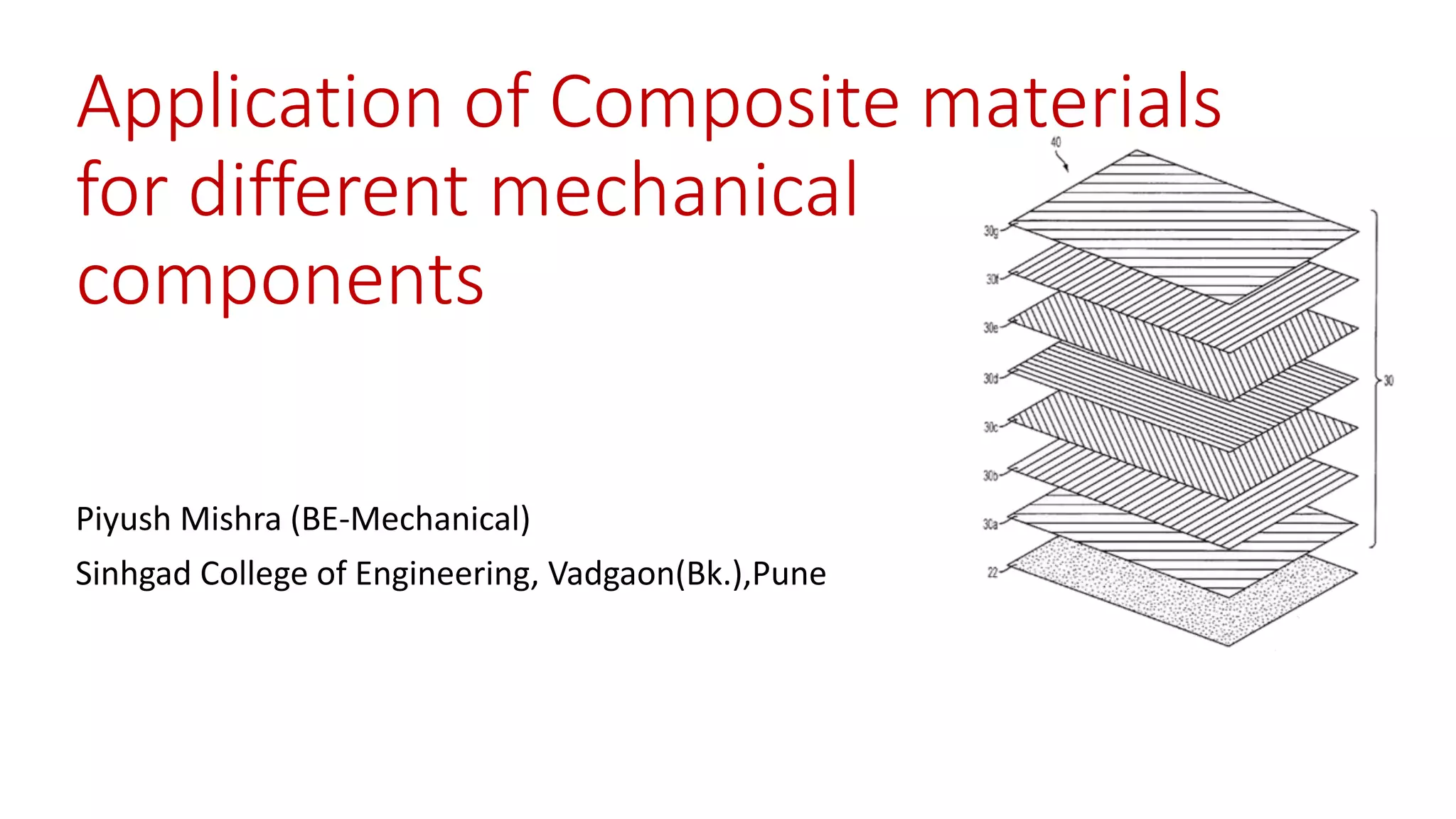

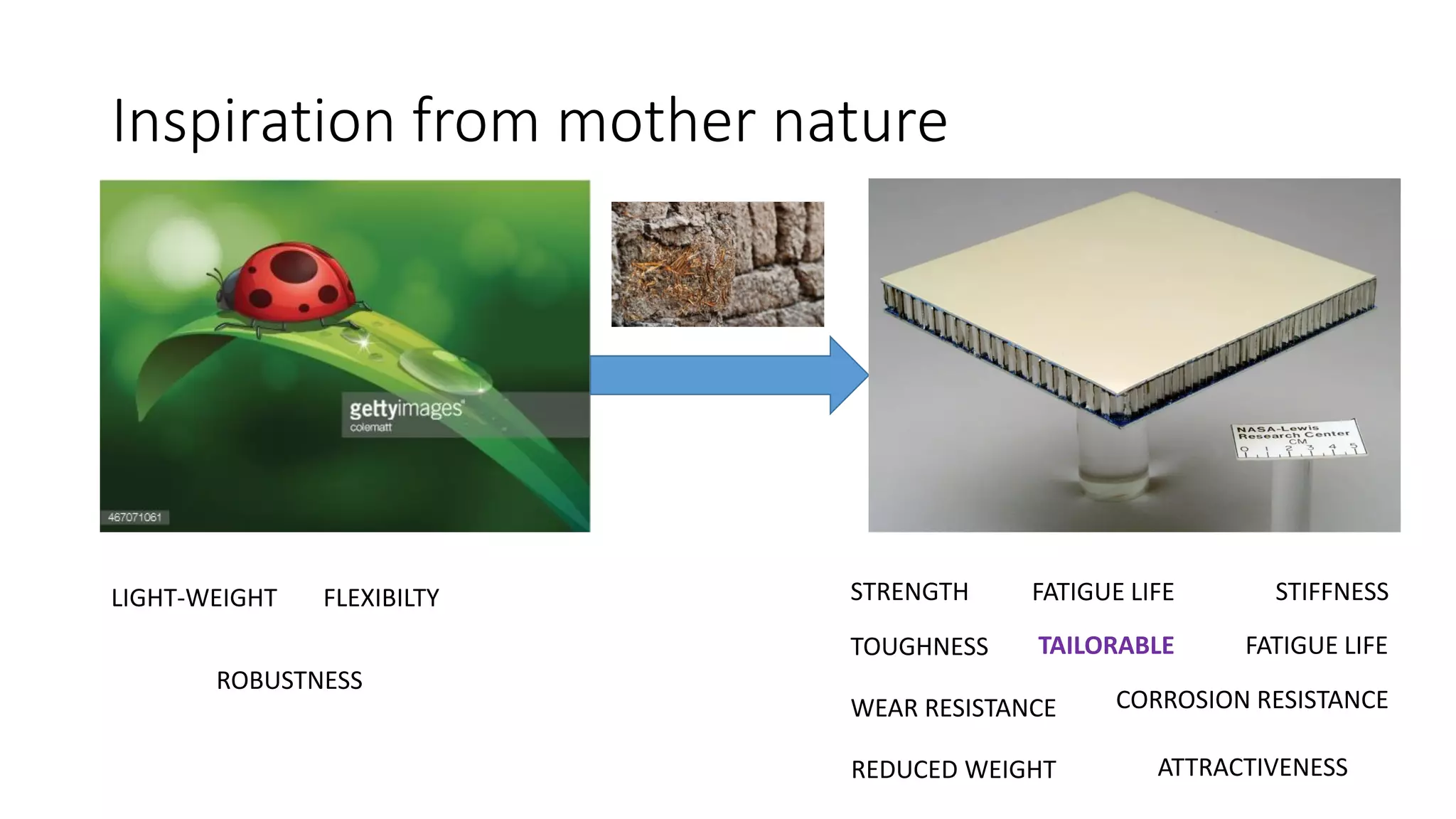

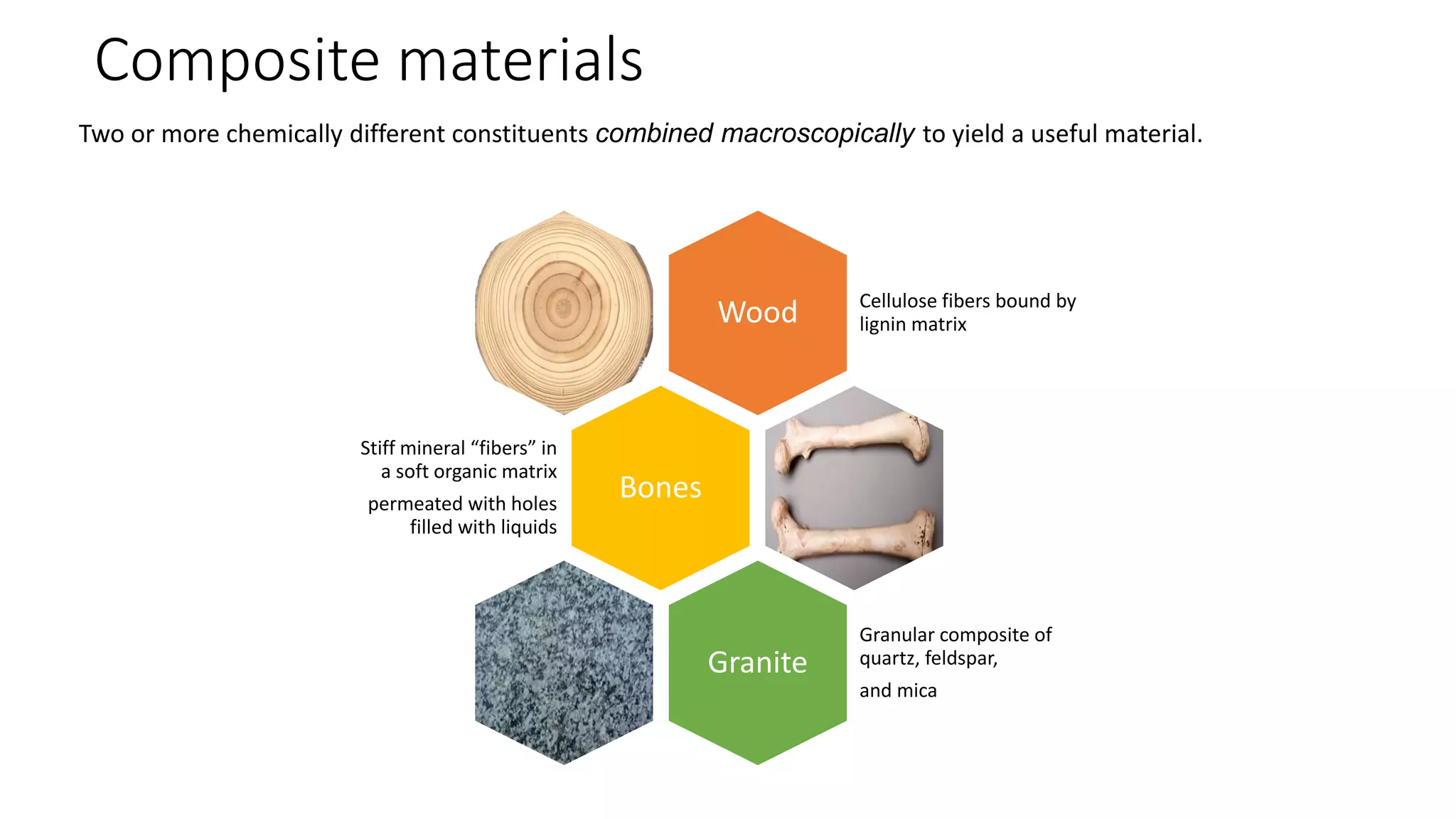

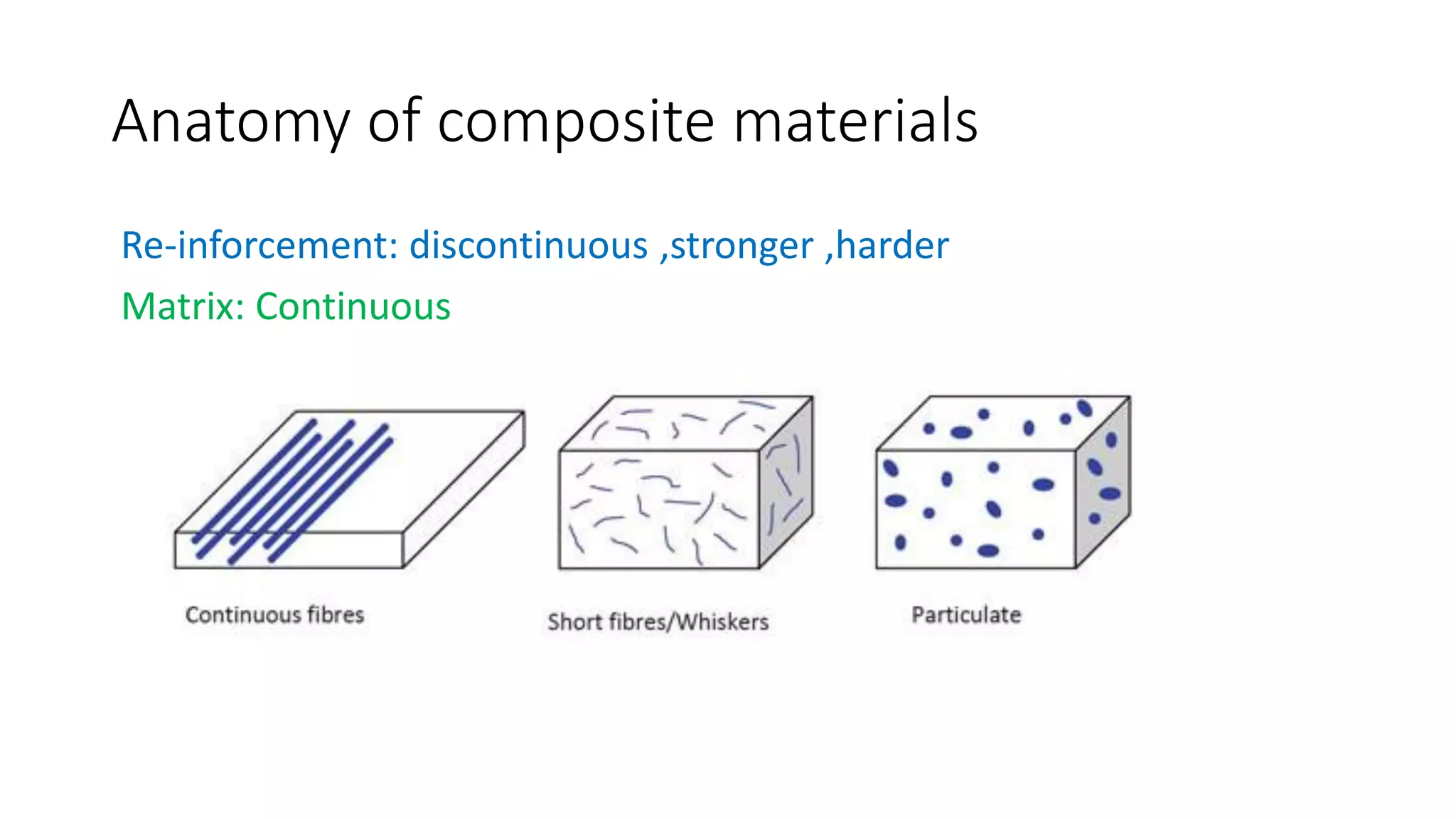

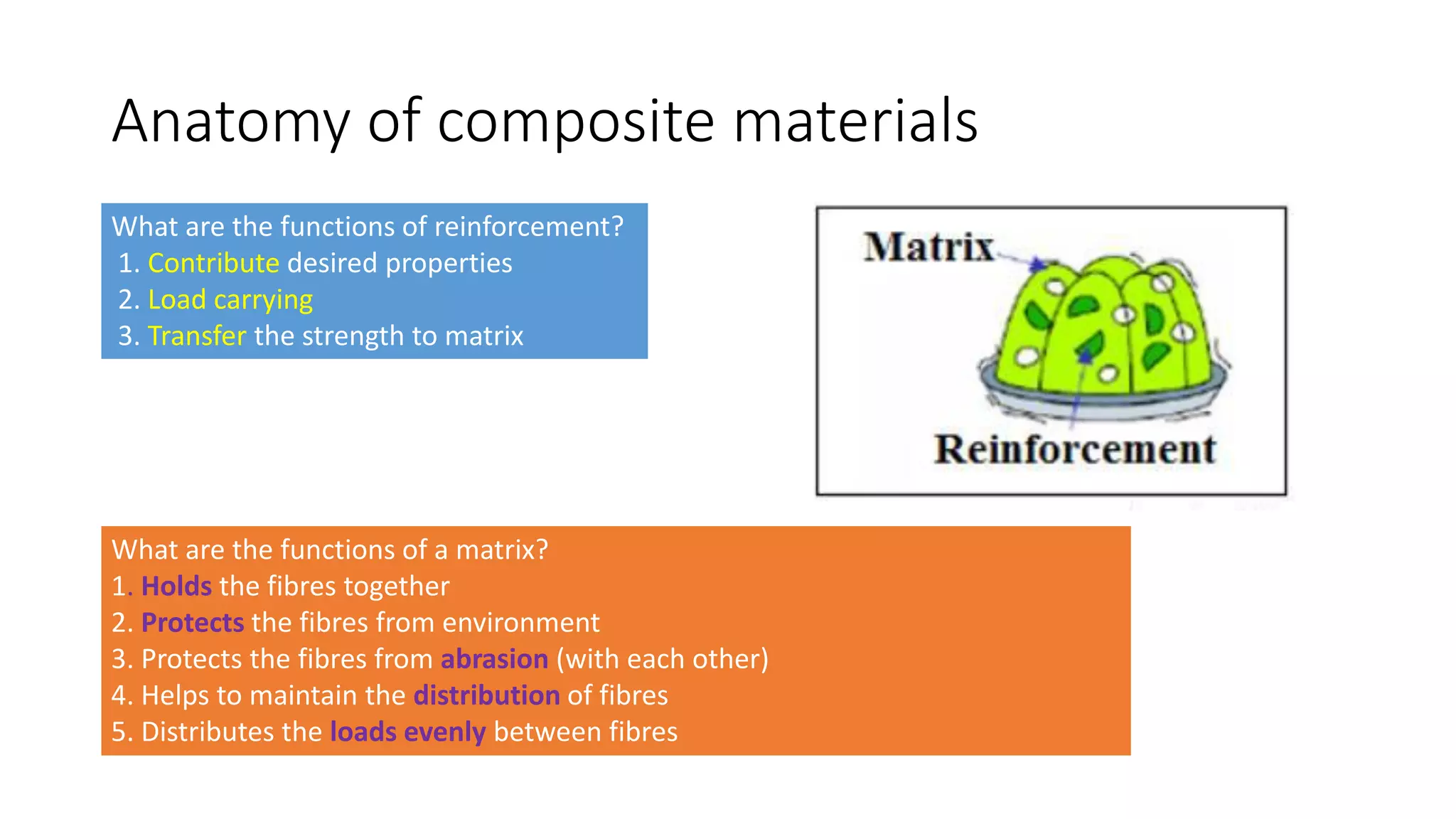

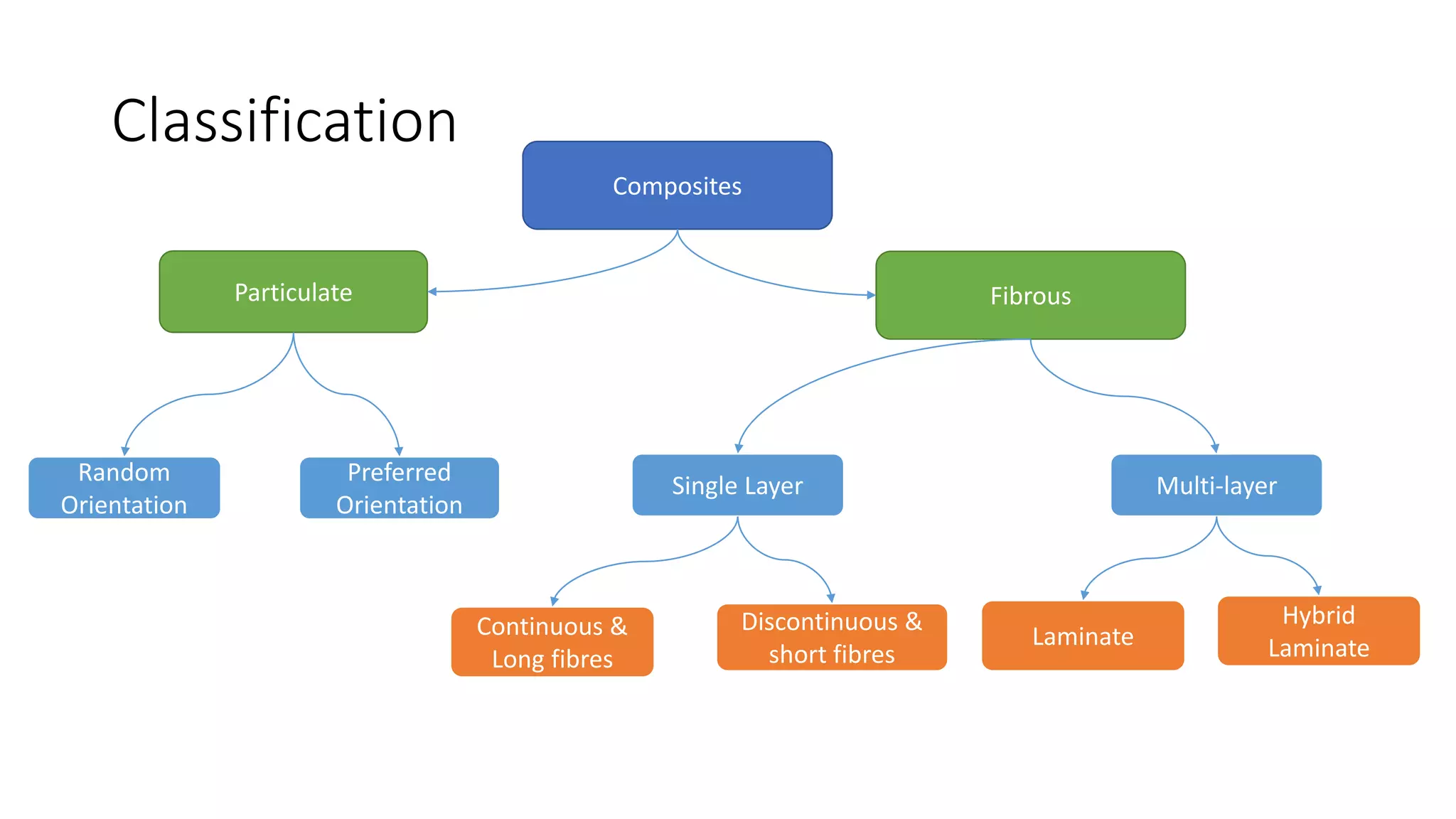

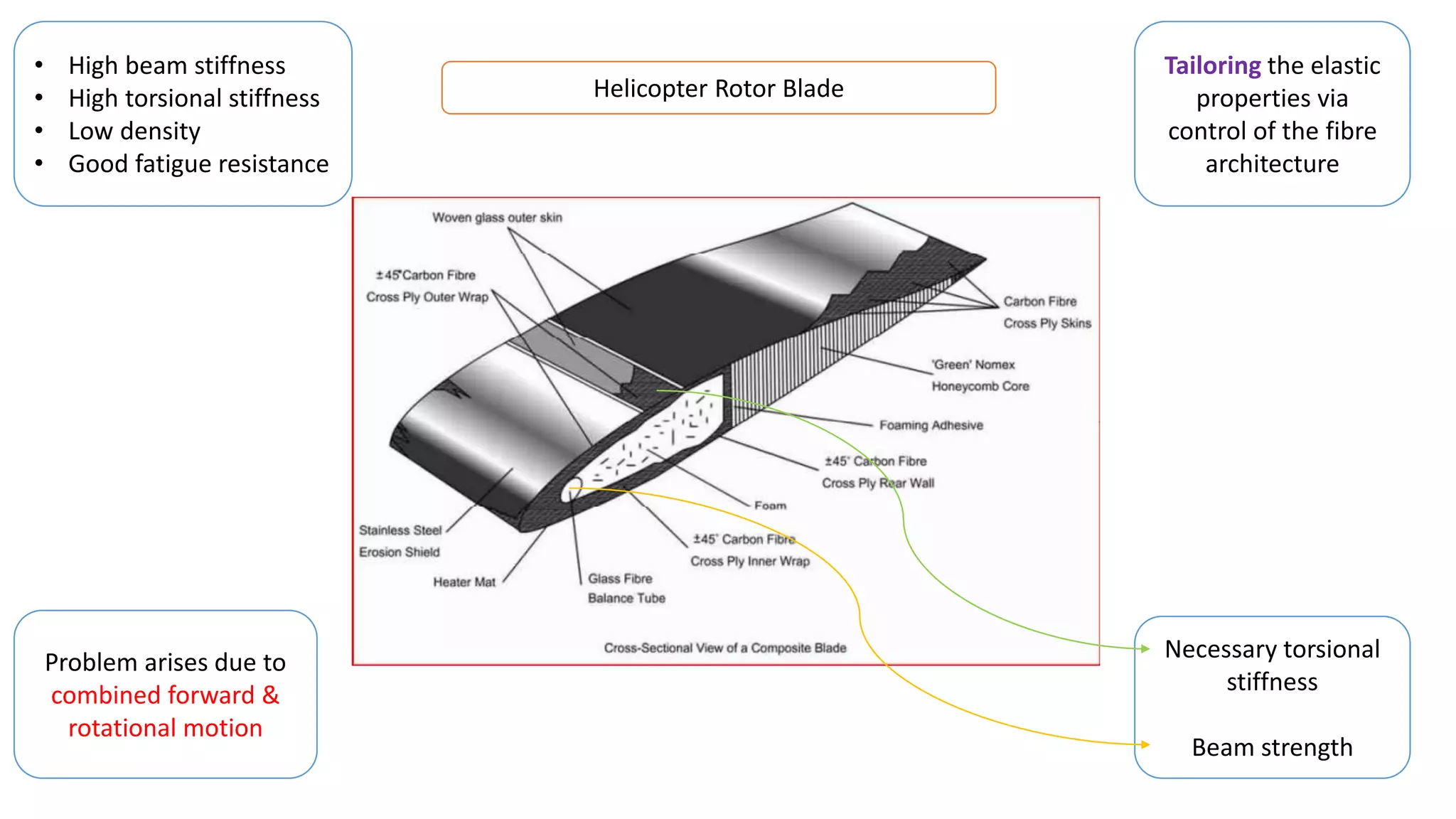

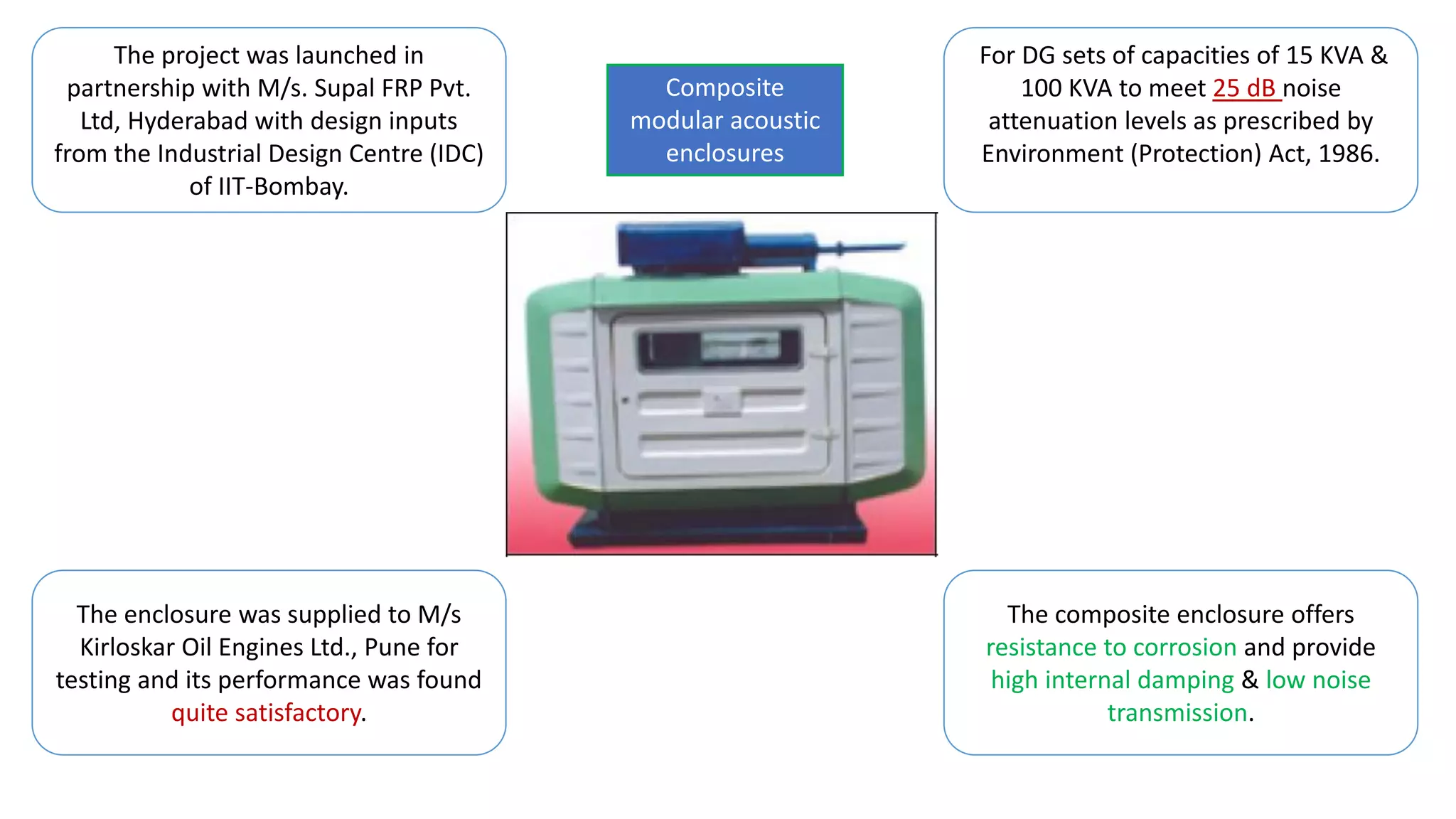

The document discusses the application of composite materials in various mechanical components, emphasizing their lightweight, robustness, and versatility derived from nature. It details the anatomy of composite materials, including the roles of reinforcement and matrix, and their classification based on fiber orientation and structure. The document also highlights specific projects on composite pressure vessels and acoustic enclosures, as well as the development of below-knee artificial limbs featuring advanced composite technology.