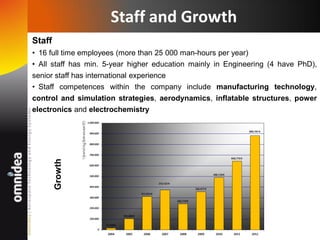

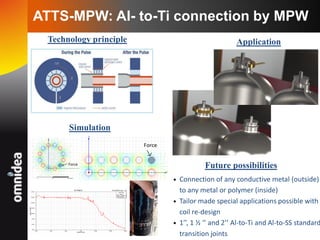

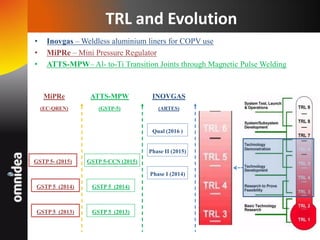

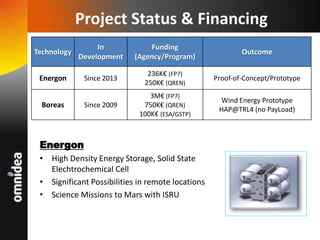

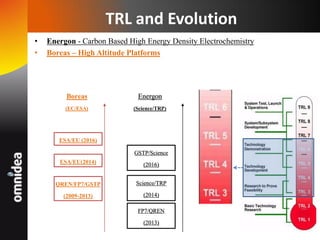

Omnidea is a Portuguese SME that develops technologies for space and energy applications. For space, they are developing weldless aluminum reservoirs, miniature pressure regulators, and aluminum-titanium transition joints. These technologies are at TRL 4-5 and being funded by ESA programs. For energy, they are working on high energy density batteries and high altitude wind energy platforms. Boreas, a tethered airship, is at TRL 4 while Energon batteries are in proof-of-concept testing. Omnidea has 16 employees with engineering expertise and collaborates with universities and research centers in Portugal and Europe.