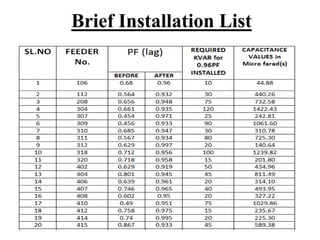

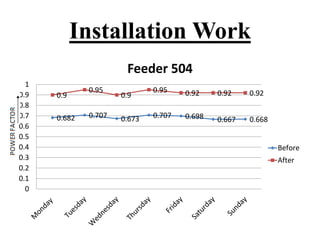

This document analyzes improving the power factor at a Bosch shop floor by installing a capacitor bank. It defines power factor and discusses causes of low power factor like induction motors and transformers. Installing static capacitors is identified as a remedy to compensate for reactive power consumption. Calculations show the capacitor bank improved the power factor from 0.763 to 0.96, reducing power losses by 2.621KW and saving 1179.45KWh per year, equating to cost savings of 84920.4 rupees annually. Installation work and its effects on various feeders are discussed. In conclusion, the power factor was improved from 0.65-0.85 to 0.95-0.99,