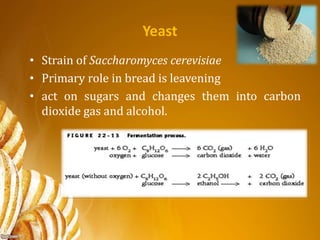

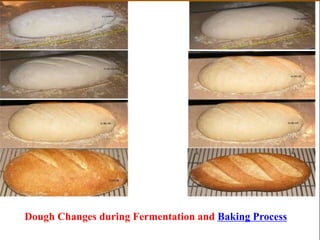

Breadmaking has evolved over thousands of years. The earliest breads in 4000 BC were flat and unleavened. The Egyptians later invented grinding materials and ovens and used leavening to produce lighter breads. Breadmaking skills were further refined by the Greeks and Romans, with the UK later establishing the first guild to standardize baking practices. Modern bread is made through a process including mixing ingredients like flour, water, yeast, and salt; proofing and shaping the dough; and baking. Yeast produces gases that cause the dough to rise during fermentation and baking.