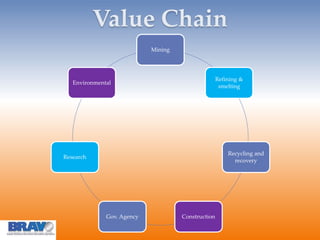

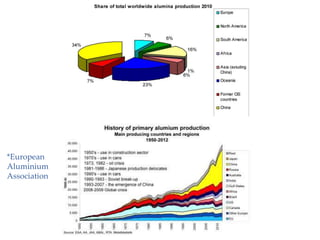

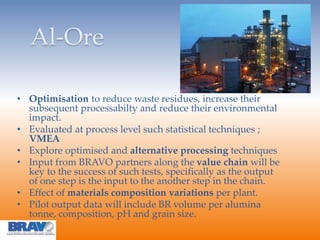

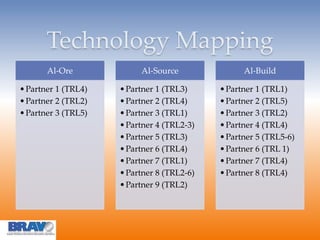

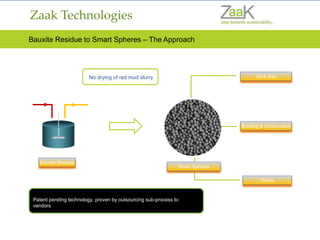

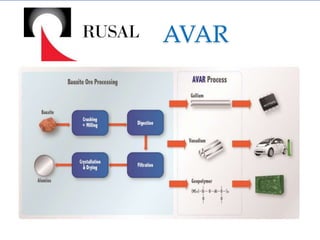

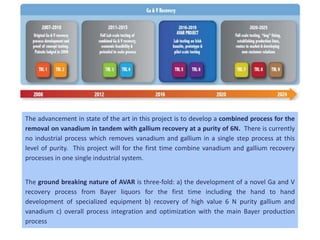

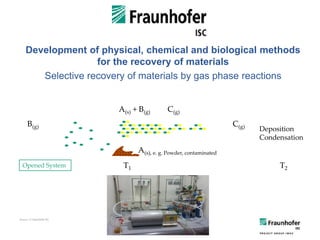

The document summarizes the objectives and activities of the BRAVO EIP project, which aims to boost innovation in the aluminum value chain to increase recovery of secondary raw materials. The project will foster cooperation among 40 organizations in mining, refining, recycling and other areas. It seeks to develop new value chains for recovered materials and test solutions through pilot actions. Key challenges addressed include managing bauxite residue and improving European competitiveness. The project involves several technology development modules focusing on optimizing residue, extracting valuable materials from it, using bulk residue in construction, and increasing awareness and skills. Partner organizations are mapped by technology readiness levels. Examples of innovative residue management technologies are provided.