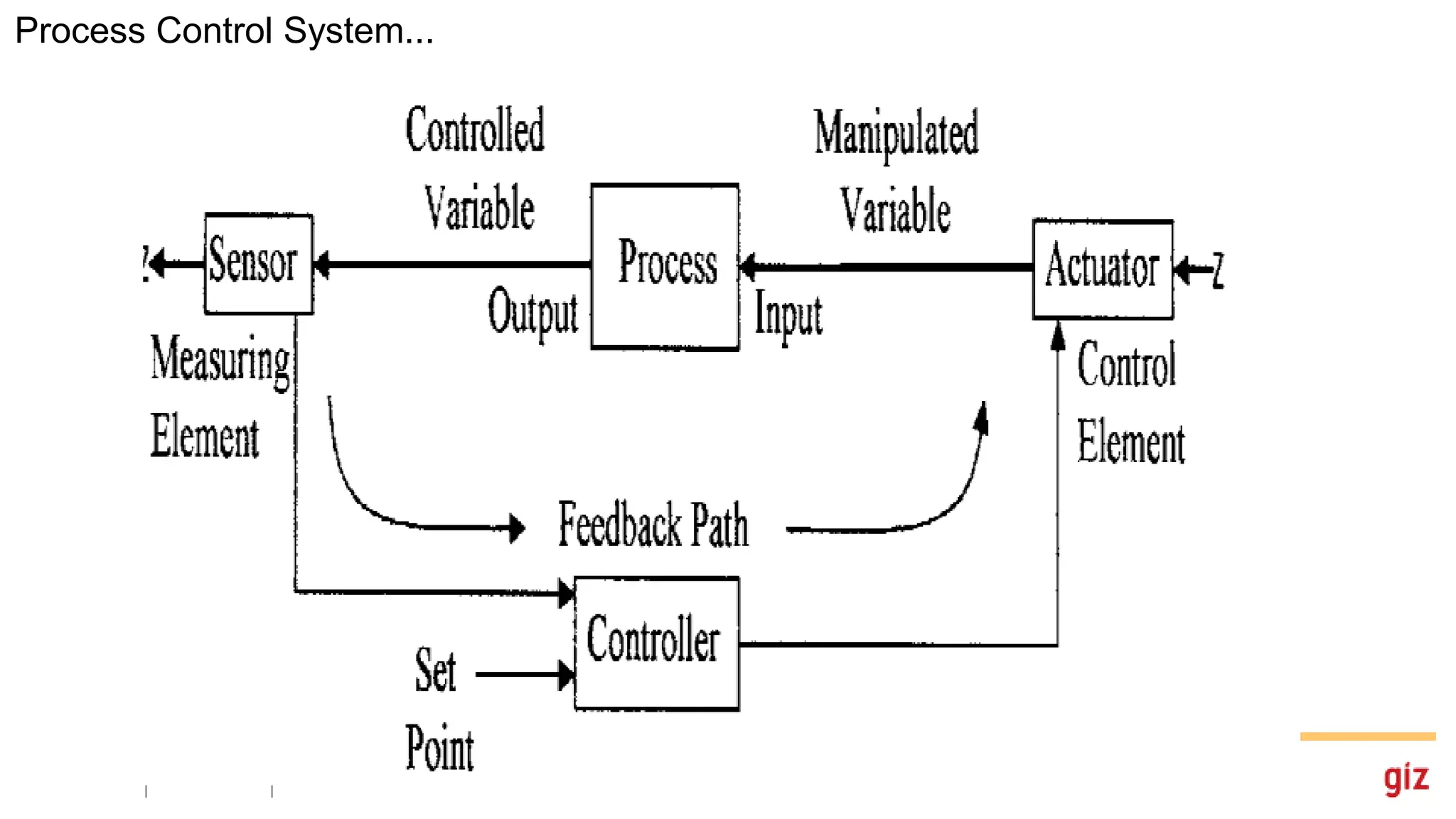

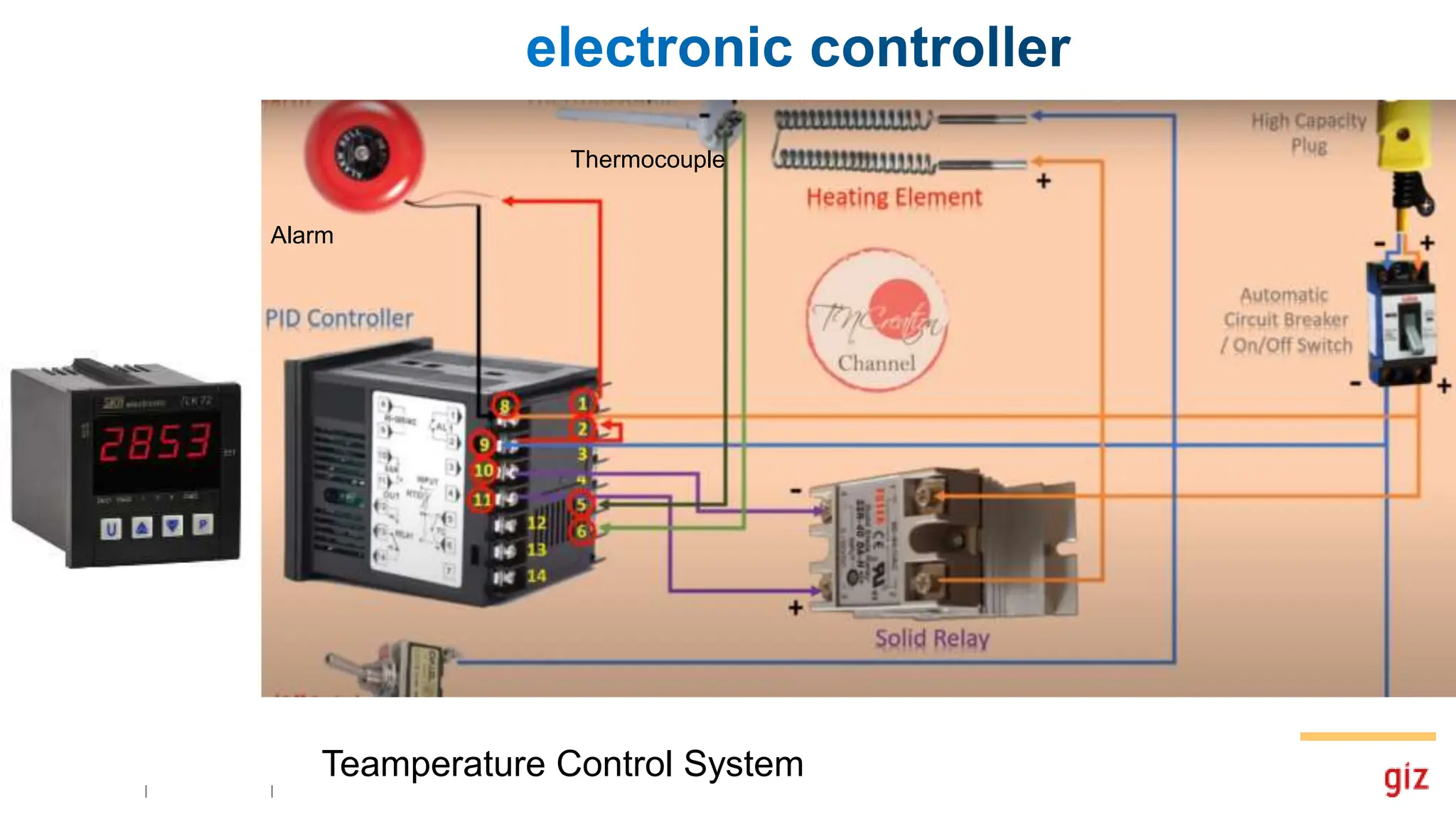

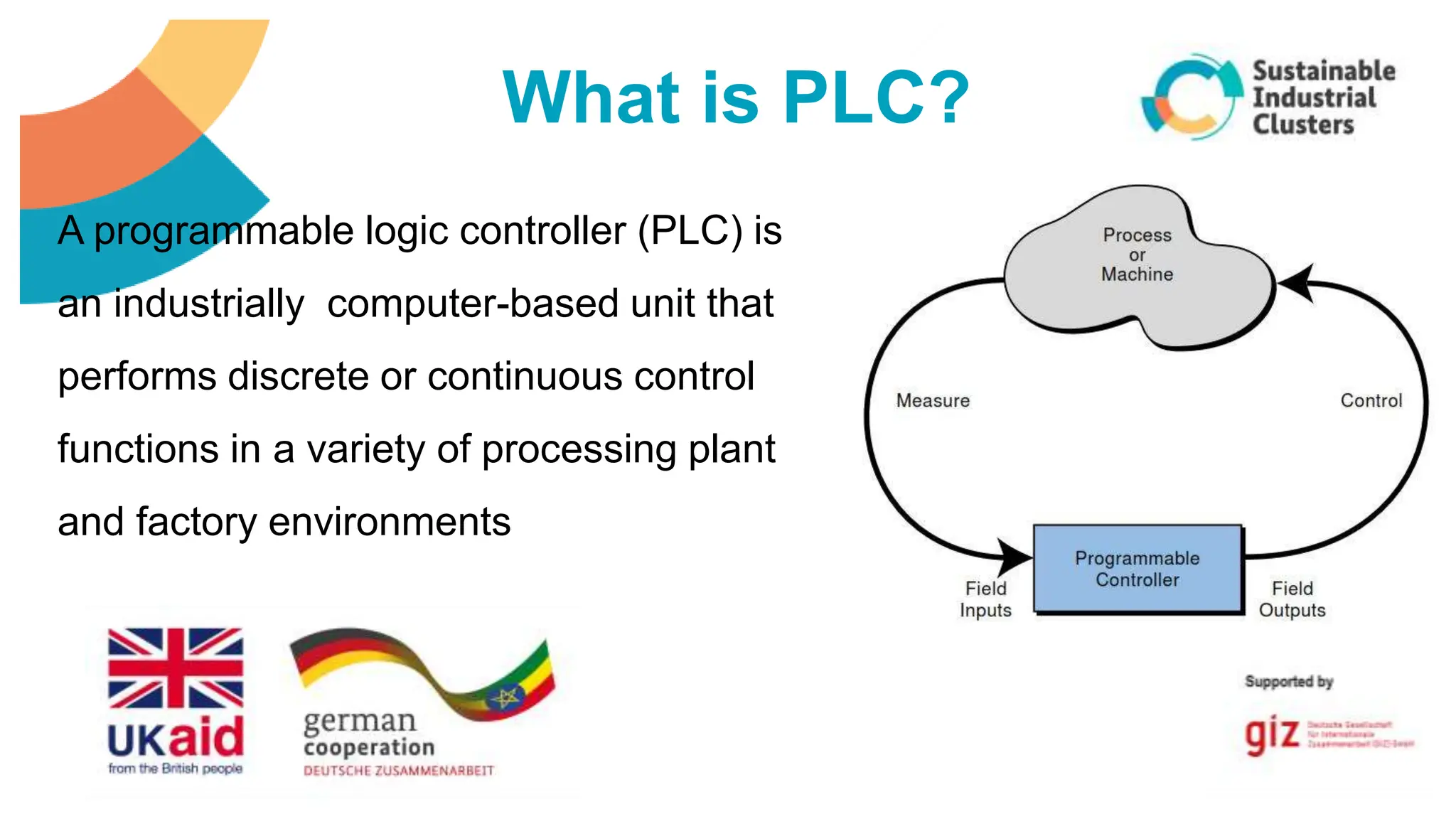

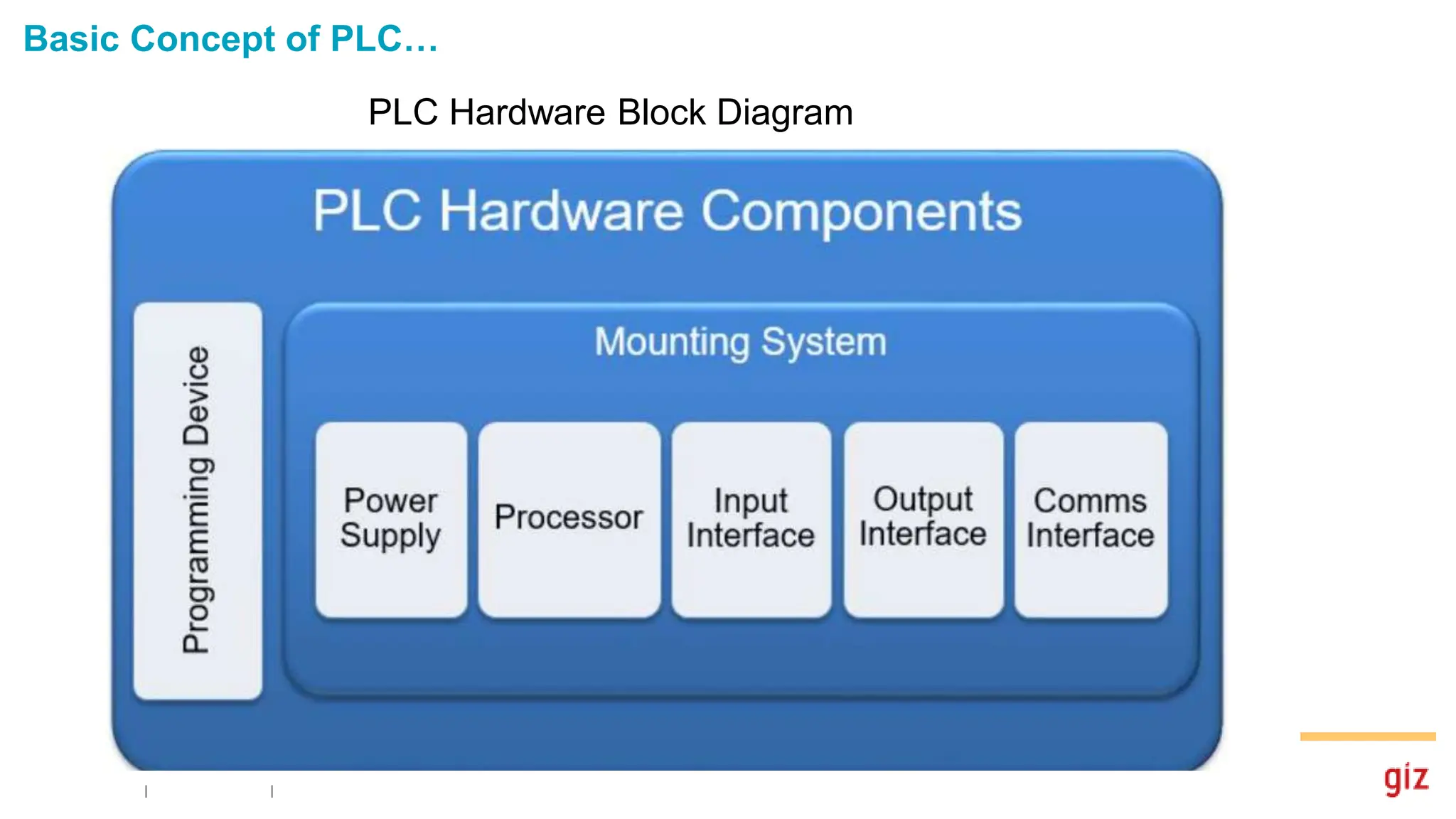

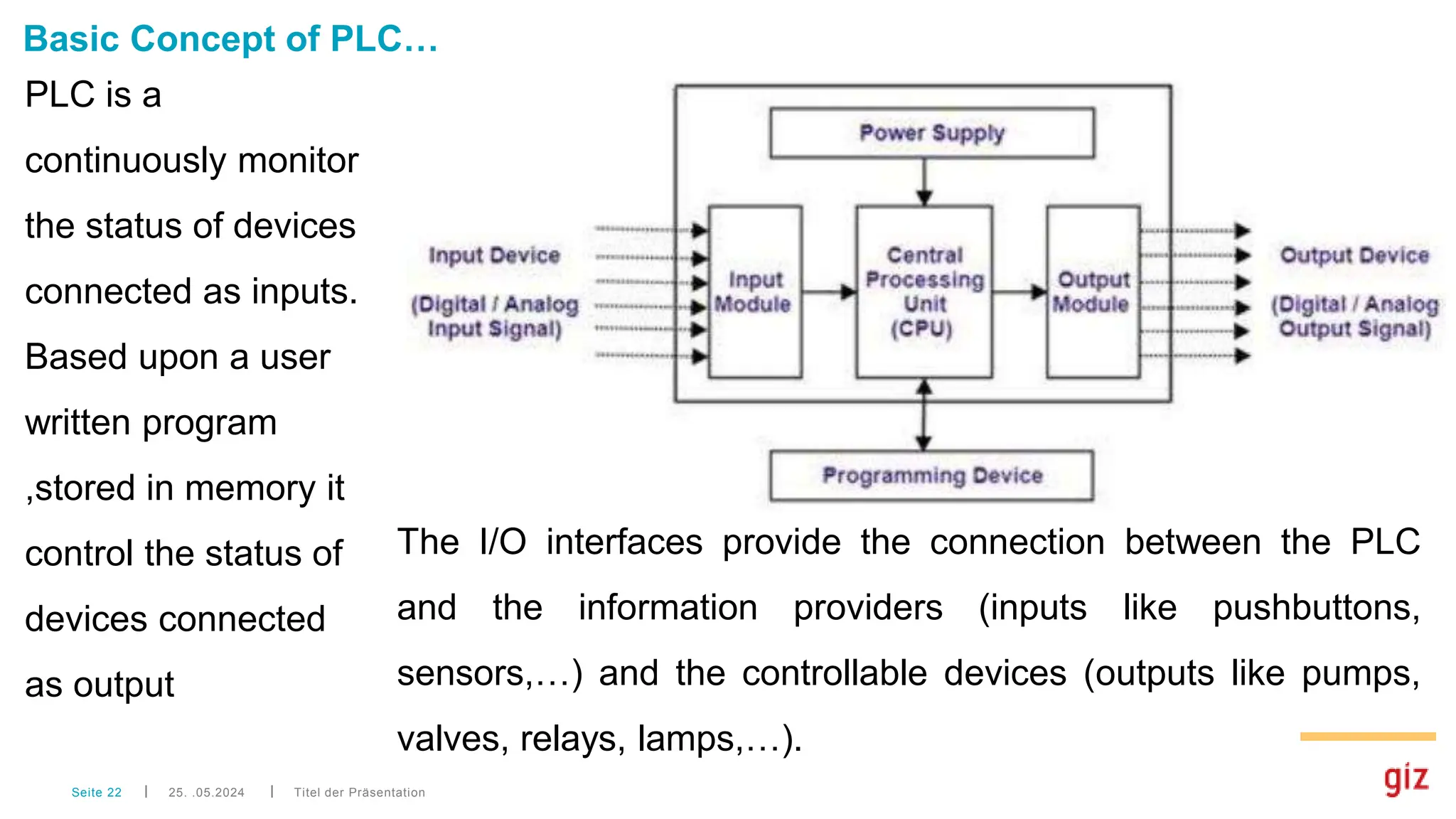

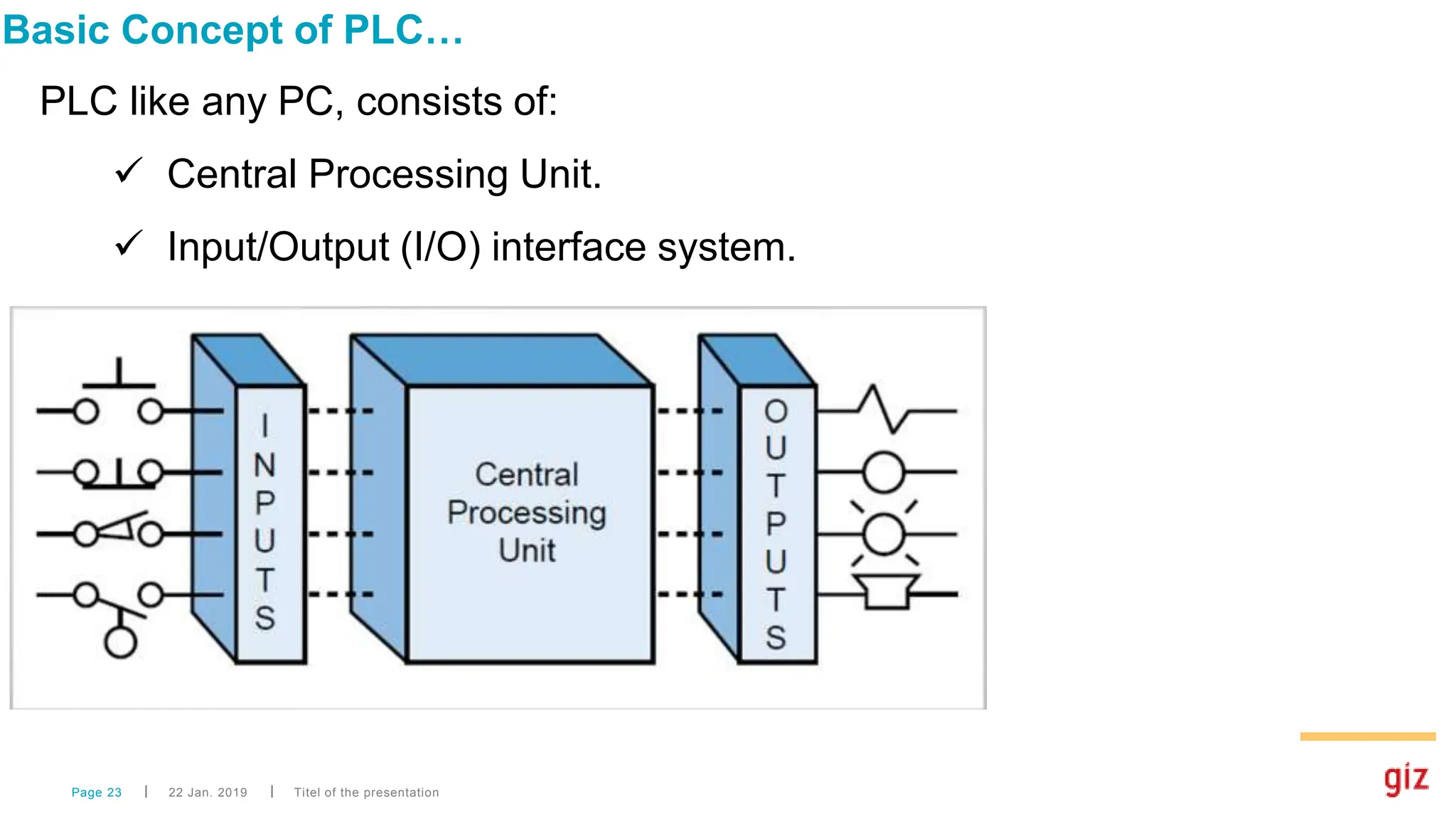

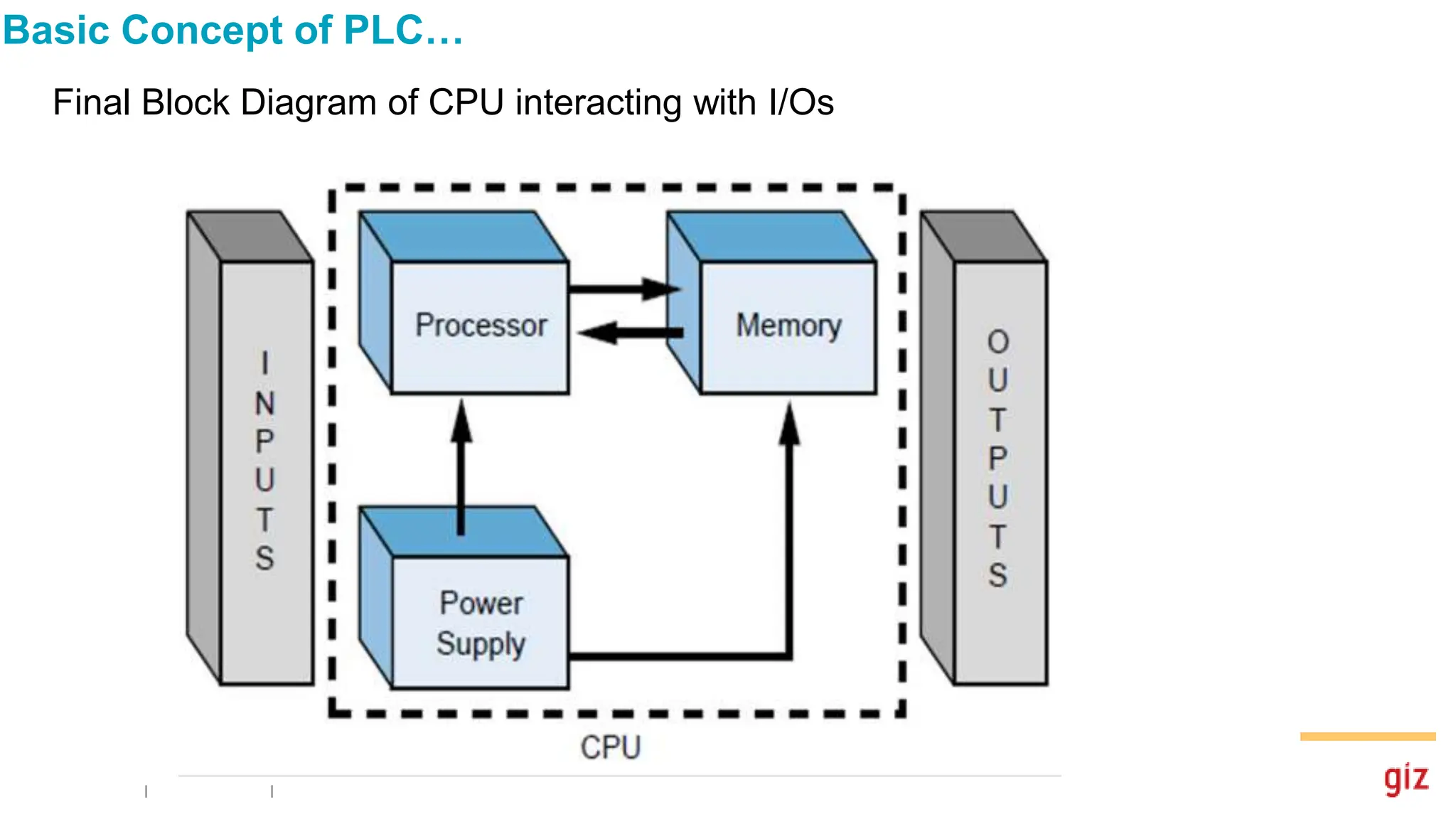

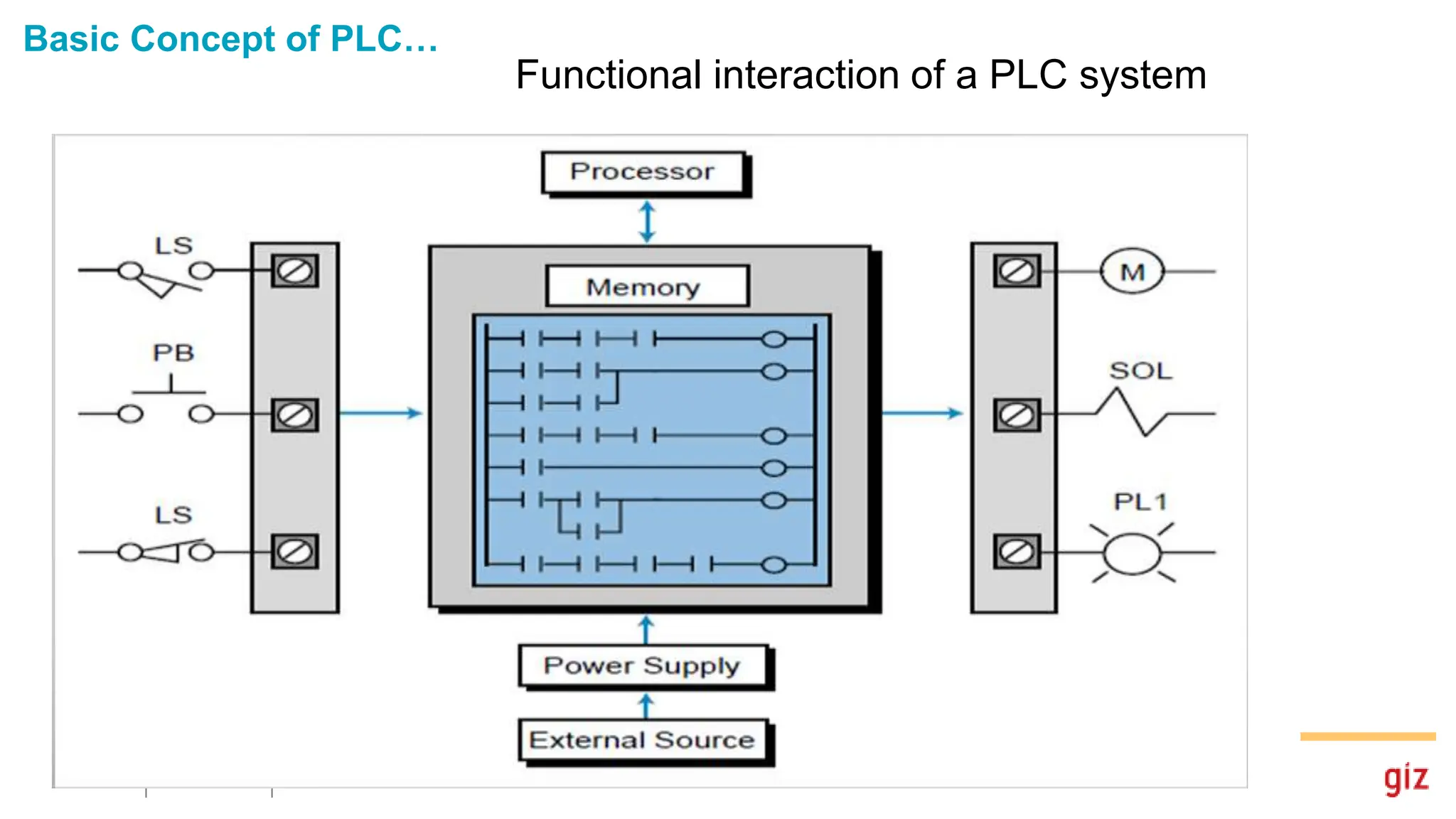

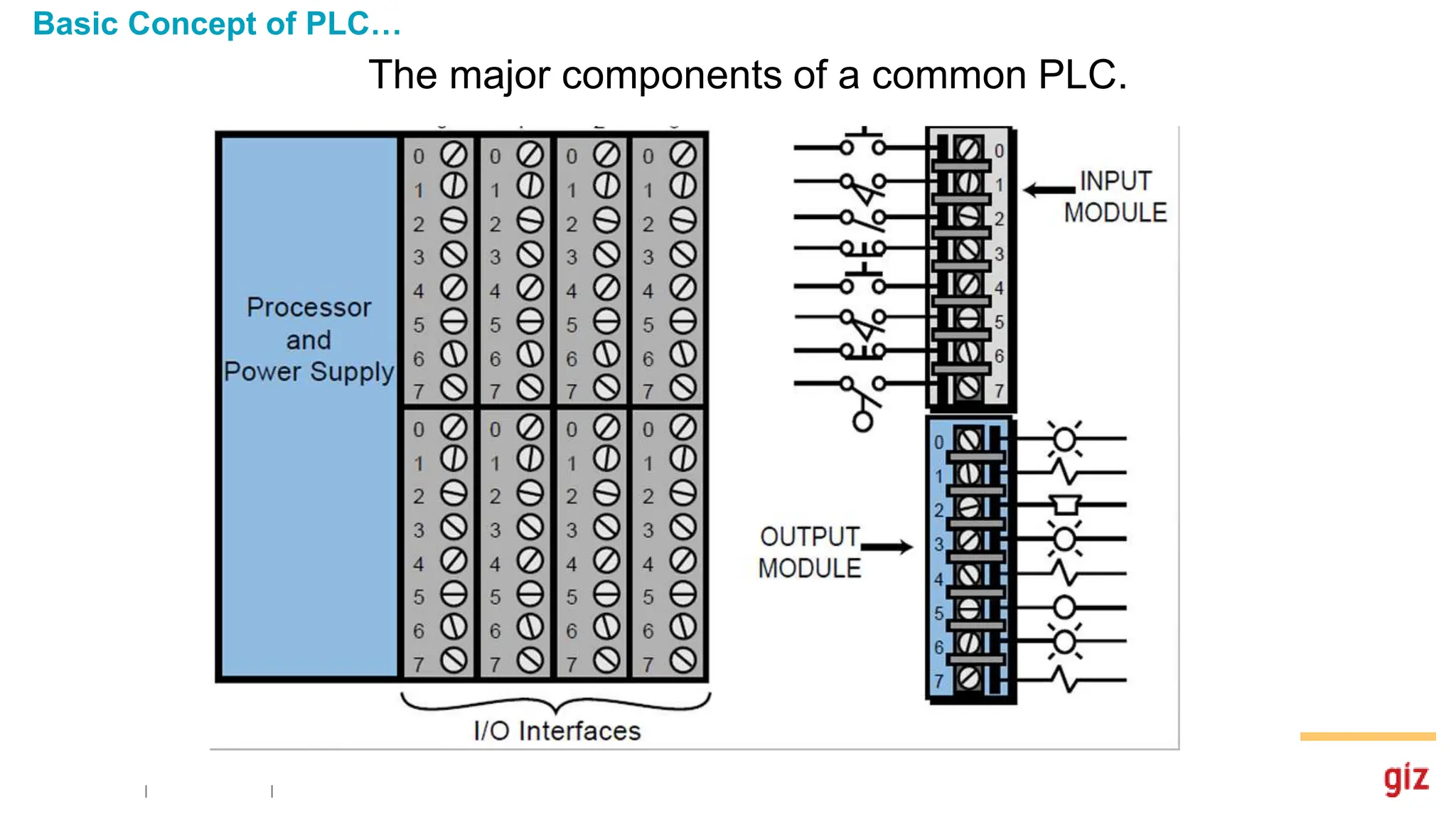

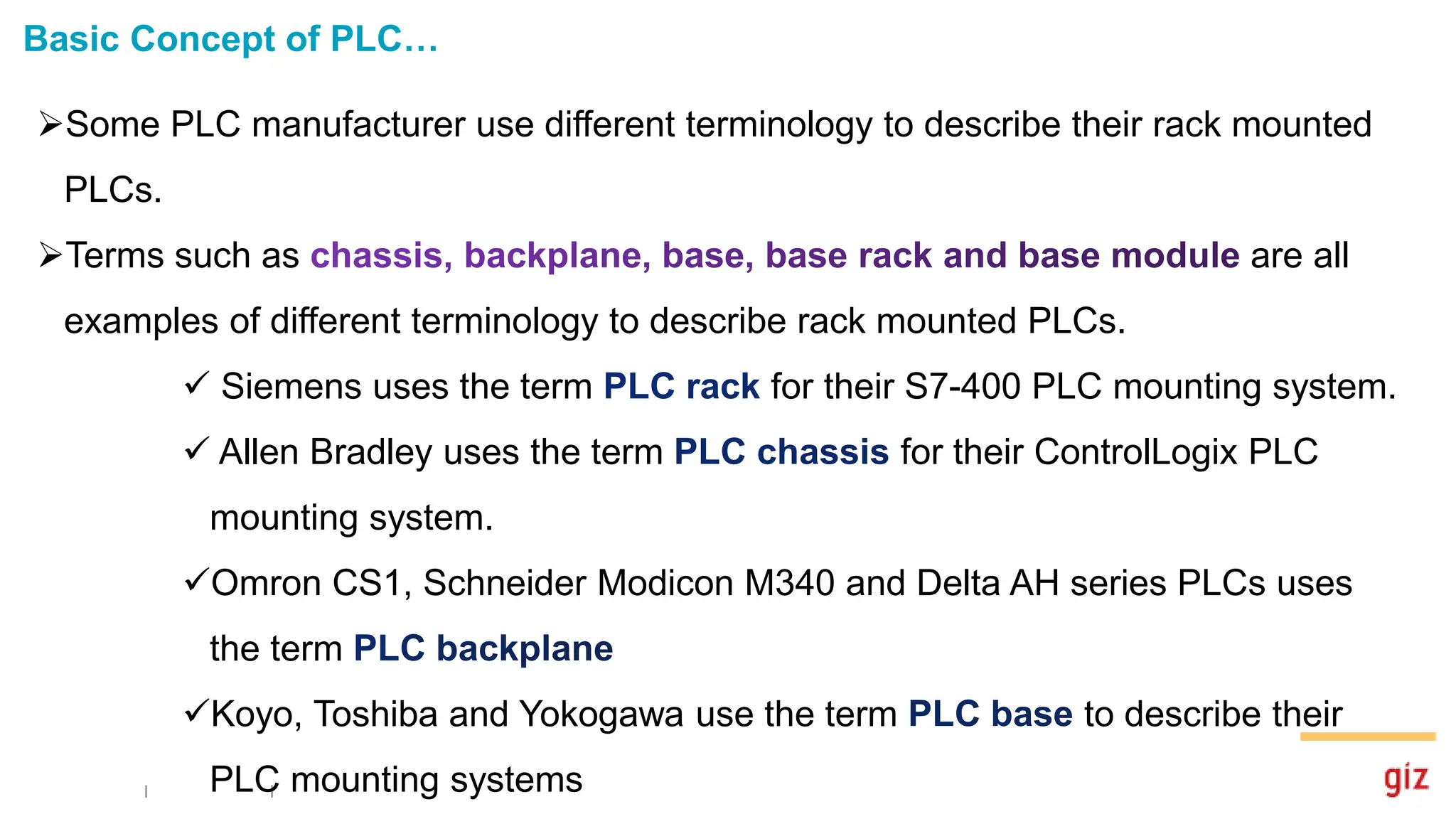

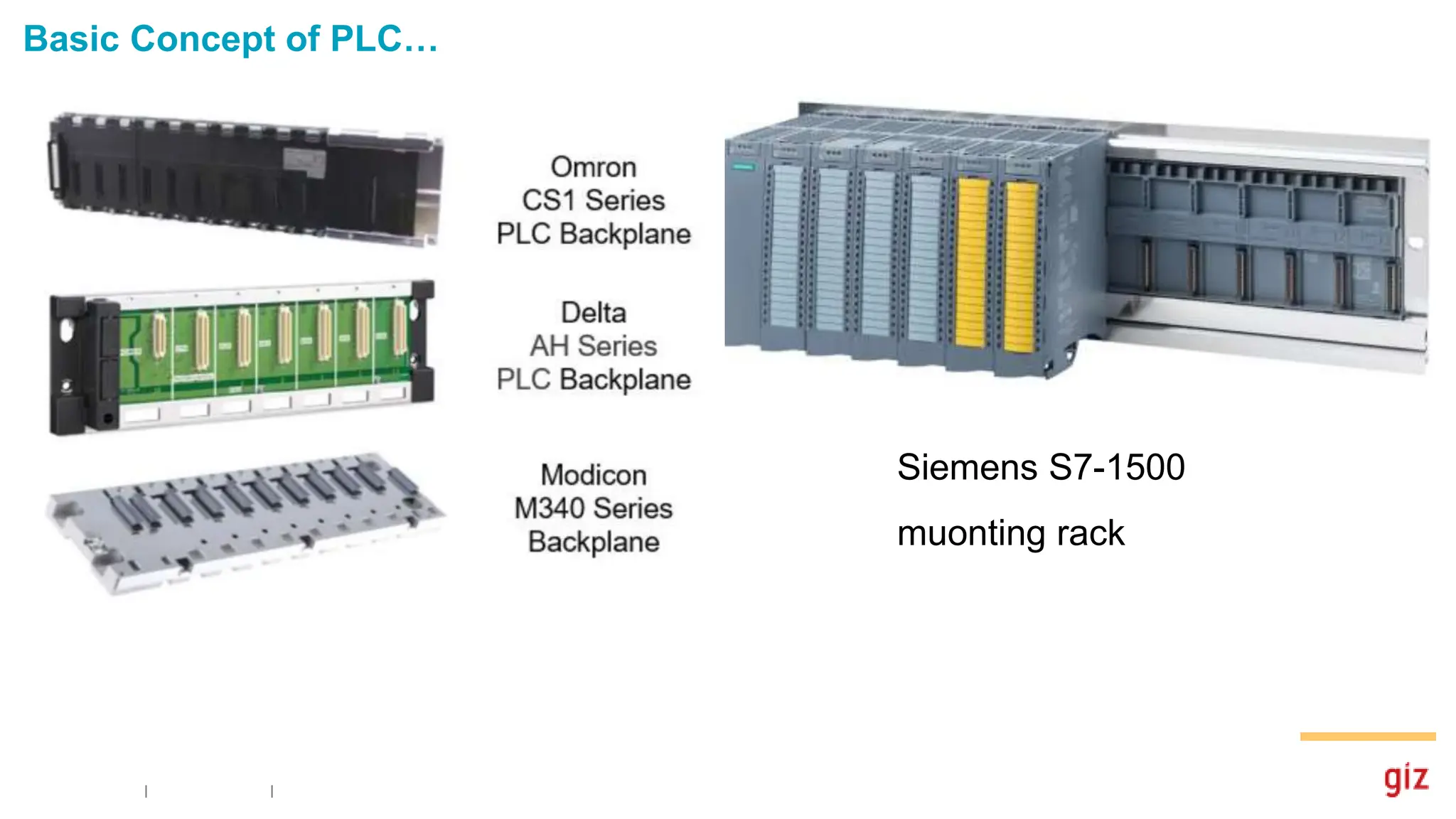

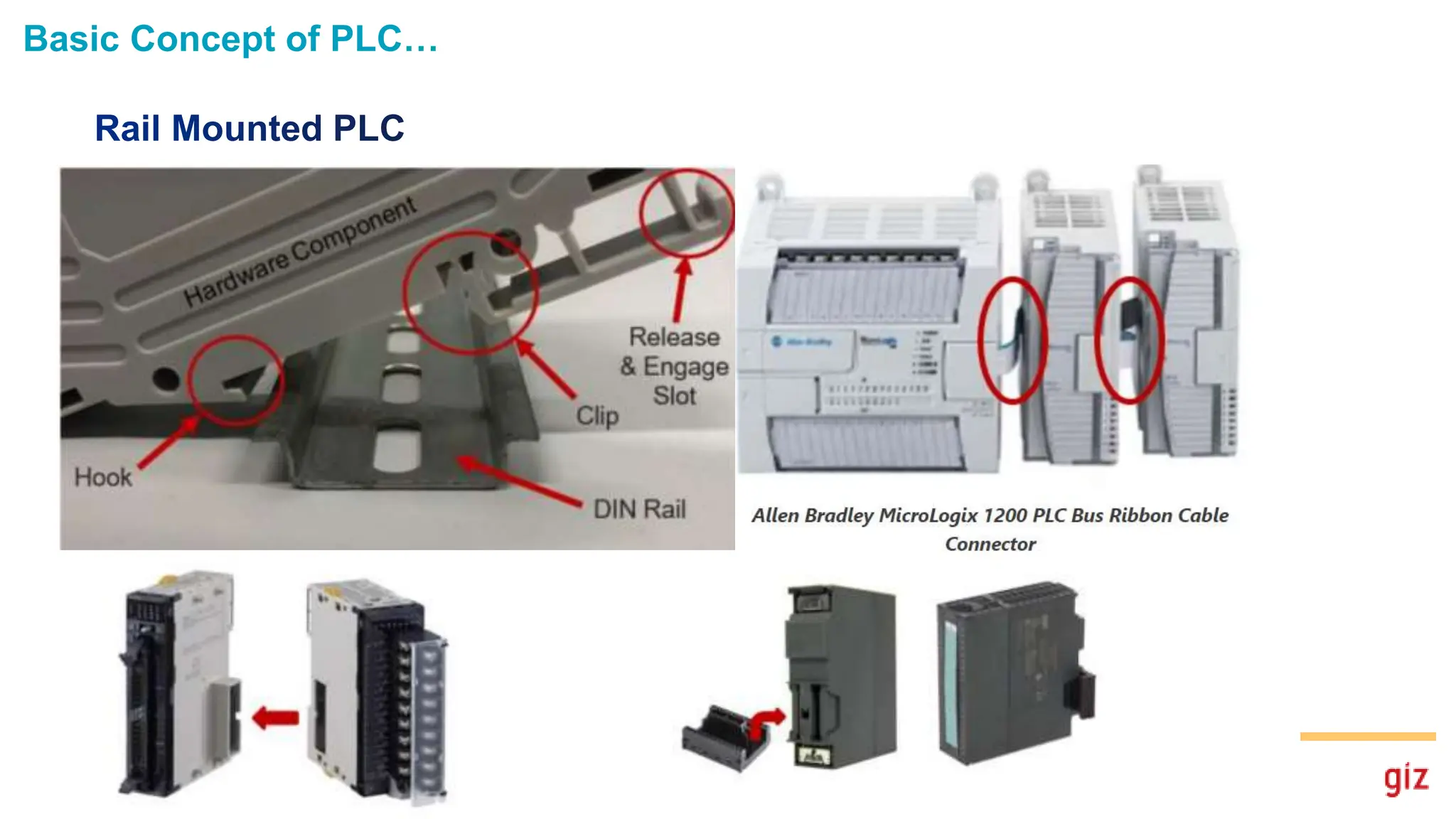

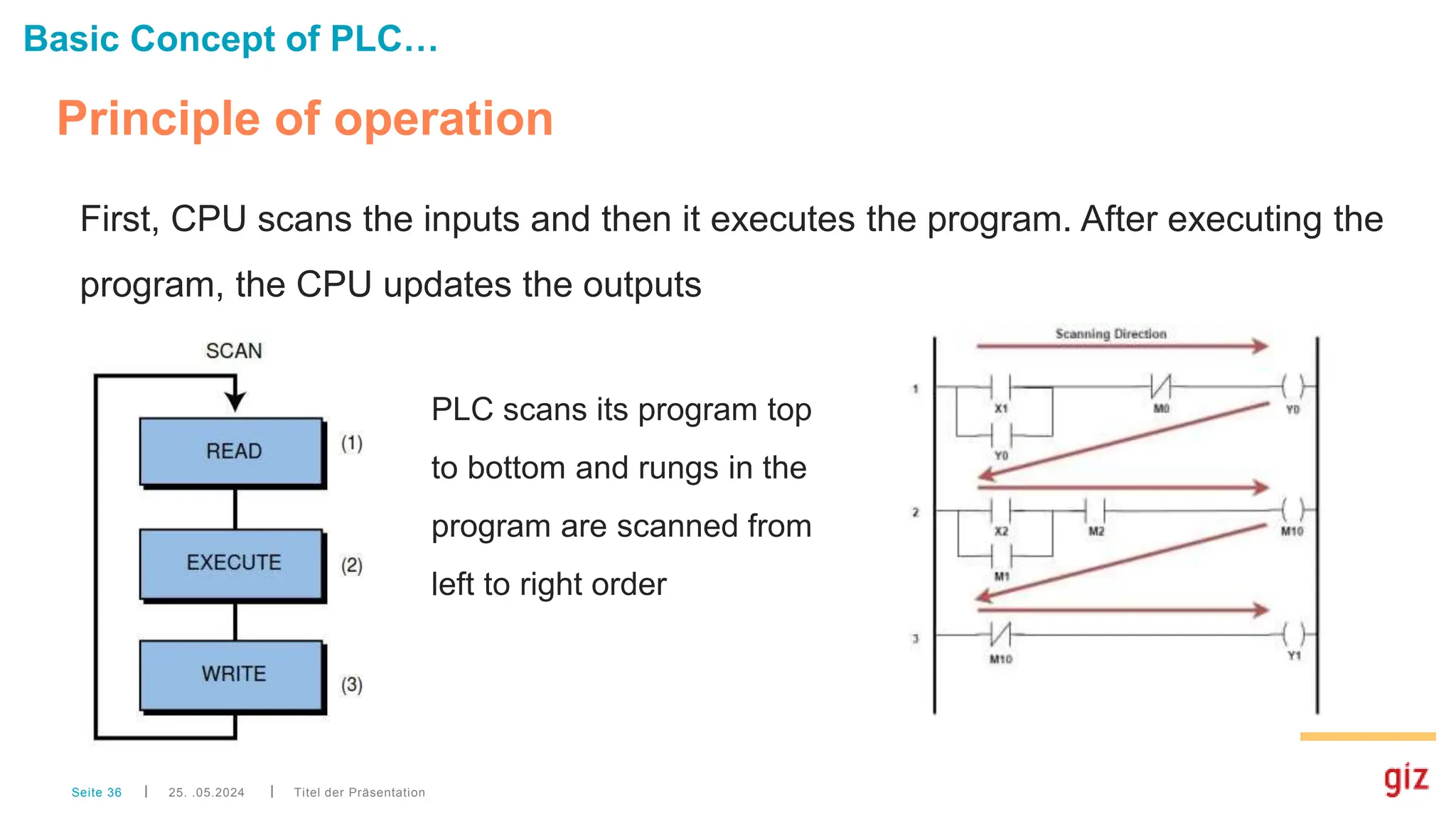

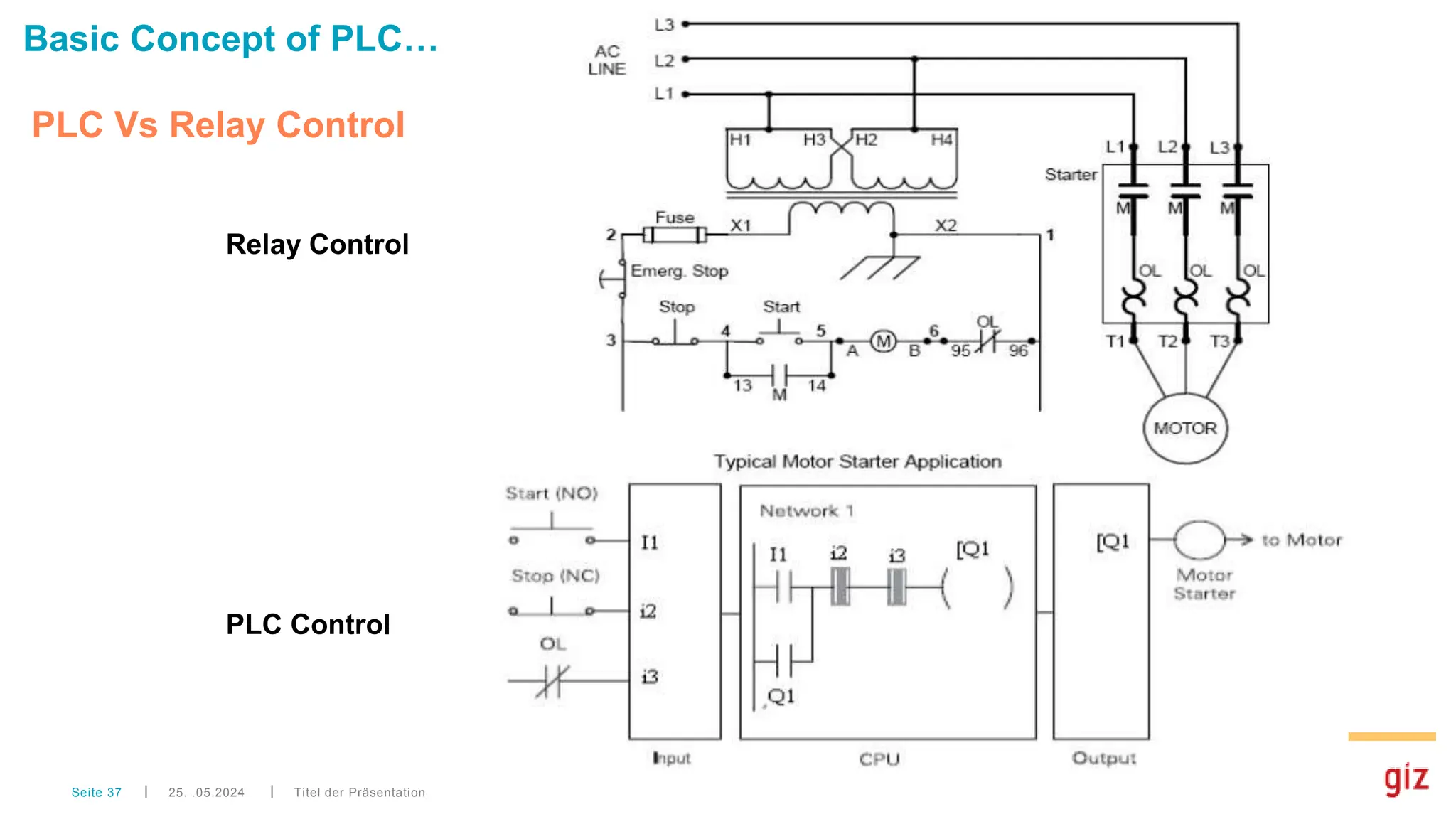

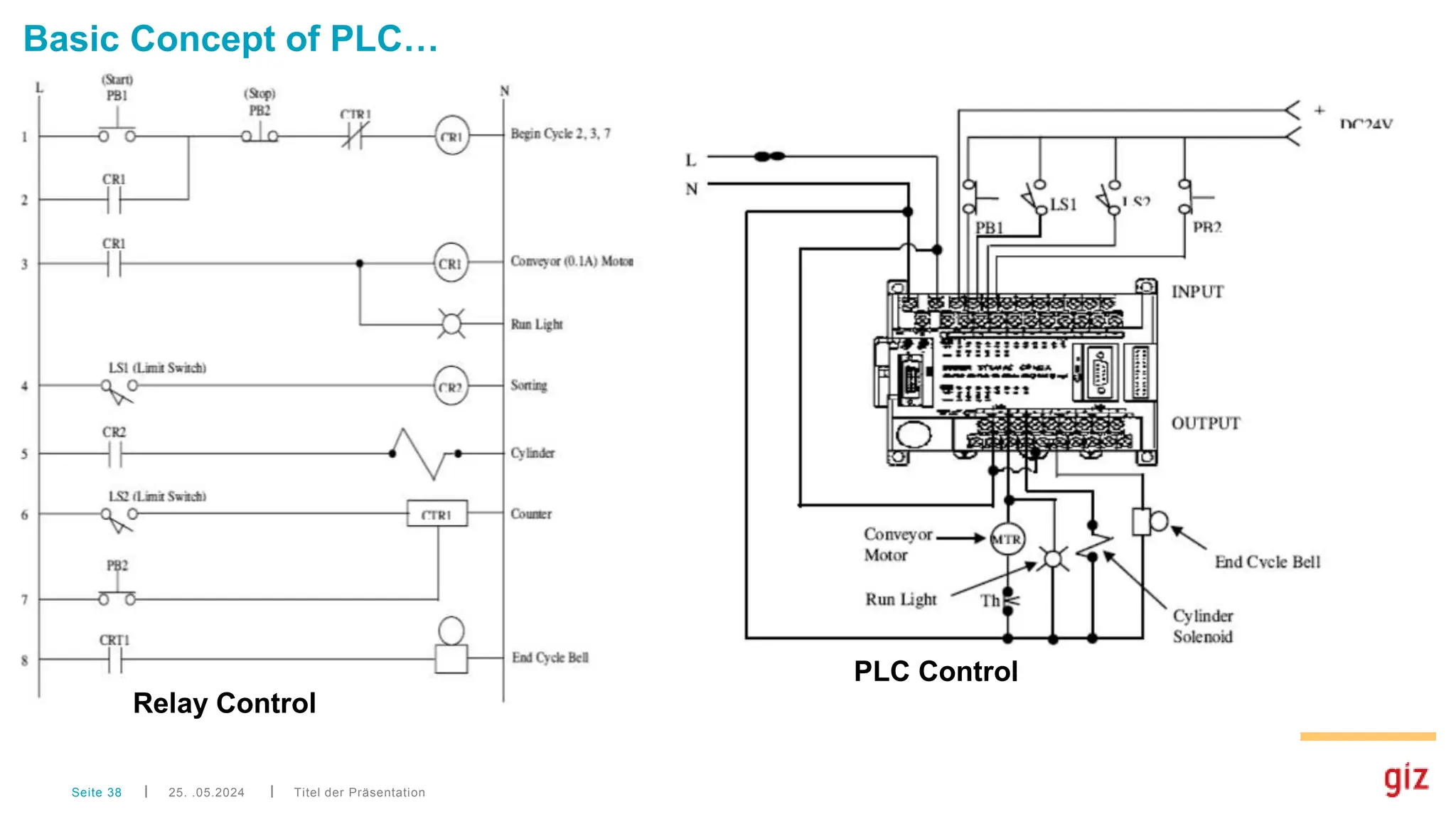

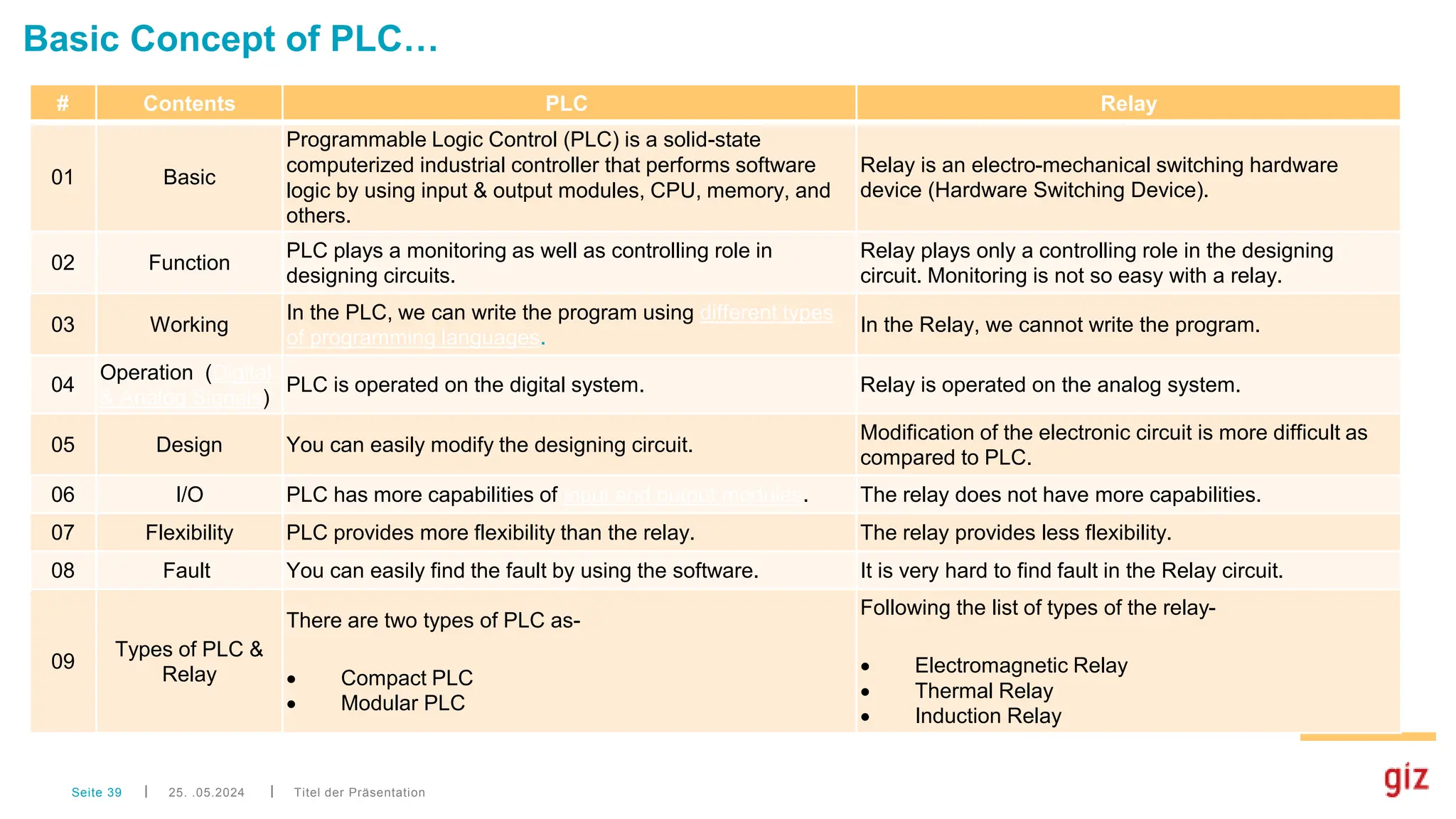

The document outlines the training on SCADA systems and process control, emphasizing the importance of process control in ensuring product quality, efficiency, and safety. It details the components involved in the process control systems, including measuring elements (sensors), controllers, and actuators, as well as the functions of Programmable Logic Controllers (PLCs) in industrial automation. Lastly, it contrasts PLCs with traditional relays, highlighting the advantages of PLCs in terms of flexibility, monitoring, and fault detection.