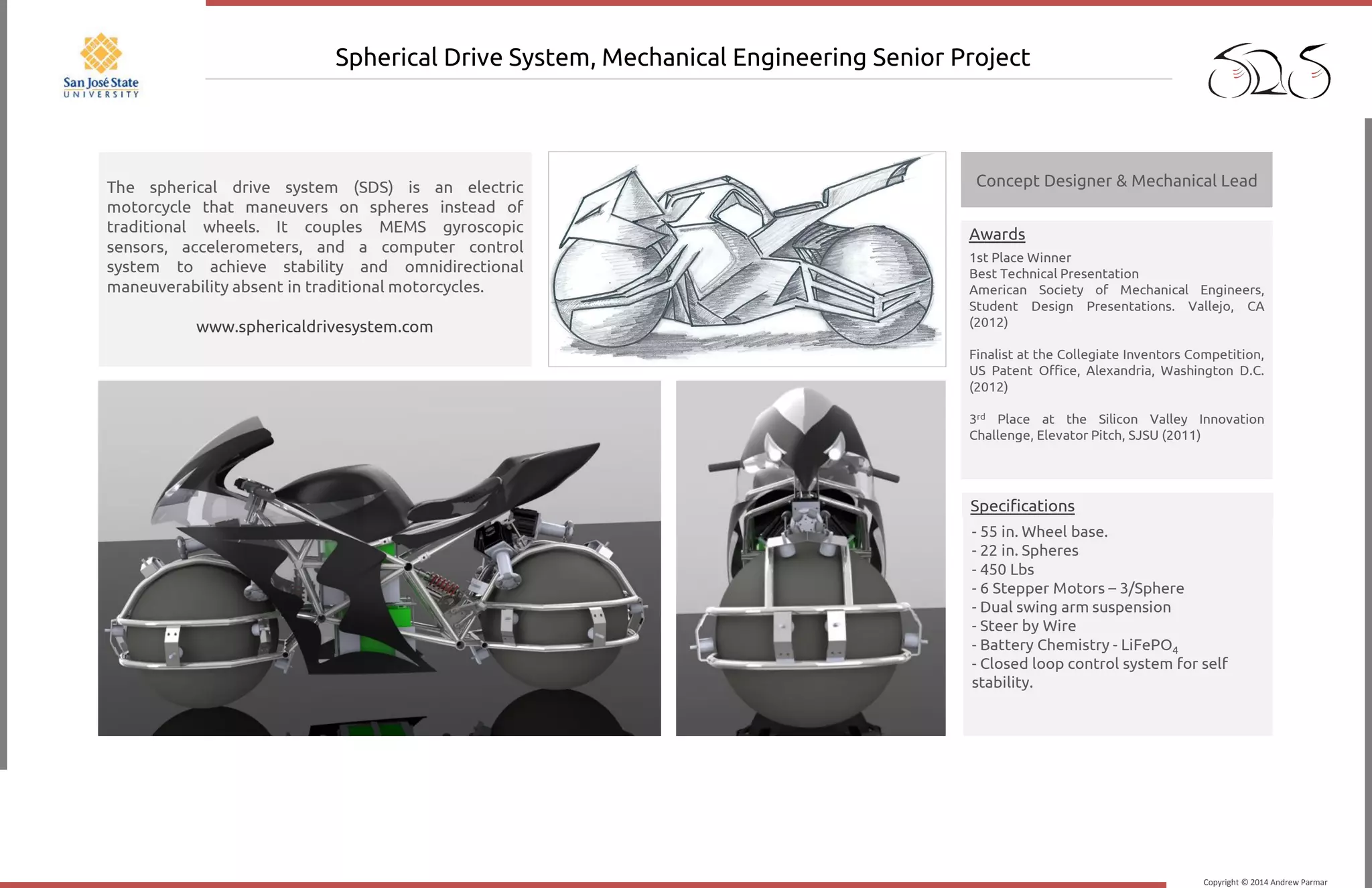

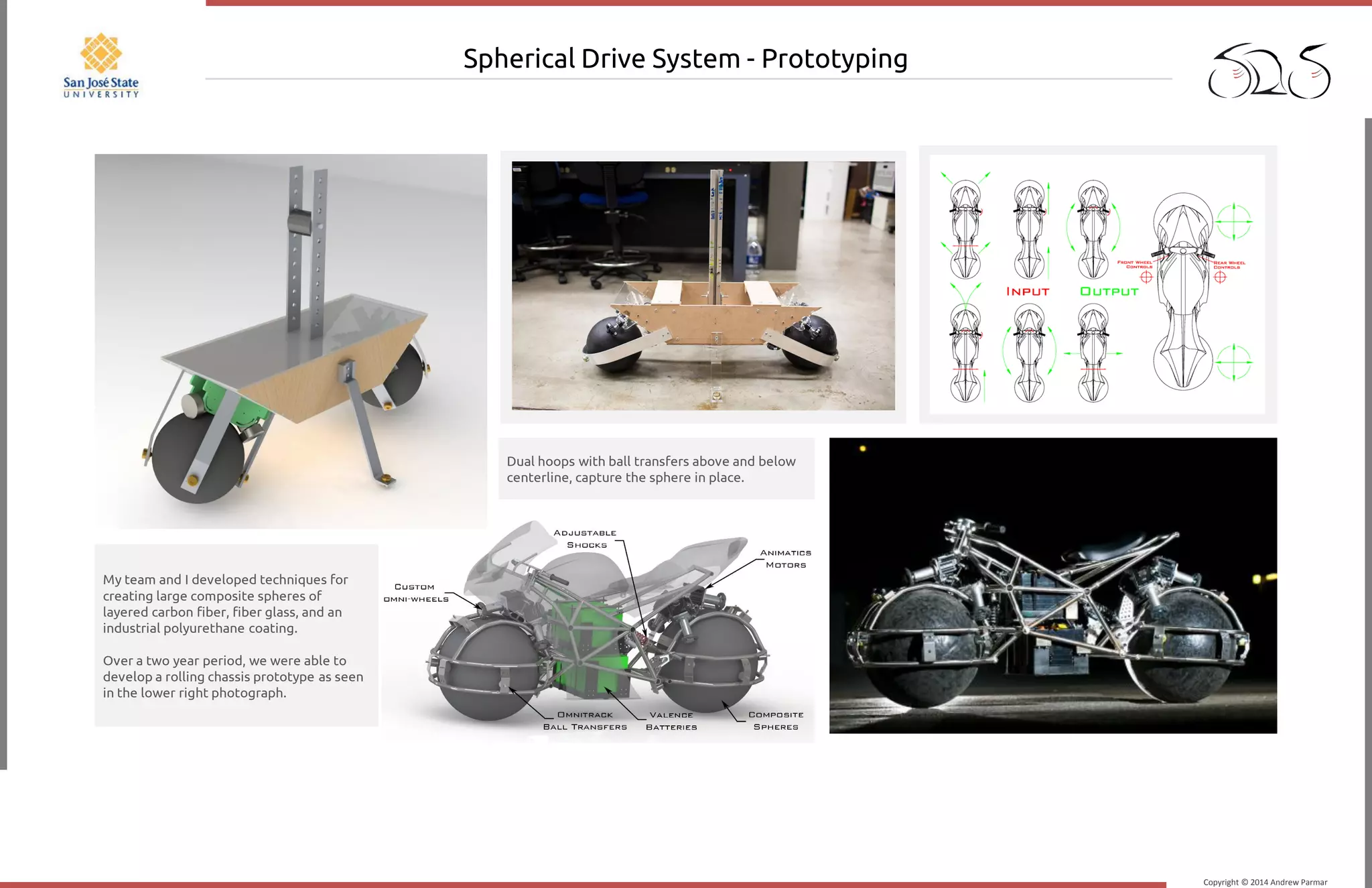

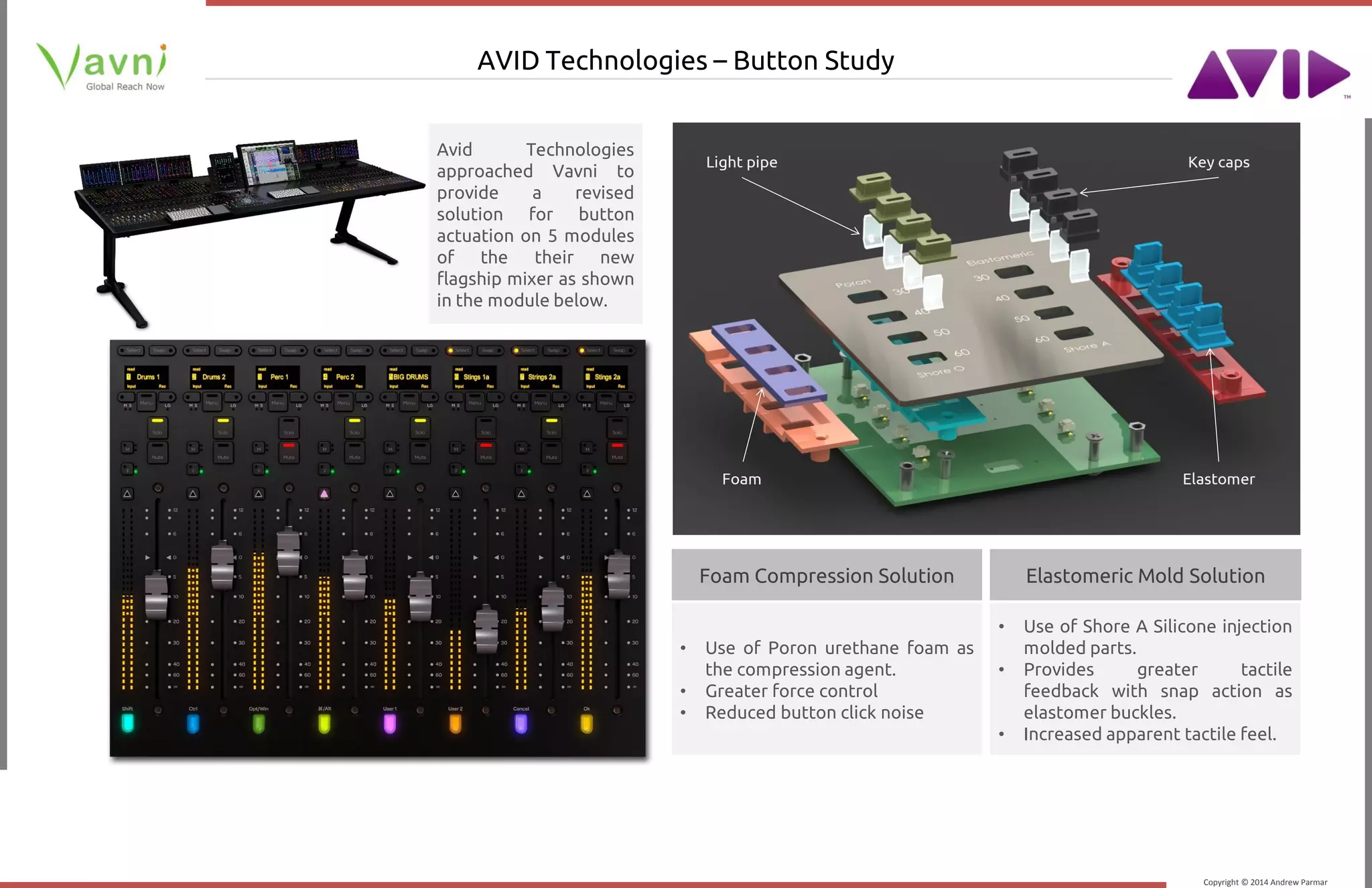

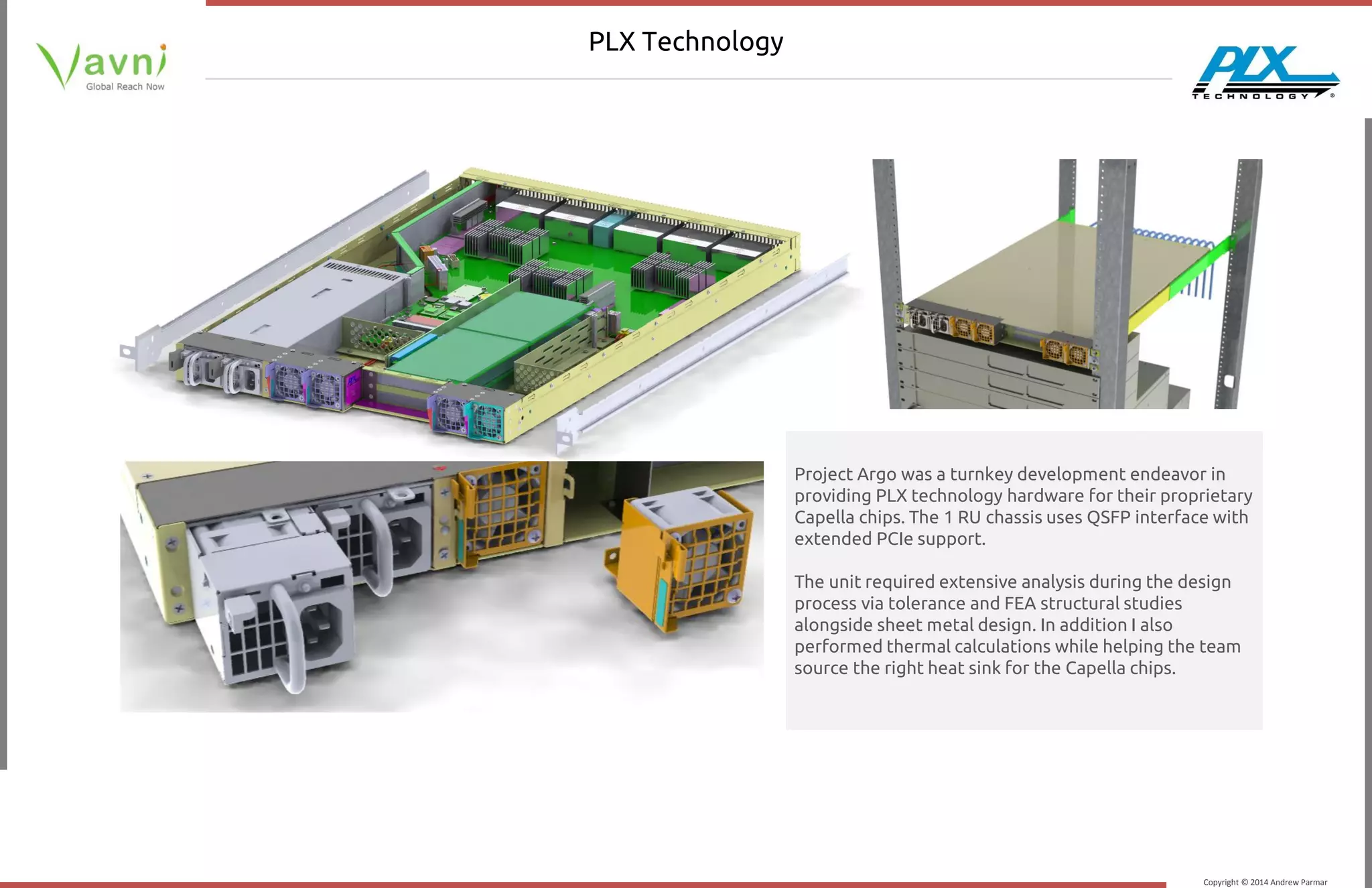

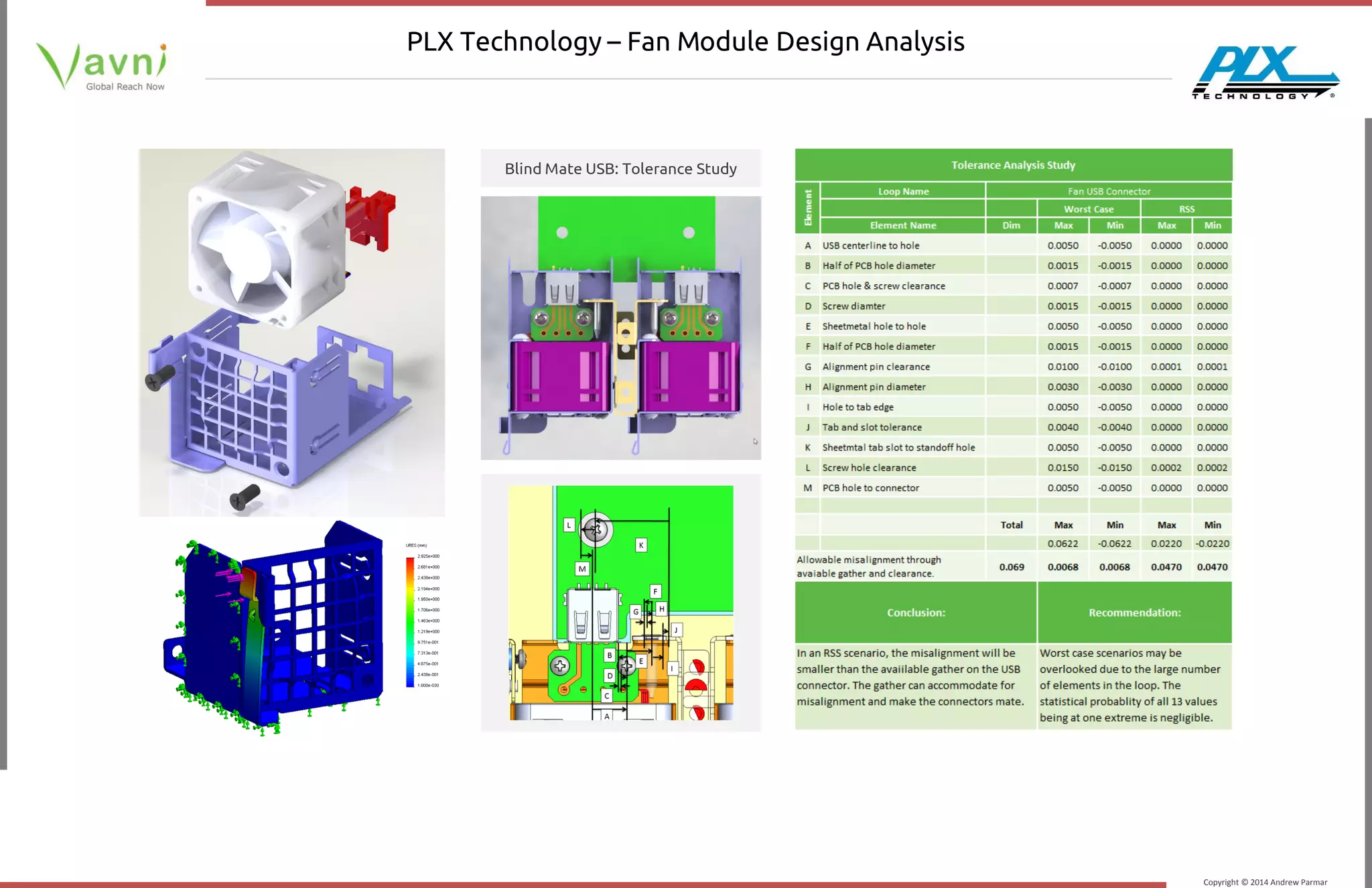

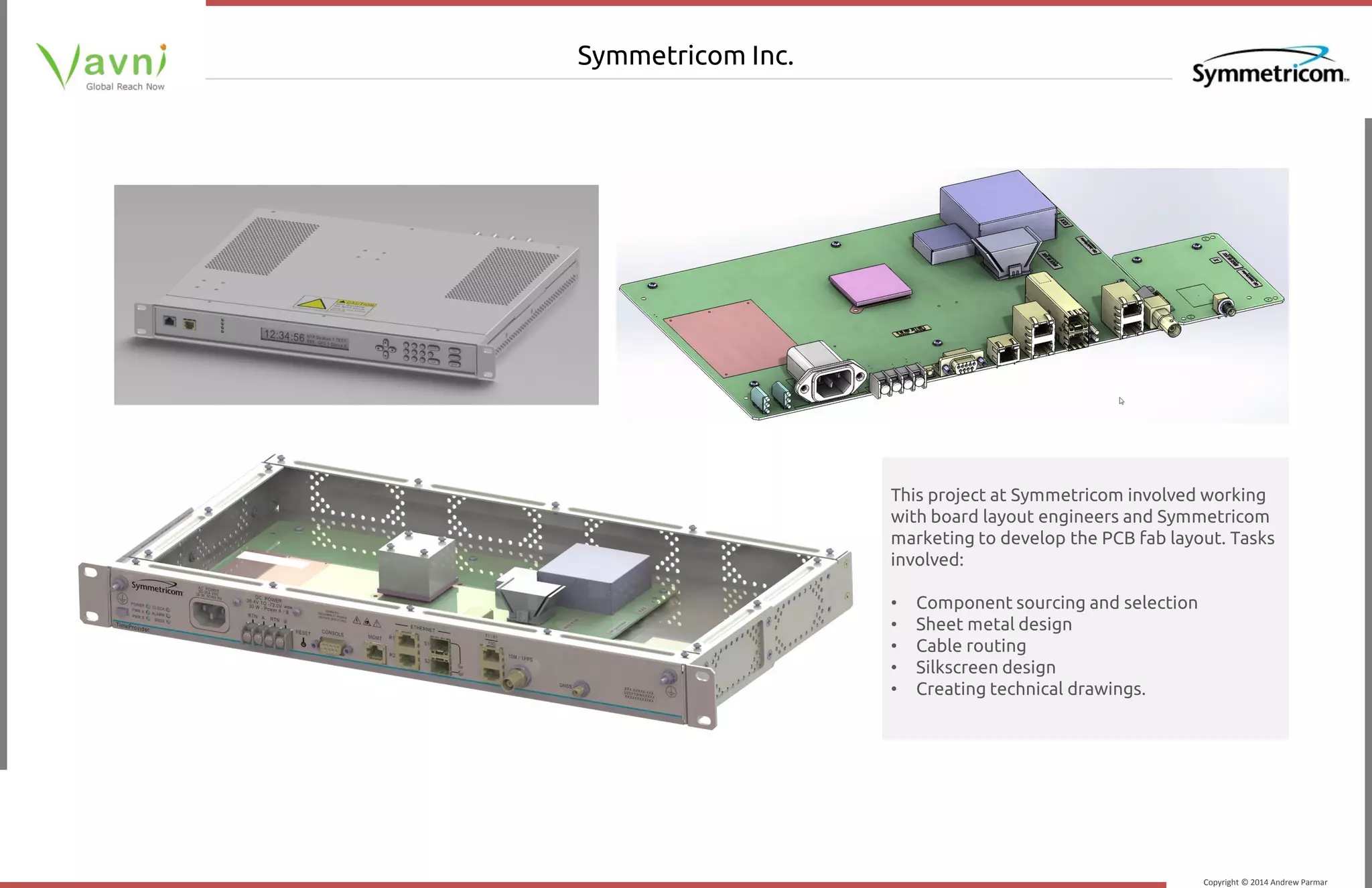

This document is Andrew Parmar's design portfolio. It summarizes his educational background in mechanical engineering and interests in areas like concept development, mechatronics, and CAD software. It then highlights some of his project experience, including designing a spherical drive system motorcycle that won awards, prototyping techniques for large composite spheres, conducting a button study for improved tactile feedback, providing hardware design for PLX Technology including thermal and tolerance analysis, and helping with PCB layout for Symmetricom.