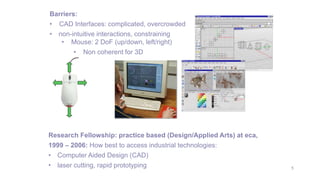

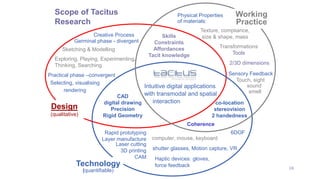

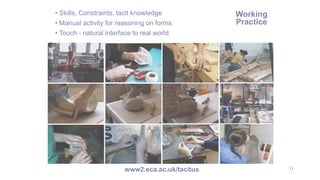

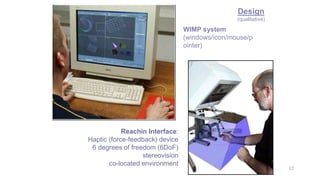

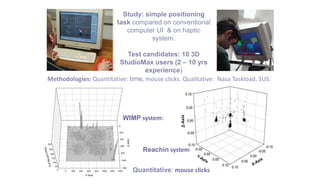

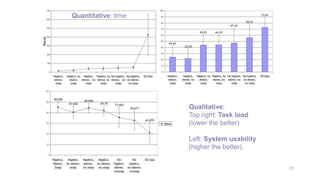

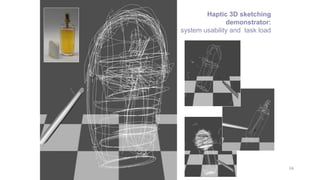

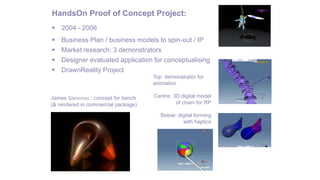

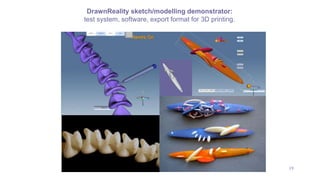

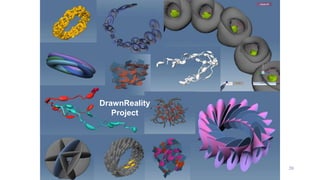

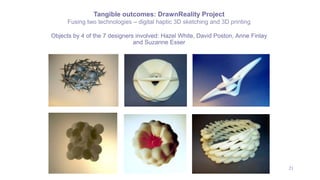

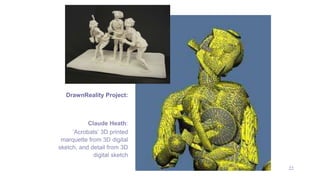

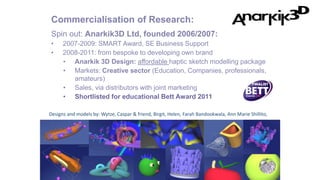

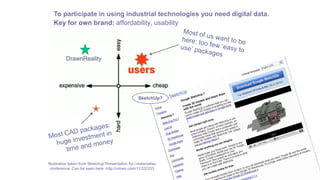

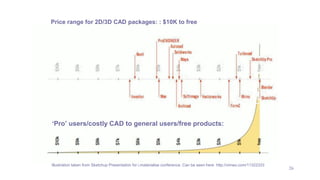

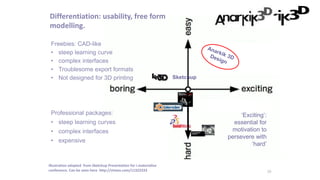

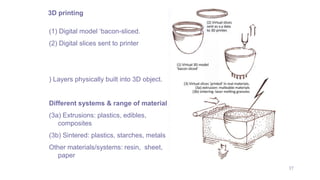

The document presents the research and development of haptic technology and its application in digital design for artists and designers, led by Ann Marie Shillito at Edinburgh College of Art. It discusses barriers in current CAD systems and the aim of projects such as 'Tacitus' and 'DrawnReality' to enhance intuitive interaction through haptic devices for 3D modeling and rapid prototyping. The outcomes include the commercialization of the Anarkik3D software and hardware, aimed at making digital design more accessible and affordable for various sectors.