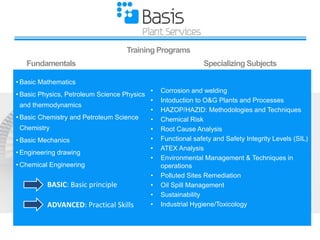

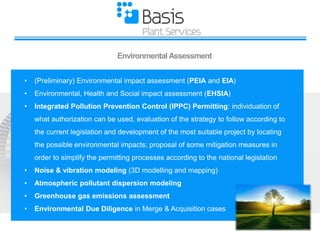

This document describes HSE (health, safety, and environment) services provided by Basis Plant Services. They offer (1) HSE training programs covering topics like environmental management, occupational health and safety, and risk analysis; (2) HSE supervision and coordination to support HSE policies and procedures; and (3) development and auditing of integrated HSE management systems to ensure compliance with standards. Their specialists have experience in risk assessment, permitting, and environmental impact evaluation to provide high quality HSE consulting services.