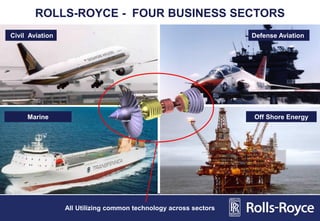

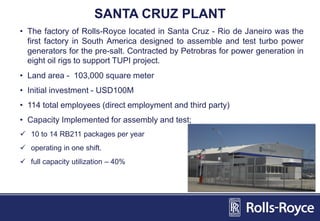

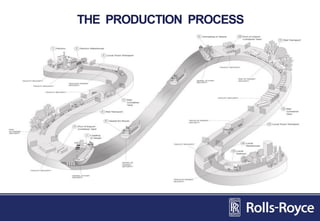

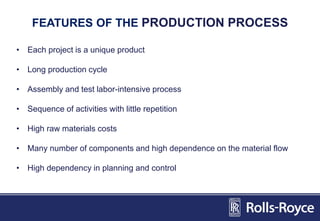

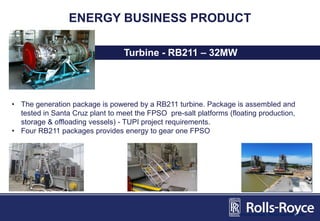

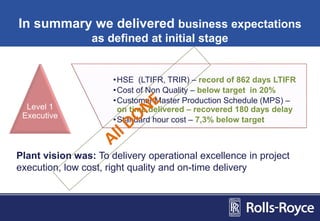

The document summarizes the processes and results of Rolls-Royce's Santa Cruz plant in Brazil, which assembles and tests turbo power generators for offshore oil rigs. Key points:

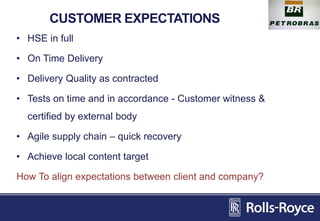

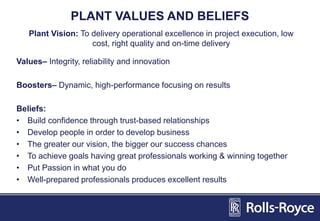

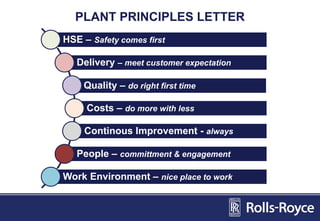

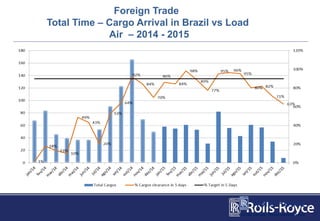

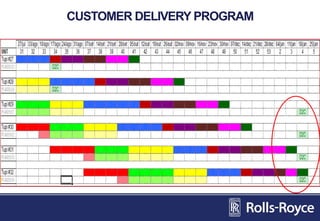

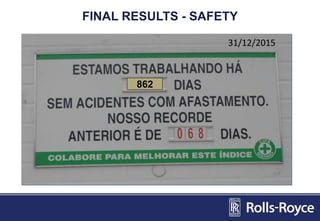

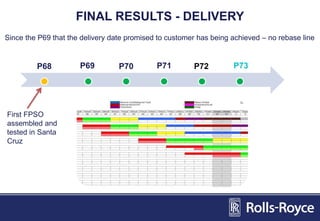

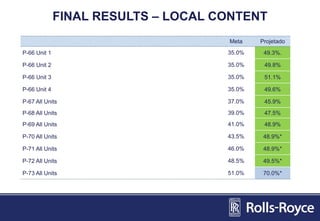

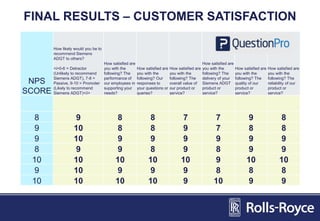

- The plant delivered on its customer expectations around safety, on-time delivery, quality, supply chain agility and local content targets. It achieved record safety performance and was on or below cost targets.

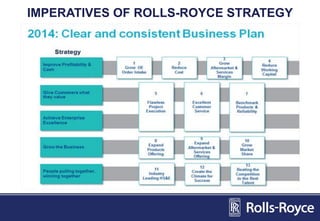

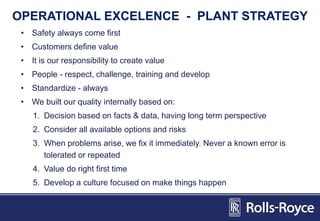

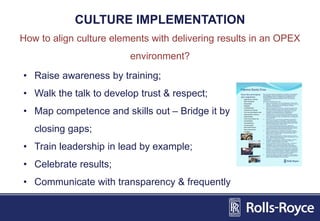

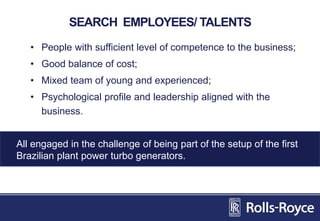

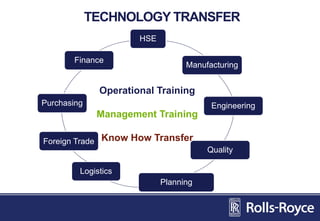

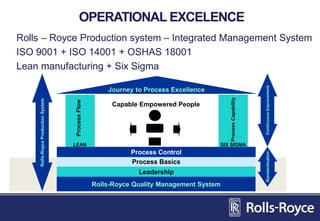

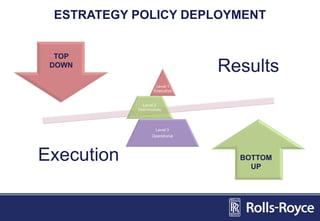

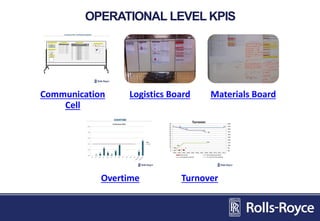

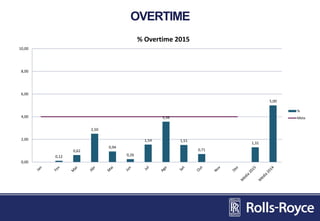

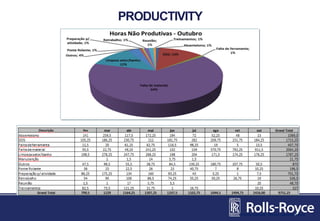

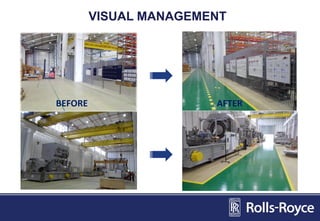

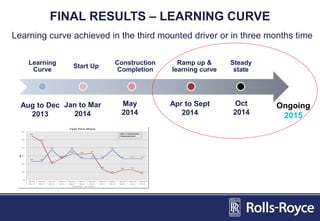

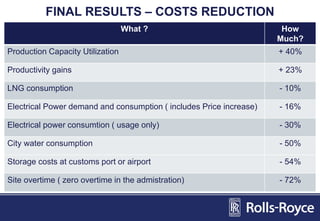

- Through implementing Rolls-Royce's operational excellence strategies around standardization, continuous improvement, visual management and a focus on people, the plant recovered from an initial 180 day delay and is now delivering consistently on schedule.

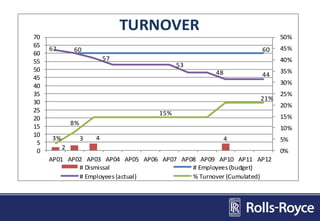

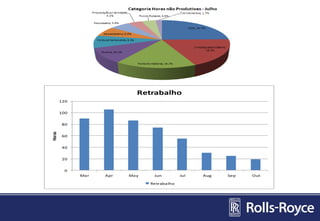

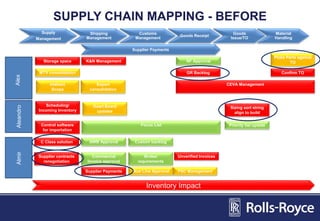

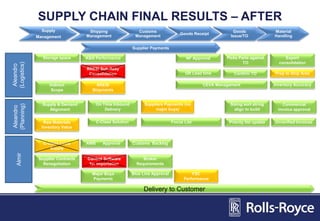

- Results showed improvements in various metrics like utilization, productivity, costs, inventory, and customer