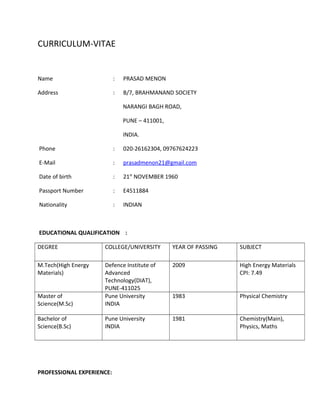

Prasad Menon has over 30 years of experience working with energetic materials and explosives at the High Energy Materials Research Laboratory in India. He has a M.Tech in High Energy Materials and B.Sc degrees in chemistry, physics, and math. His experience includes developing and producing explosives like dense nitrocellulose, HMX, TATB, and FOX-7. He has trained personnel and given lectures on properties and safety of energetic materials. Menon is looking for a position that offers a competitive salary commensurate with his extensive experience in the field of energetic materials research and production.