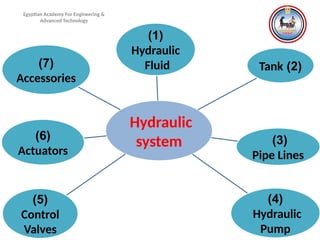

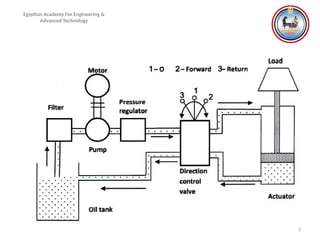

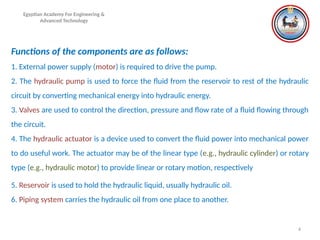

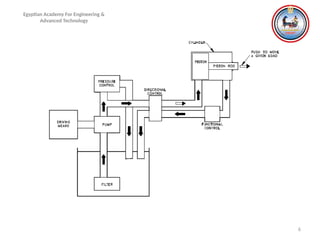

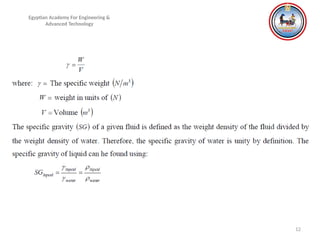

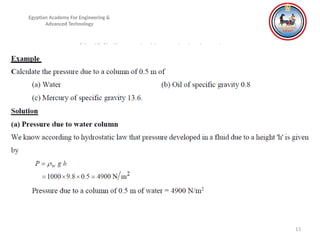

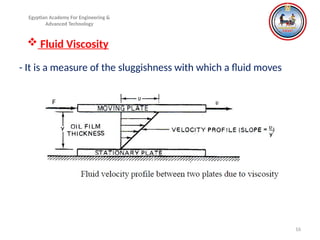

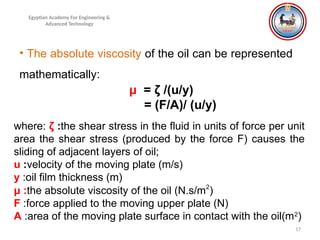

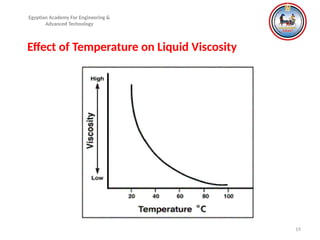

The document explains the basic components and functions of hydraulic systems, detailing how pressurized liquids transmit energy in these systems. It covers essential elements such as hydraulic pumps, valves, actuators, and fluids, emphasizing the roles of hydraulic fluids in power transmission, lubrication, and cooling. Additionally, it discusses mathematical equations related to hydraulic pistons and the properties and viscosity of ideal hydraulic fluids.