This document provides an introduction to case studies of air conditioning systems that were analyzed as part of the AuditAC project. It describes 22 case studies from various countries in Europe that covered different building types and HVAC system configurations. The case studies aimed to demonstrate real-world examples of different AC systems, potential issues identified, and modifications or improvements that were suggested. Highlights from several of the office building case studies are also provided.

![Office Building • Maribor

The energy system of an office business building is presented, where at minimal energy

consumption, optimal working conditions are achieved. The investment costs are in the

same range as the investment costs for a traditional building. Building is heated with a

combined heat pump (water – water), which prepares heating and cooling medium for

the whole building. Heating source is ground water from a spring. Heat and cooling

energy are partly transmitted into the object by thermal activation of concrete

construction and by supplied air of ventilation units. Local regulation of temperature is

possible through local heating coils, built in special displacement air distributors. Whole

space is ventilated with high energy efficient ventilation / air conditioning units with

energy recovery more than 90%.

Problems

There are no problems reported for this building. In fact, this case study aims to report

that is possible to combine technology, comfort and reasonable expenses.

Accomplishments:

As said, the building was designed to achieve high energy performance thus reducing

the energy consumption. This global goal was approached by several sides: the building

envelope [sun exposure and wall and glazing materials] and the HVAC systems

installed.

The glazing is a two – layer glass type, argon filled. It is combined with high quality

aluminium profiles, with interrupted thermal bridges, thermal insulated. There is also a lot

of innovative details of interruption of thermal bridges at connections glazing to concrete

constructions.

Performance of the cooling system is optimized for lowest possible energy consumption.

Big amount of sensible heat is cooled with thermal activation of concrete construction it

goes on large surface area, which means high cooling medium temperature – low

energy consumption.

18](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-18-320.jpg)

![Design Details

The HVAC system installed in below grade floor of

CICA building is an all refrigerant system, where,

all units work with R22 refrigerant. In D-102 and D-

104 rooms, there are ceiling splits with 5 kW of

cooling power, connected to the condenser units

installed in the building’s rooftop, Error! Reference

source not found.. The rooms, D-101, D103 and D-

104 are equipped with close control units; one unit

in the first two places and two units in the last one,

Error! Reference source not found., an individual

condensing outdoor unit is also located in the

building rooftop. The Close control units allow

humidity control inside the spaces.

Figure 2 - Schematic of the ventilation

systems distribution

Figure 2 illustrates the functionality of the close

control units installed in the different zones where

reheated /re-cooling air is supply by grids under

the floor.

Figure 3 - Schematic of the close control Figure 4 - Schematic of the condensers existing in the building rooftop

Building envelope

The table below shows the configuration of the building envelope.

External wall e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Gypsum 0.015 1.150 837.0 1950.0

Concrete 0.220 1.750 1080.0 2200.0

0.683

Polystyrene 0.040 0.035 1250.0 32.5

Gypsum 0.015 1.150 837.0 1950.0

Internal wall e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Gypsum 0.020 1.150 837.0 1950.0

Brick 0.150 1.750 1080.0 2200.0 1.833

Gypsum 0.020 1.150 837.0 1950.0

Internal floor e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Linoleum 0.003 0.169 1000.0 1000.0

1.490

Light Slab 0.450 0.931 965.0 1320.0

91](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-91-320.jpg)

![Ceiling e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Plaster 0.050 0.220 1085.0 1680.0 2.517

External floor e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Linoleum 0.003 0.169 1000.0 1000.0

Concrete 0.200 1.750 1080.0 2200.0 0.692

Polystyrene 0.040 0.035 1250.0 32.5

False floor e [m] λ [W/mºK]] cp [J/kgºK] ρ [kg/m3] U [W/m2K]

Linoleum 0.003 0.169 1000.0 1000.0

Agglomerated 0.030 0.056 1000.0 300.0 1.374

Aluminium 0.001 200.000 3430.0 2700.0

Table 2 – Building envelope constitution

Control Strategy

The HVAC system works in continuous throughout the year where the indoor air set-

point temperature is 25ºC and the relative humidity is 50%. Each close control unit

performs the specified set-point of the air conditioning space.

Control strategy

set-point schedule

Close control 24ºC 24h

Split units 19ºC - 23ºC 9h - 18h

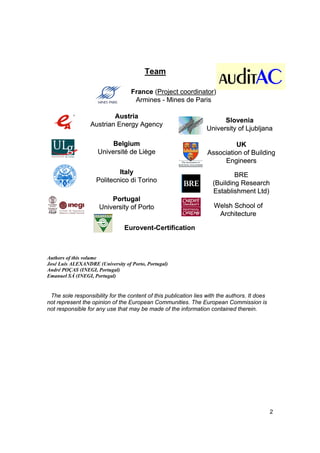

Performance Data

Cooling demand

Using a dynamic simulation software package, it was possible to obtain the cooling loads

for each space.

Figure 5 shows the results of the simulation for cooling demand and the sensible cooling

load of the installed systems.

25

20

15

kW

10

5

0

D -101 D -102 D -103 D -104

Installed capacity Sensivel load

Figure 5 – Sensible cooling load

As shown above in figure 6 the installed cooling powers inside the analyzed spaces are

not enough to remove the thermal load, which justifies the overheating that sometimes

occurs.

92](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-92-320.jpg)

![The considered HVAC system can be defined as an air/water system. It will be

composed by a cold-water central producer (chiller), located in the building covering, and

by a cold water distribution net with two pipes, for supply and return. This circuit will

supply the existing cooling coils in the independent Close Control units. These units are

located inside climatized spaces or, if not possible, near them. An adequate ventilation

system can also be installed to guarantee the indoor air quality. This system will also

include the possibility of free-cooling the spaces, given adequate exterior air conditions.

The following equipments form the proposed system:

- Chiller with scroll compressor with 100 kW of cooling capacity;

- Four Close Control units supplied with cold water which integrates system of

humidification and electric resistance for heating;

- Ventilation, piping and control system…

Performance data

These spaces are characterized by its high internal gains, as shown bellow

Zone UPS -101 FCCN -102 Servers -103 Networks-104

Equipment gains [kW] 6,4 4,6 20,7 13,57

Light gains [W] 108 144 288 288

Occupancy - - - -

2

Overall internal gains [kw//m pav] 0,42 0,15 0,42 0.30

Table 3 – Internal gains

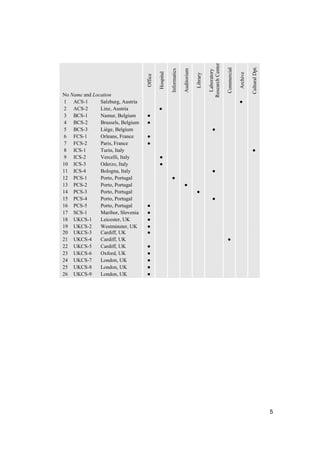

Energetic Analysis

The energetic and power consumptions of the existing Close Control units in the 4

zones, was obtained through dynamic simulation, was 128 MWhe/year. It should be

noted that this analyses considers the consumption of the compressor, the ventilation,

the reheat coils and humidification.

Using once again the dynamic simulation, we could calculate the energy consumption

for the proposed solution, 87 MWhe/year. The following figure shows the comparison

between the solutions.

[MWh(electric)]year [MWh(termal)]year t CO2

180 40.0

160 35.0

140

30.0

CO2 emissions [ton/year]

120

Energy [MWh] year

25.0

100

20.0

80

15.0

60

10.0

40

20 5.0

0 0.0

Electirc resistence Hot Water Electric resistence Hot Water Electric resistence

Actual system New system without free-cooling New system with free-cooling

Figure 8 – Comparison between the simulated systems

94](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-94-320.jpg)

![The new system with free-cooling and electrical reheat is much more effective than the

others, except the system which uses hot water for reheat. However this system would

require a boiler, so the system would consequently become more complex and

expensive.

120

Actual system

100 Centralized system without

Electric anual consumptionl [MWh]

free-cooling

Centralized system with free-

80 cooling

60

40

20

0

Figure 9 – Comparison of cooling electric energy required in the three different simulated systems

Once again is shown that the system with free-cooling is the most effective for this case.

As it is verified by the energy earnings, of the floor -1, with the substitution of the current

system for the proposed one, we can achieve savings of around 41 MWh (Figure 8). This

value correspond to 2.870,00 Euros a year of economic won (the price of the electric

energy was esteemed to be 0,070 €/kWh).

Construction and Operating Costs of New System

According to the proposed HVAC system, the expected budget rounds 80 000 € and the

operating costs will decrease in comparison to the current system.

We shouldn’t forget that the new proposed system will have the responsibility of

climatizing the whole building, therefore we have to make an estimate of earnings for the

whole building, and not only for the floor -1. Having this in mind a new estimate was

obtained, a value of around 7.000,00 euros a year of economics earnings. With such

earnings, it is possible to have a capital return of about 11 years (payback of 11 years),

the lifetime of an HVAC installation of this type is a proximally 20 years, turning the

investment a little more tangible.

Final Analysis

The proposed solution presents certain advantages when compared with the existing

system:

a. The cooling capacity can be increased with the connection of one or more

chillers. According to the type of equipment, it is possible to connect them and

optimize its functioning. All these systems allow a centralized management and

partial loads according to the thermal needs.

95](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-95-320.jpg)

![As a response to the topology of the building there was the need to include direct

expansion units (designated commercially by splits) on the south facade of the building,

middle floors, being used preferentially during the cooling station.

Figure 3 – View of the Chiller Figure 5– View of the Boiler Figure 4–Cooling towers

Building envelope

For better evaluate the energy needs of the building it was necessary to typify the

materials used in the construction of the envelope. The following table describes the

type of building envelope and respective values for the thermal transmission coefficients,

U [w/m2], of each constructive element.

U Umáx

Description 2

(W/m .ºC) RCCTE2006 (I1)

Exterior wall 0.681 1,8

Interior wall 1.833 2

Slab 1.327 1,65

Roof 0.514 1,25

Glazed 4.5

Table 5: Thermal transmission coefficients

Climatic data of the place (external temperature; total monthly incident

radiation). According to RCCTE (Portuguese building thermal regulation) the

building in study is located in the area I2V1 and it presents the following values:

Degree Days (20ºC) 1610

Duration of the heating station (months) 6.7

2

Medium solar energy incident Gsul (kWh/m . month) 108

Exterior Temp. of project (ºC) 30

Thermal width (ºC) 9

Table 6: Climatic data

Control Strategy

The comfort conditions are established for the circulation of air inside the areas to

acclimatize. The circulation of the air is assured by the air distribution system constituted

by AHU’s and ducts.

108](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-108-320.jpg)

![6.00 Supply 25.00 Supply

5.50

5.00 REAL PROJ. 20.00

Thousands [m^3/h]

4.50

4.00

3.50 15.00

Thousands [m^3/h]

REAL PROJ.

3.00

2.50 10.00

2.00

1.50 5.00

1.00

0.50

-

-

AHU 5.1

AHU 2.1

AHU 3.1

AHU 4.1

AHU 6.1

and 6.2*

to 3.4*

to 4.4*

to 5.4*

AHU_NA 0.1

AHU 0.2

AHU 0.1

AHU_NA 1.1

AHU 1.1

AHU 1.2

AHU 6.3

AHU_NA 6.1

AHU 7.2

AHU 7.1 and

to 2.4

7.3

Graph 5 - Comparison between the project and real air Graph 6 - Comparison between the project and real

supply for the floors -1, 0, 5 e 6 air supply for the floors 1,2,3,4 e 6

This results in a impasse situation if the ventilation fans aren’t properly controlled.

There’s a decrease in terms of the thermal comfort. In other hand, if the ventilation fans

are controlled properly there's an acoustic discomfort.

Energy analysis

In the year of 2005 the annual consumption of the Library was the following:

3

MWh m tep

Electric energy 512* - 148

Natural gas - 46869 43

TOTAL 125

Table 3: Energetic consumption - 2005

* Obtained value based on measurements

The values presented in the previous table are shown in the figure 5. The electric energy

represents the larger consumer of the library global consumption being 78% of the total

consumption.

The natural gas consumption, regarding the AVAC system of the building, is due to the

boilers and chillers, equipments responsible for the production of hot and cold water. All

the remaining energy needs, are established through electric energy.

The energy consumption breakdown showed in figure 5 was based on the measurement

of electric power made during the audit. The main consumers are: illumination,

equipments, ventilation fans of the AHU’s, extraction fans and direct expansion systems

distributed along the building (splits).

112](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-112-320.jpg)

![Cooling Heating

Model Air flow Water temperature 7-12 ºC Water temperature 80-60 ºC

(m3/h)

Total Sensible Dry bulb air Heating Dry bulb air

cooling cooling outlet power outlet

power temperature temperature

(kW) (ºC) (kW) (ºC)

(kW)

VC 1 187 0.8 0.72 12.6 0.96 35.0

VC 2 227 0.9 0.84 13.0 1.10 34.0

VC 3 281 1.03 1.0 13.5 1.65 37.0

VC 4 374 1.2 1.2 14.4 1.98 35.4

VC 5 400 1.79 1.61 12.0 2.50 38.2

VC 6 500 2.19 1.96 12.0 2.89 36.8

VC 7 774 2.33 2.33 15.0 4.55 37.1

VC 8 928 2.67 2.67 15.5 5.0 36.0

VC 9 1062 4.0 3.55 14.0 6.68 38.0

VC 10 1213 4.66 4.0 14.2 7.24 37.0

Ice storage

Designation BG1

Storage capacity (kWh) 670

Max functioning temperature ºC 38

Quantity 2

Building Envelope

The constitution of the building envelope is given in the table bellow

3 2

Exterior Wall e [m] Cp [kJ/kgºK] λ [W/mºK] r [kg/m ] U [W/m K]

Plaster 0.015 0.837 1.150 1950

Concrete 0.3 1.080 1.750 2200

0.560

Polystyrene 0.05 1.250 0.035 32.5

Plaster 0.015 0.837 1.150 1950

3 2

Interior Wall e [m] Cp [kJ/kgºK] λ [W/mºK] r [kg/m ] U [W/m K]

Plaster 0.02 0.837 1.150 1950

Brick 0.15 1.080 1.750 2200 2.774

Plaster 0.02 0.837 1.150 1950

123](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-123-320.jpg)

![Slab between 3 2

e [m] Cp [kJ/kgºK] λ [W/mºK] r [kg/m ] U [W/m K]

floors

Linoleum 0.002 1.0 0.169 1000.0

Light slab 0.30 0.965 0.931 1320 1.313

Gypsum 0.05 1.085 0.220 1680

3 2

Ground Slab e [m] Cp [kJ/kgºK] λ [W/mºK] r [kg/m ] U [W/m K]

Linoleum 0.002 1.0 0.169 1000.0

Concrete 0.3 1.080 1.750 2200

0.567

Polystyrene 0.05 1.250 0.035 32.5

Plaster 0.015 0.837 1.150 1950

3 2

Door e [m] Cp [kJ/kgºK] λ [W/mºK] r [kg/m ] U [W/m K]

Wood 0.03 2.750 0.150 550 2.703

Solar and Overheating Protection

The glazing constitution and properties are showed in the table below:

3 2

Glazing e [m] Cp [kJ/kg.ºK] λ [W/m.ºK] r [kg/m ] U [W/m K]

Double glass 6mm/6mm 0.850 4000 2800 4.00

Solar transmittance = 0.75

The shading of the building is composed basically by vertical and horizontal shading

devices. There is no interior shading.

Control Strategy

The HVAC systems works according to a schedule that varies with the rooms

application. The table bellow resumes the different room’s existent in INESC as well as

their typical utilization schedule.

Type of room Functioning schedule

Offices and common areas From 9:00 to 20:00, 5 days a week

Reunion offices and audience rooms From 10:00 to 13:00, once a week

Server rooms and common areas with natural

24 hours a day, 7 days a week

ventilation

124](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-124-320.jpg)

![Fig. 2: Screenshot of the management program

The temperature set points are:

Summer: 25 ºC

Winter: 20 ºC

Performance Data

Building Energy Performance

The amount of energy used in the year of 2005 is described below. The natural gas is

used for heating only. Some measurements were done between January 28th and

February 5th. The results showed in fig. 4

INESC Energy consumption for 2005

Electricity Natural gas Natural gas [m3] Electricity [kWh]

[kWh] [m ] 3 50000 1600

45000 1400

January 32774 904 40000

E le c tric ity [k W h ]

1200 N a tu ra l g a s [m 3 ]

February 32836 849 35000

30000 1000

March 34340 855

25000 800

April 42732 396 20000 600

15000

May 37162 41 400

10000

June 43540 2 5000 200

0 0

July 38299 9

ly

ne

ri l

ch

ay

ce r

August 42146 1

y

st

ry

No ber

r

O c er

De be

Ju

ar

Ap

be

Ju

gu

ua

ar

M

b

nu

m

to

m

em

M

Au

br

ve

Ja

Fe

pt

September 40924 4

Se

October 45872 706

November 43766 1243 Fig. 3: Energy consumption for the year of 2005

125](https://image.slidesharecdn.com/auditactg10casestudies-120120080701-phpapp01/85/Auditac-tg10-case-studies-125-320.jpg)