This document provides a final report on an embedded systems project to build an autonomous line-following buggy. It summarizes the key components of the buggy, including the mechanical design, electronic circuits for line and speed sensing, use of an ultrasonic sensor and RF link, and software programming. It describes the group's organization, budget, testing process, and performance at races, where the buggy placed fifth. Detailed diagrams and the pseudo code used are included in appendices.

![15

Overshooting

sequence:

Group

6

had

developed

a

feature

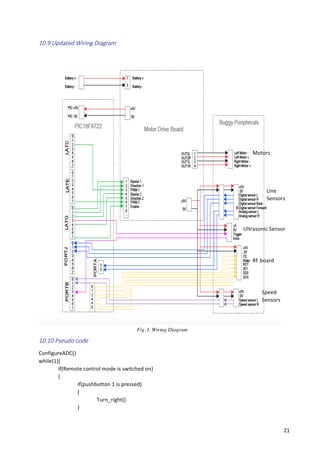

to

make

the

buggy

complete

the

track

in

a

more

reliable

way.

Overshooting

sequece

is

a

programming

feature

that

helps

the

buggy

to

take

sharp

turns

at

high

speeds.

This

feature

relies

on

the

fact

that

if

a

buggy

overshoots

a

line

at

the

corner,

the

last

sensor

sensing

the

line

would

have

been

one

of

the

end

sensors.

If

such

is

the

case,

the

buggy

would

try

to

rejoing

the

track

by

taking

a

sharp

turn

in

the

direction

depending

in

the

sensor

that

sensed

the

line.

If

,however,

any

of

the

middle

3

sensors

were

the

last

sensors

to

detect

the

line,

the

buggy

would

understand

that

it

has

reached

the

end

of

the

line

and

hence

would

stop.

8.0

Conclusion

The

buggy

was

able

to

achieve

most

of

its

aim

except

reaching

the

final

race.

It

was

capable

of

taking

turns

in

a

smooth

and

fast

way,

go

up

or

down

the

slope

while

maintaining

the

speed

and

stop

on

reaching

the

end

of

the

course.

The

total

cost

of

the

buggy

was

calculted

to

be

£32

including

recycable

items

which

is

underr

the

allocated

budget.

All

aims

were

accompilshed

while

abiding

by

the

regulations

of

maximum

6

sensors

and

budget

of

£50.

Many

new

innovative

features

such

as

RF

link

debugging

tool

and

ultrasound

sensor

not

only

eased

the

process

of

programming

but

also

improved

the

manoeuvrability

of

the

buggy

through

the

track.

During

the

two

heats,

group

6

had

mixed

fortunes.

For

the

first

heat,

the

group

concentrated

on

completing

the

track

in

respectable

time.

The

buggy

was

able

to

complete

the

track

without

any

difficulty

in

8.3

seconds.

In

the

second

heat,

the

group

concentrated

on

posting

a

faster

time

to

qualify

for

the

final

race.

However

the

buggy

had

more

oscillations

than

before

which

resulted

in

more

time

to

settle

down

on

a

straight

line.

This

costed

time

and

place

in

the

final

race

as

the

best

time

posted

by

group

6

was

only

7.1

seconds,

5th

fastest

in

the

stream.

After

critical

analysis

of

the

race,

the

following

steps

were

noted

which,

if

implemented,

could

have

improved

the

fastest

time

for

the

buggy:

• The

buggy

was

heavier

than

expected

which

compromised

not

only

the

stopping

distance

but

also

the

manoeuvrability

of

the

buggy

• One

reason

for

increased

oscillation

was

pointed

towards

the

sunlight

in

the

room

of

race.

The

buggy

should

have

been

tested

in

sunlight

before

coming

to

race.

• Better

PID

control

should

have

been

implemented

to

improve

oscillations

that

were

observed

in

a

straight

line.

In

conclusion,

even

though

the

buggy

was

not

able

to

reach

the

finals,

it

was

able

to

complete

the

track

in

fast

time

and

hence

can

be

declared

as

a

success.

9.0

References

[1]

Apsley,

J,

Green

PN,

Embedded

Systems

Project:

Project

Handbook,

School

of

Electrical

and

Electronic

Engineering

(2014),

the

University

of

Manchester,

Sept

2014.

[2]

Microchip.

(2008)

PIC18F8722

Family

Data

Sheet.

Available:

http://ww1.microchip.com/downloads/en/DeviceDoc/39646c.pdf.

[3]

Vishay.

(2009).

TCRT5000L

Datasheet.

Available:

http://www.vishay.com/docs/83760/tcrt5000.pdf.

[4]

Foster,

DA,

Breakout

Interface

Schematic,

School

of

Electrical

and

Electronic

Engineering

(2014),

the

University

of

Manchester,

Sept

2014.

[5]

Apsley,

J,

Drive

Board

Circuit

Diagram,

School

of

Electrical

and

Electronic

Engineering

(2014),

The

University

of

Manchester,

Sept

2014

[6]

Farnell.

electronic

components.

Available:

http://uk.farnell.com/

[7]

Chen,

CW,

Embedded

System

Project-‐Wireless

Link

Documentation,

School

of

Electrical

and

Electronic

Engineering

(2014),

The

University

of

Manchester,

Sept

2014

[8]

ITead

Studio.

(2010).

Ultrasonic

ranging

module

:

HC-‐SR04

(Data

Sheet).

Available:

http://www.electroschematics.com/wp-‐content/uploads/2013/07/HC-‐SR04-‐datasheet-‐version-‐2.pdf](https://image.slidesharecdn.com/thefinalreportgroup6-170822015551/85/Autonomous-Linke-Following-buggy-17-320.jpg)