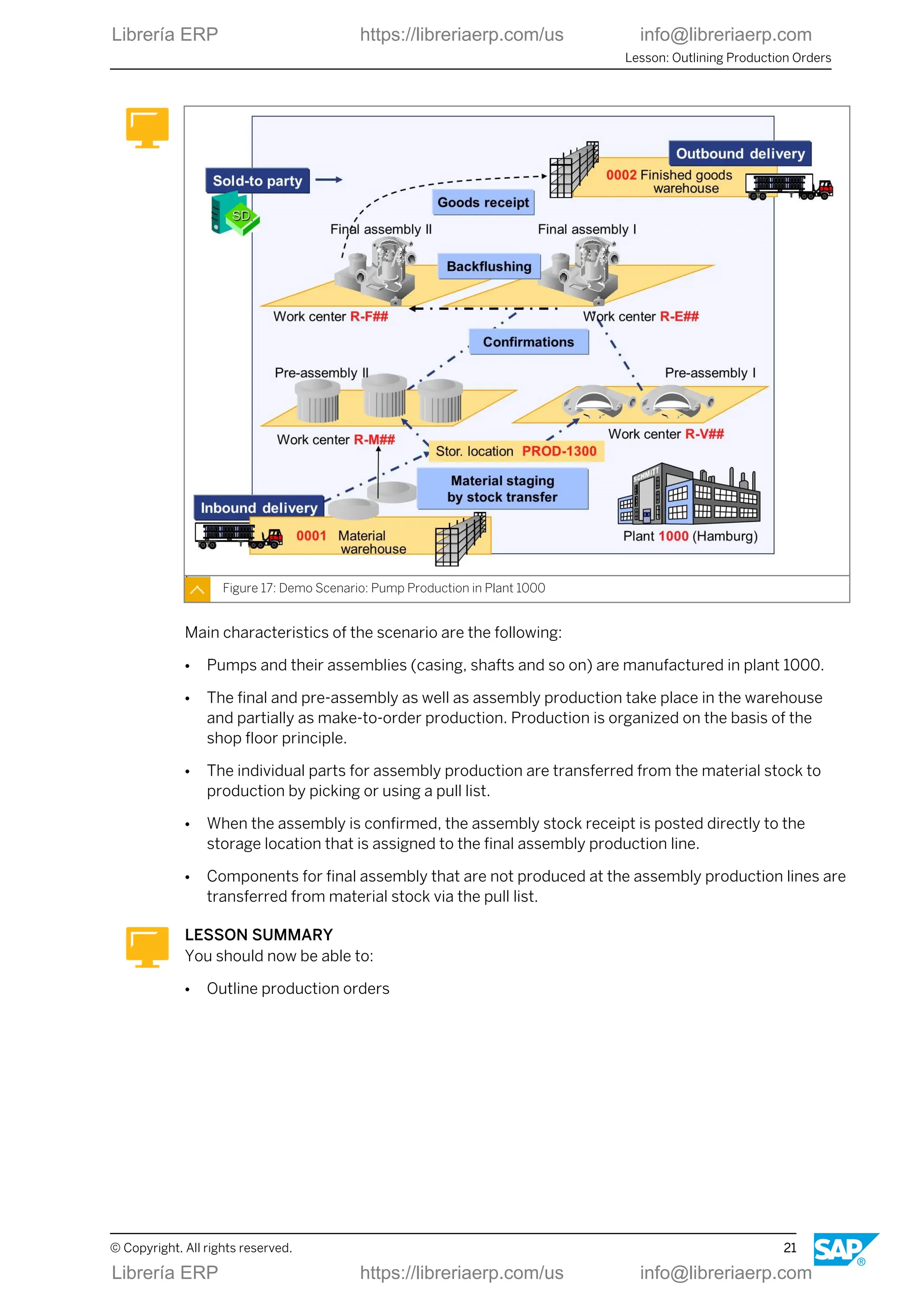

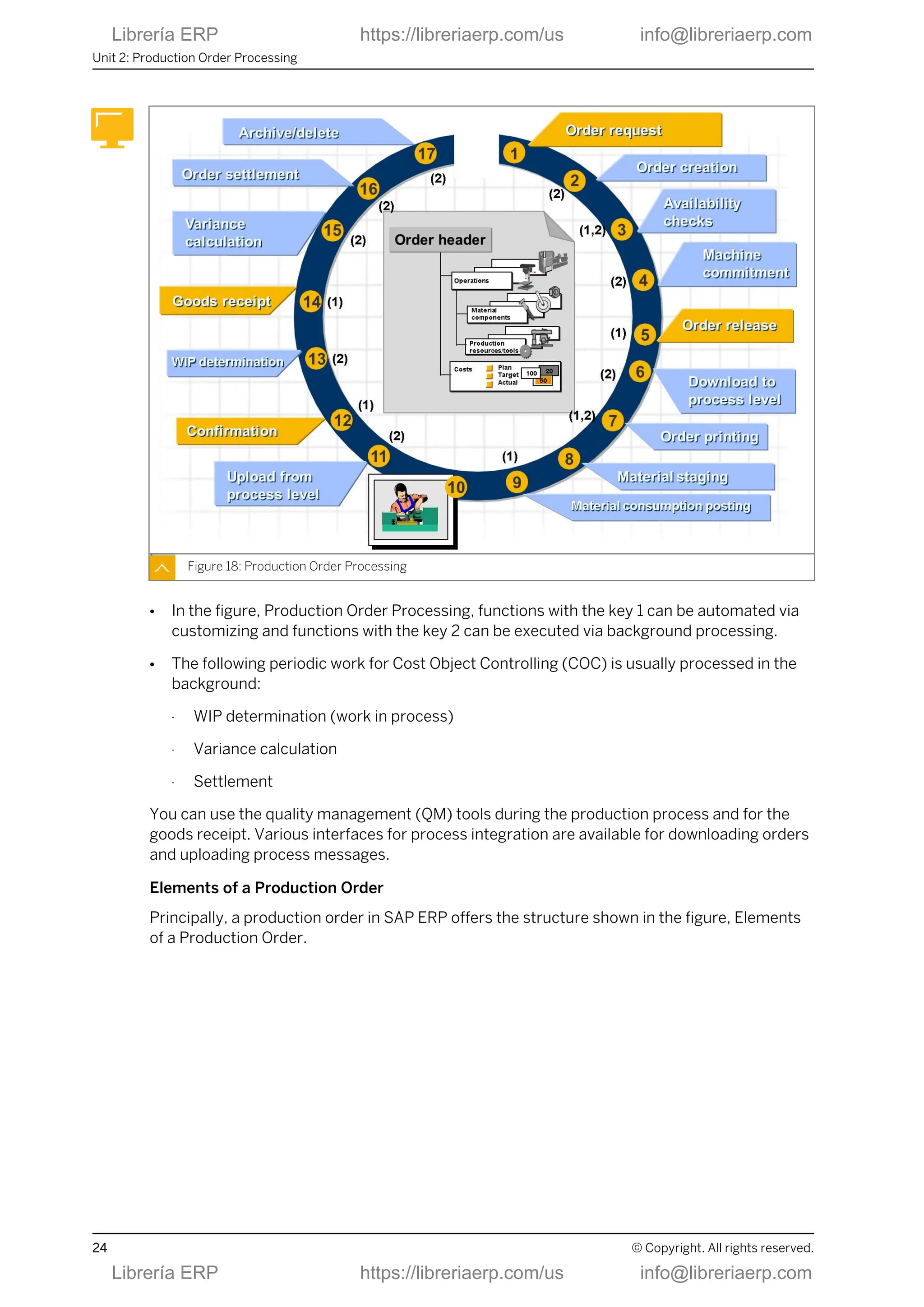

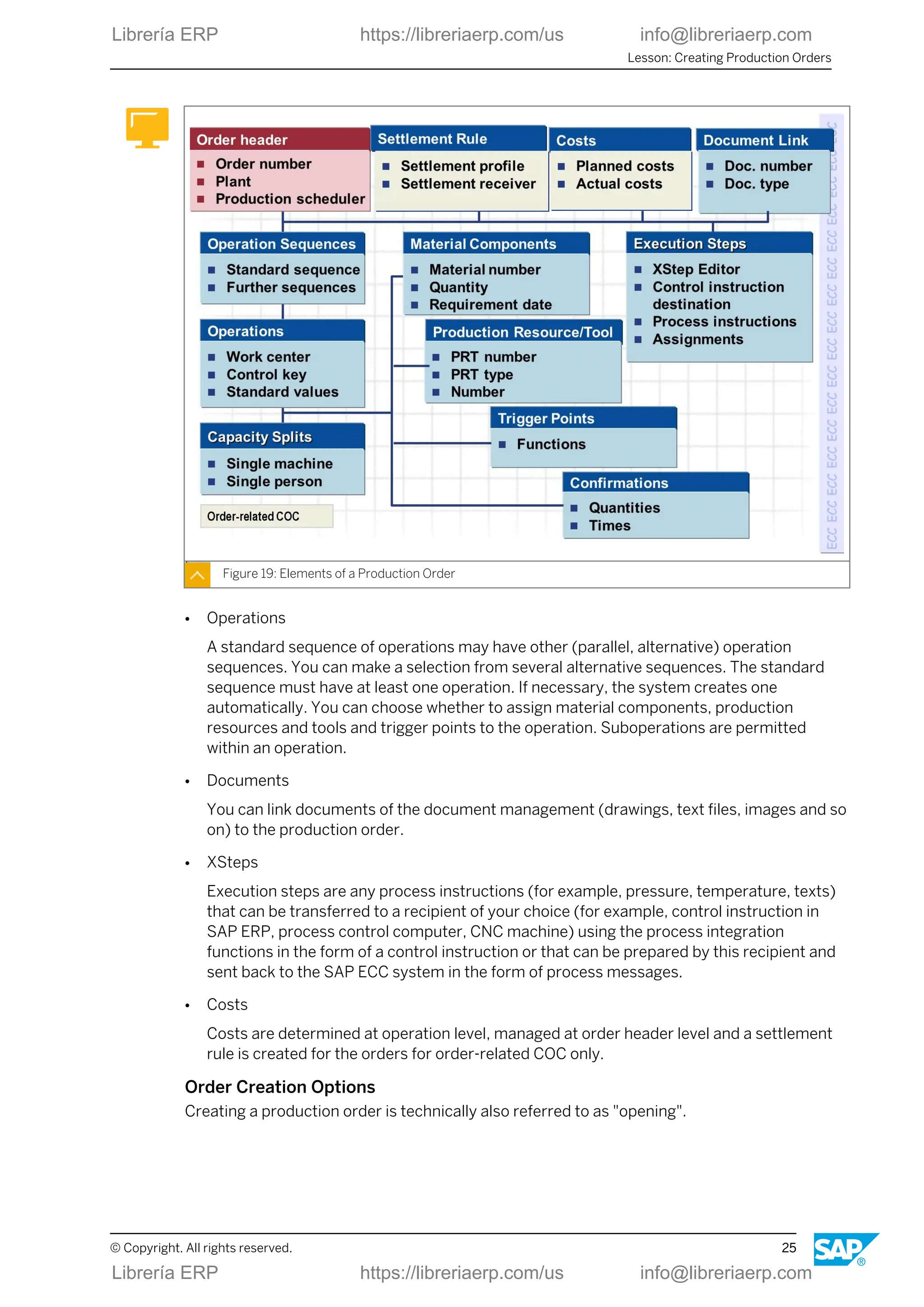

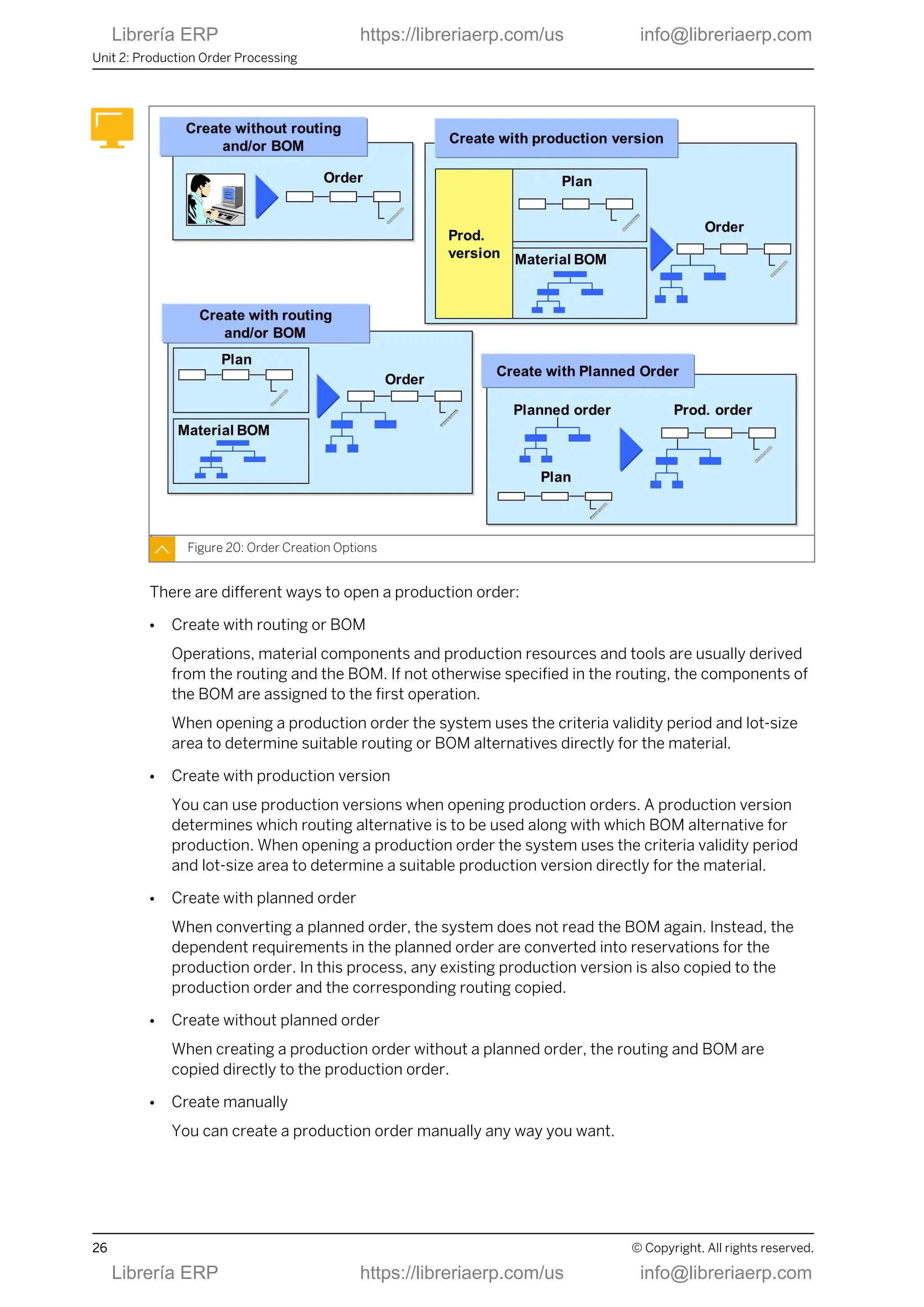

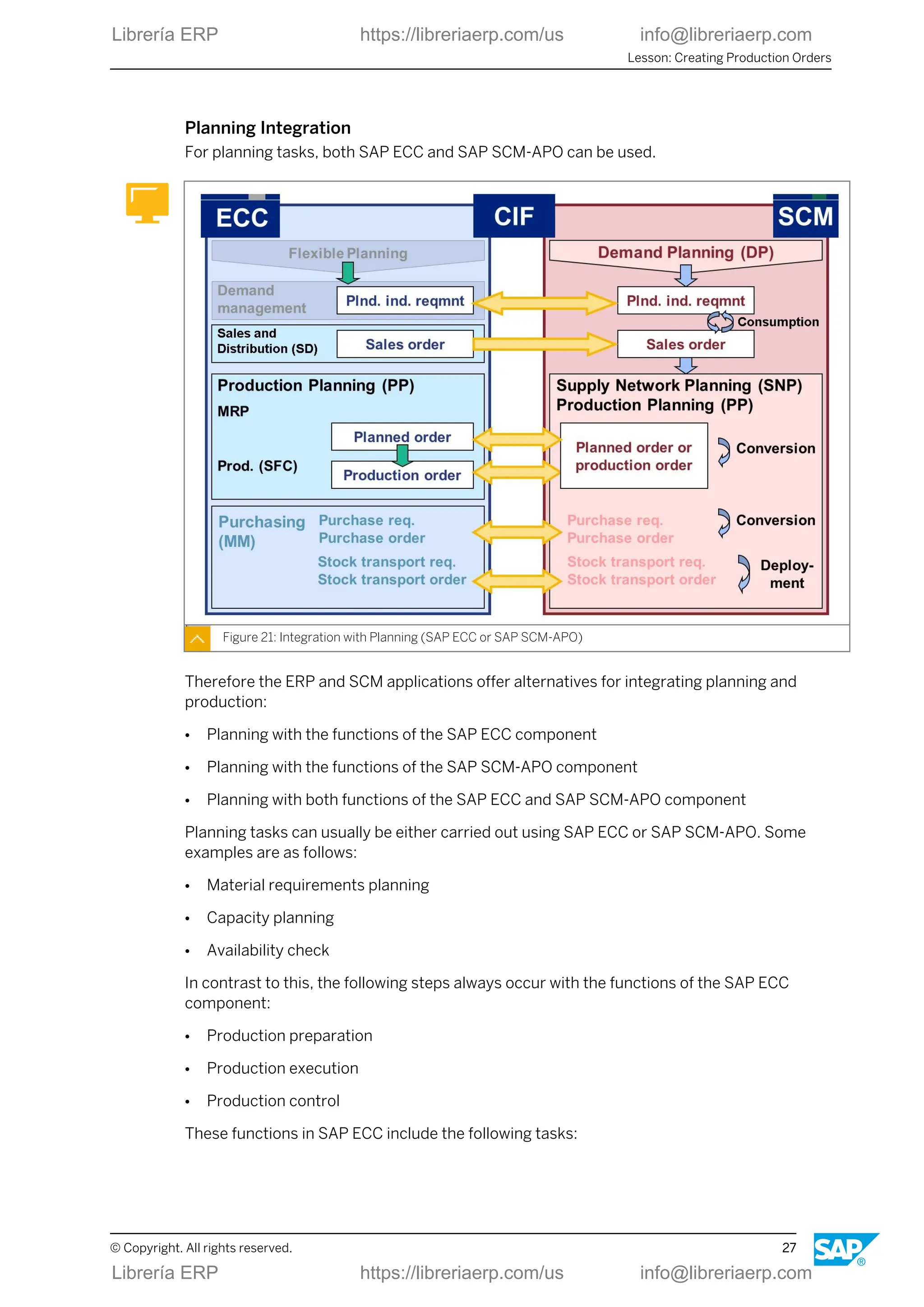

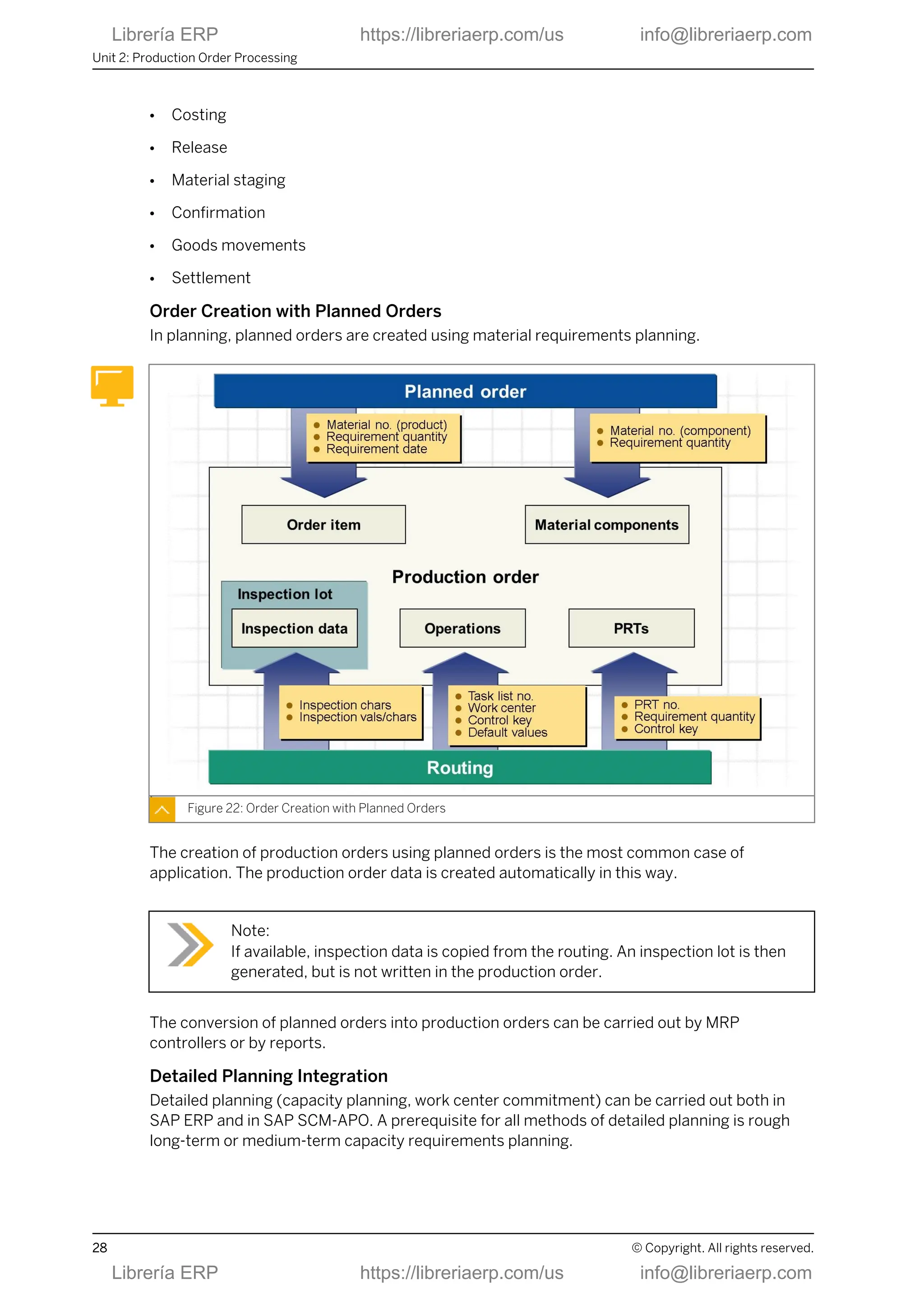

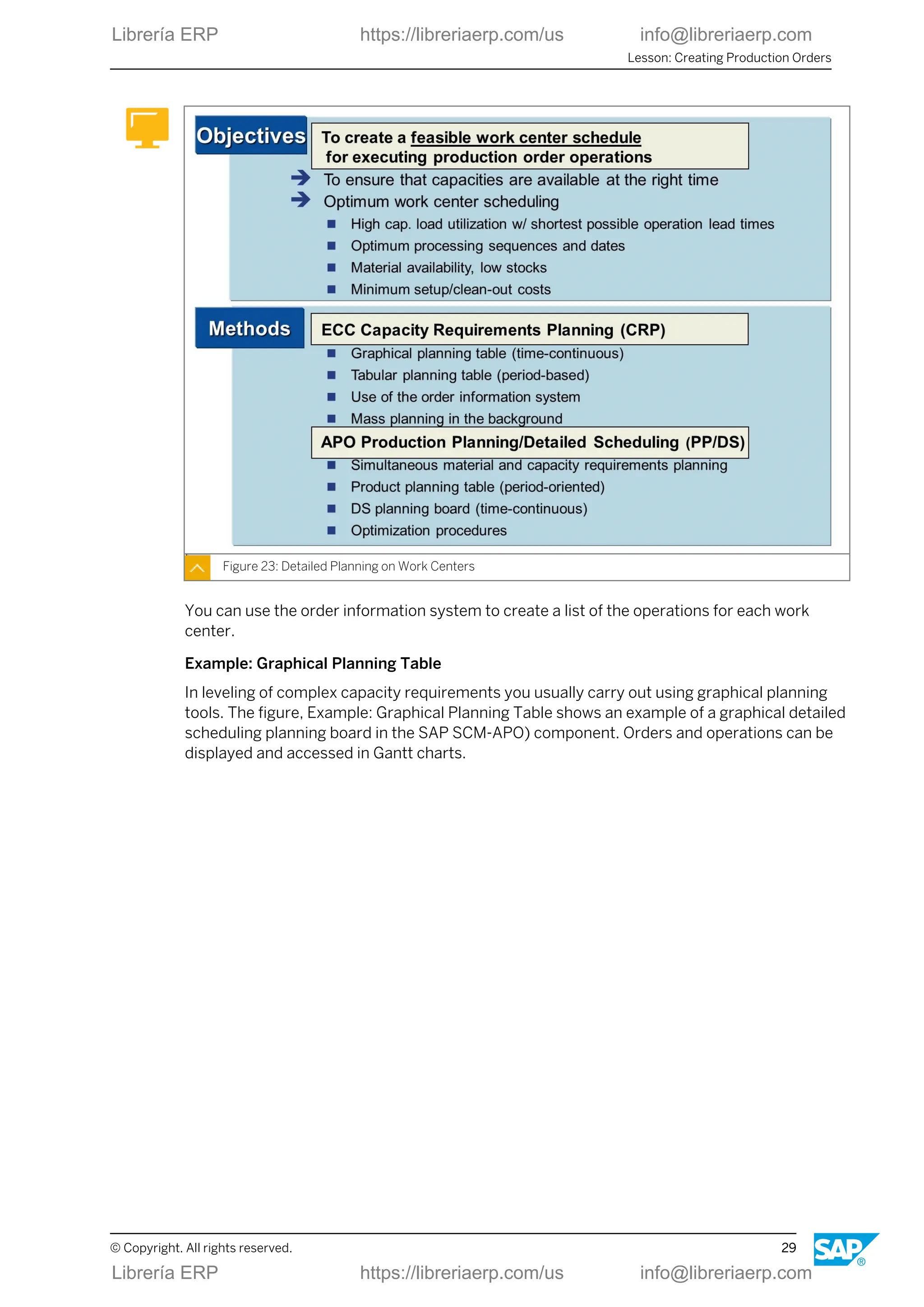

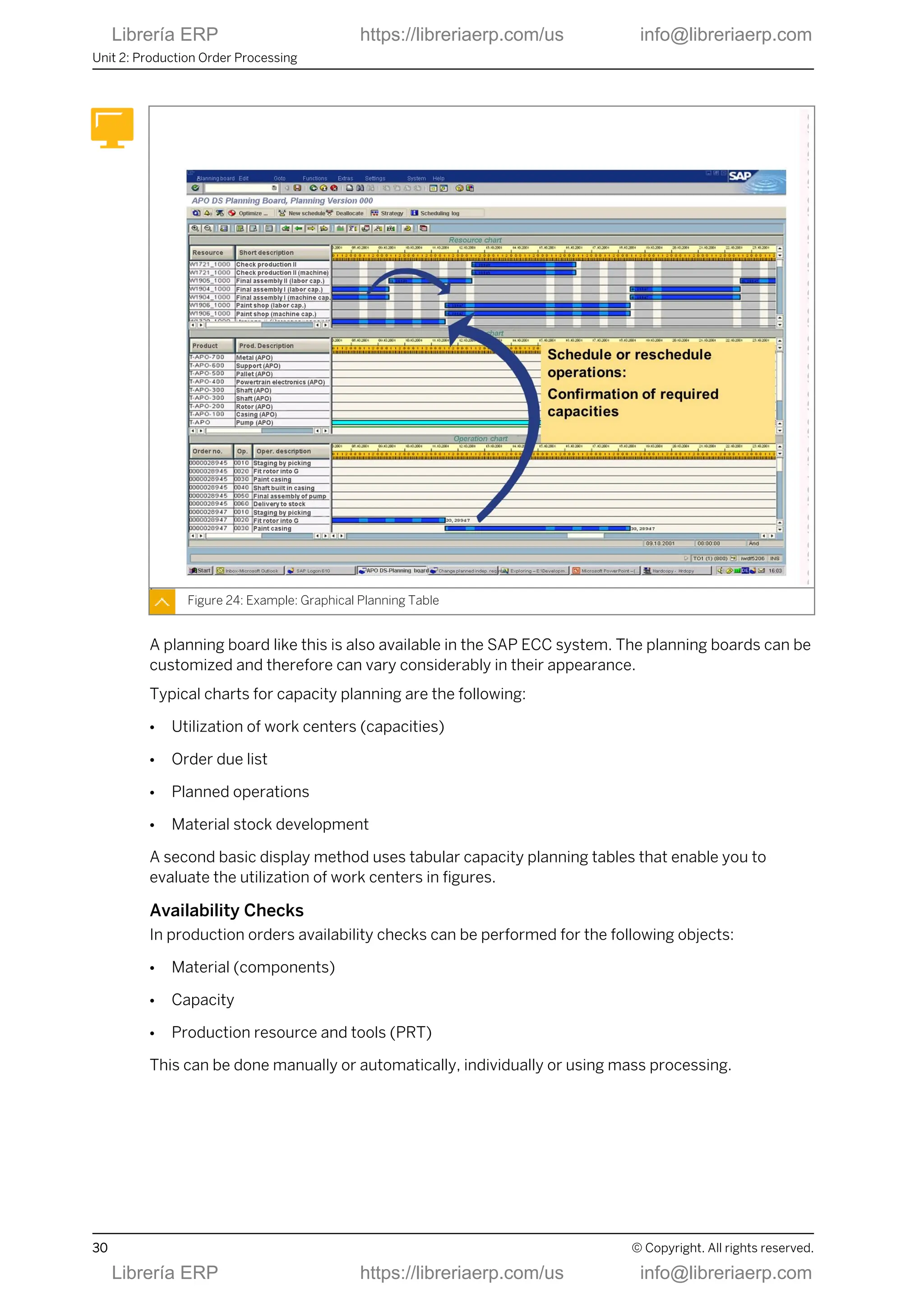

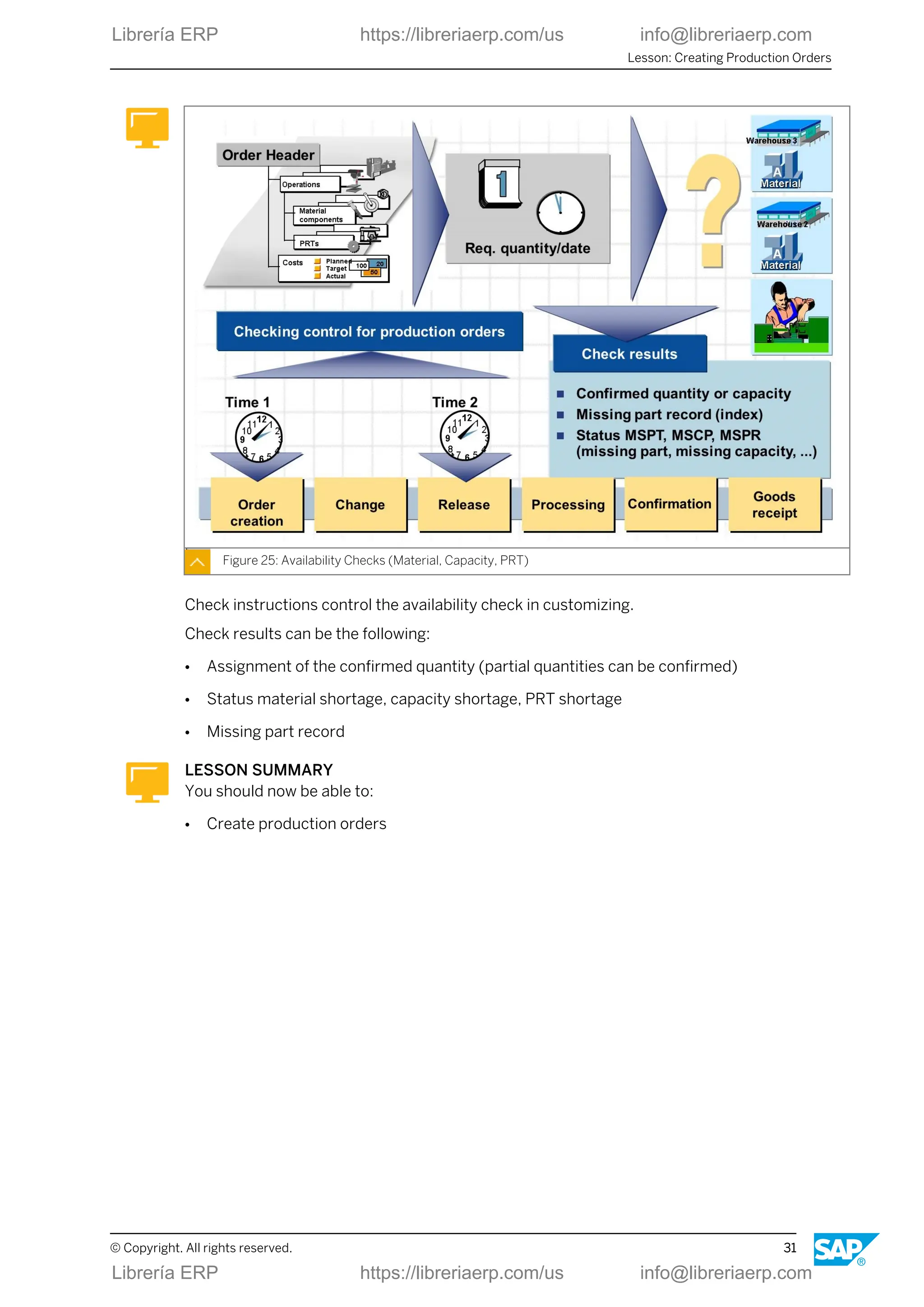

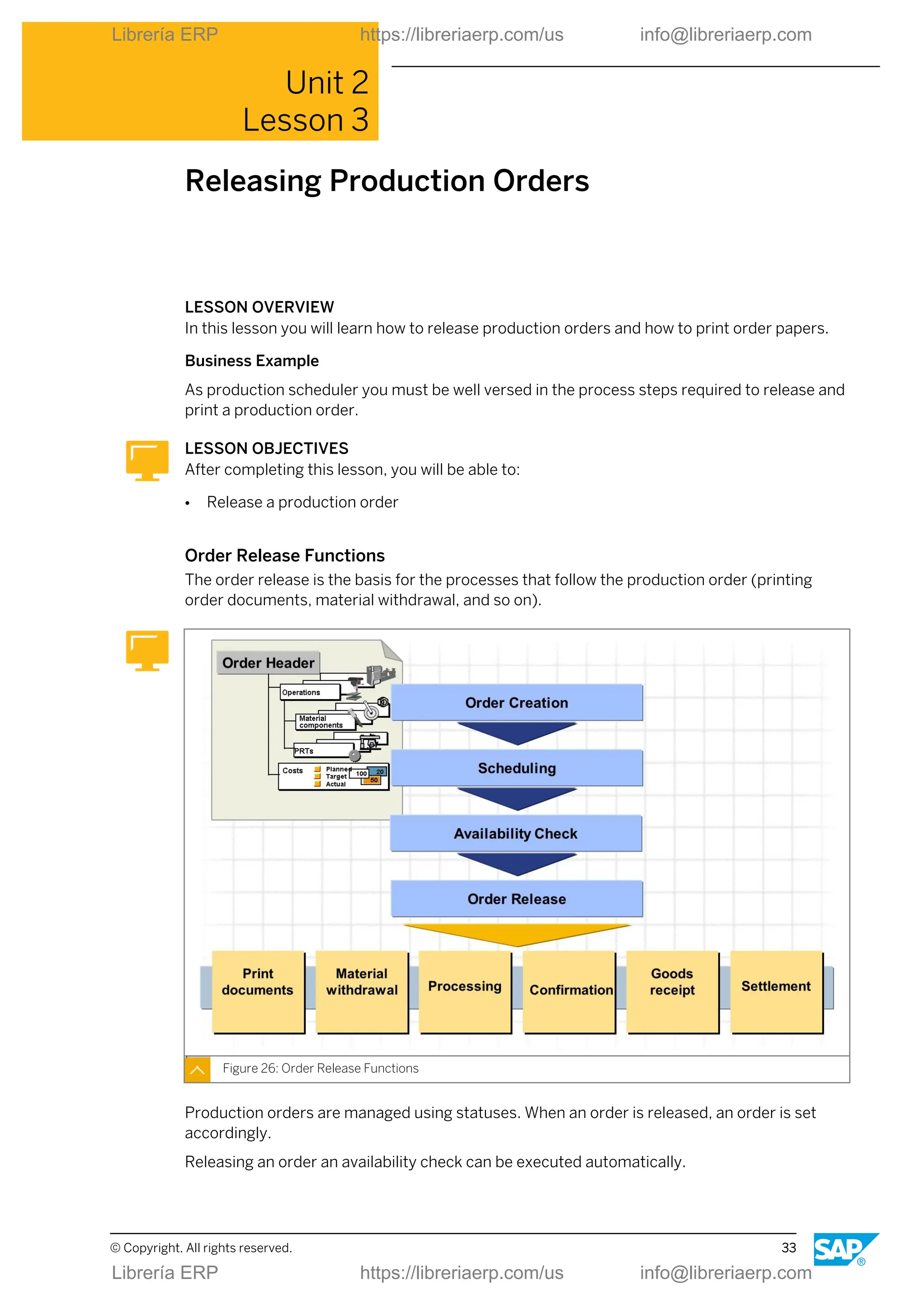

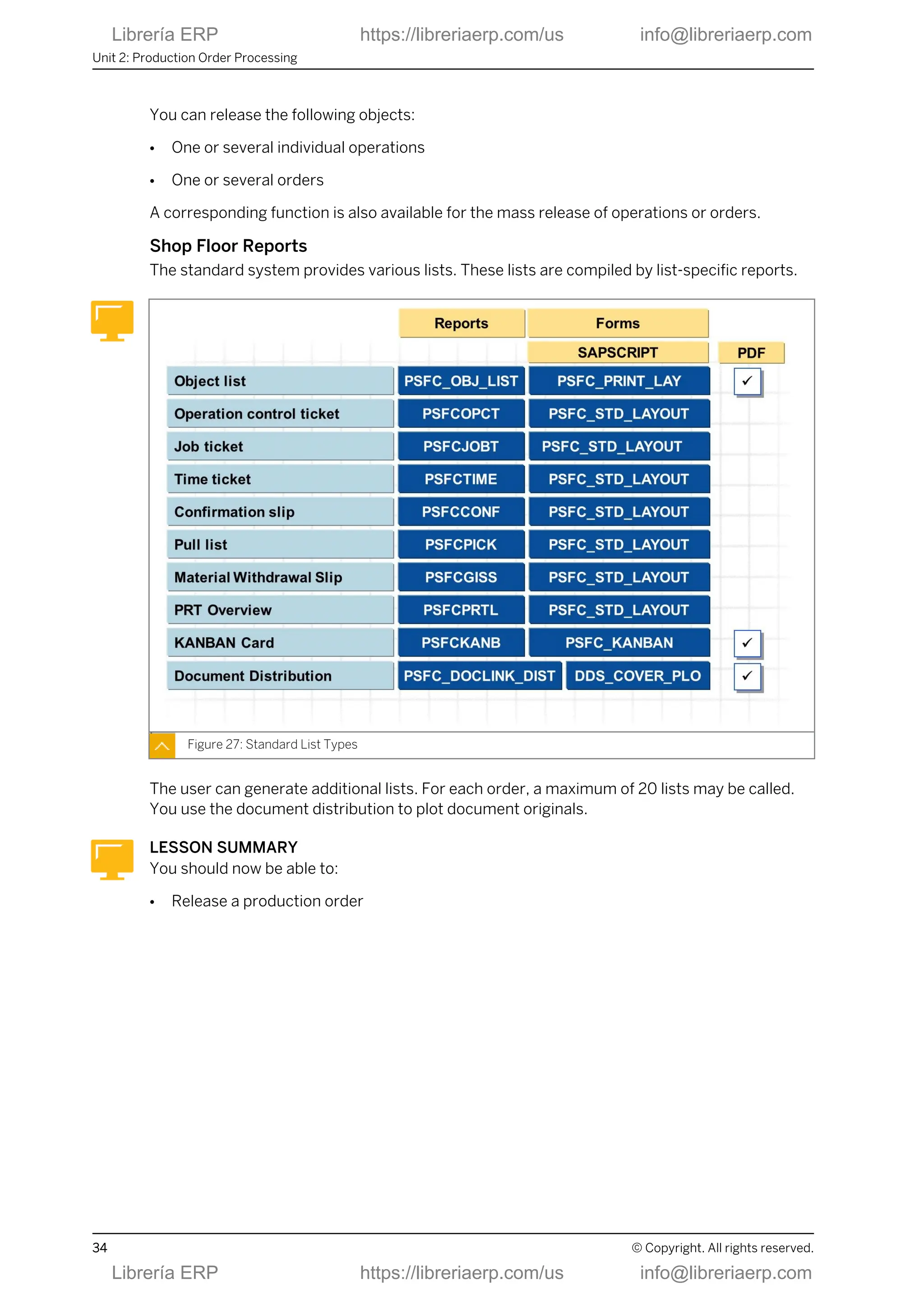

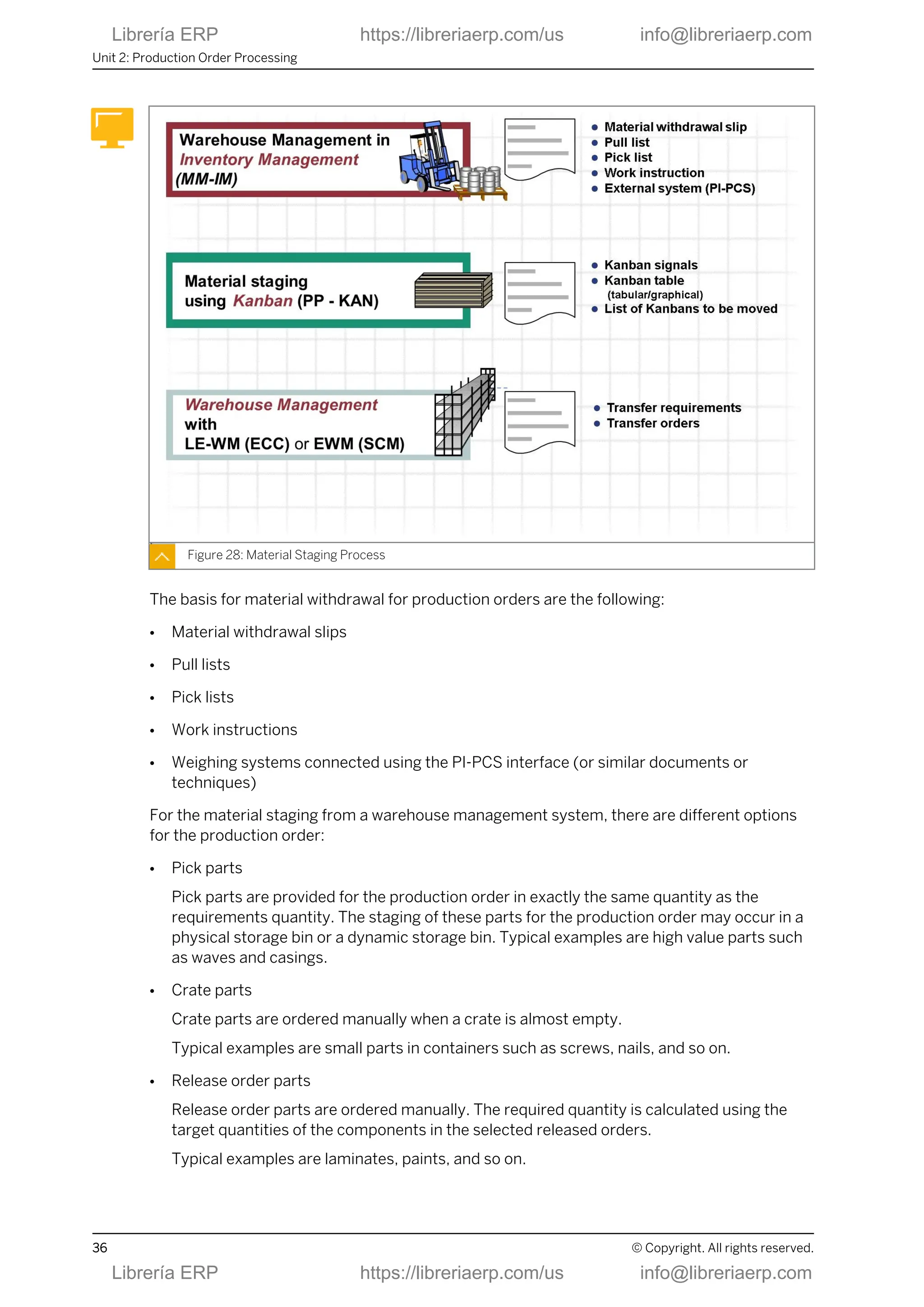

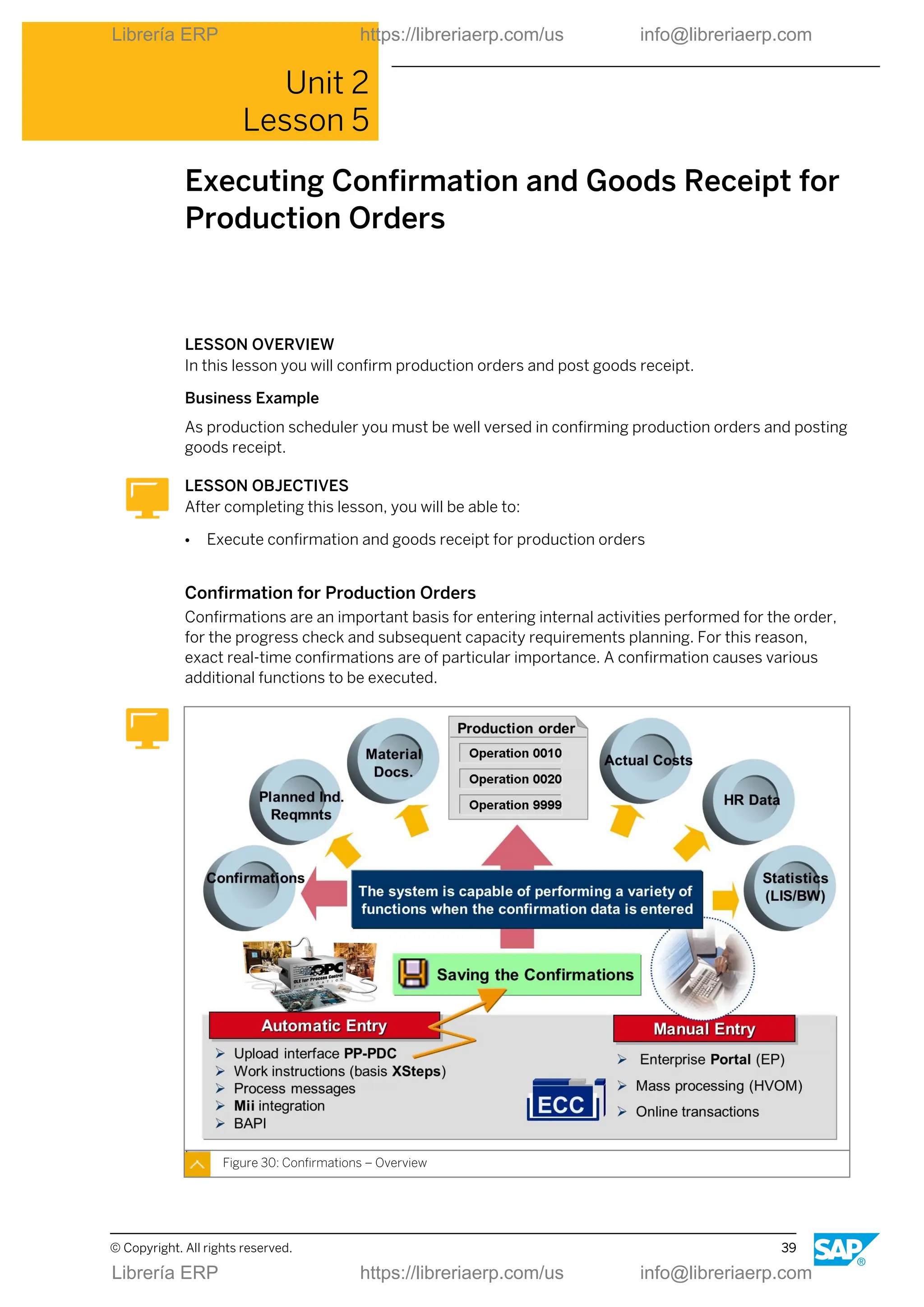

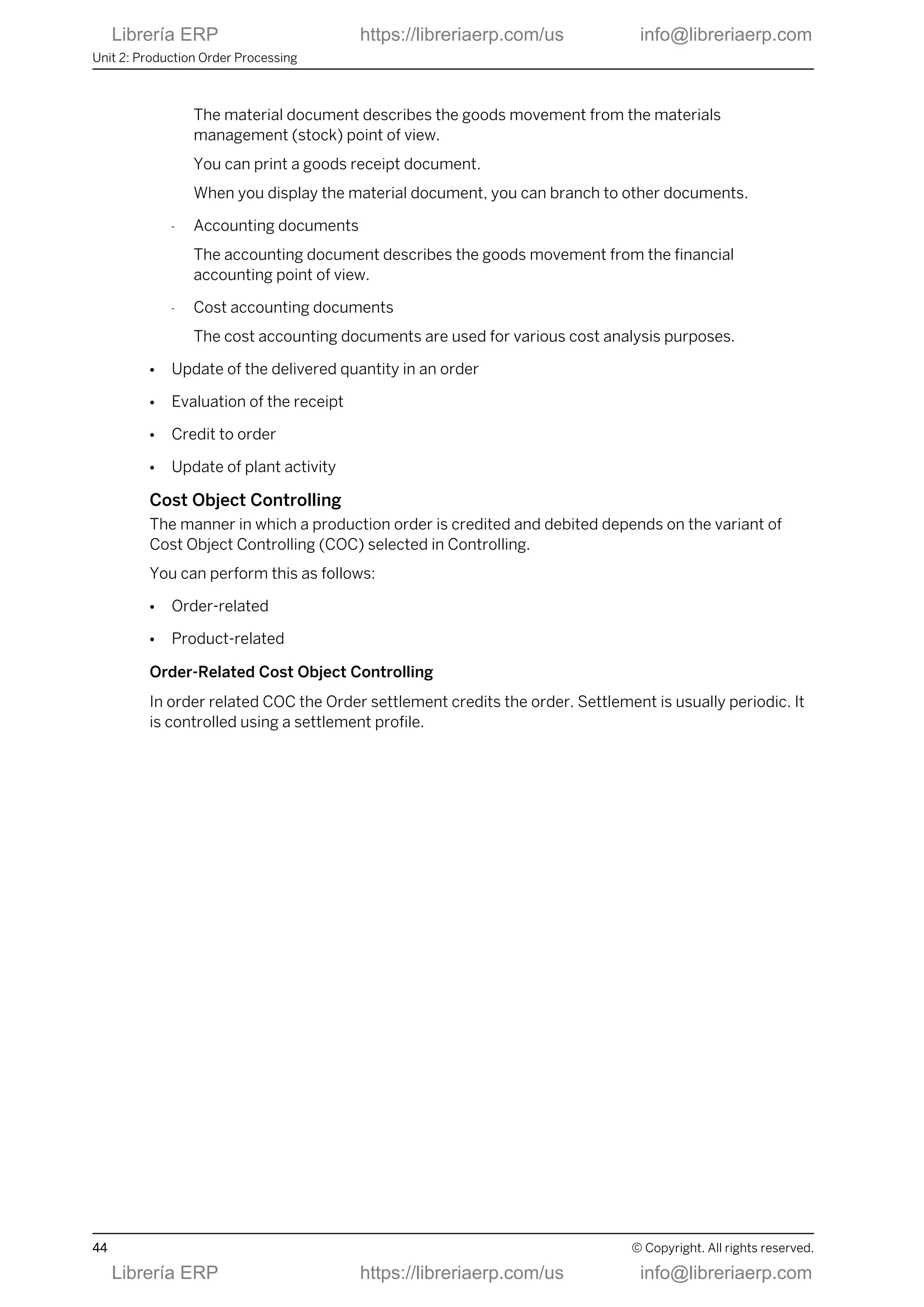

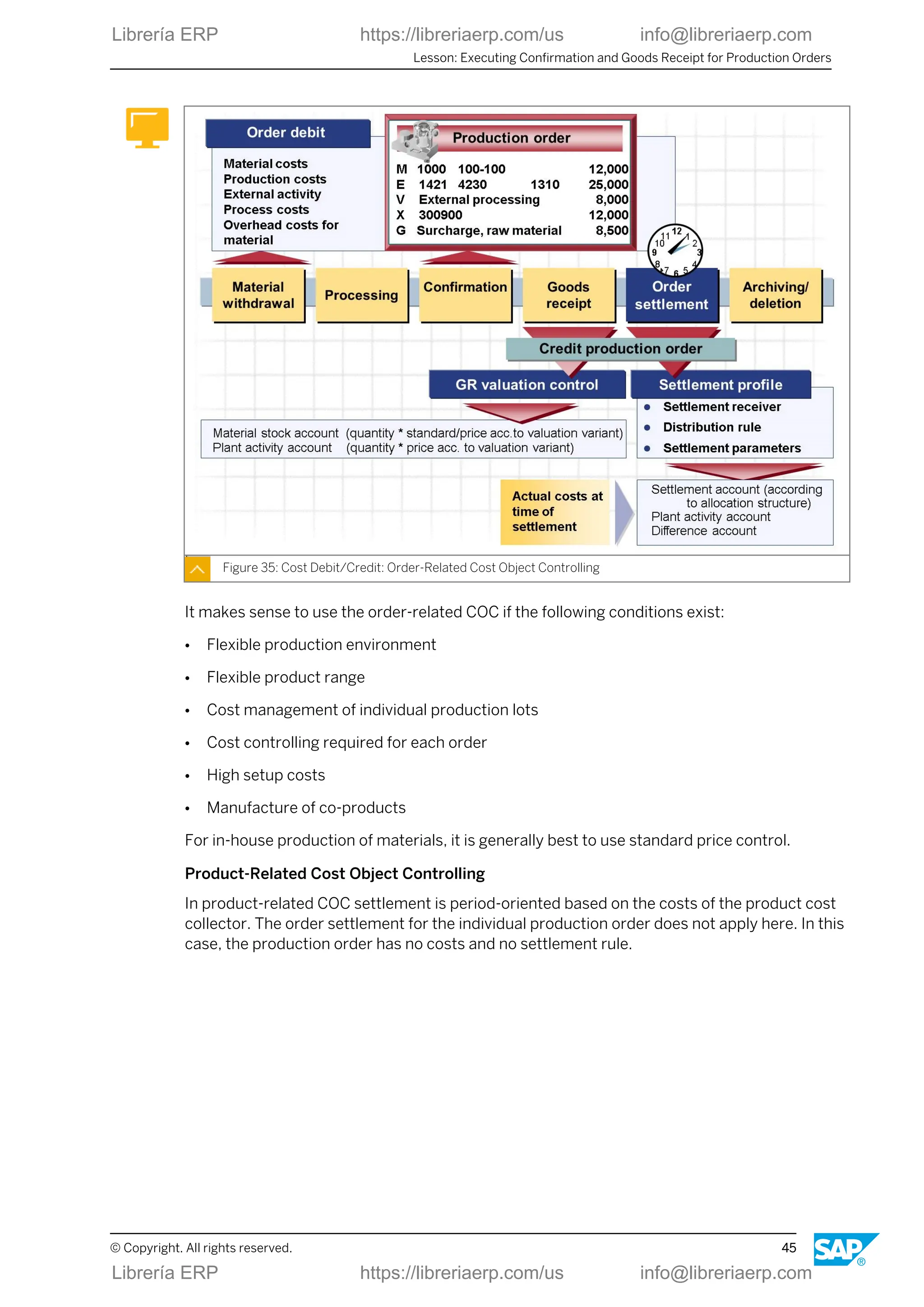

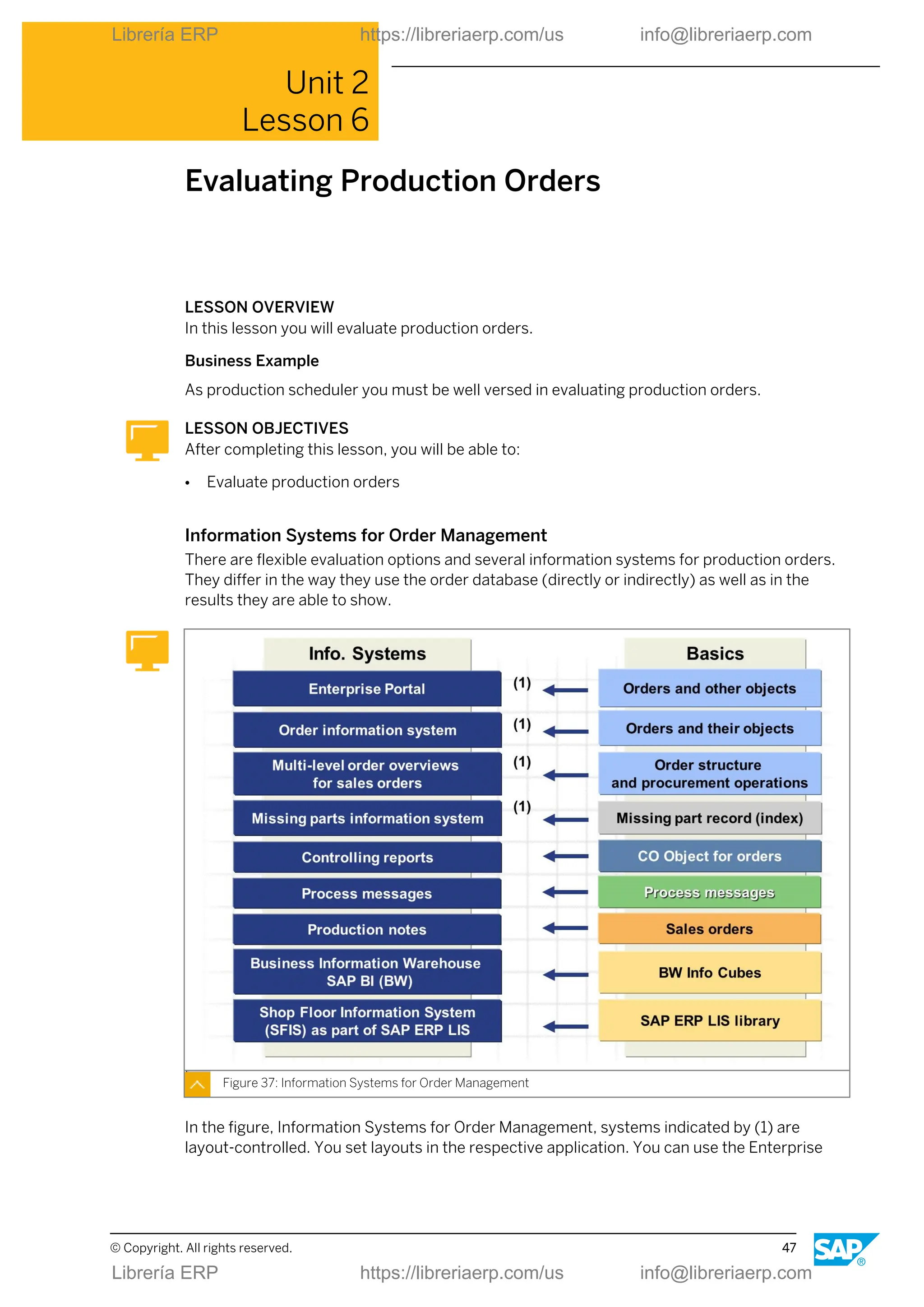

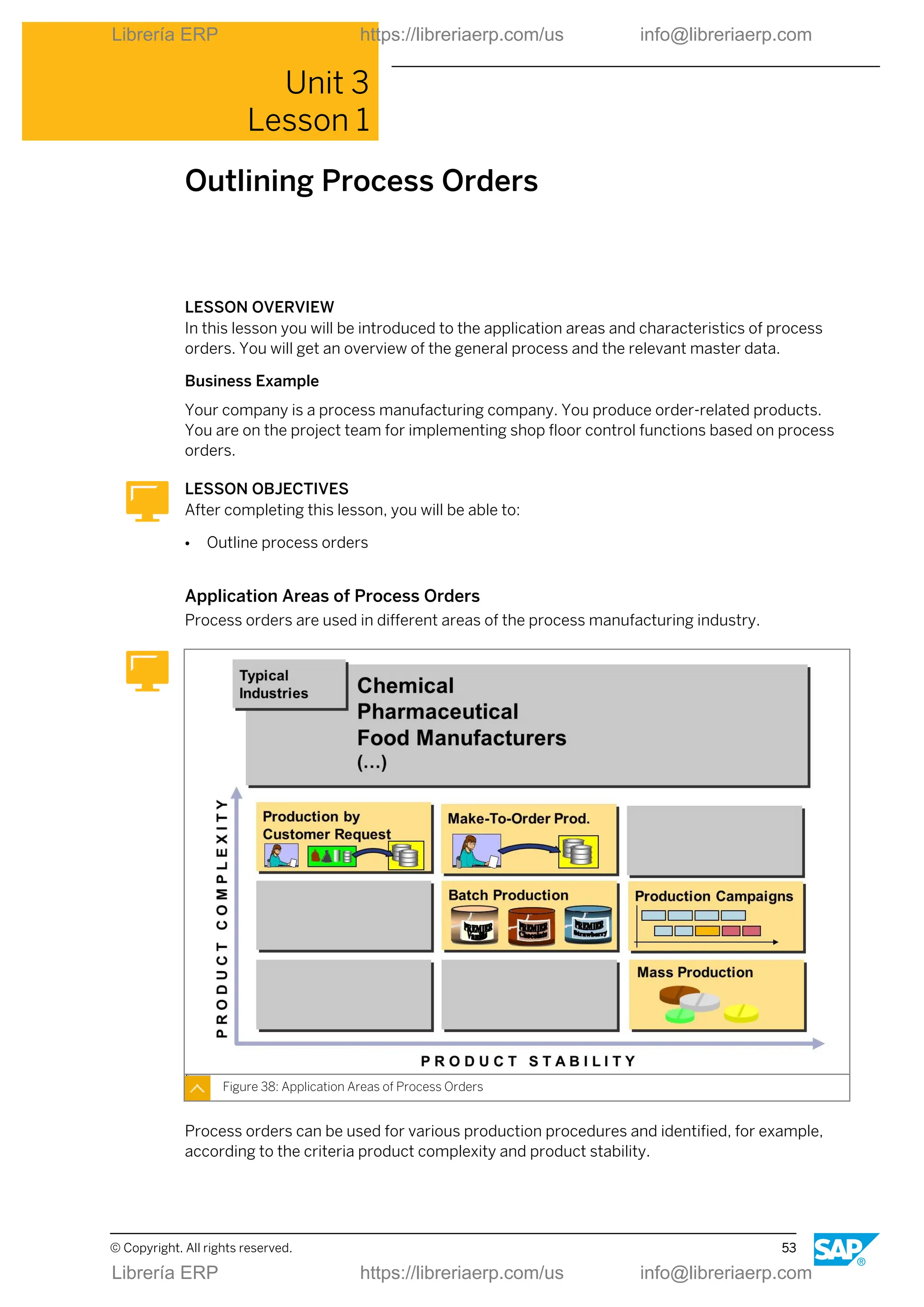

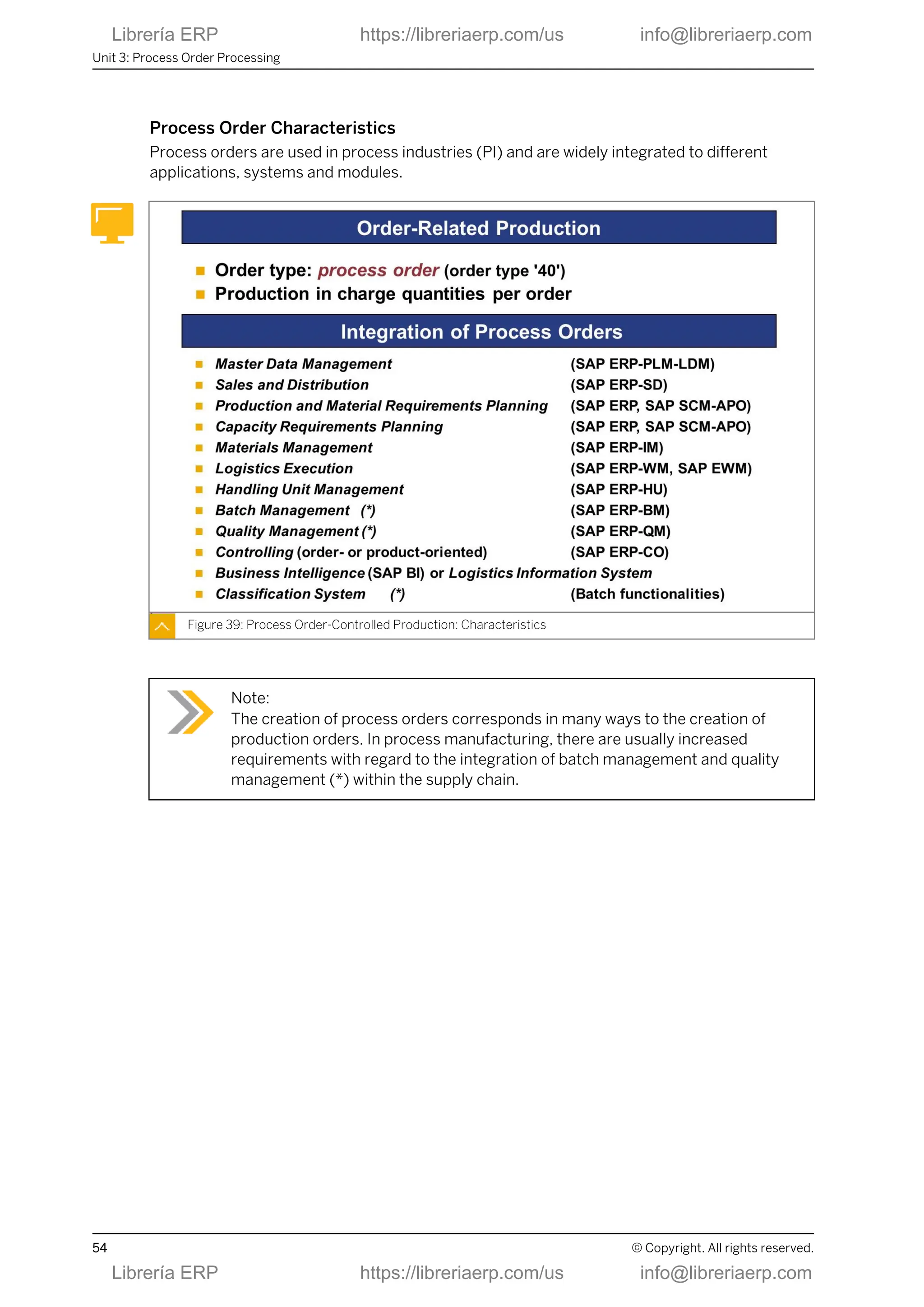

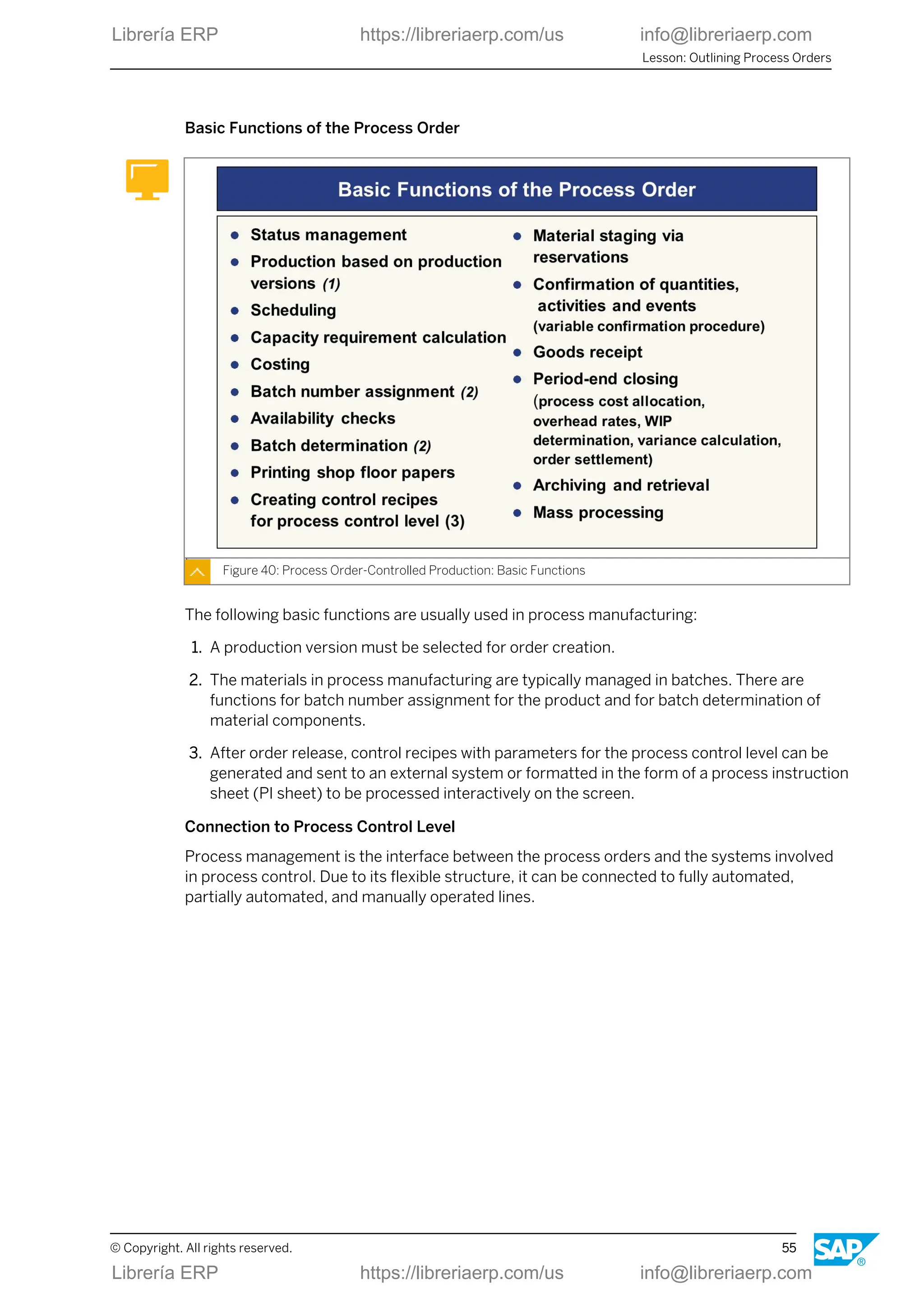

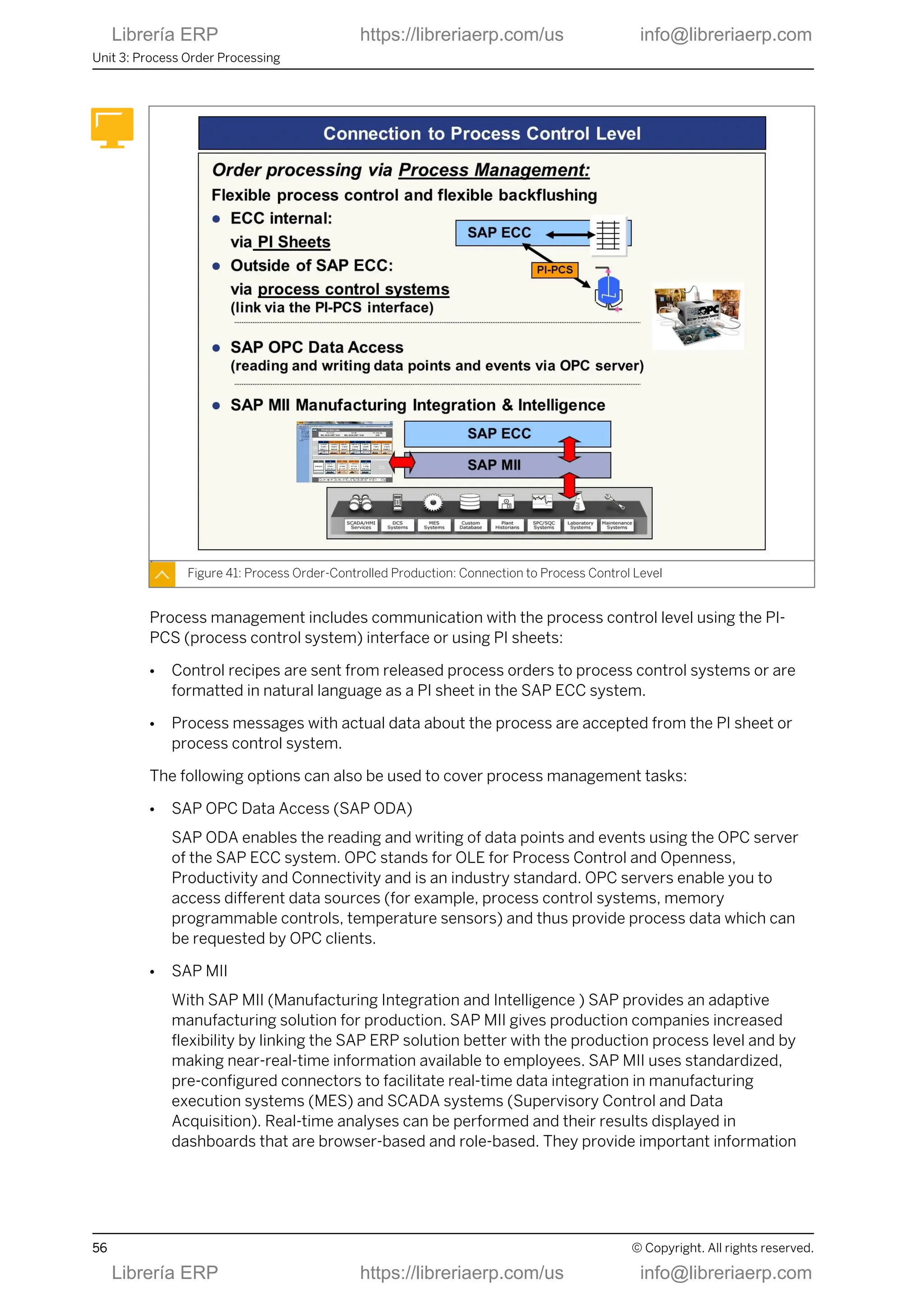

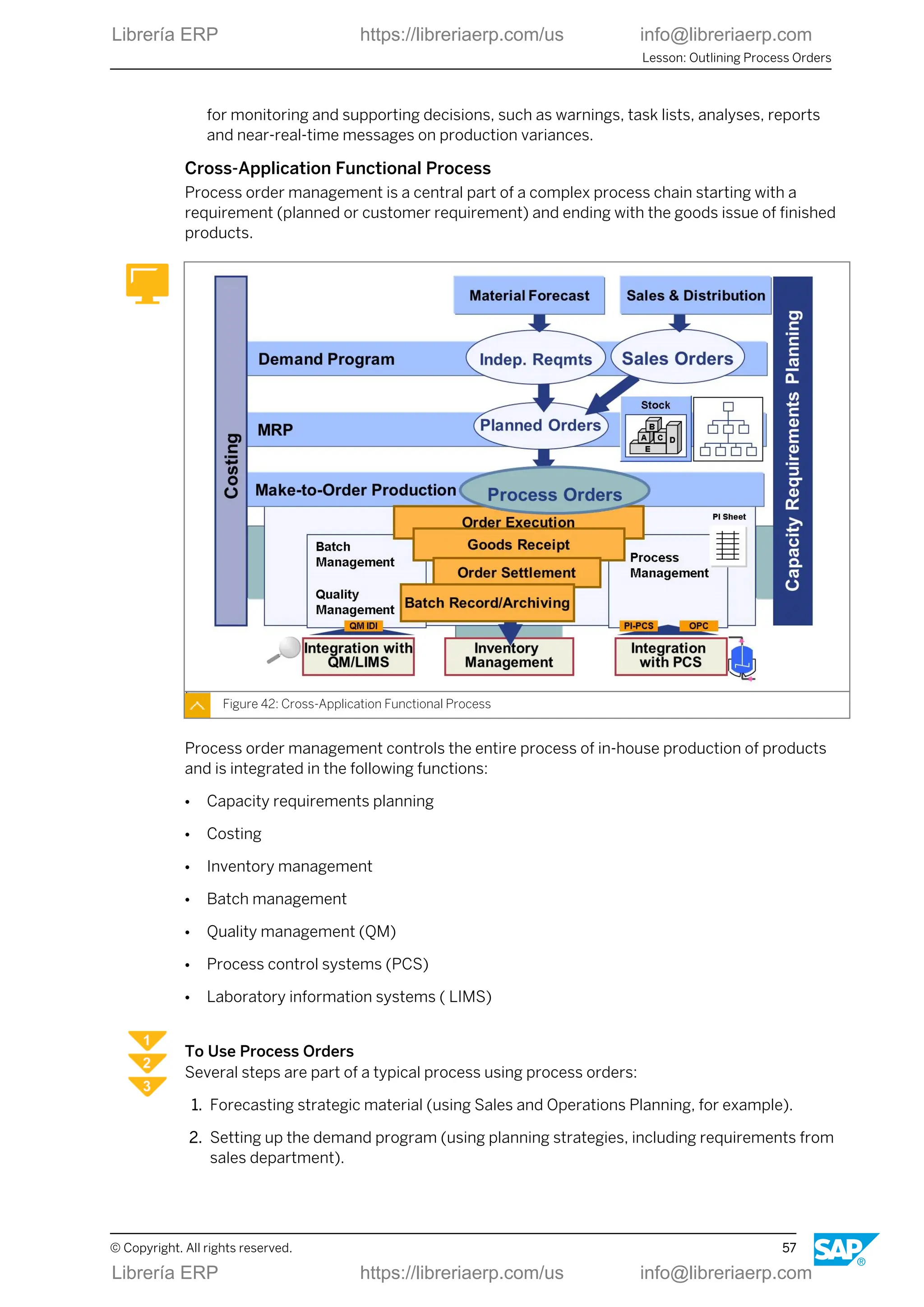

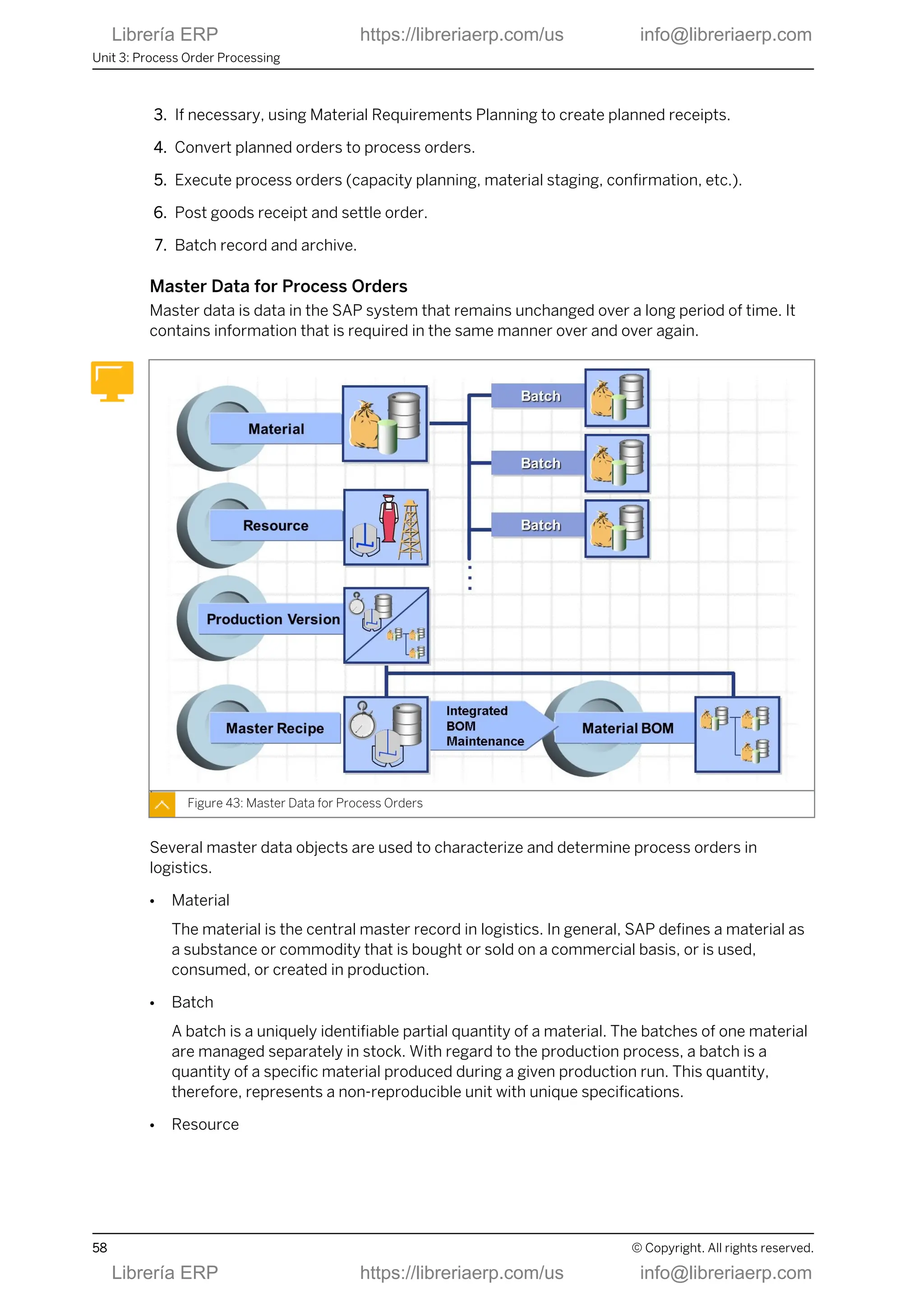

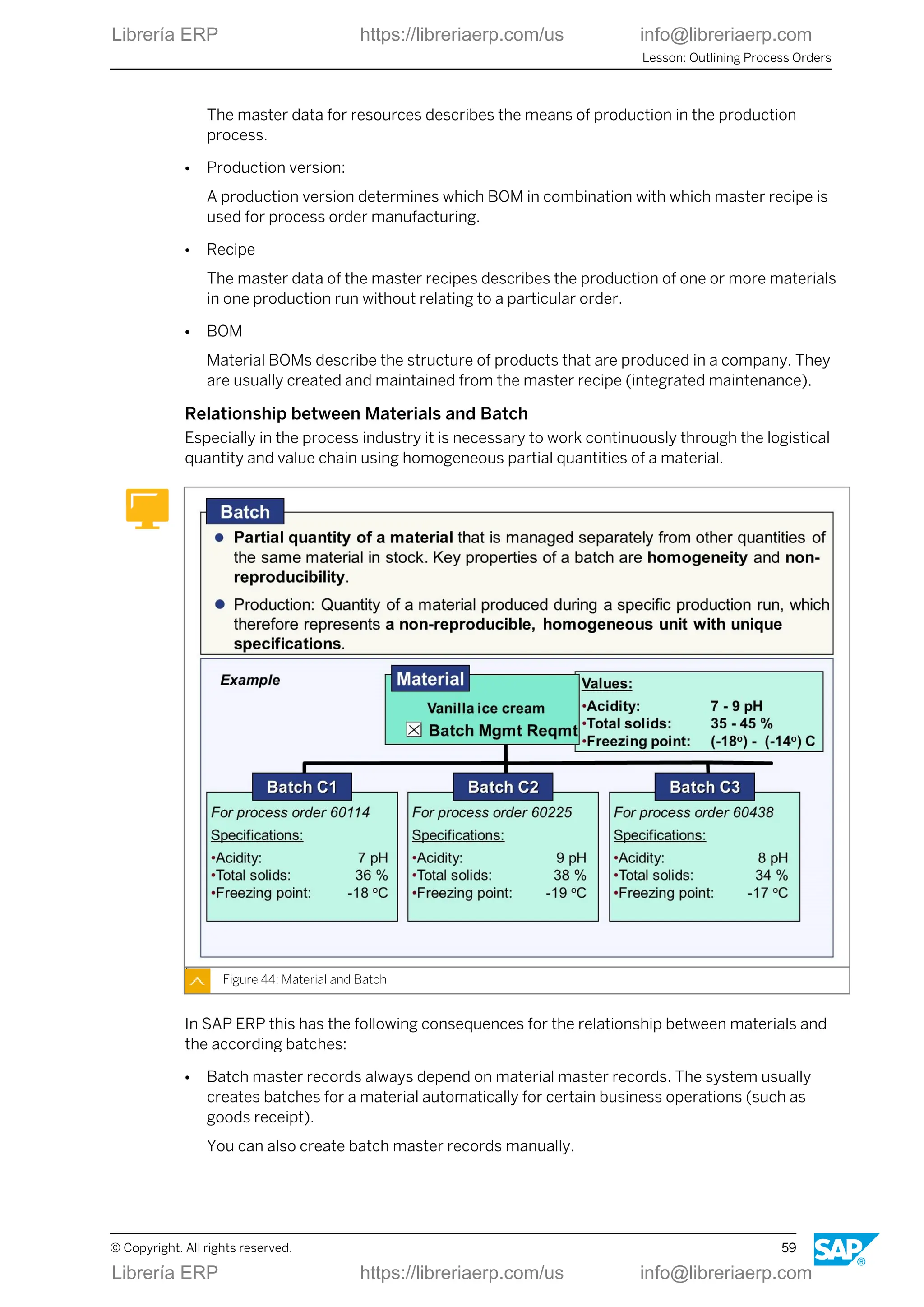

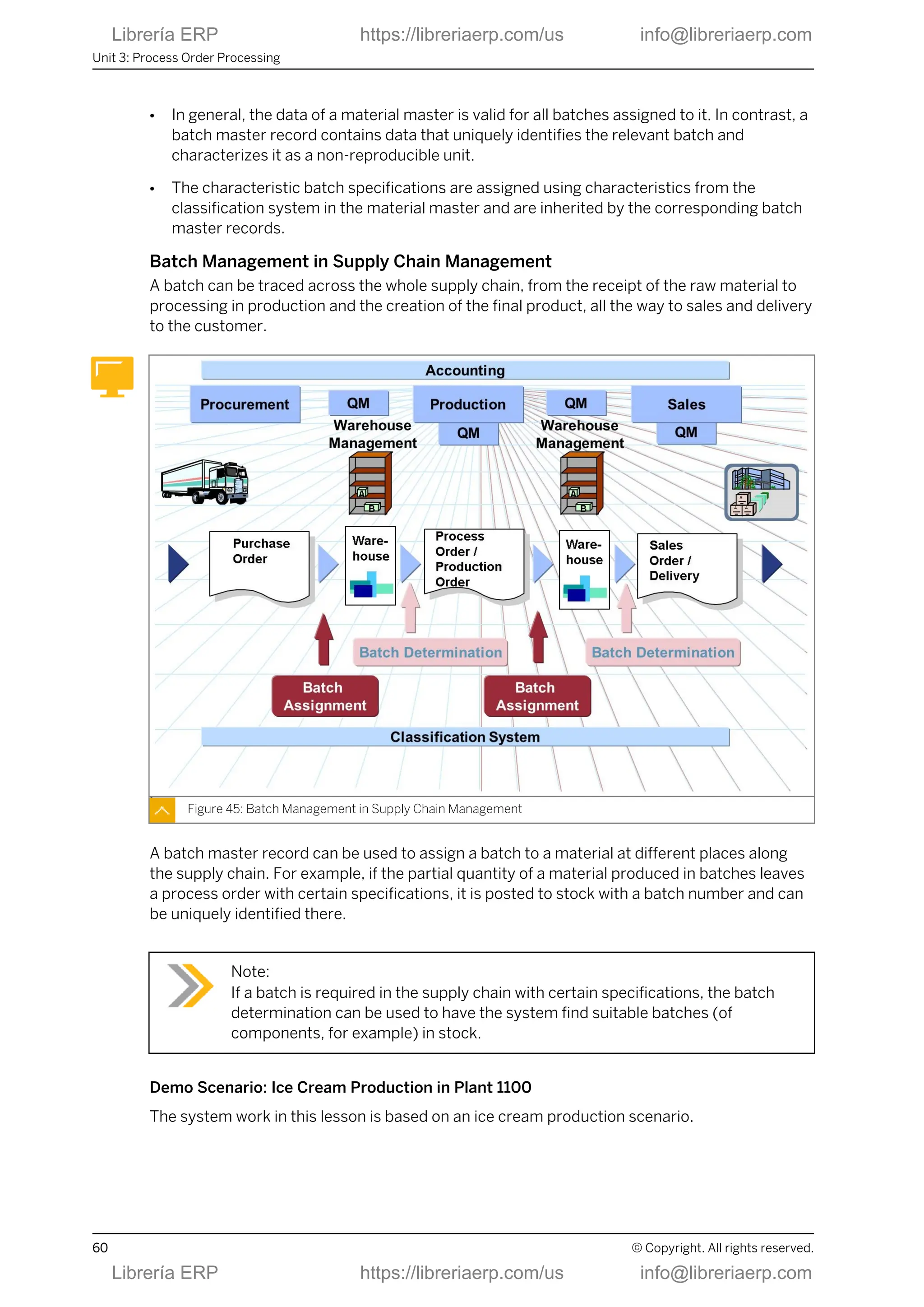

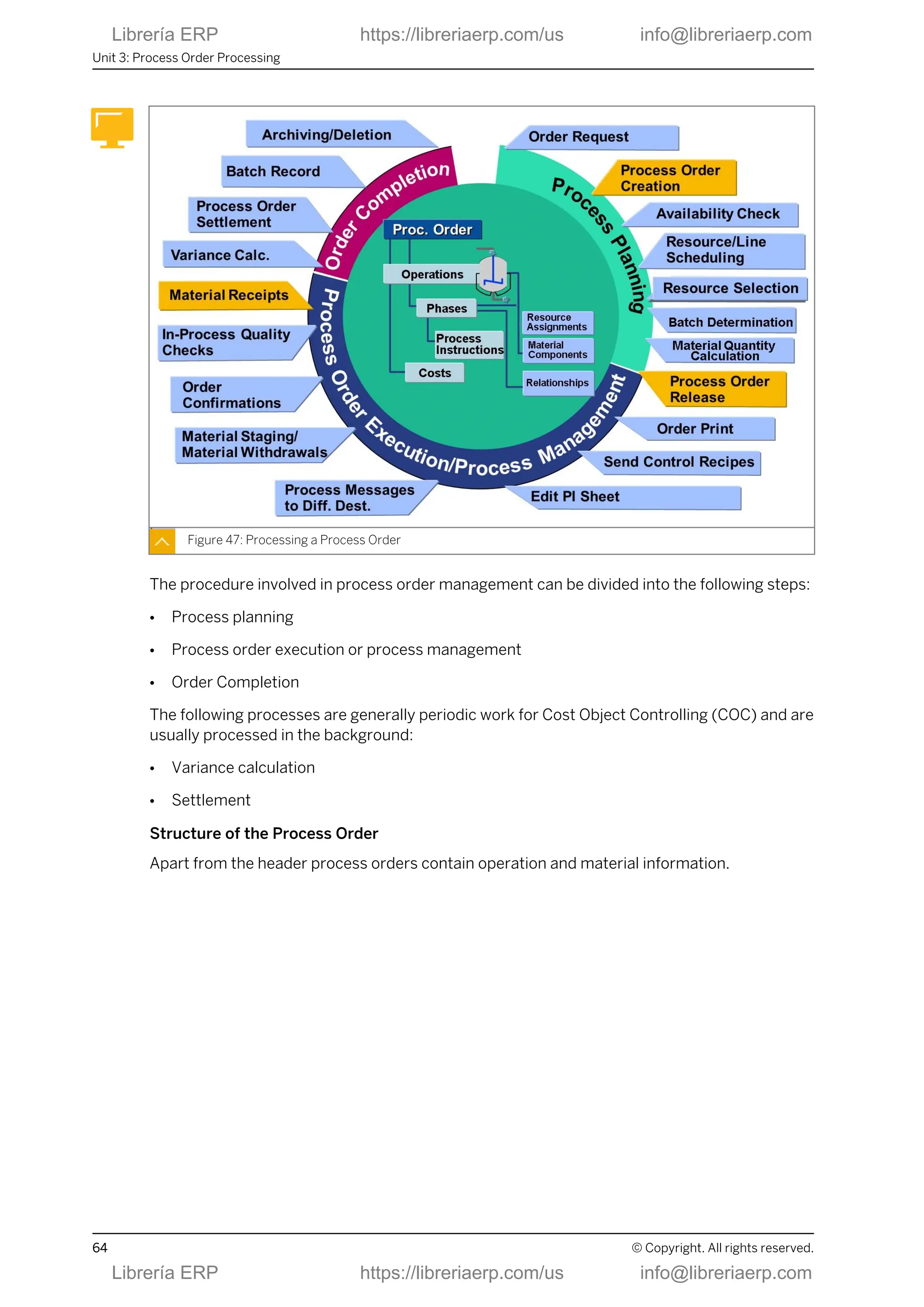

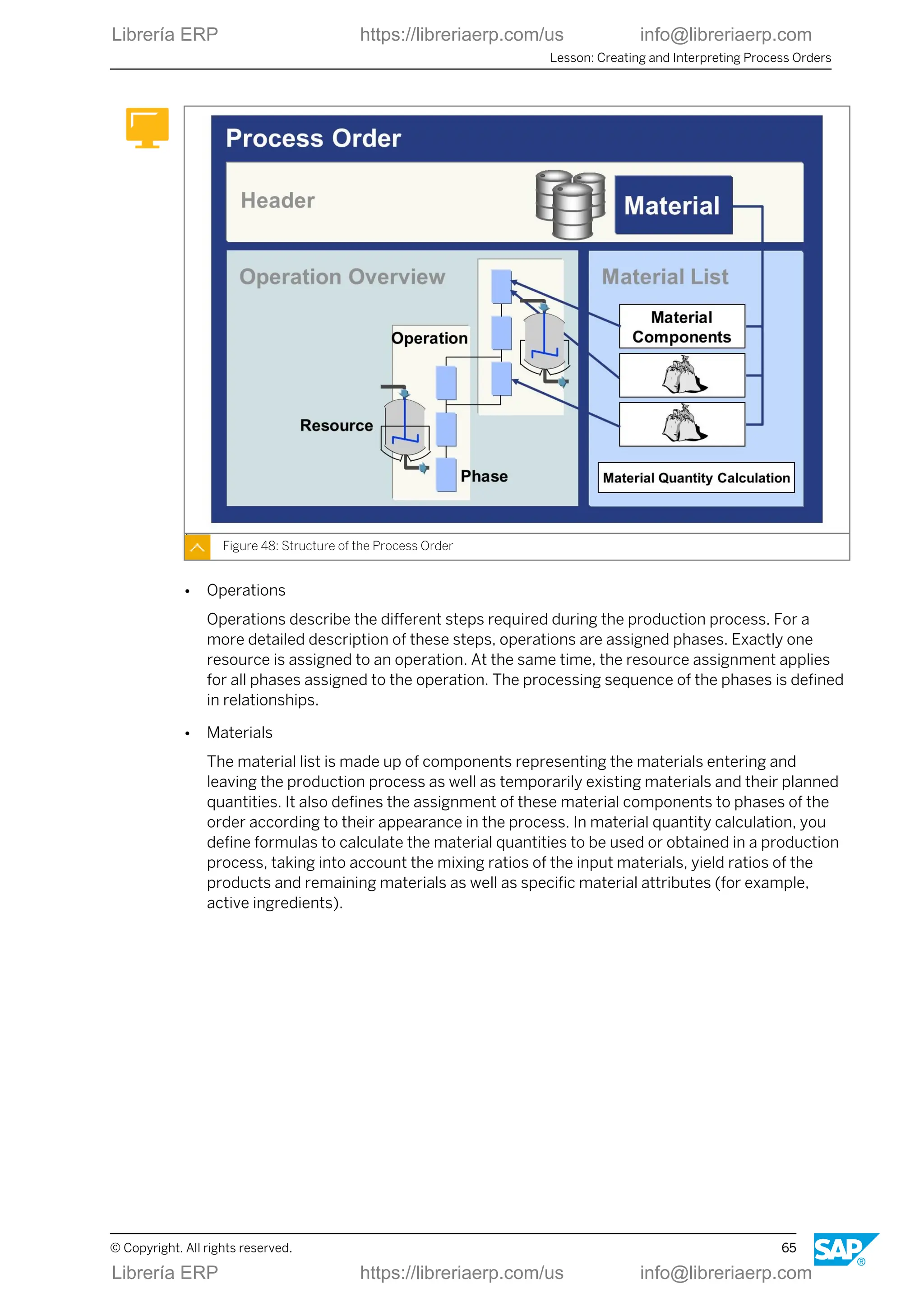

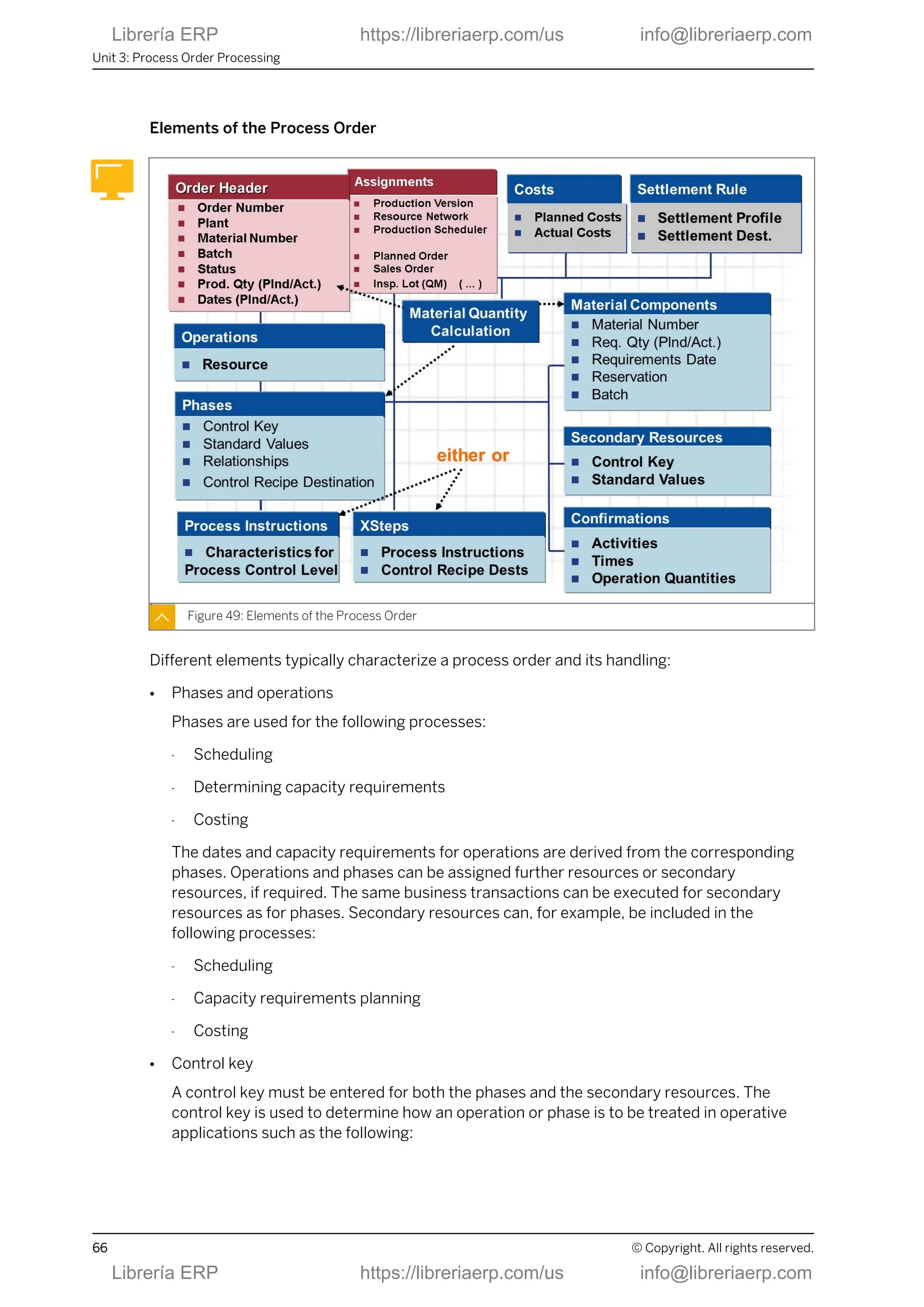

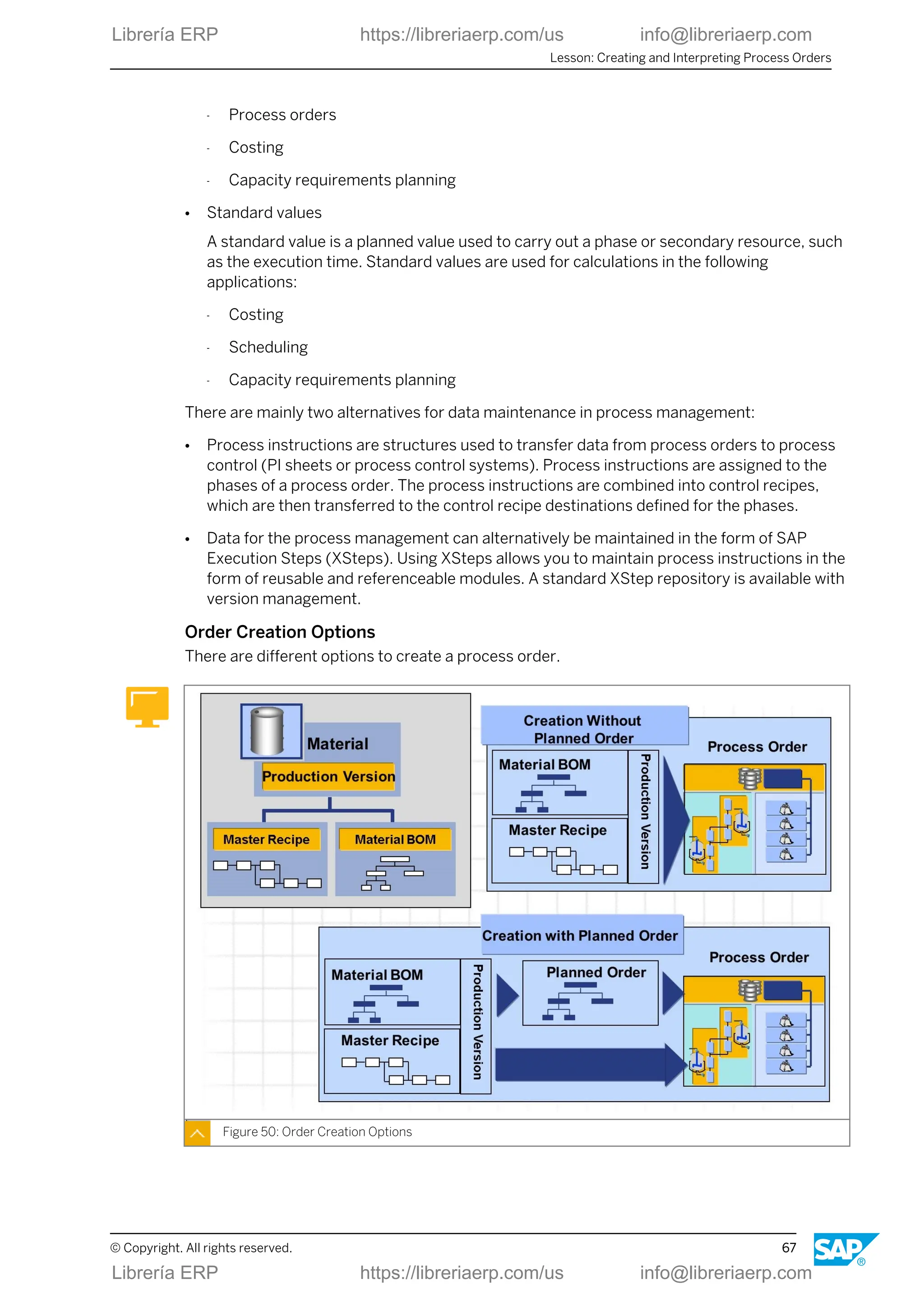

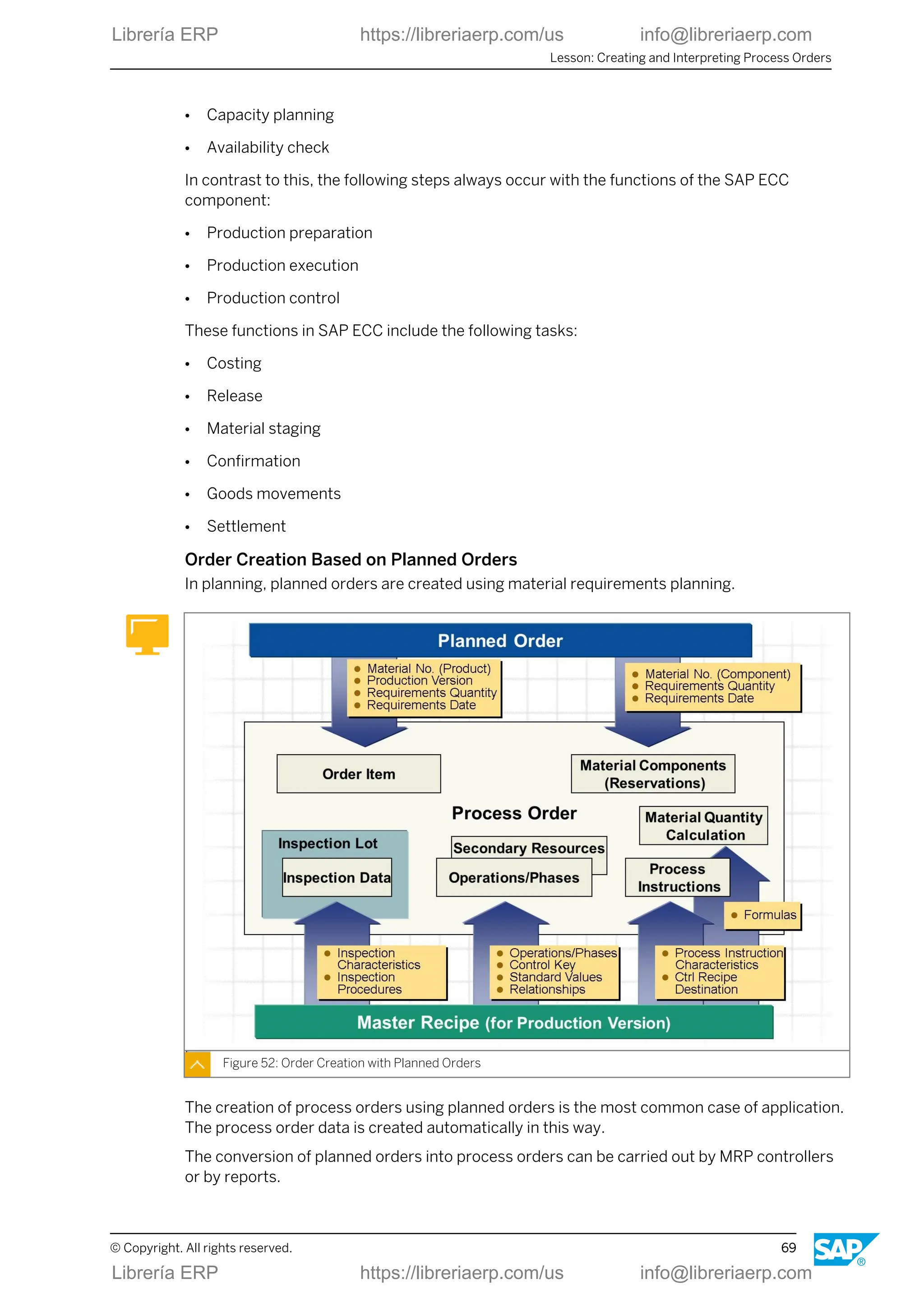

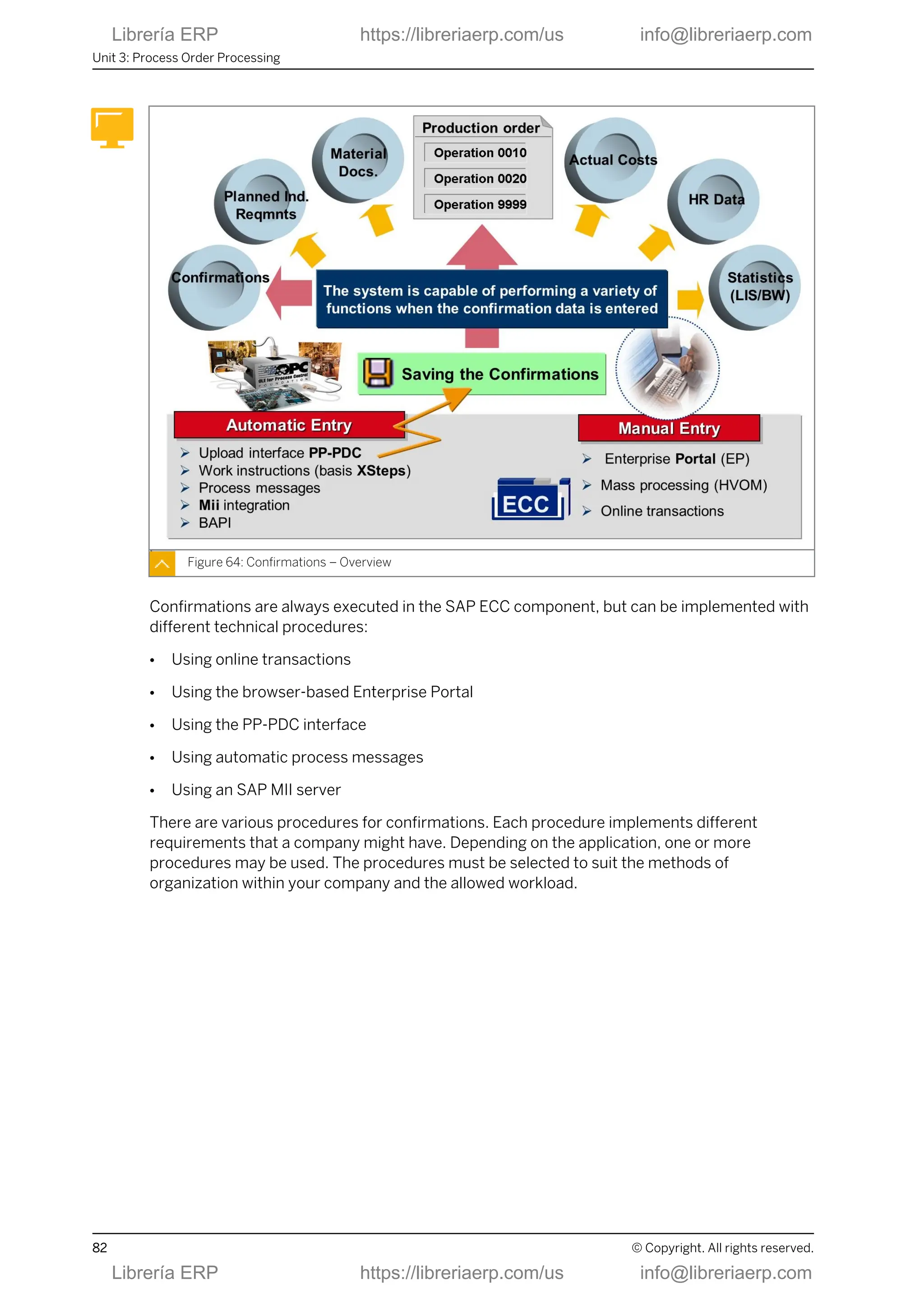

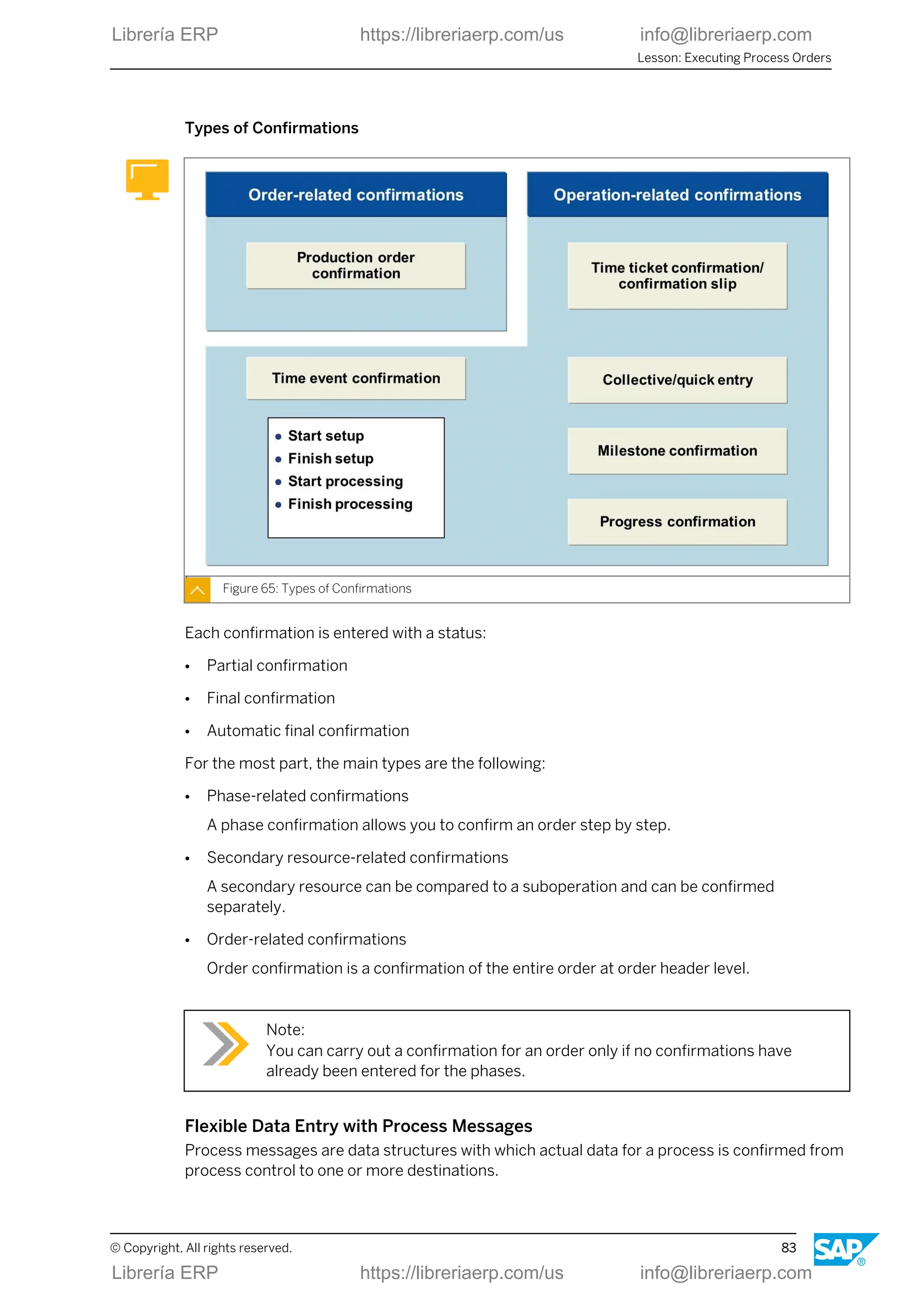

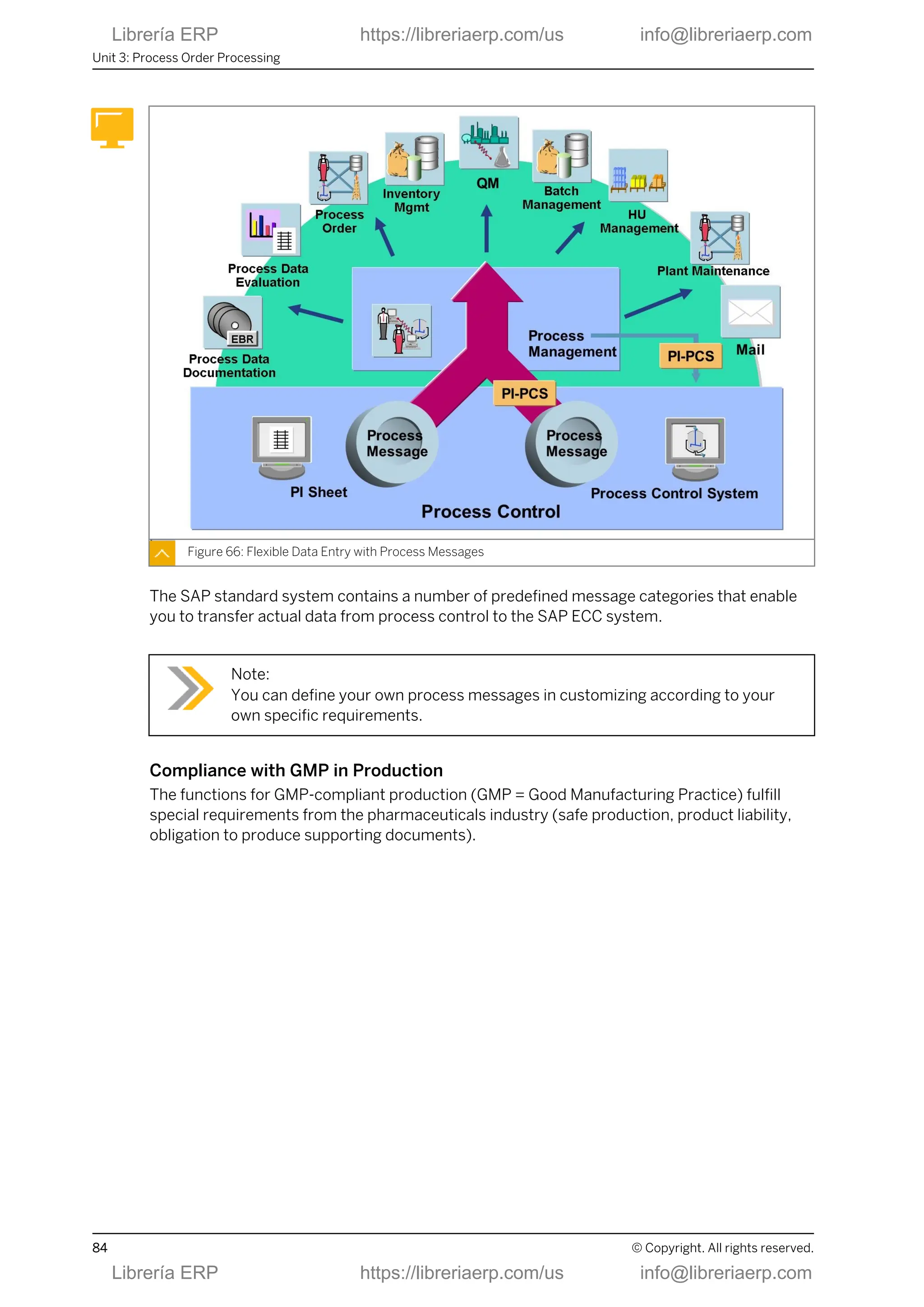

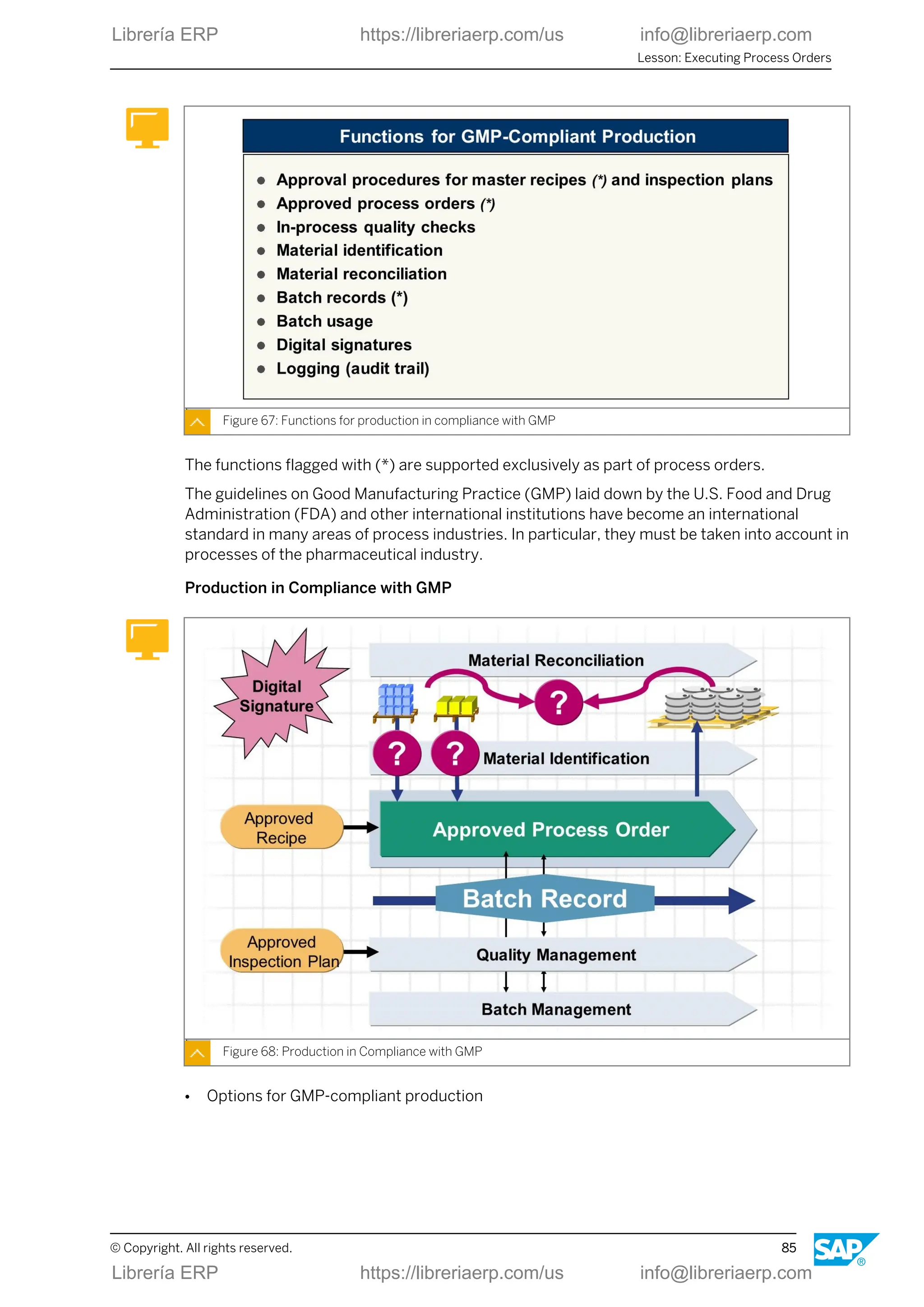

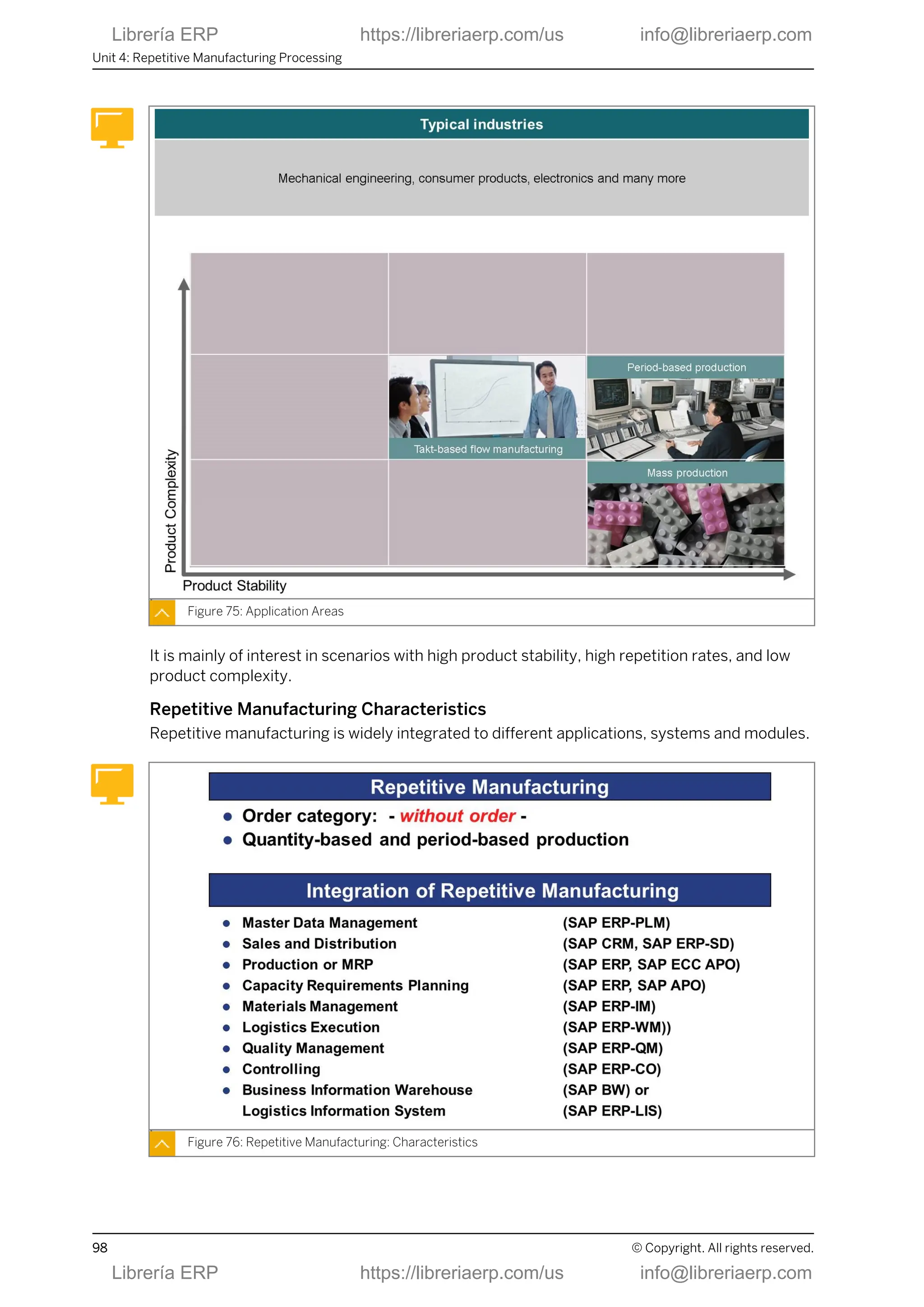

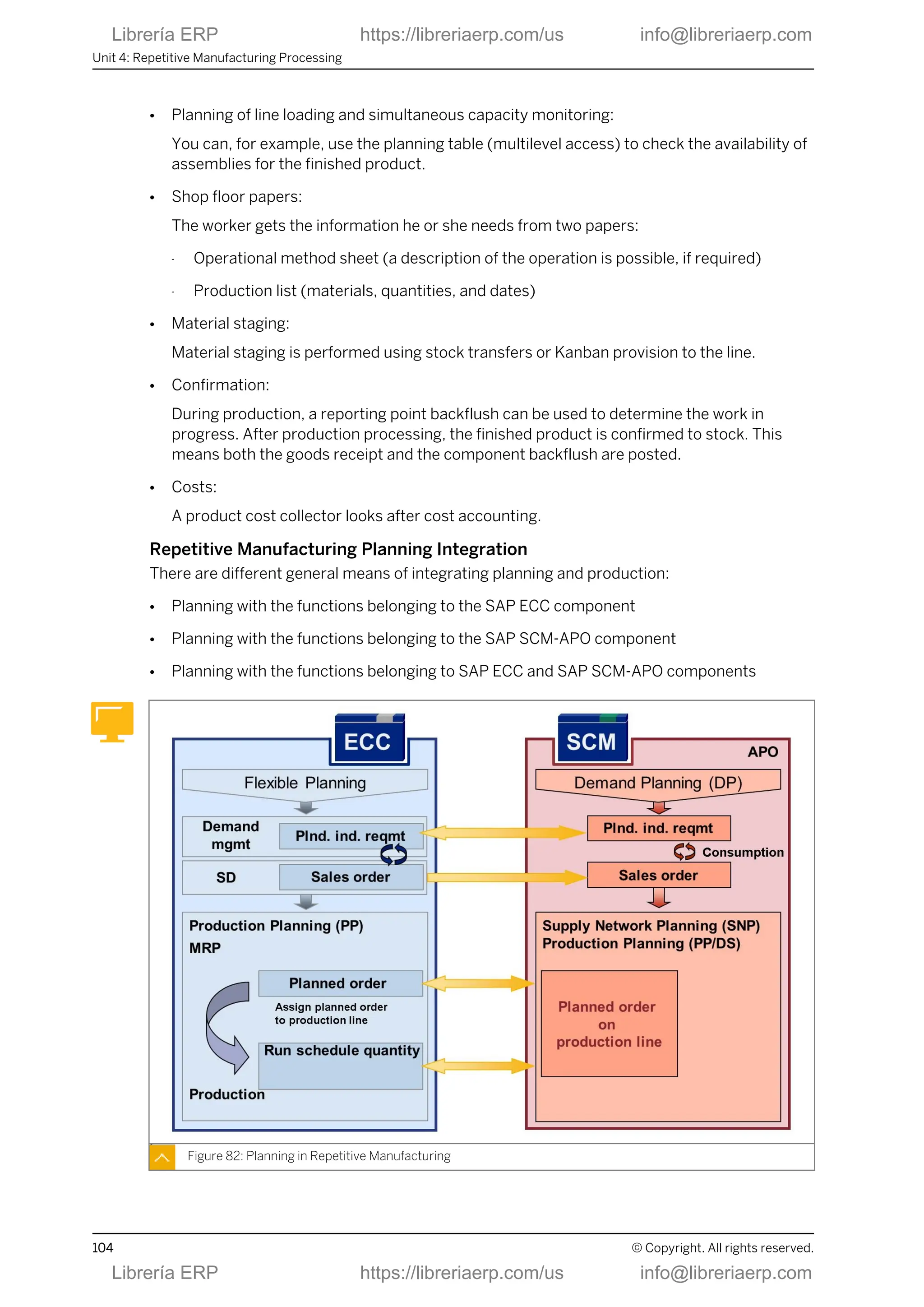

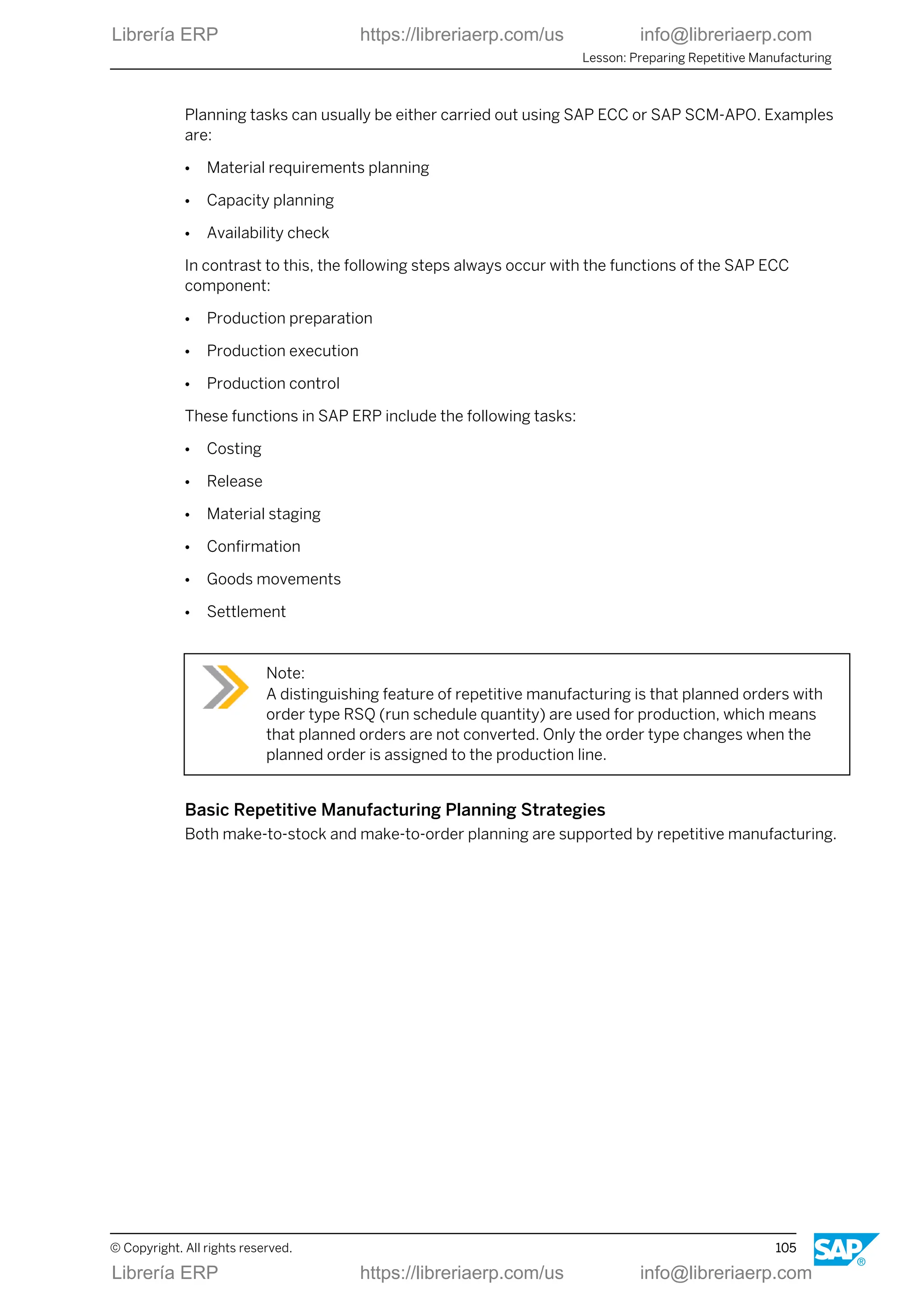

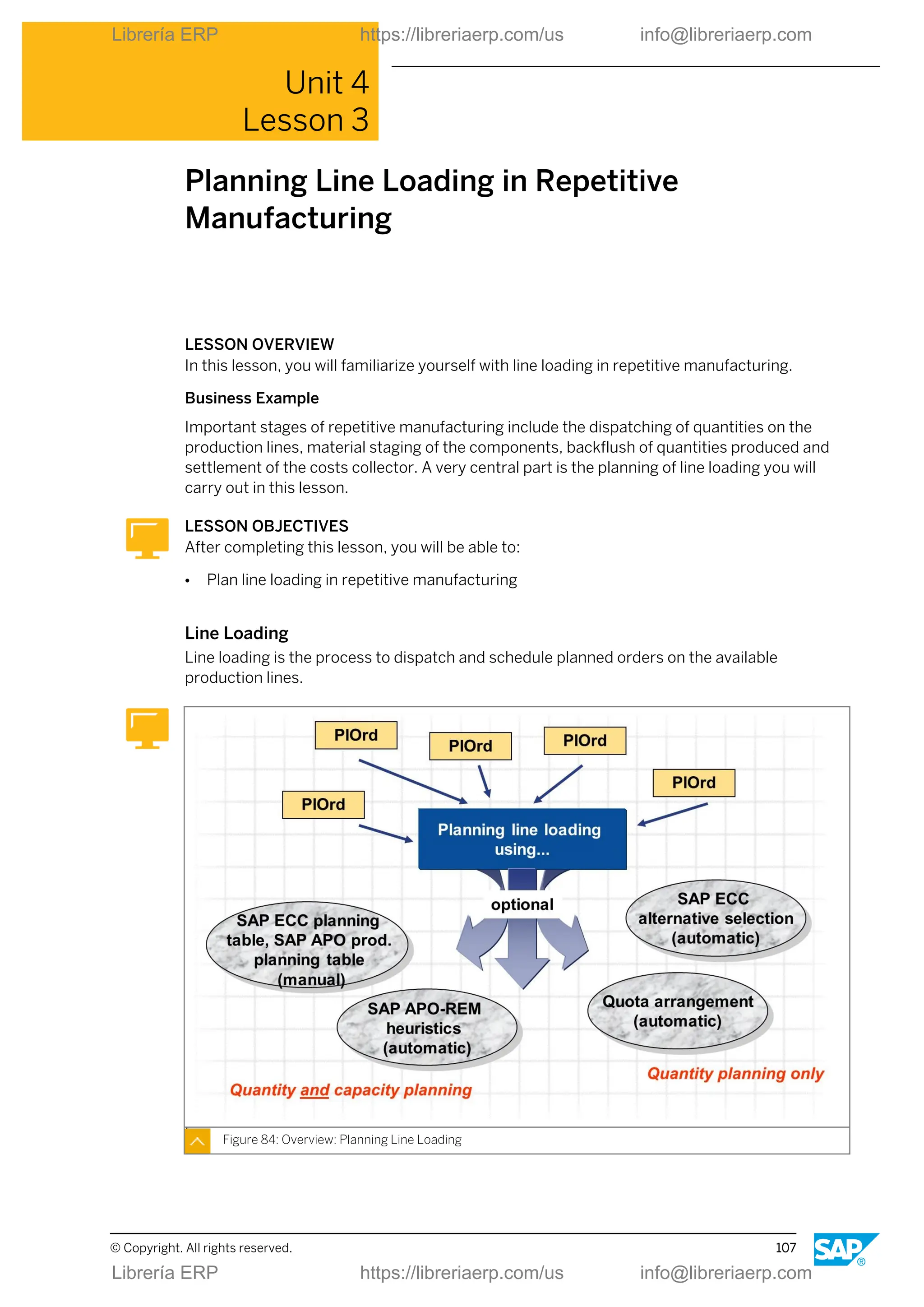

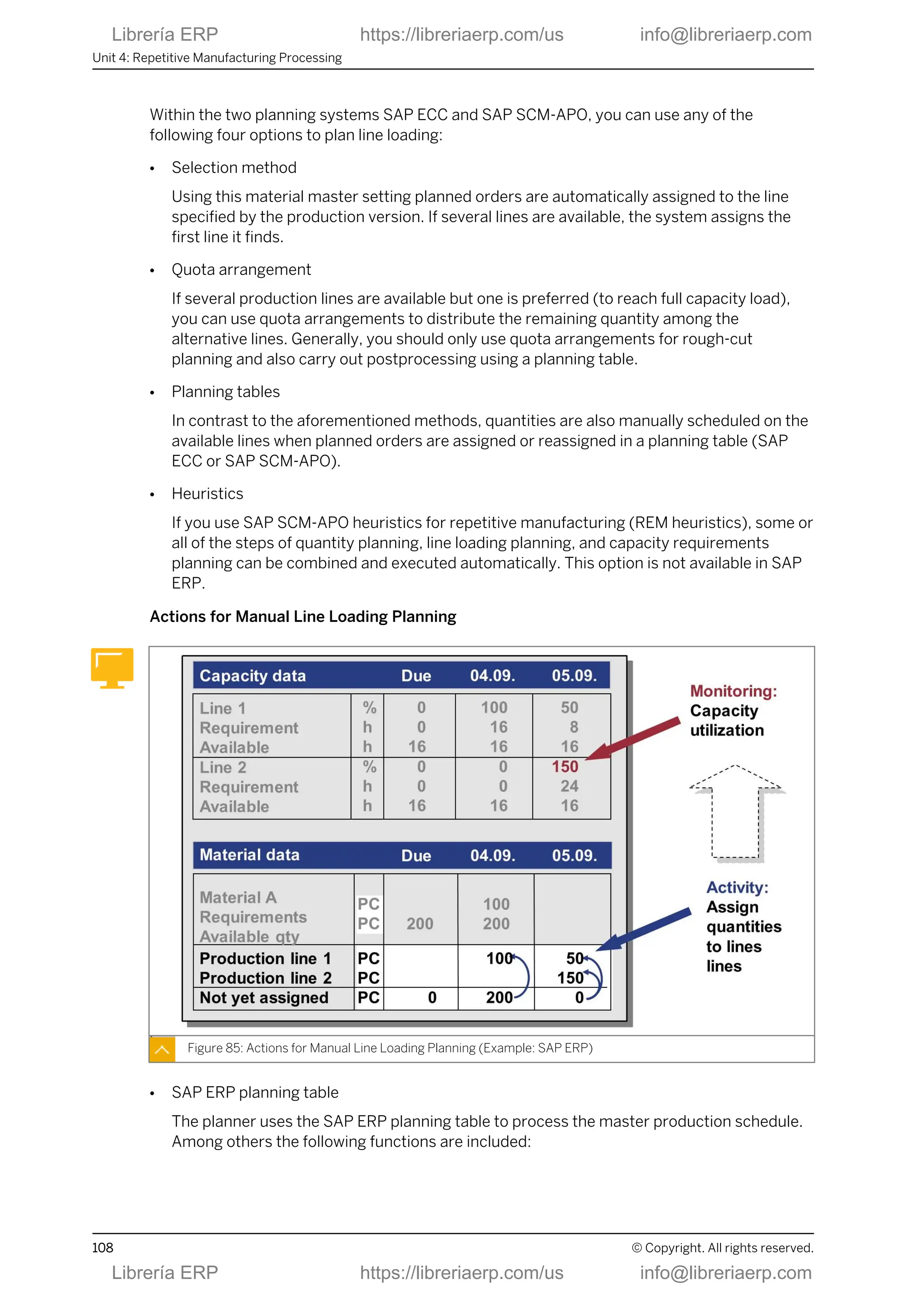

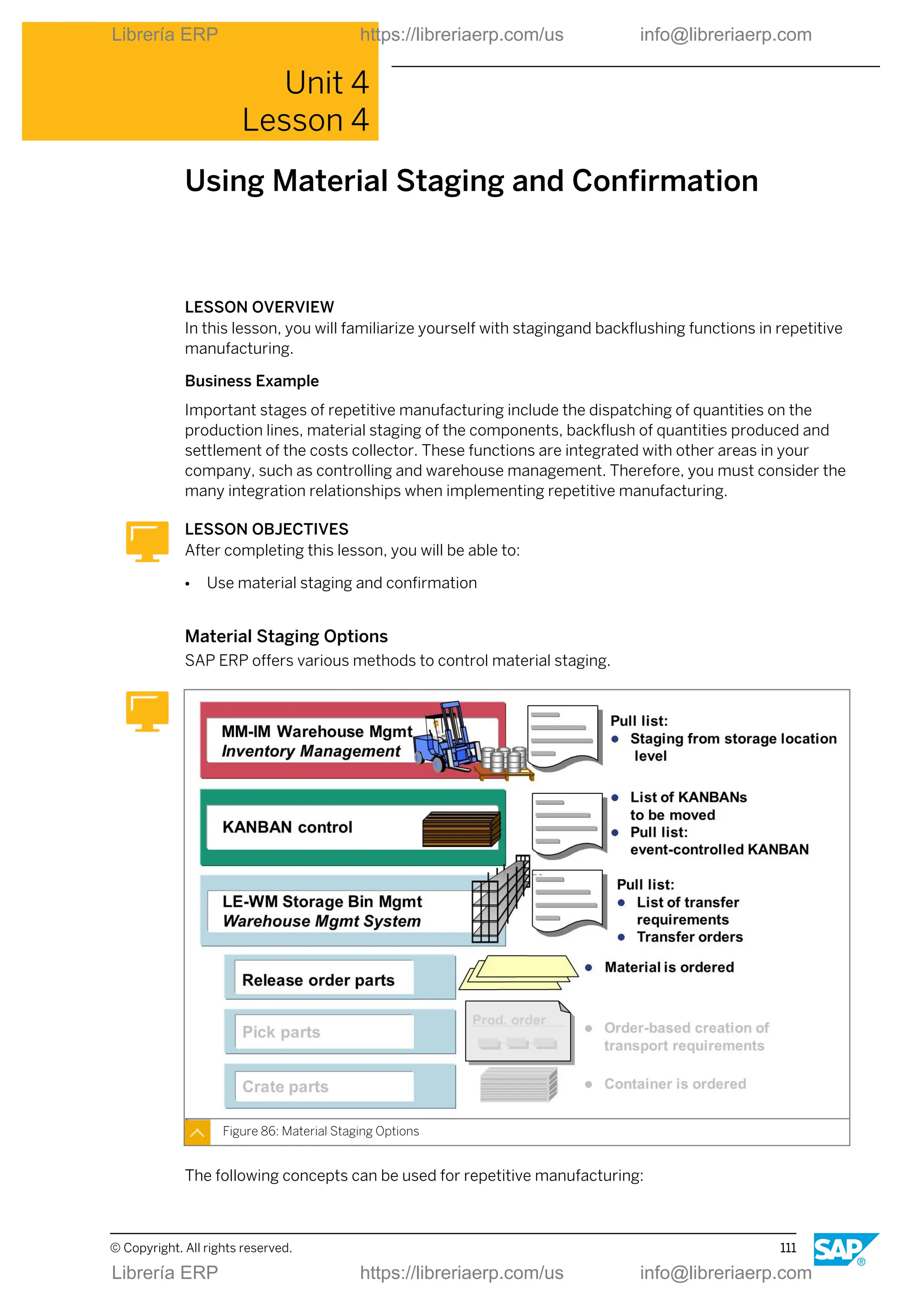

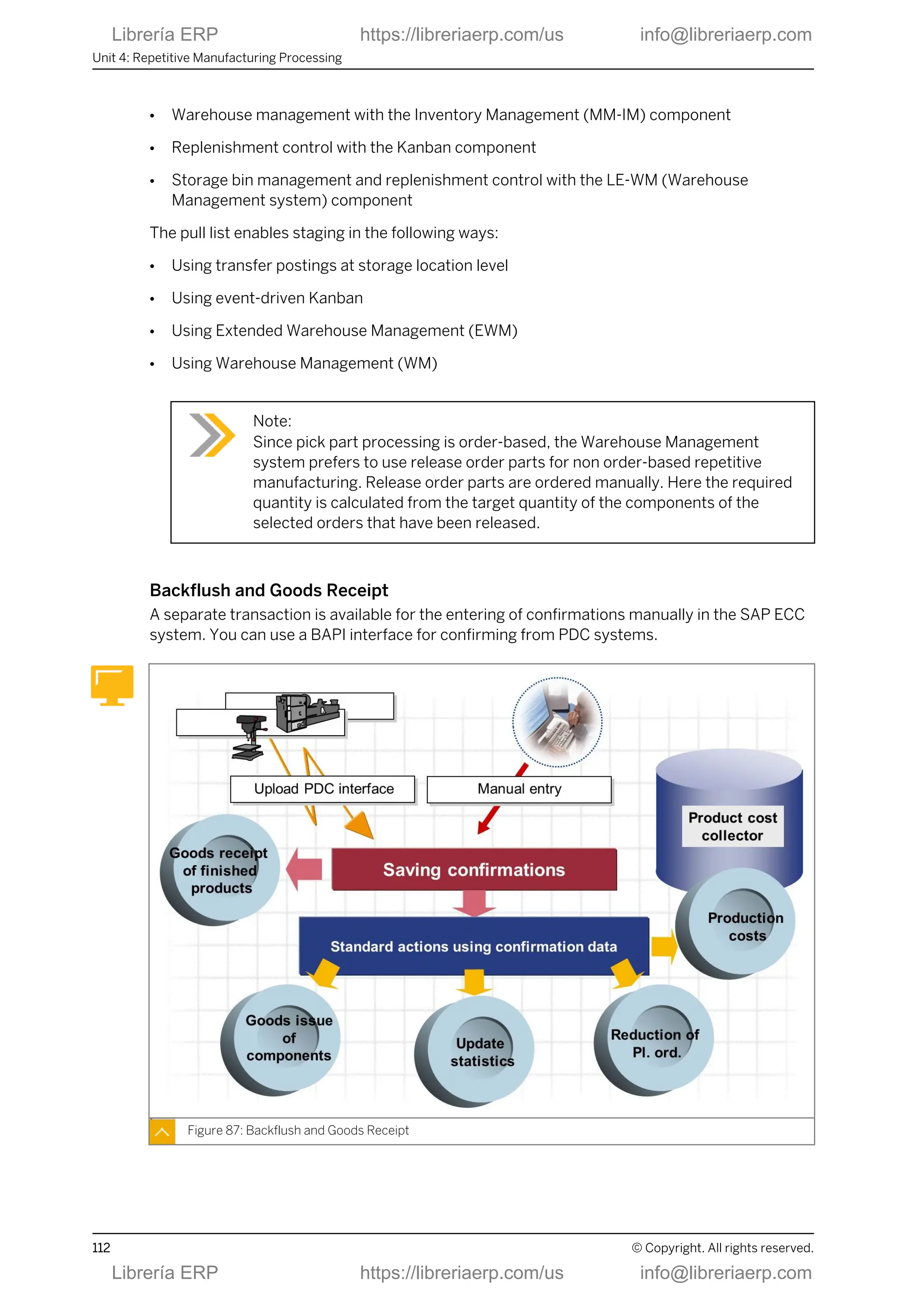

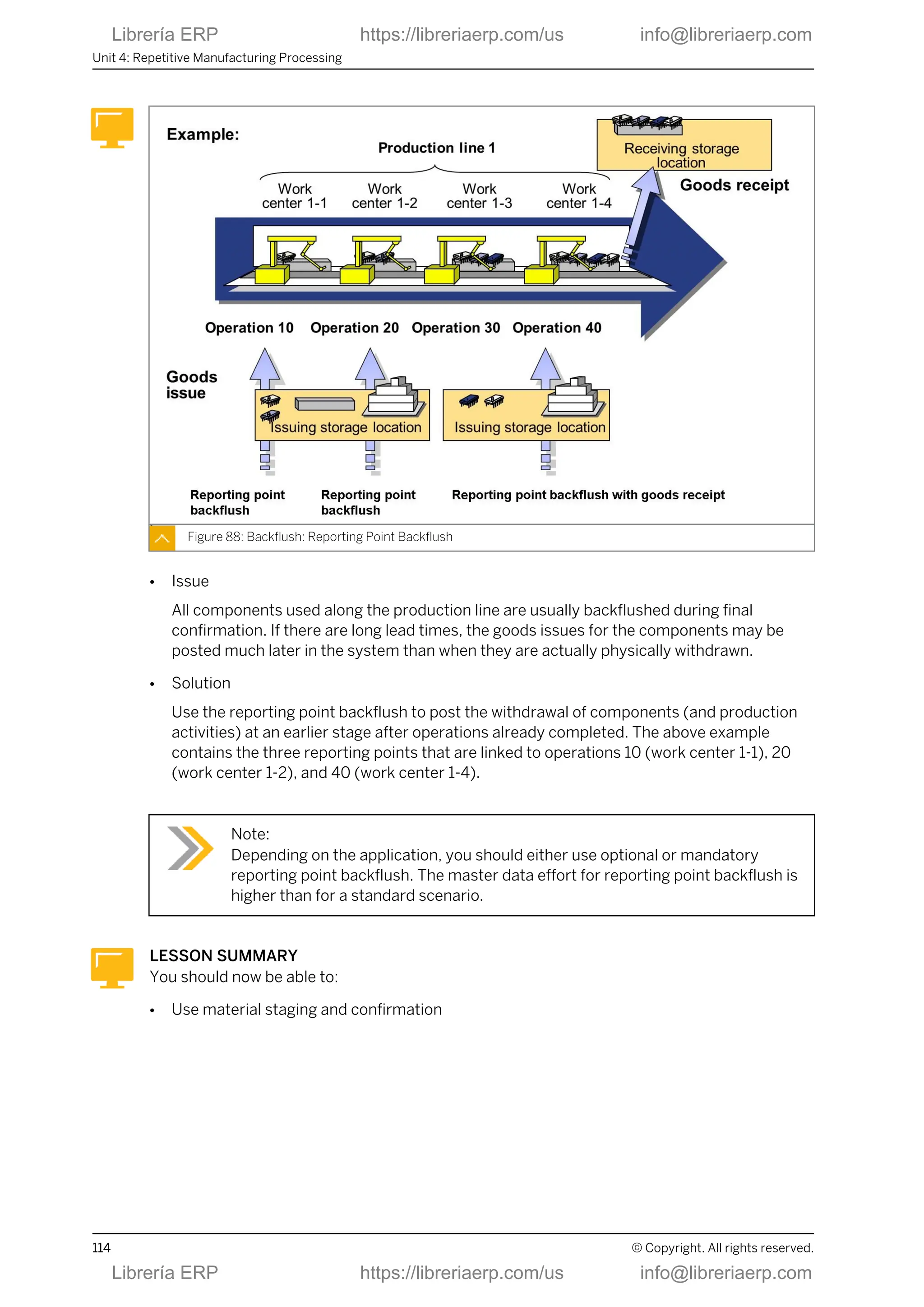

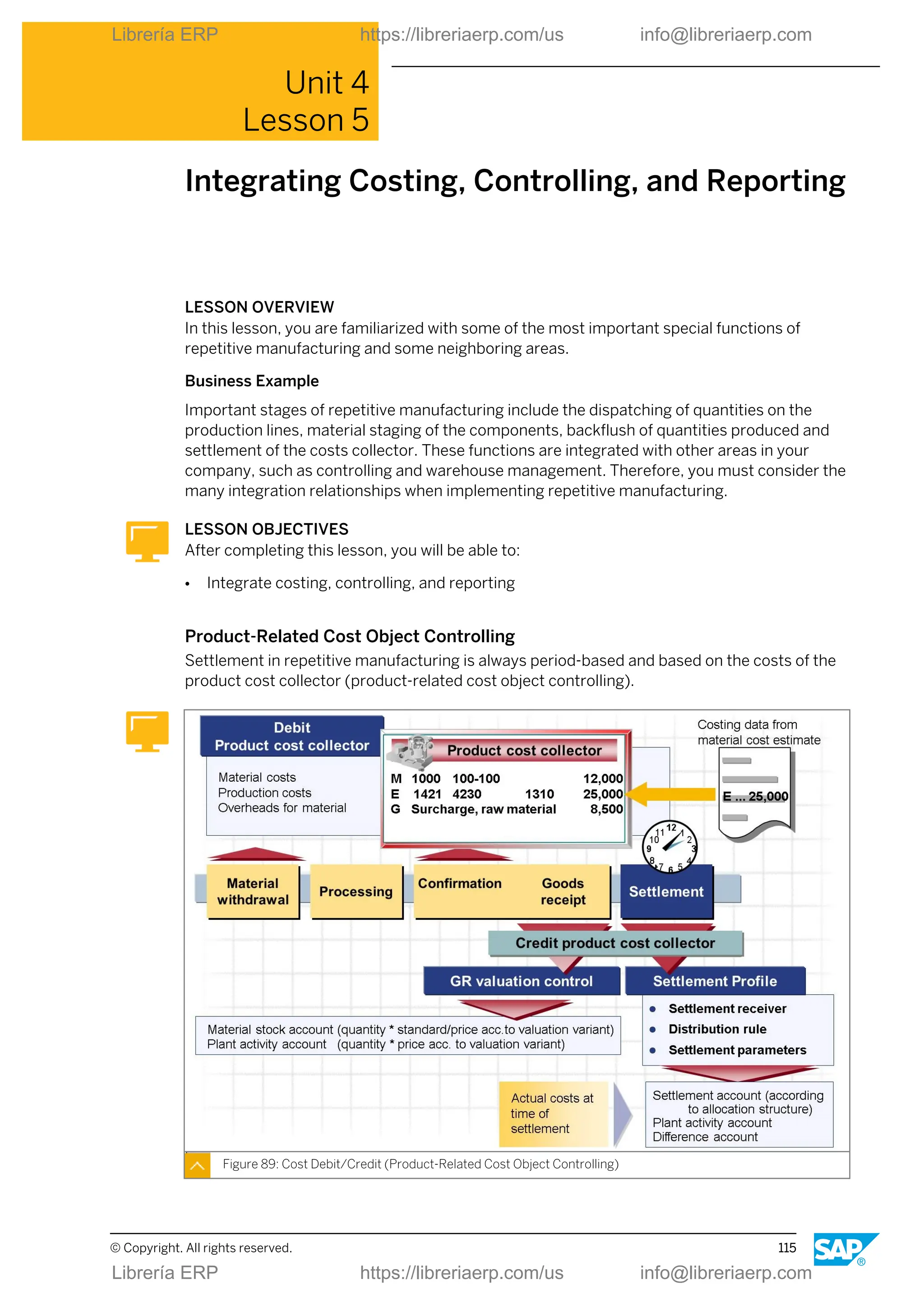

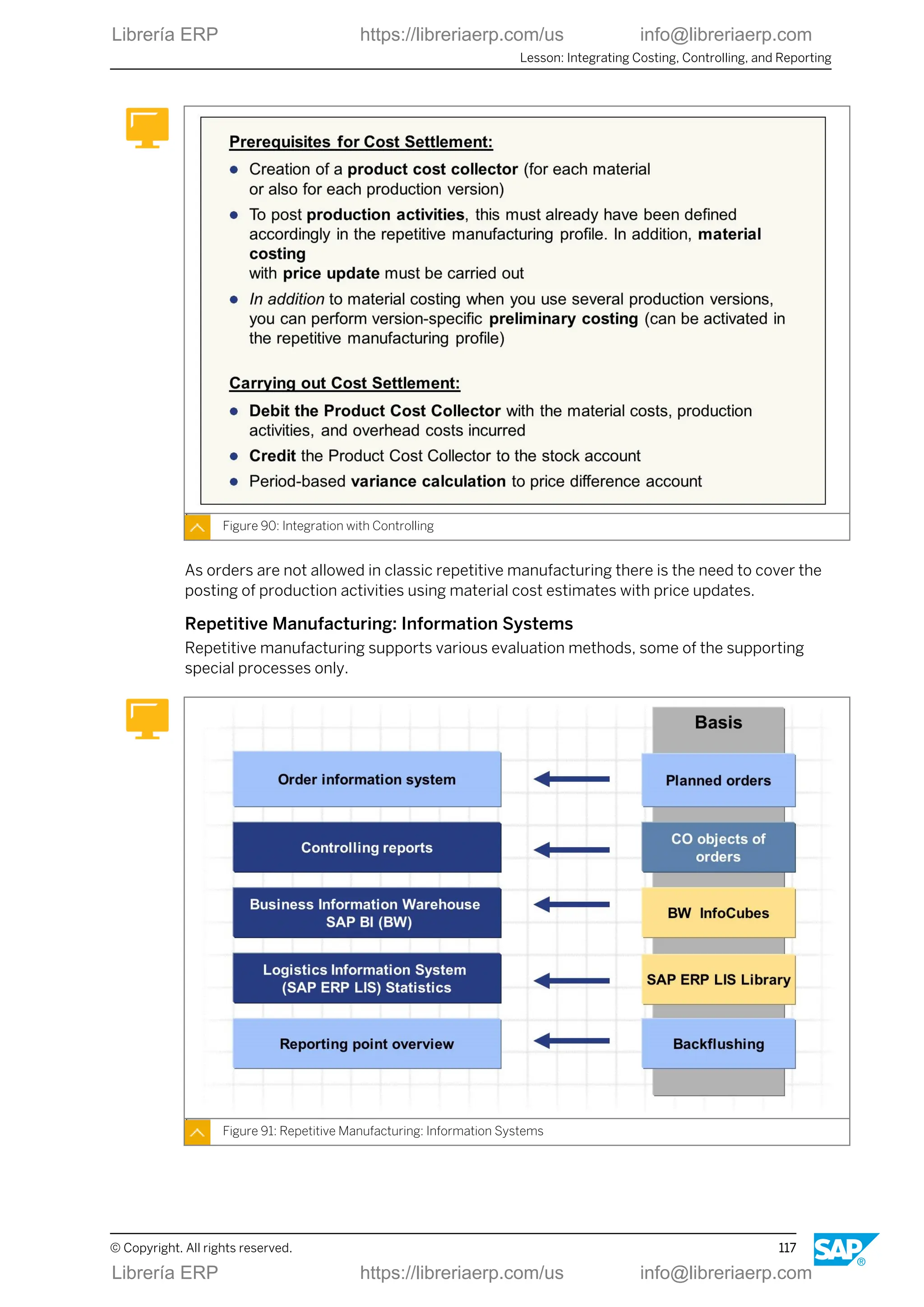

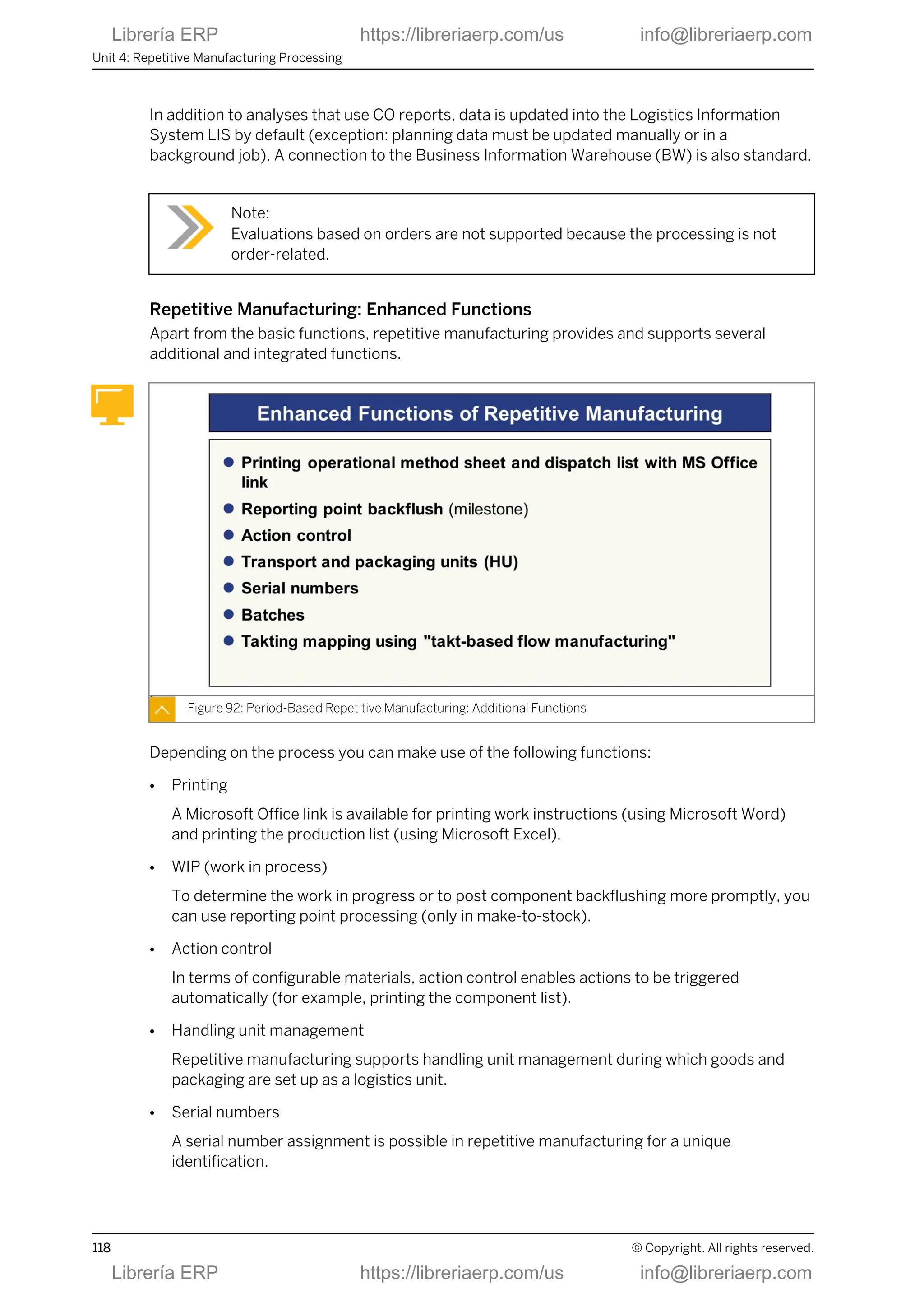

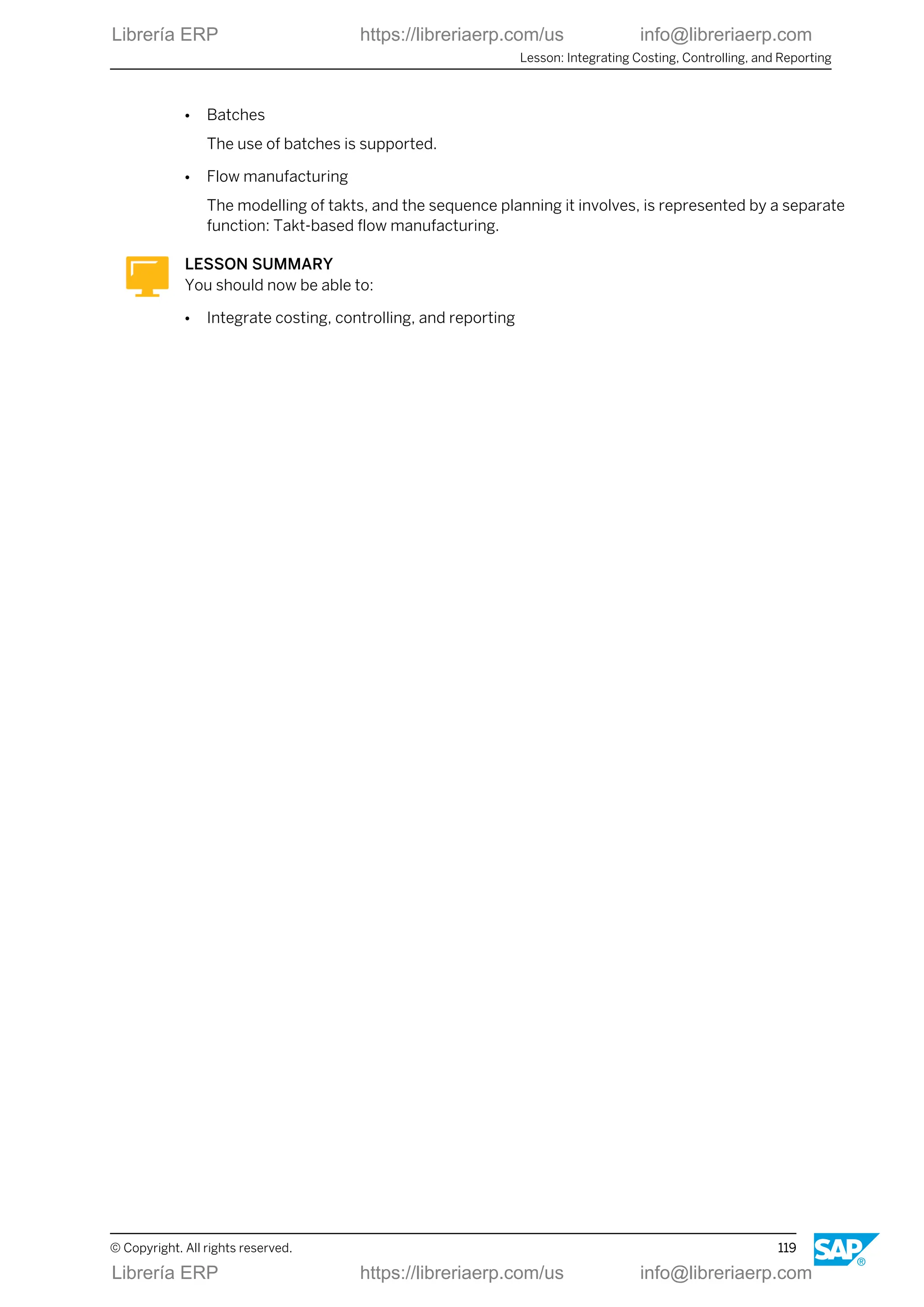

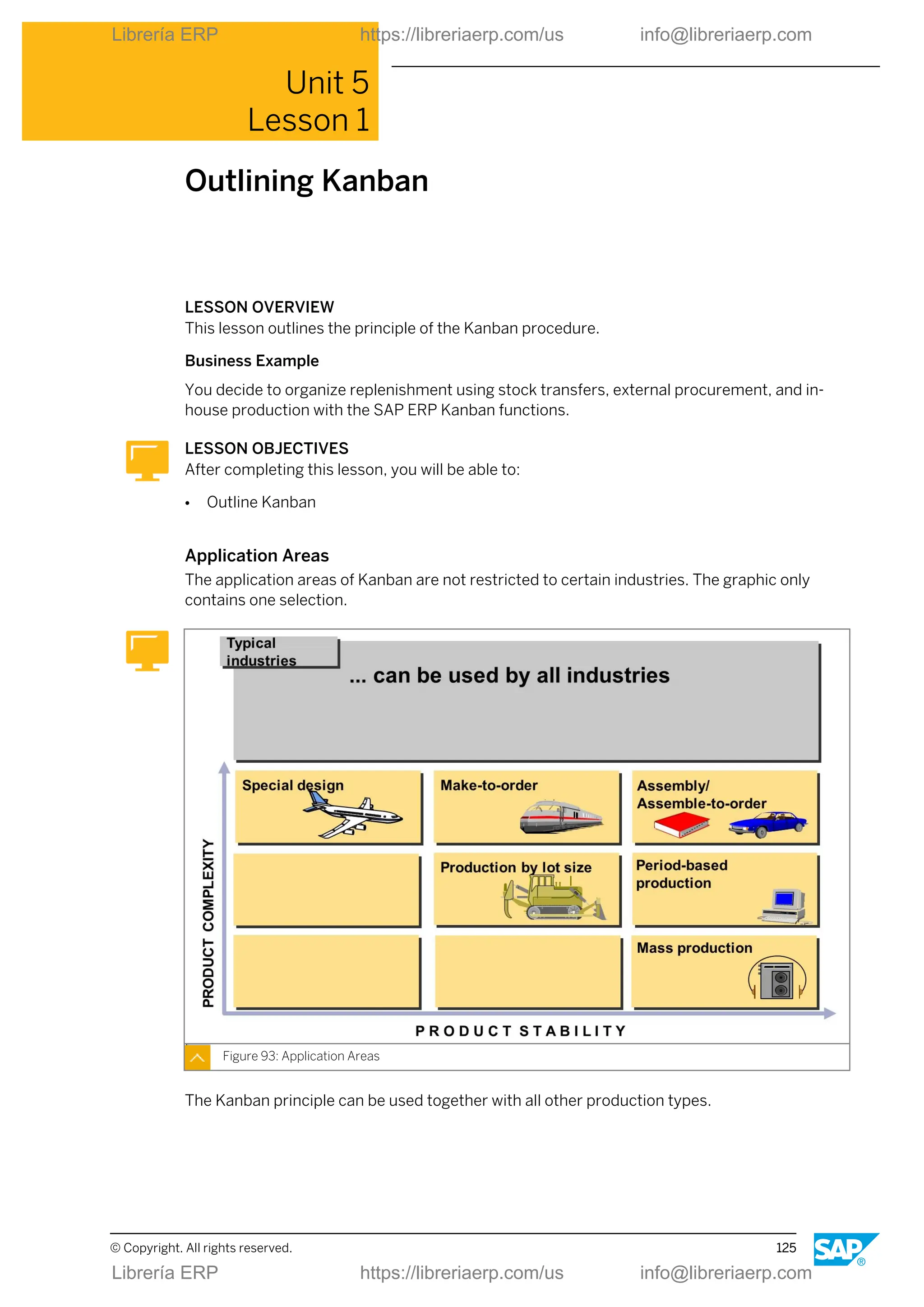

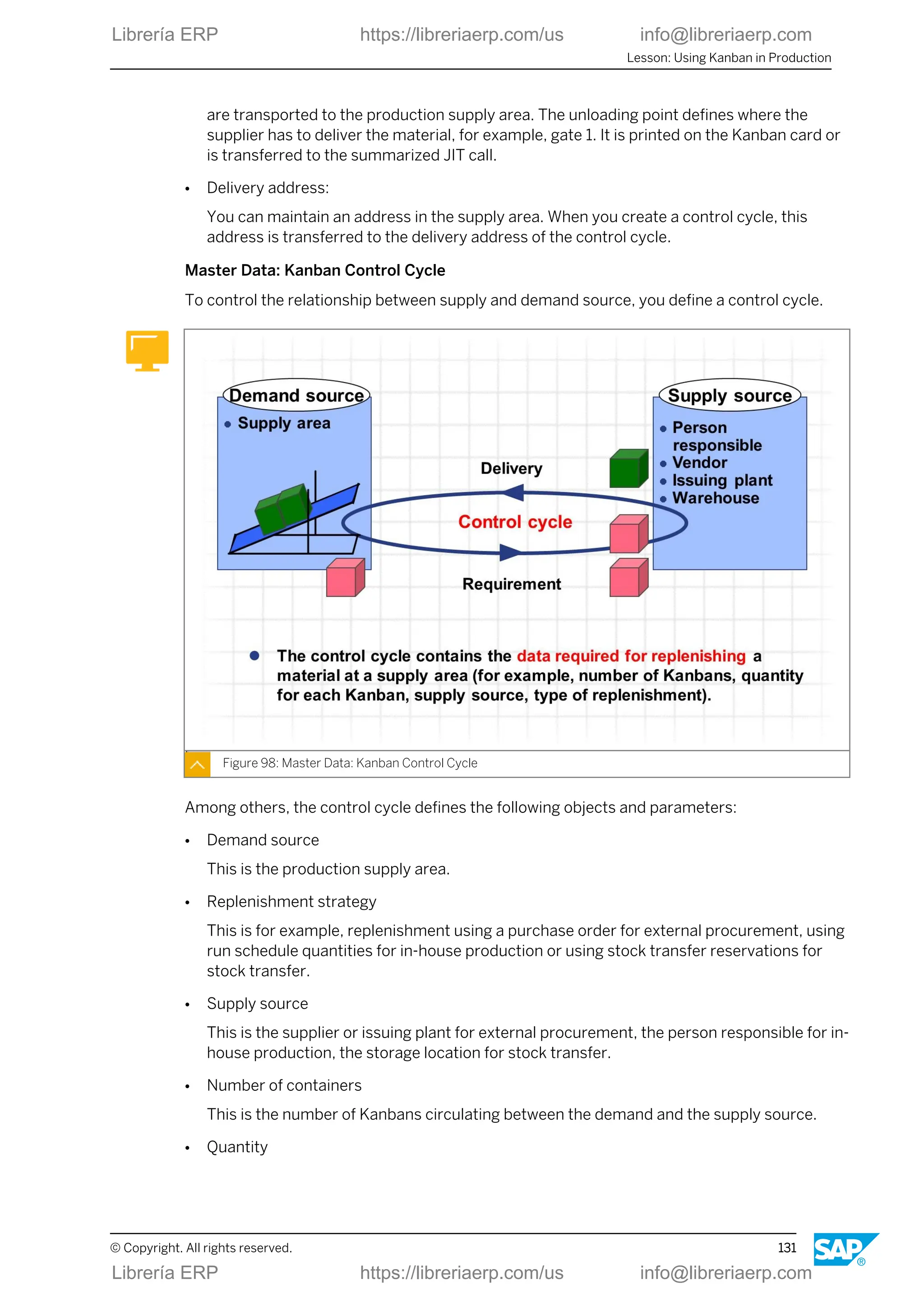

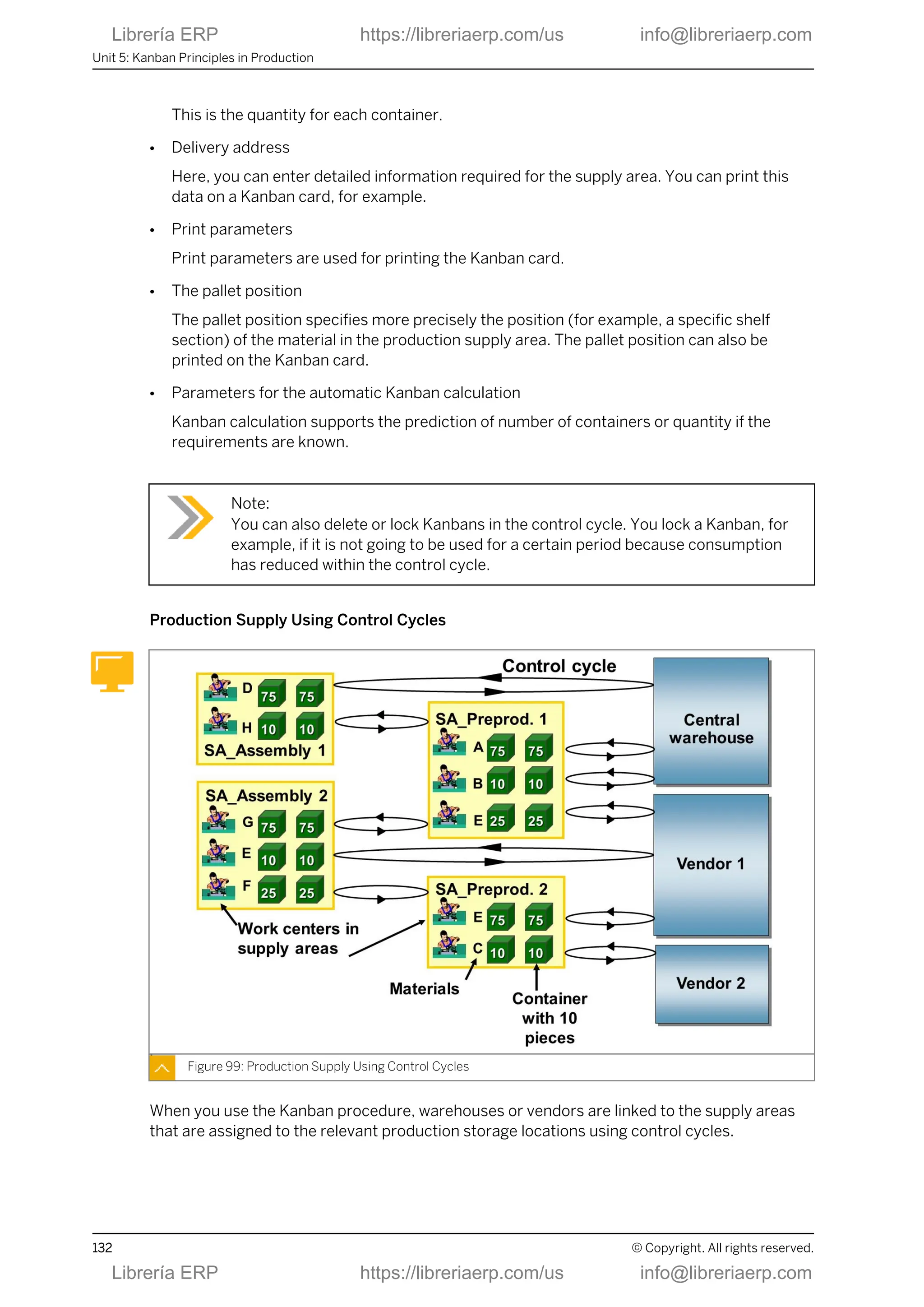

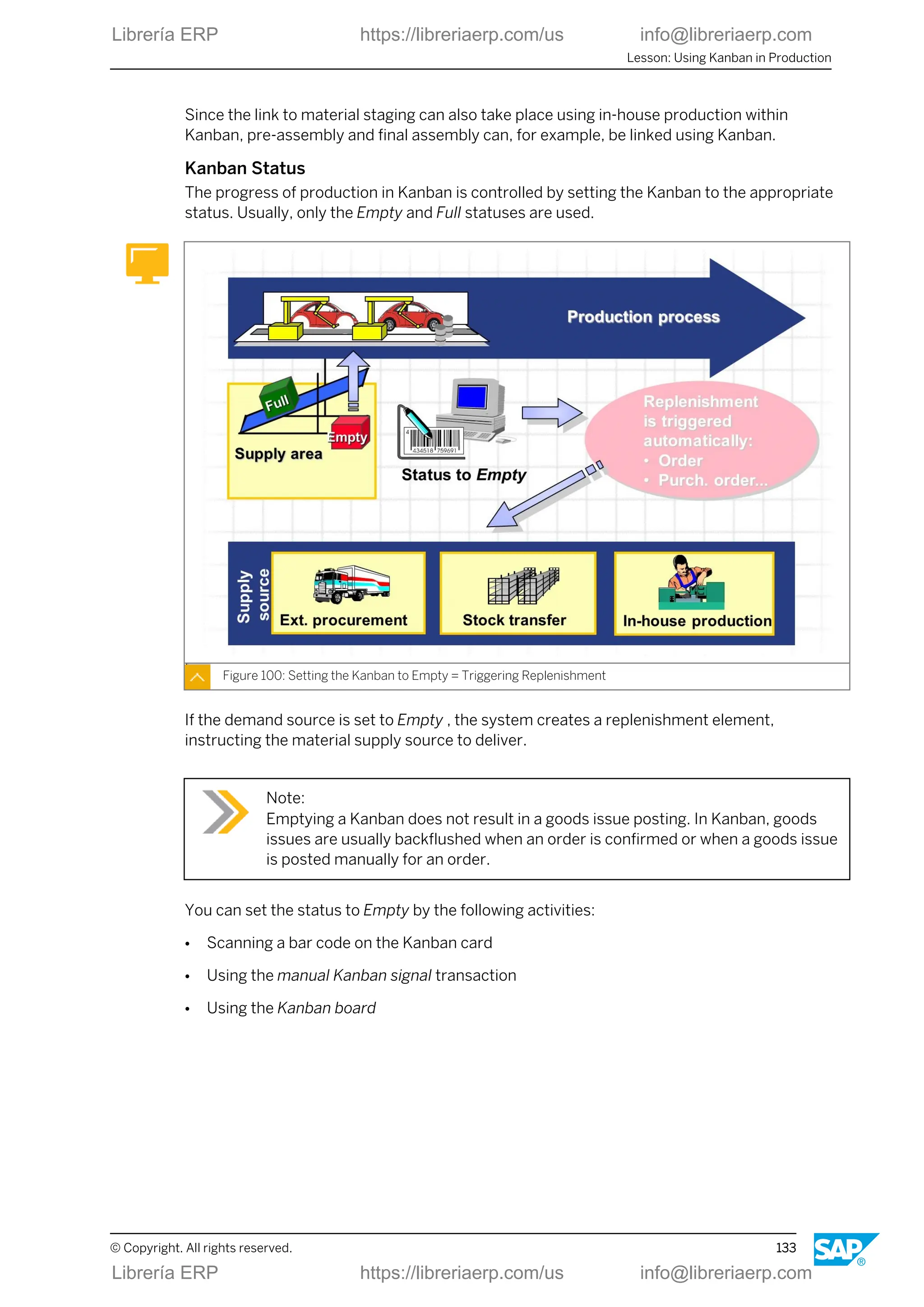

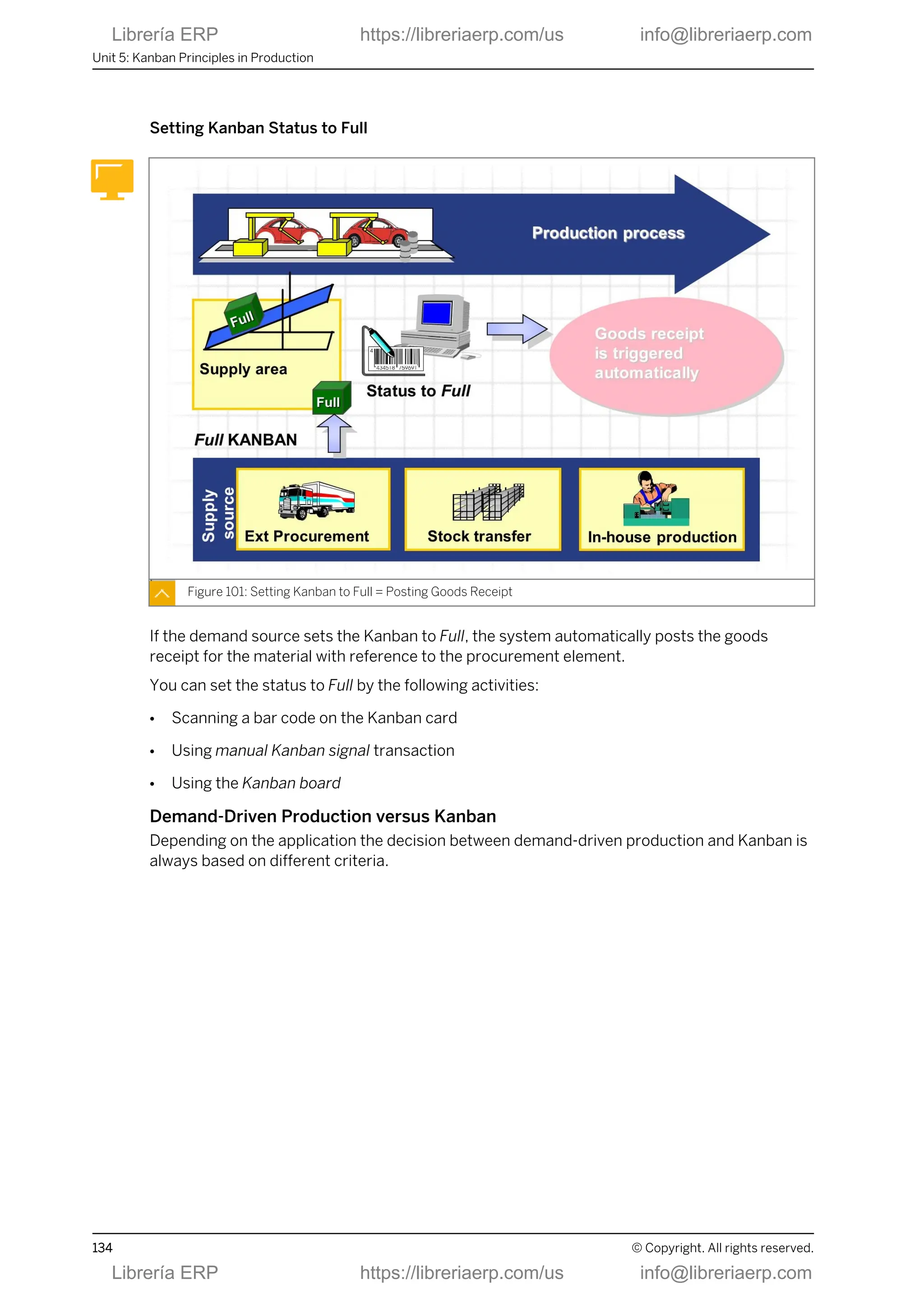

Discover the key manufacturing processes supported by SAP ERP. This guide provides an in-depth overview of production execution, process orders, repetitive manufacturing, and Kanban principles. Learn how to create and manage production orders, execute material staging, and integrate costing, controlling, and reporting for streamlined production operations.