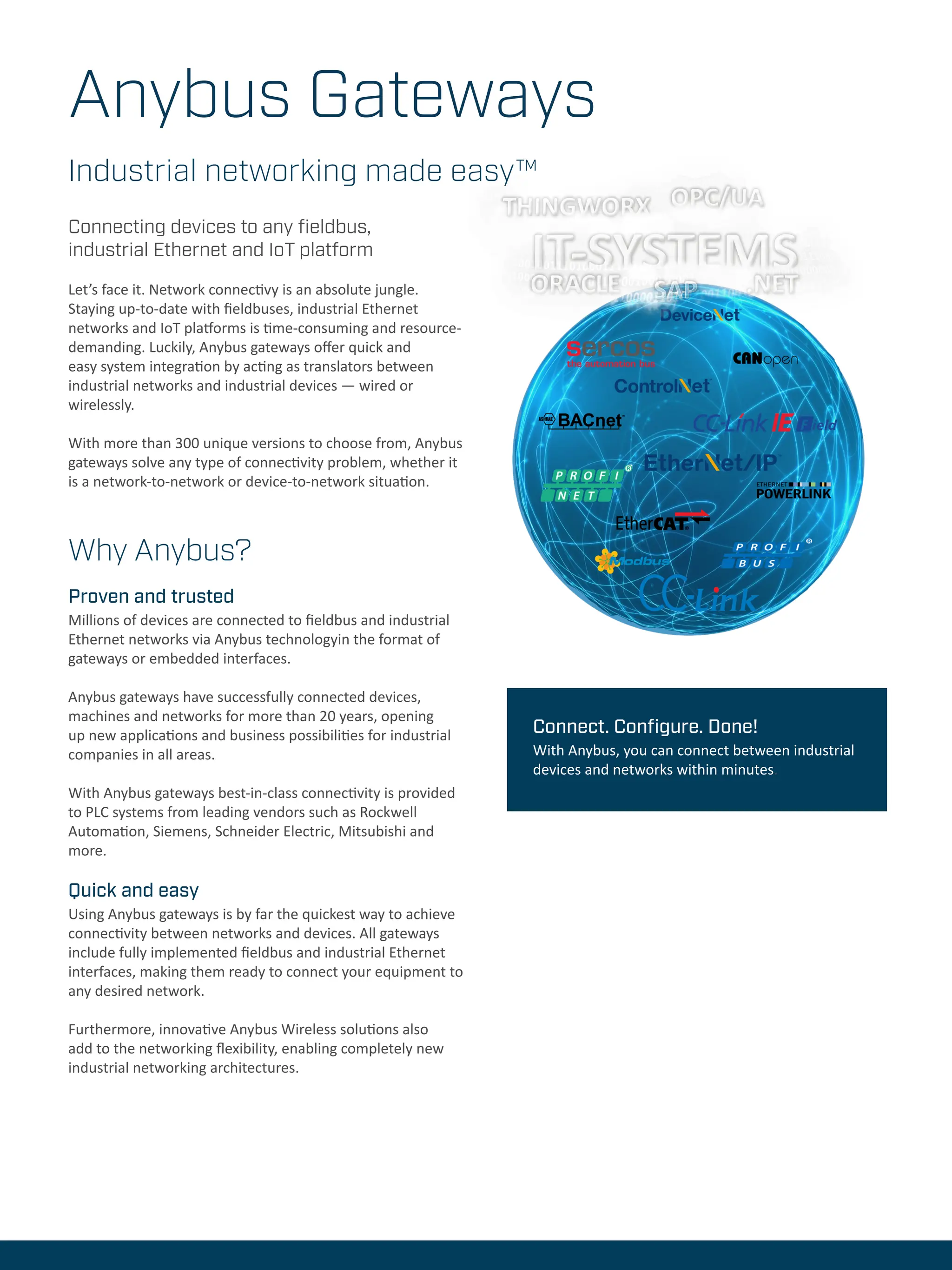

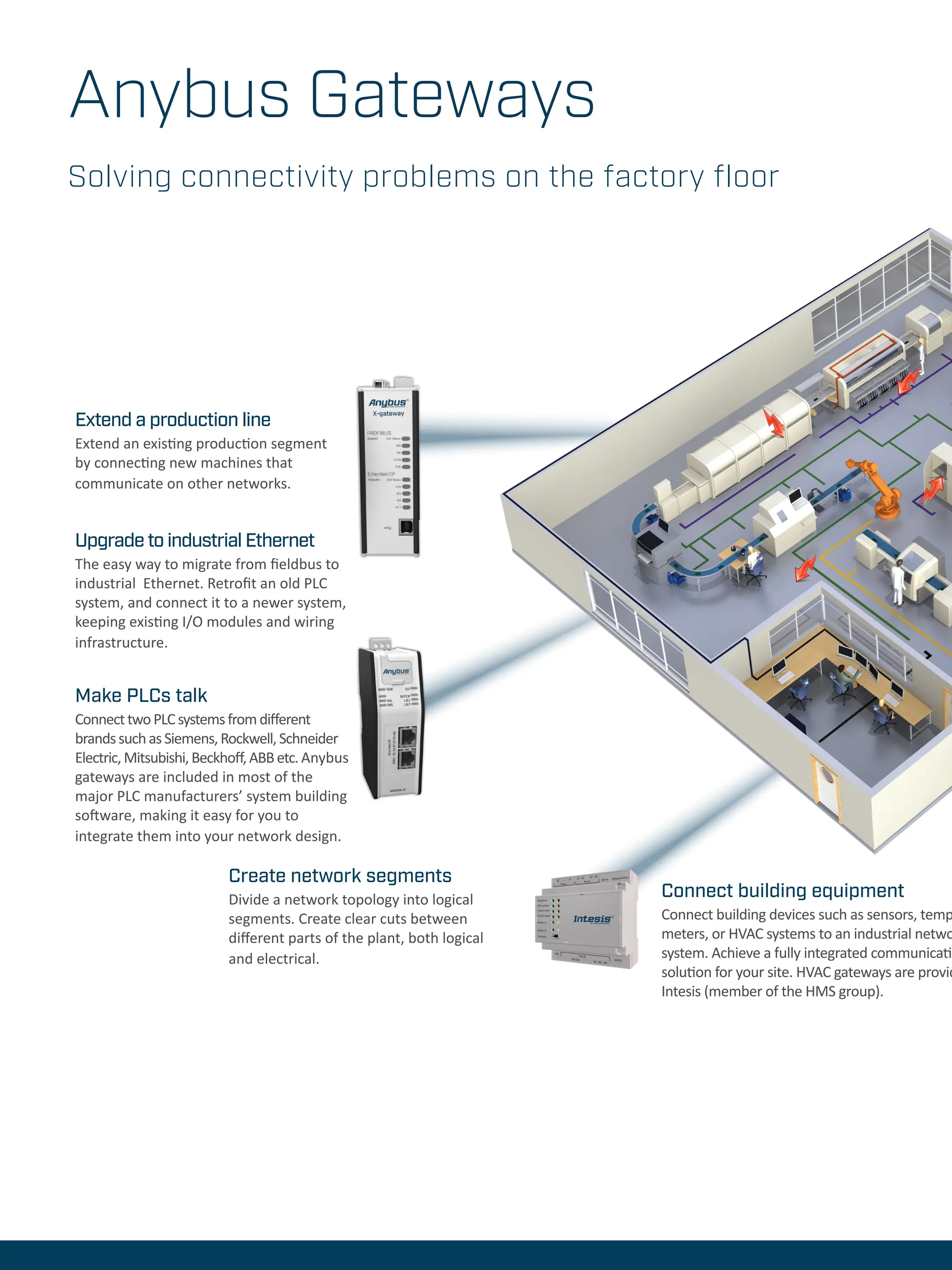

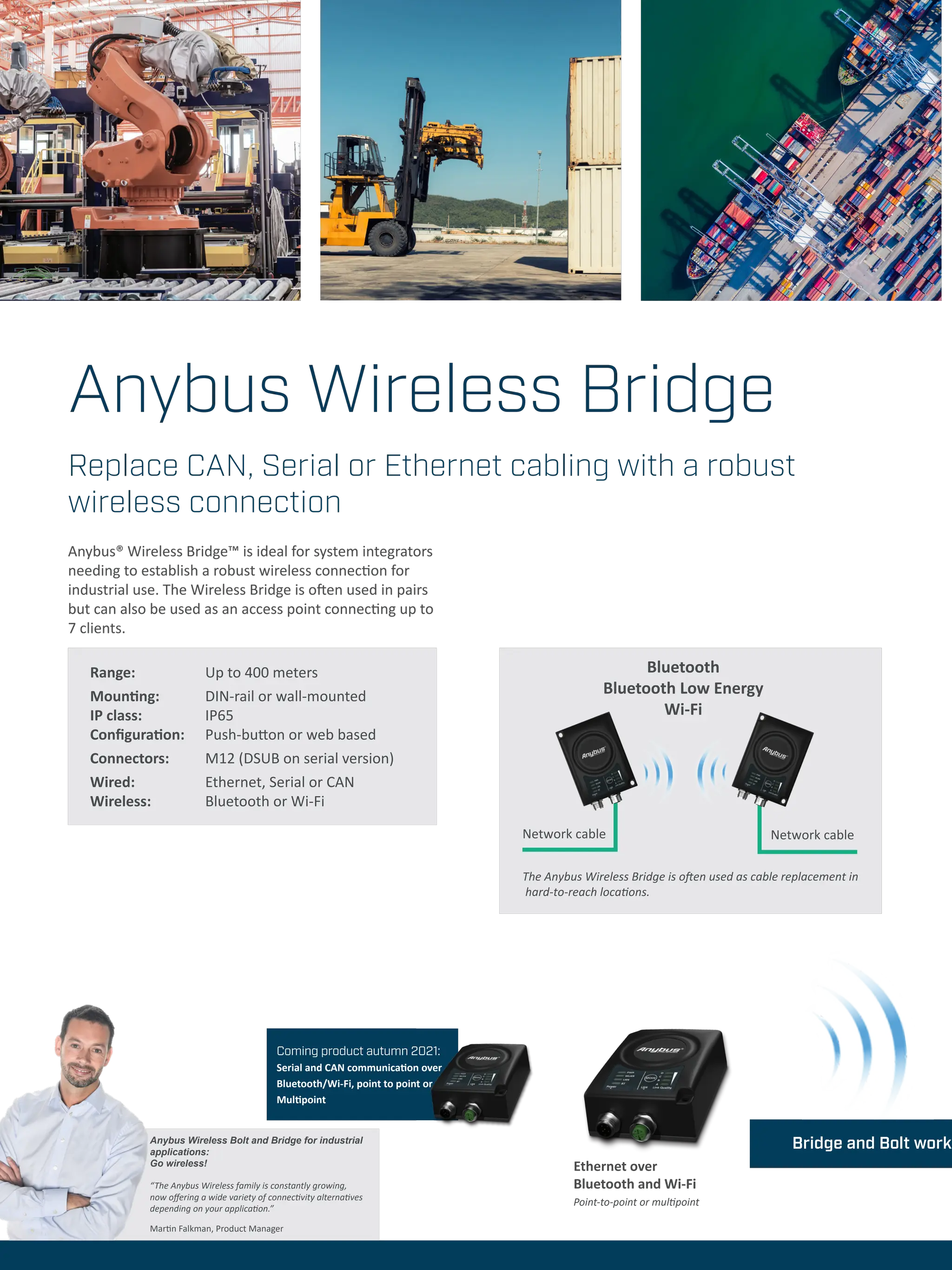

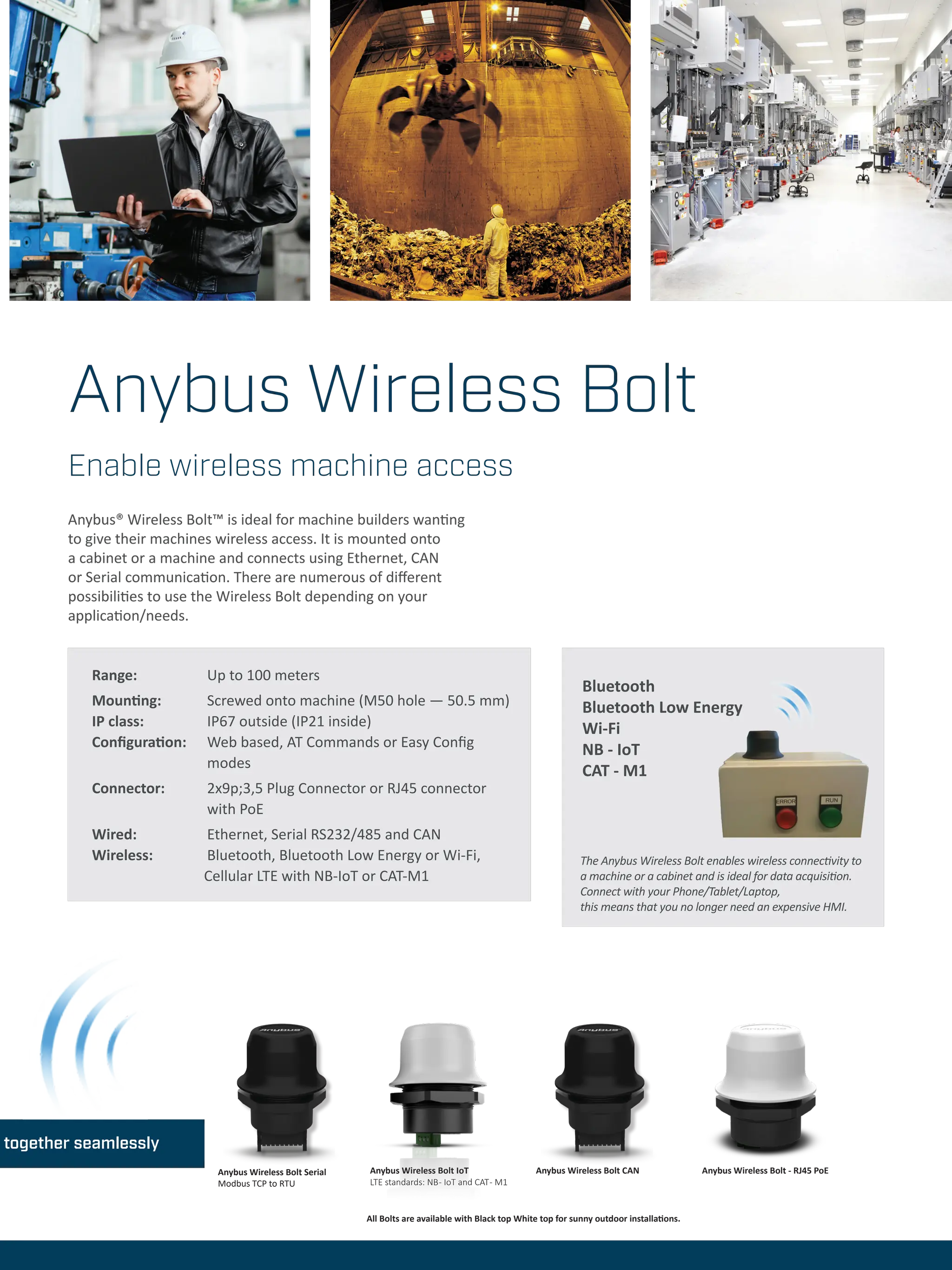

This document discusses various gateway and wireless solutions from HMS including the Anybus X-gateway, Anybus Communicator, Anybus Wireless Bolt, and Anybus Wireless Bridge. The Anybus products provide connectivity between different industrial networks and devices through wired or wireless gateways and protocol converters. The solutions can connect PLCs, machines, sensors and other devices to networks like PROFIBUS, EtherNet/IP, Modbus TCP and more. The gateways and communicators offer easy configuration through software tools to quickly connect devices and networks.