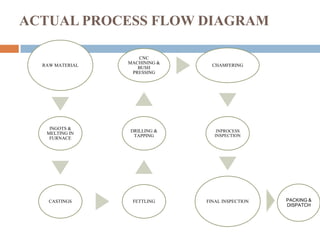

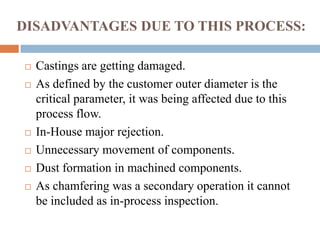

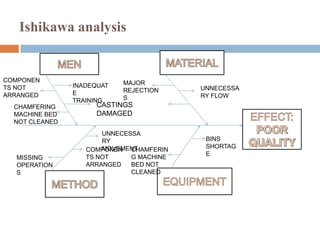

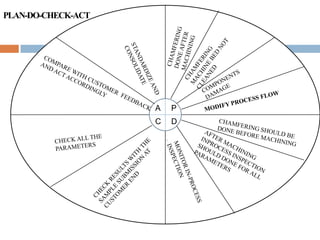

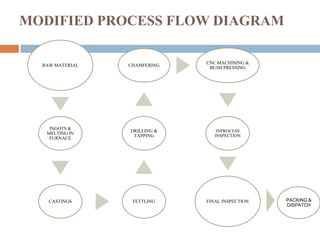

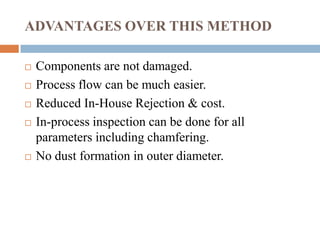

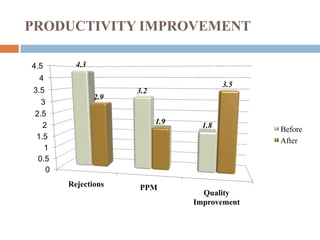

This document describes a process modification to improve the brake drum assembly process. The original process had chamfering as a secondary operation, which could damage components and lead to rejections. The modified process moves chamfering earlier in the process flow. This allows for in-process inspection of all parameters, prevents component damage, reduces rejections and costs, and improves quality and productivity. A pilot lot was submitted to the customer demonstrating the benefits of the new process flow.